Roll changing mechanism for working roll of rolling mill

A technology of work roll and roll structure, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of low work efficiency, time-consuming and labor-intensive work roll, etc., and achieve convenient roll change and easy roll change , the effect of high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

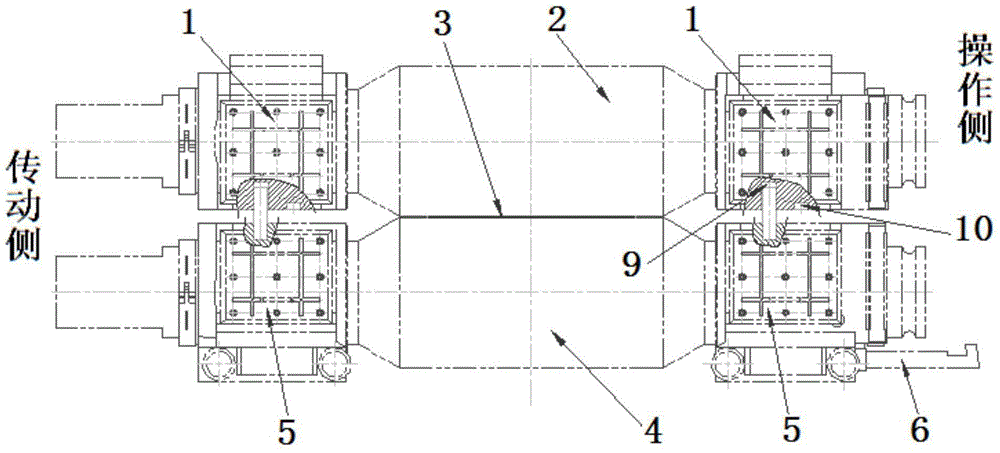

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

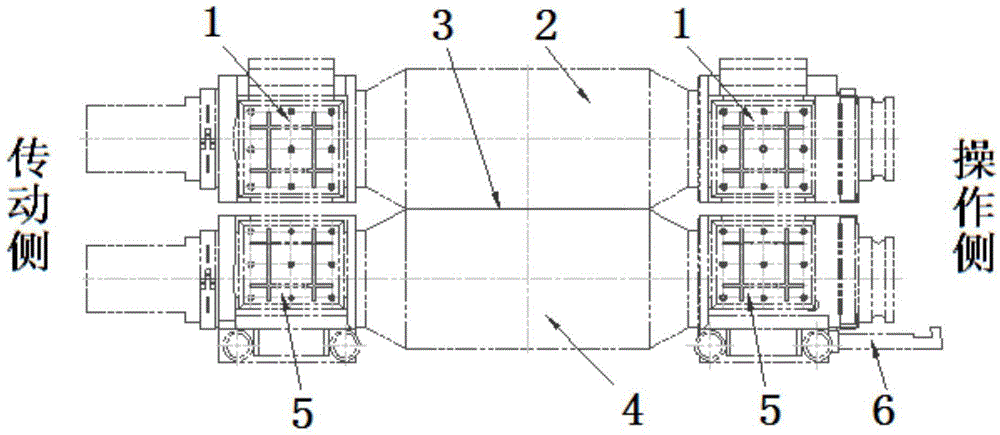

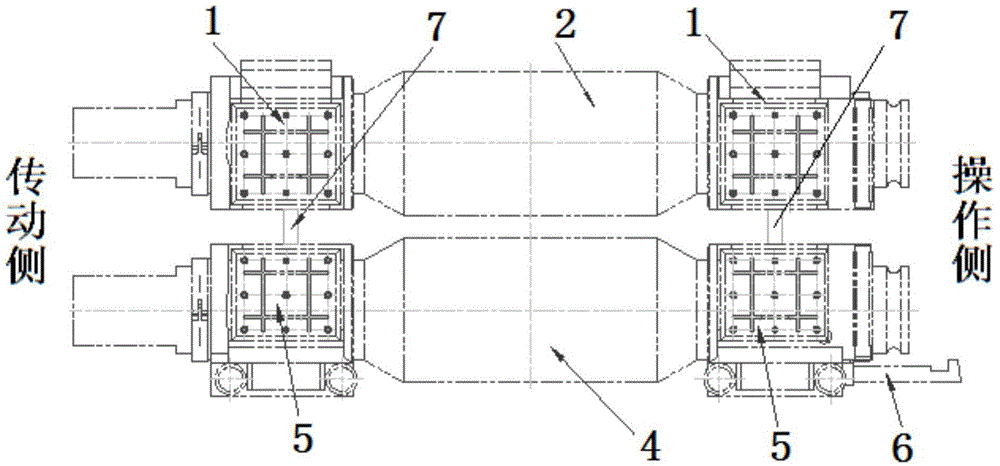

[0016] refer to figure 1 , figure 2 , the structure of the prior art (before improvement) is that an upper bearing seat 1 and a lower bearing seat 5 are respectively arranged on the working side and the operating side mounting seat, and the upper bearing seat 1 and the lower bearing seat 5 are arranged parallel to the axis line up and down; The upper bearing housing 1 and the lower bearing housing 5 are respectively worn with an upper working roll 2 and a lower working roll 4, between the roll surfaces of the upper working roll 2 and the lower working roll 4 is a rolled strip 3, the upper working roll 2, the lower working roll The work roll 4 is pulled out by the roll changing hook 6 when taking it out.

[0017] When the work roll needs to be replaced, such as figure 2 As shown, first use the balance cylinder (not shown) to lift the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com