Solar water tank end cap sealing tape applicator

A sealing technology for solar water tanks and end caps, which is applied in the direction of sending objects, thin material handling, transportation and packaging, etc., and can solve problems such as difficulty in tape uniformity, low production efficiency, and high labor intensity for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

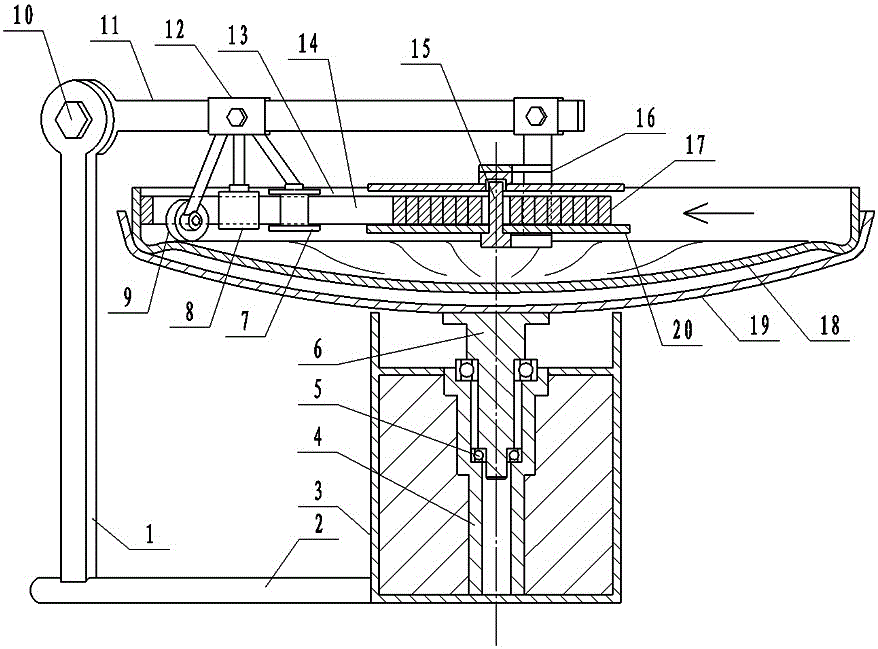

[0006] Example: such as figure 1 Shown, a kind of solar water tank end cap sealing tape applicator, this applicator comprises a base 3, and axle seat 4 and bearing 5 are installed in base 3, and rotating shaft 6 is installed in bearing 5, and the upper end of rotating shaft 6 is fixed on At the center of the lower bottom of a circular turntable 19, the water tank end cover 18 is fixedly installed in the circular turntable 19, and a support bottom bar 2 and a vertical bar 1 are installed on the lower side of the base 3, and the upper end of the vertical bar 1 is movable with a bolt 10 Cross arm 11 is fixed, and the front end of cross arm 11 is fixed with the mounting frame 16 of sealing tape roll, is positioned at the mounting frame 16 of circular turntable 19 circle center tops and is equipped with fixed shaft 15, and the set sealing tape roll fixed disk 20 on the fixed shaft 15, The sealing tape roll 17 is installed in the sealing tape roll fixing plate 20, and in the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com