Rough rolling vertical roller mill

A technology of vertical roll mill and rough rolling, which is applied in the direction of metal rolling stand, metal rolling mill stand, driving device for metal rolling mill, etc., and can solve the problems of lowering production efficiency, rolling roll accumulation funds, and increasing rough rolling area One-time equipment investment and other issues can be achieved to improve the transmission rigidity and service life, meet the requirements of large torque transmission, and shorten the time for online roll change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

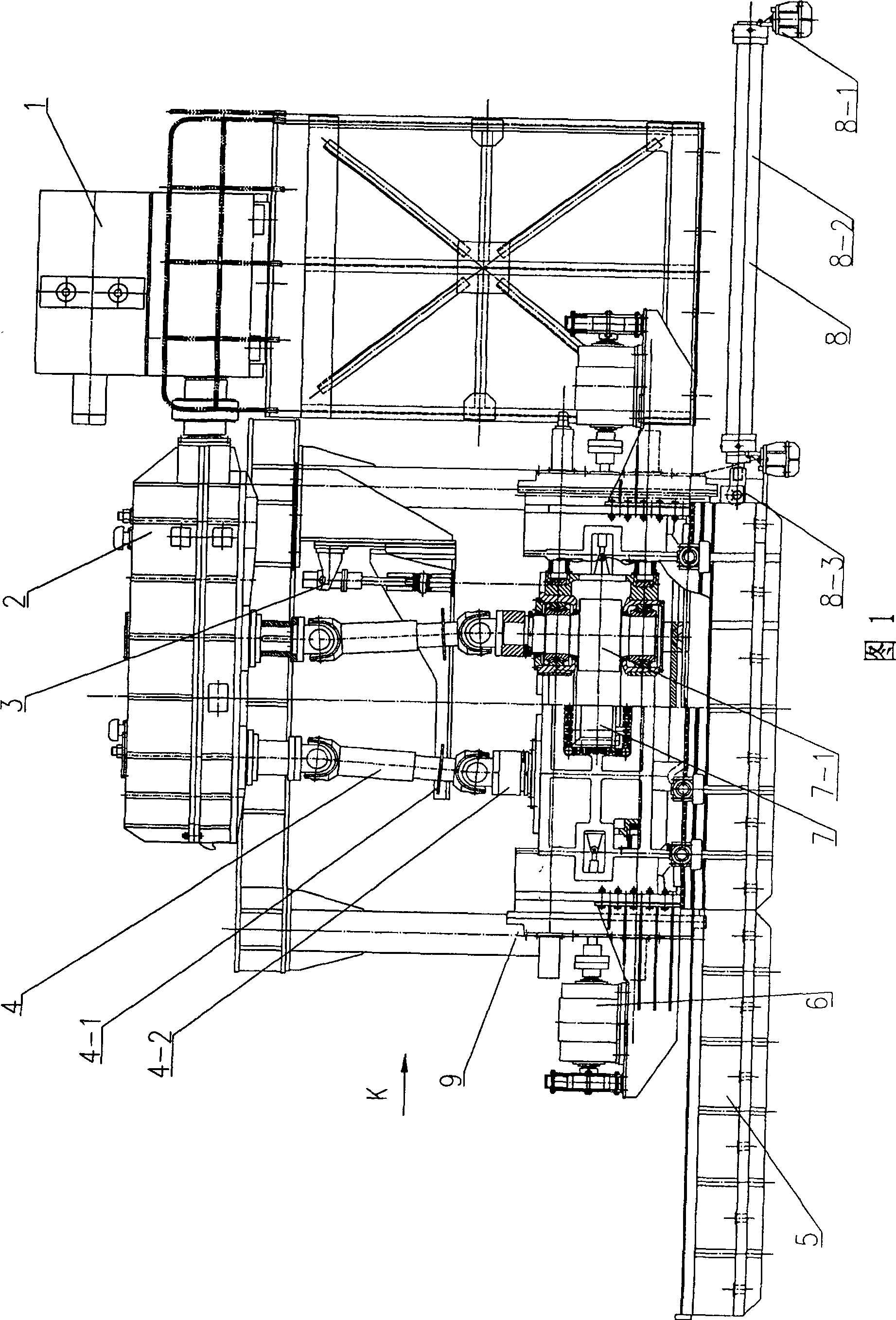

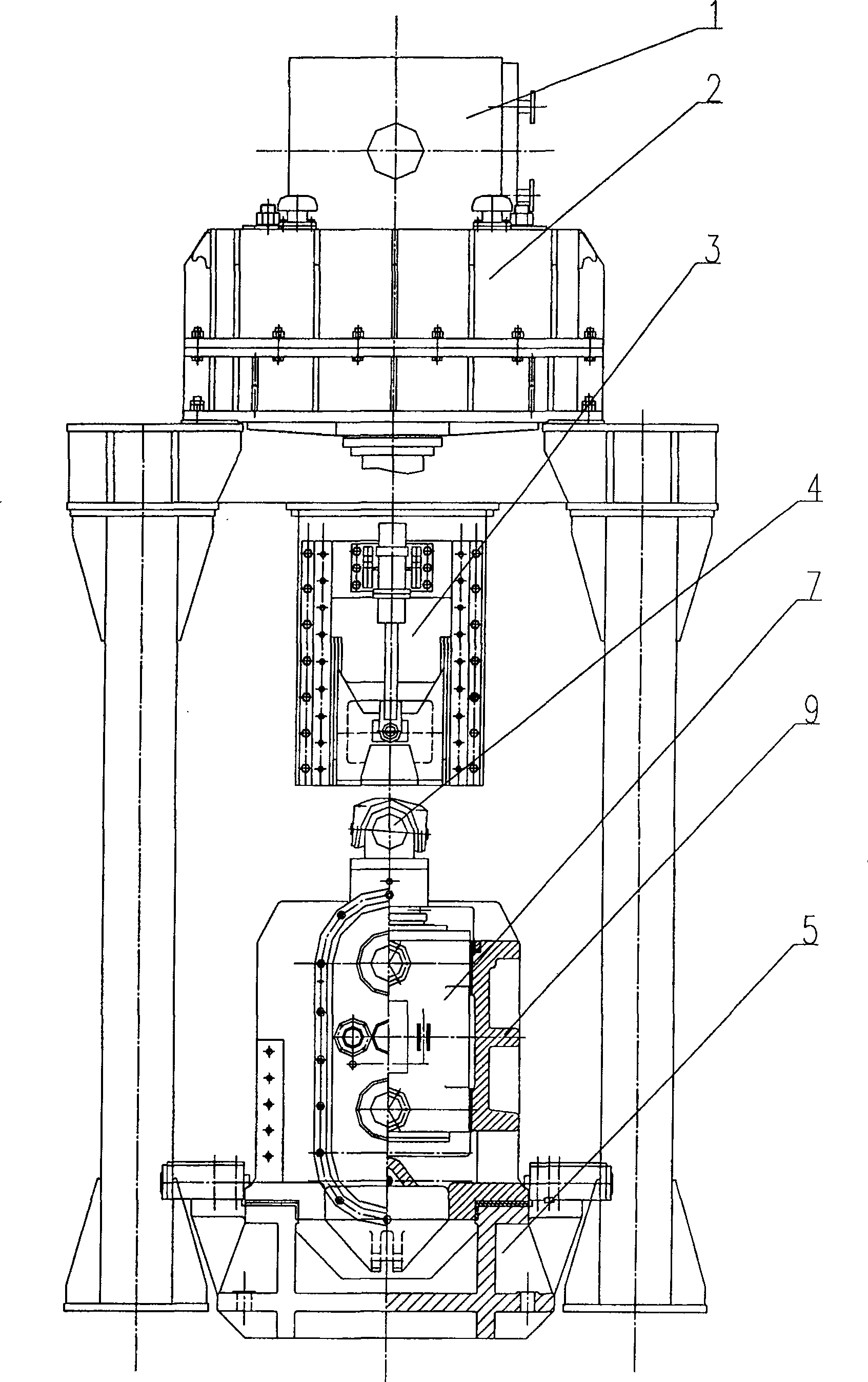

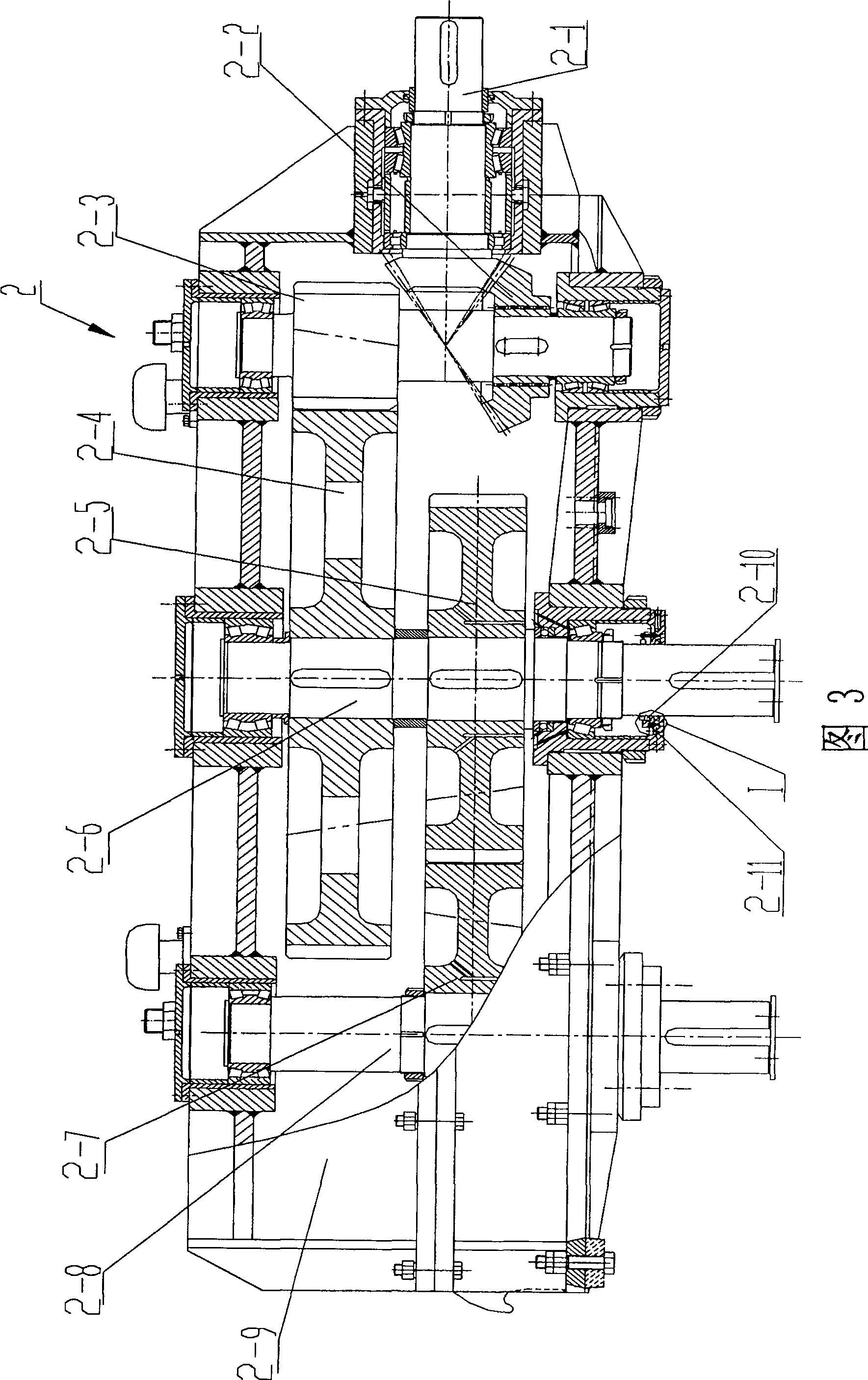

[0022] See Figure 1— figure 2 , rough rolling vertical roll mill, including: main drive motor 1, main drive combined reducer 2, cross universal joint shaft 4, frame 9, guide rail seat assembly 5, side pressing device 6, rolling mill mechanism 7 and roll change out Mechanism 8, the main drive combined reducer is an integral box structure, its output shaft is two vertically installed output gear shafts 2-6 and 2-8, the main drive motor 1 is connected to the main drive through a coupling Combined reducer 2, the two output gear shafts protruding vertically below the main drive combined reducer are connected to the cross universal joint shaft through the flange 4-1 and sleeve 4-2 of the cross universal joint shaft 4, and the cross universal joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com