Patents

Literature

108results about How to "Quick paste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

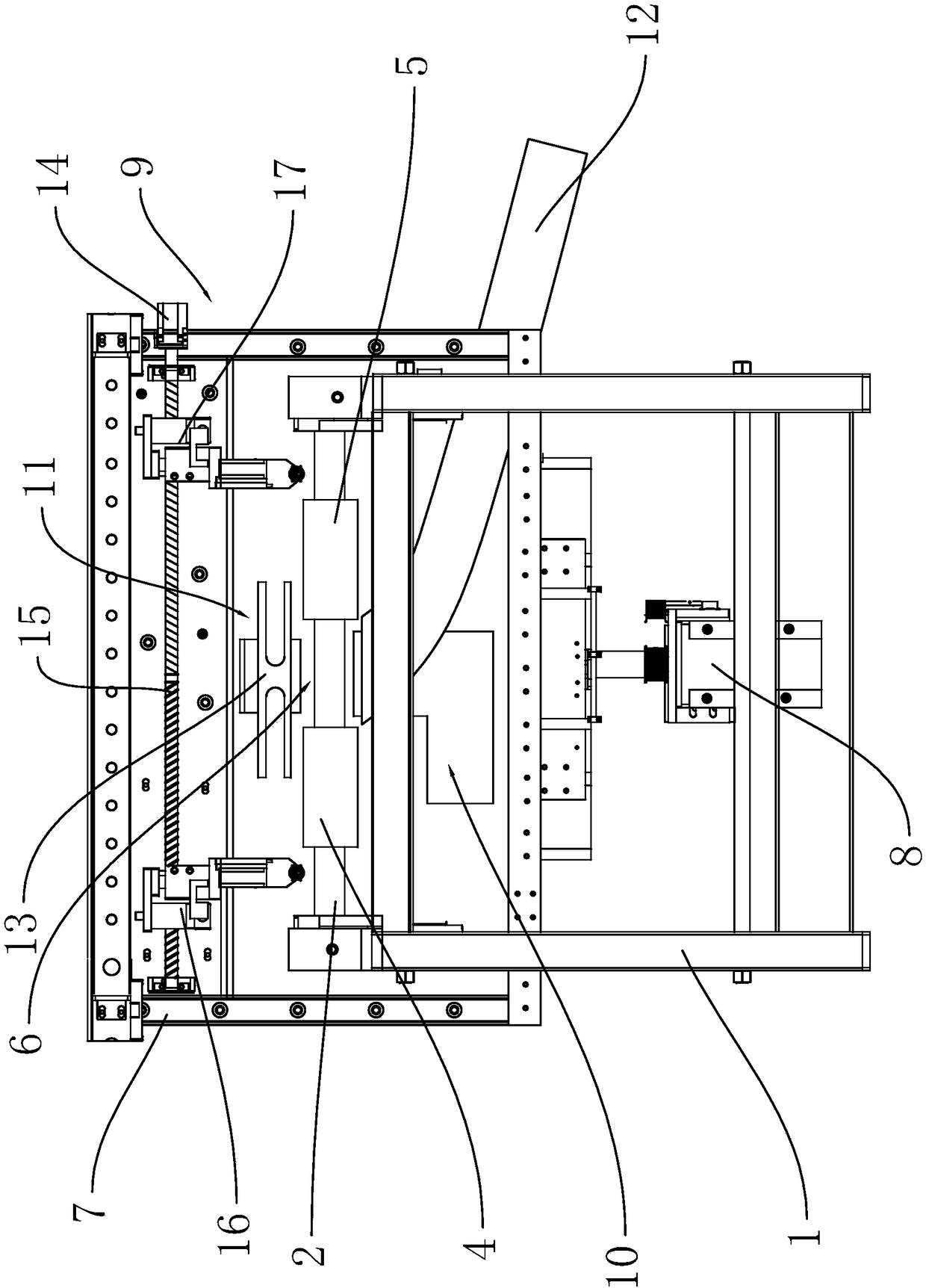

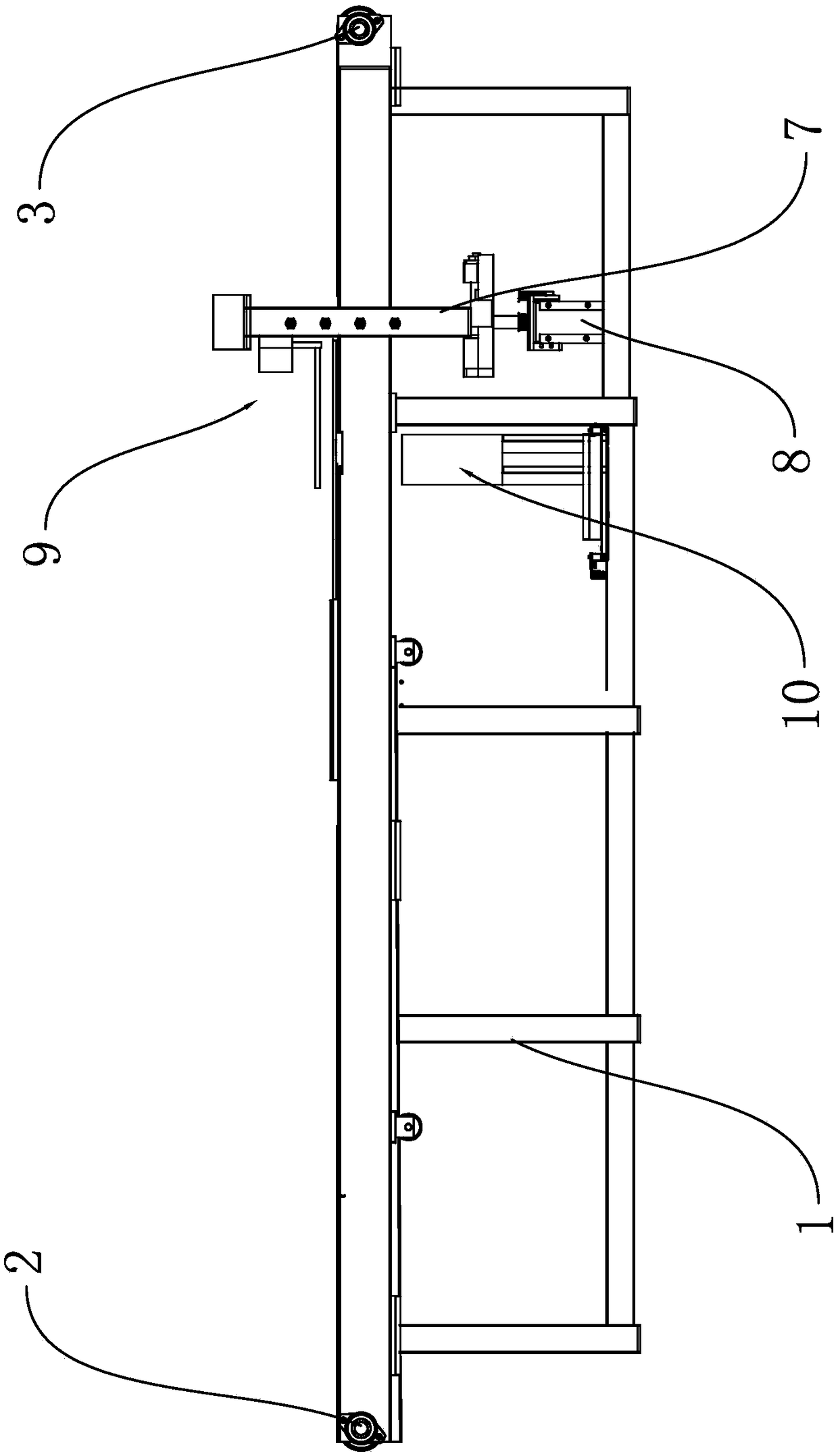

Position adjustable packing case adhesive tape sealing device

ActiveCN105000223AMeet the needs of pastingAdjust the moving distanceWrapper twisting/gatheringCouplingDrive motor

The invention discloses a position adjustable packing case adhesive tape sealing device. The device comprises a machine frame, wherein a plurality of supporting pillars are fixed to a top plate of the machine frame, two vertical blocks are fixed to the plane of an upper supporting plate, and the two ends of an adjusting screw are hinged to the two vertical blocks; a driving motor is fixed to the right side of the upper supporting plate, an output shaft of the driving motor is connected with the right end, stretching out of the corresponding vertical block, of the adjusting screw through a coupler, and a sliding block is connected to the adjusting screw in a screwed mode and inserted in a through groove in the upper supporting plate below the adjusting screw; the front side wall and rear side wall of the sliding block are abutted against the front side wall and rear side wall of the through groove, and a thrusting cylinder is fixed to the sliding block; a push rod of the thrusting cylinder is vertically downward, a pressing block is fixed to the push rod, and a bonding layer is fixed to the bottom surface of the pressing block. By the adoption of the device, adhesive tape can be automatically and quickly stuck to a packaging case, efficiency is high, manual sticking is not needed, working intensity is relieved, and the packing case can be clamped by rotating the screw so that manual clamping can be avoided.

Owner:佛山市东合众包装制品有限公司

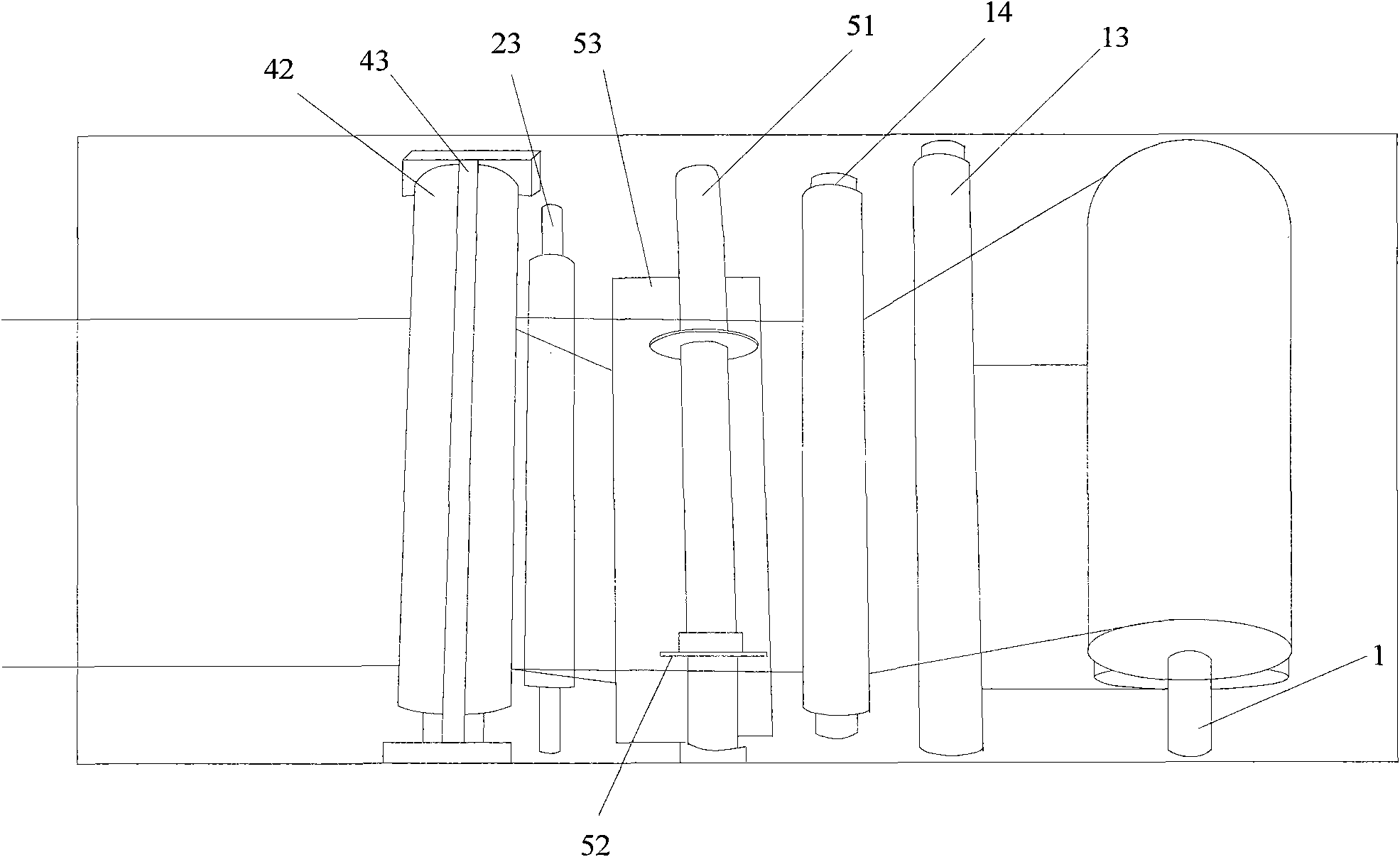

Shading glue film production method

InactiveCN101187748AEasy to tear offQuick pasteLamination ancillary operationsLaminationAdhesivePacking procedure

The invention relates to a process for preparation of a shading glue film, which provides a process for preparation that centralized light can be assuredly projected on a shading glue film of an outer frame of a display screen, when in use, the invention has more convenient employment, easy pasting and easy tearing, and no remaining trace, which can be attached for a long term. The process for preparation of the shading glue film of the invention firstly has a fist time pasting, and materials such as a separating type film membrane, a double-sided adhesive, and an auxiliary separating type film membrane are respectively arranged on each feeding shaft and are fixed, and then a separating type surface of the separating type film membrane is pasted with the double-sided adhesive, and then the separating type surface of the separating type film membrane and the double-sided adhesive which are pasted are stamped in one time to start a waste discharging procedure, and remainder of an inner frame is torn, products of waste material which is torn are cut off to get a bale packing procedure through a trimming machine and a photoinduction after a second time pasting, a second time stamping, a second time waster discharging procedure. The shading glue film of the invention is convenient for assembling staffs to tear off the shading glue film of the outer frame which is accurately pasted on the periphery of the display screen, and assembling work can be effectively simplified and working efficiency can be improved.

Owner:东莞市三贤汽车配件有限公司

Liquid-state paste for dye printing and preparation method and application of liquid-state paste

ActiveCN103643553AAppearance is clear and transparentHigh paste rateDyeing processDisperse dyeLiquid state

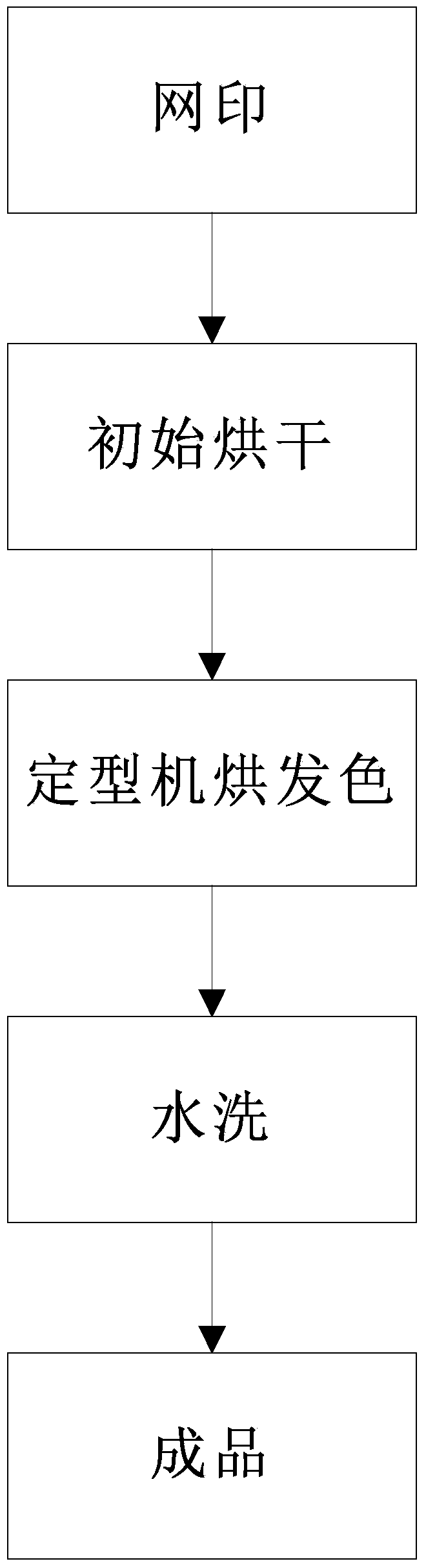

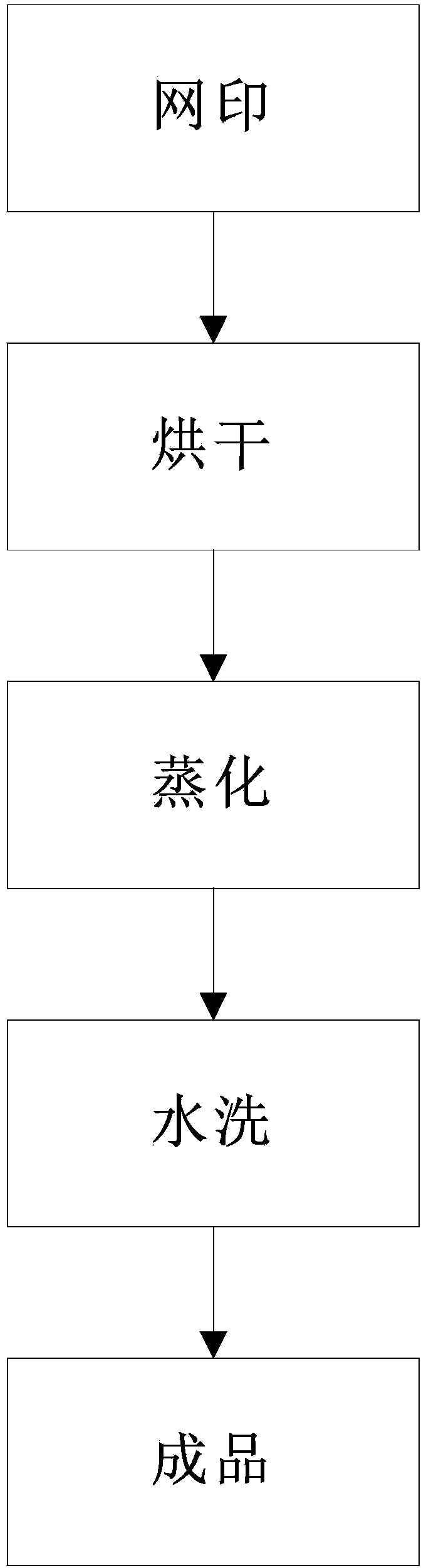

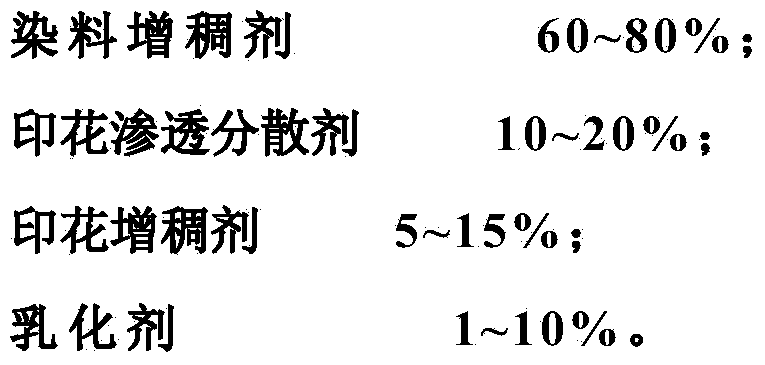

The invention discloses liquid-state paste for dye printing. The paste is characterized by comprising the following components in percentage by weight: 60-80% of a dye thickener, 10-20% of a printing permeation dispersant, 5-15% of a printing thickener and 1-10% of an emulsifier. The paste used for printing operation is convenient to operate, and paste is rapid to form. In particular, disperse dyes do not need to be evaporated after being printed and are directly dried for color development by a setting machine. The paste is convenient to remove by elution, so that the material has soft hand feel. In particular, the paste can be removed by clean water at room temperature, and no sludge pollution is generated after dyeing and finishing, so that a sludge treatment step is eliminated.

Owner:绍兴柯桥滨海飞翔化工有限公司

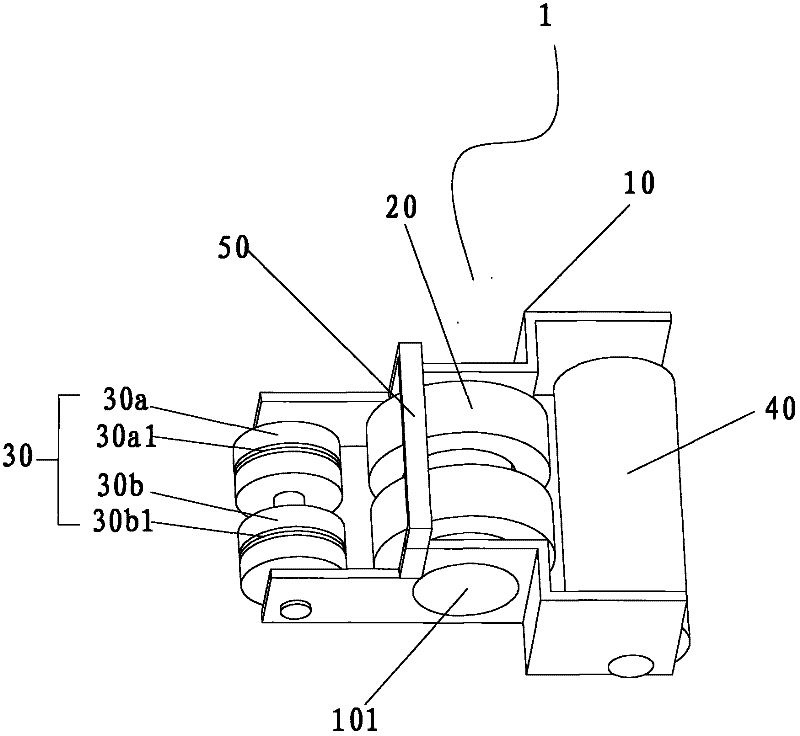

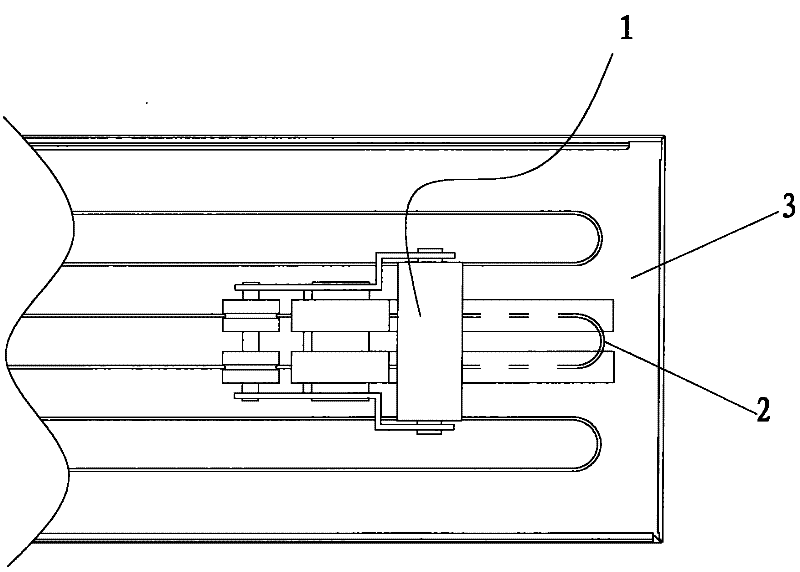

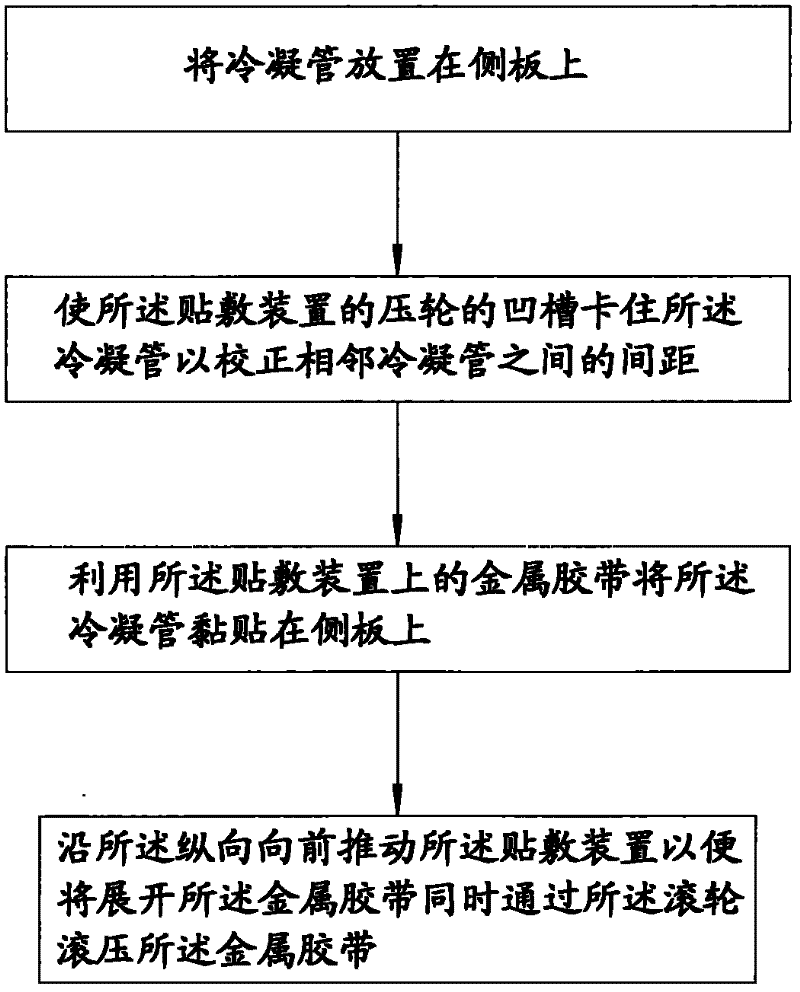

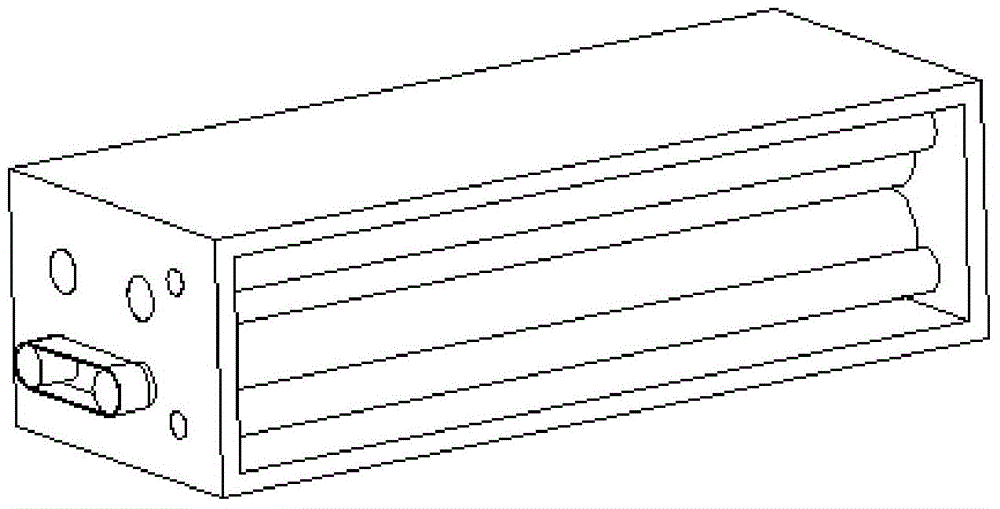

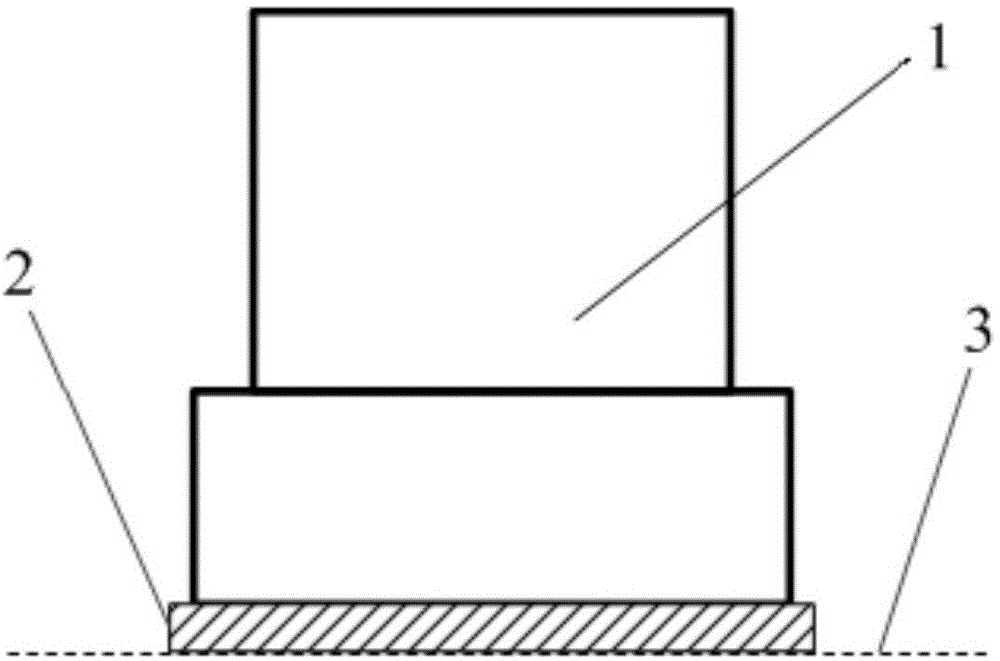

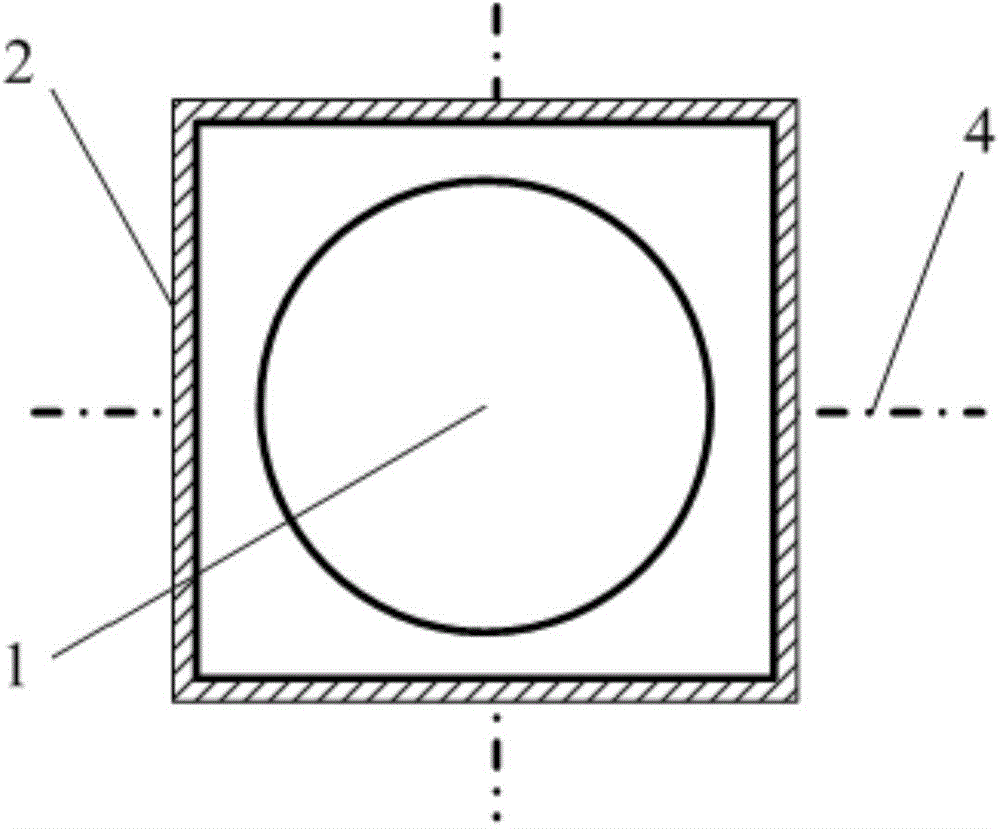

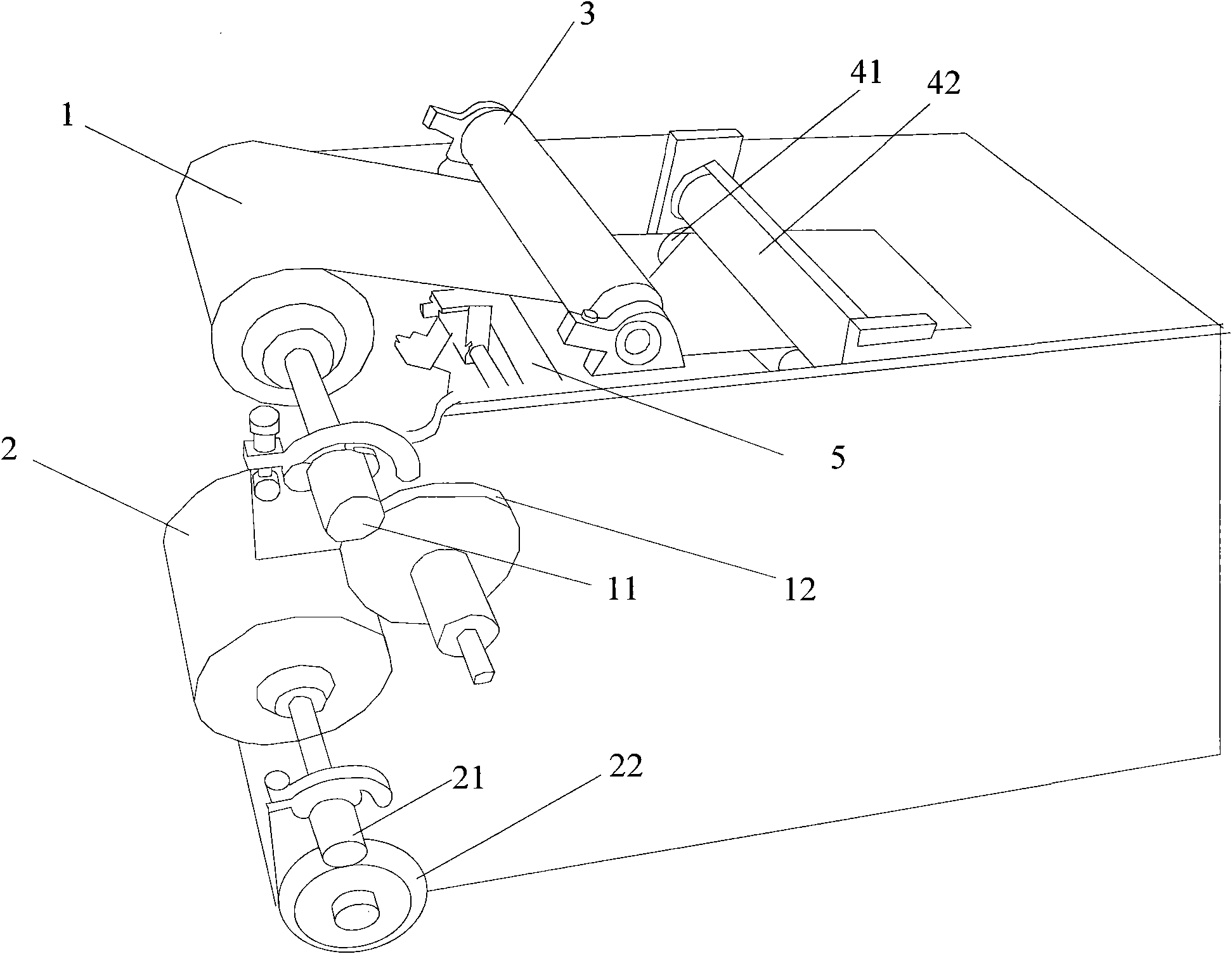

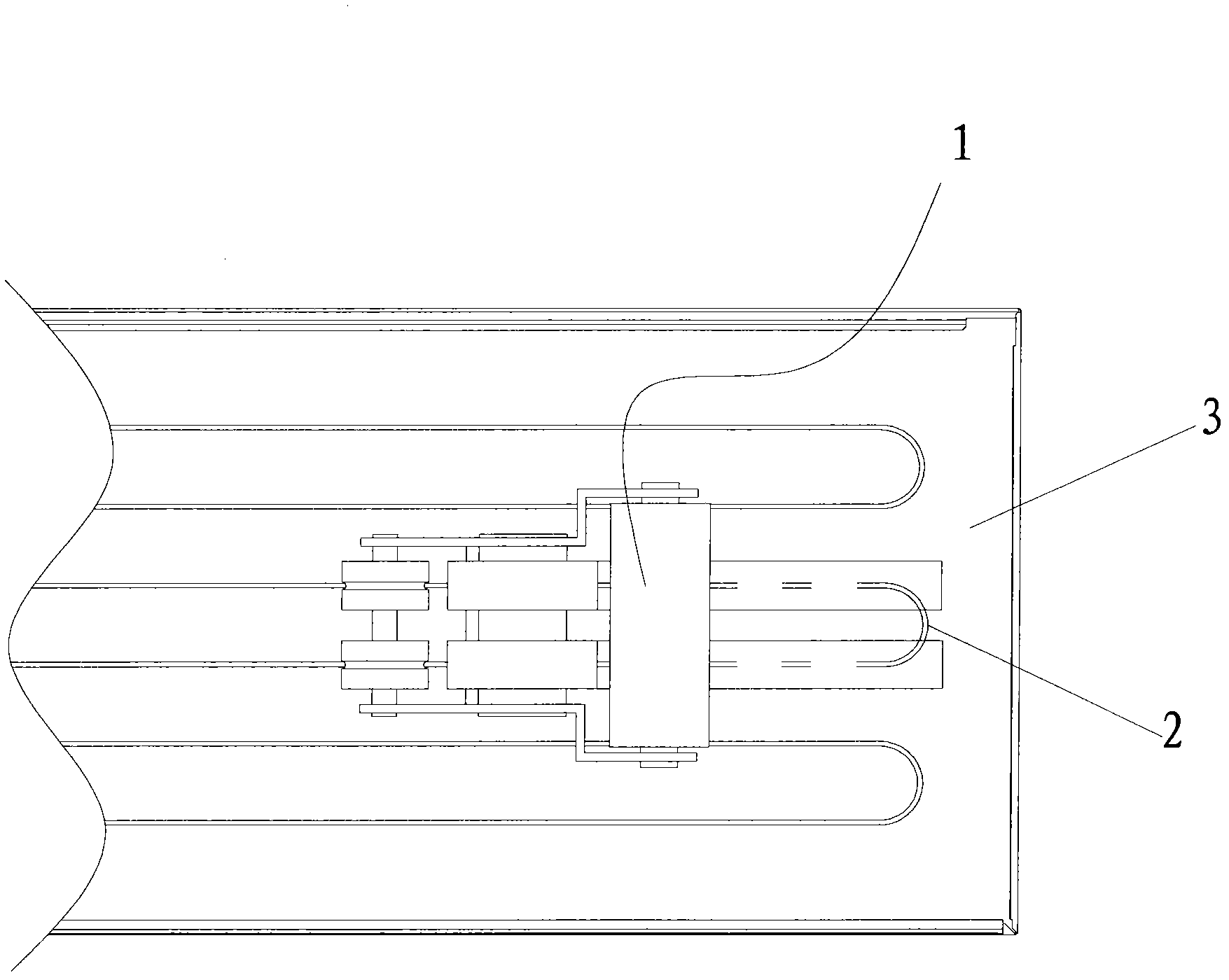

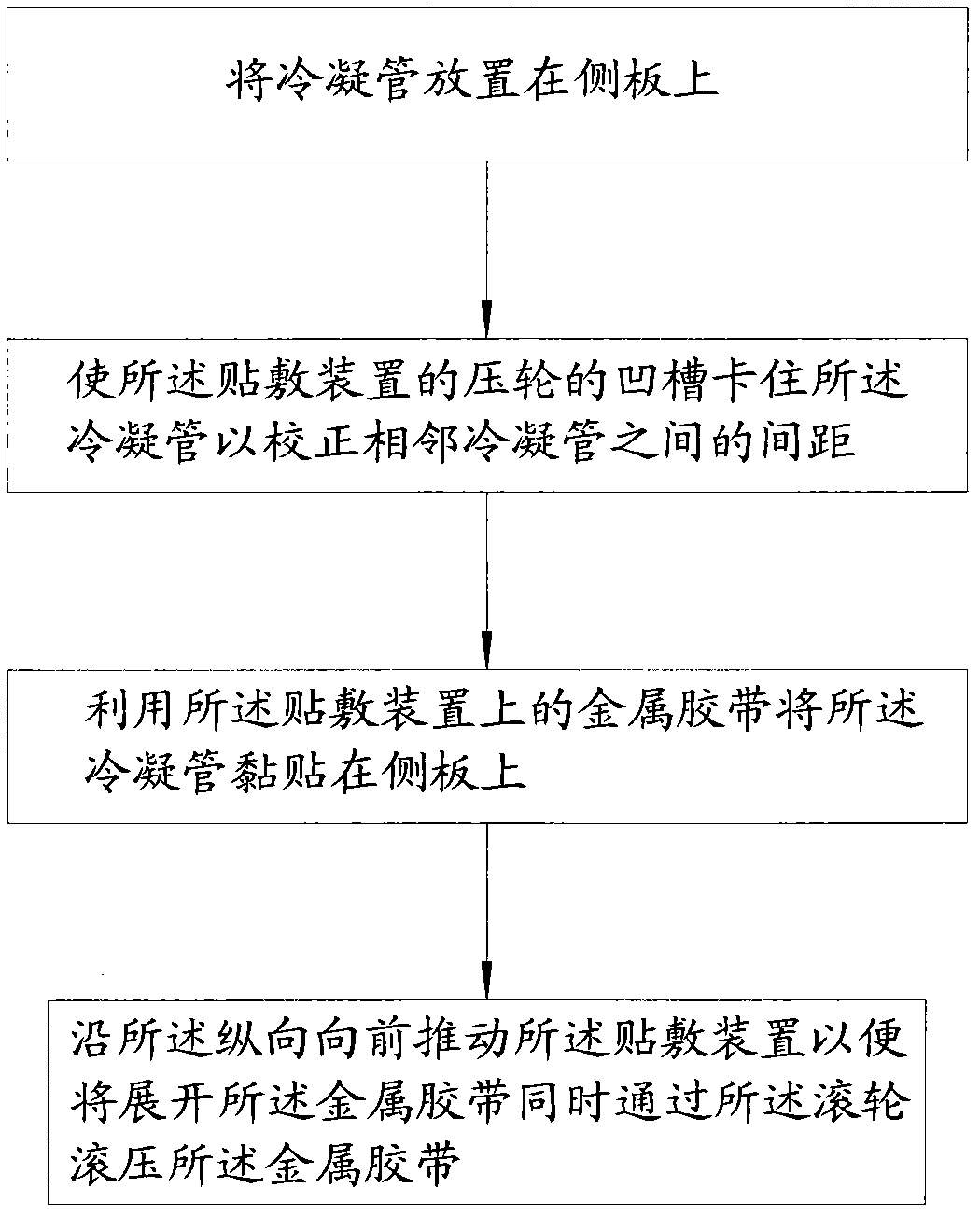

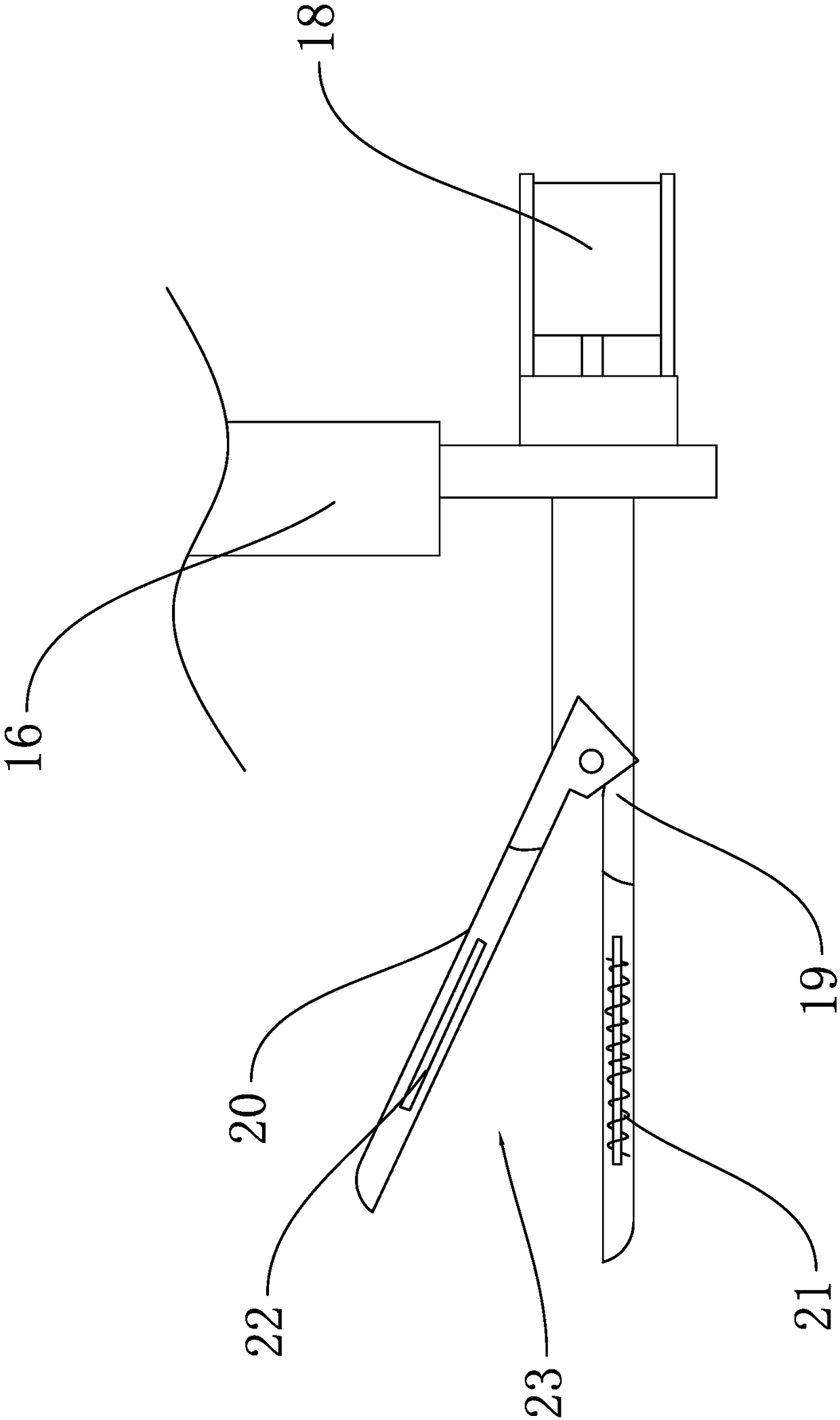

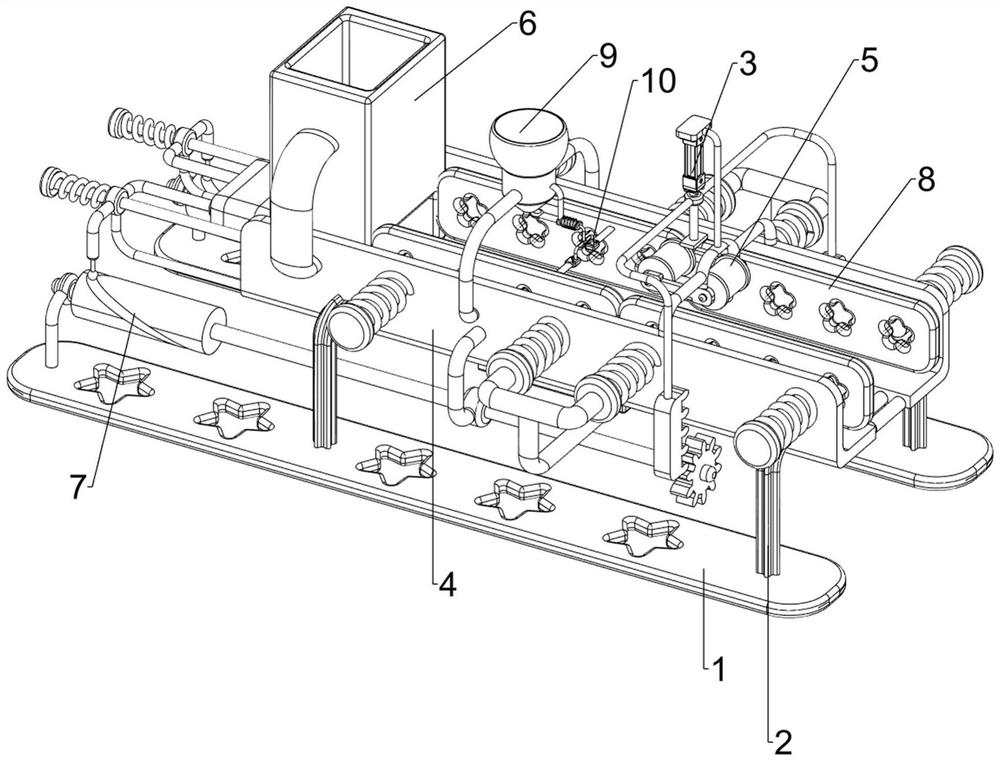

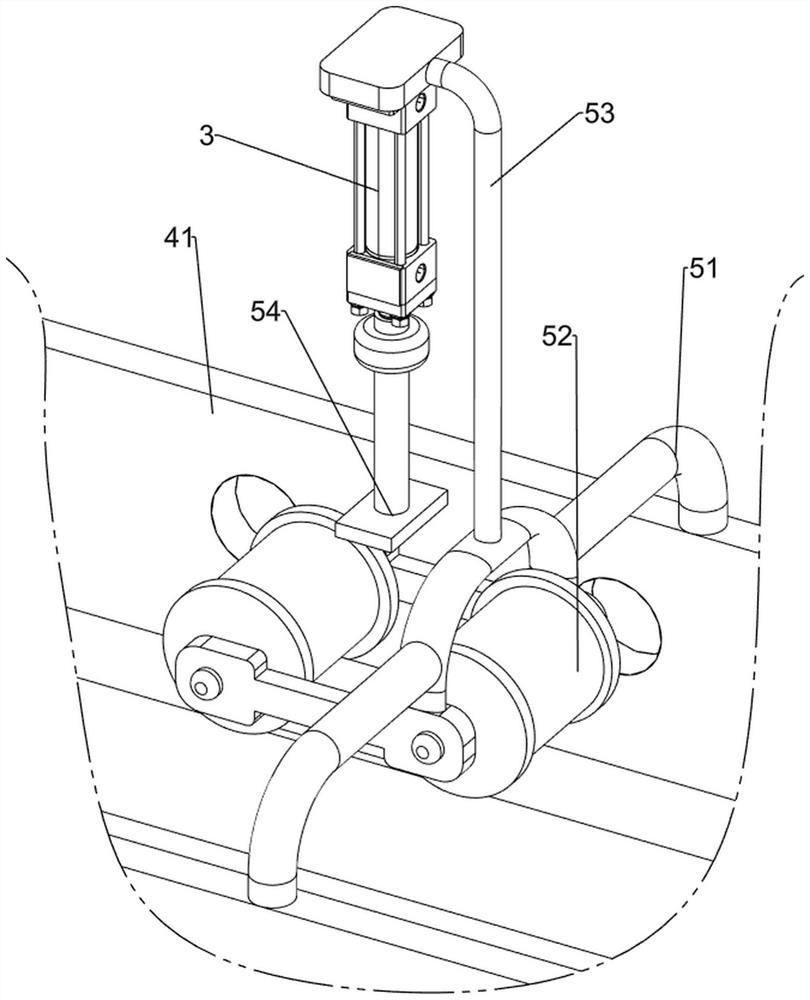

Applying device for applying condenser and production process of built-in condenser

The invention discloses a process for producing a built-in condenser by using an applying device for applying a condenser, which comprises the following steps: A, putting condenser pipes on a side plate; B, clamping the condenser pipes to correct distances between adjacent condenser pipes by using a groove of a pinch roller of the applying device; C, pasting the condenser pipes on the side plate by using a metal adhesive tape roll on the applying device; D, pushing forward the applying device along the longitudinal direction so as to fold the metal adhesive tape roll and meanwhile roll the metal adhesive tape through the roller; and repeating the above steps B-D. According to the process for producing the built-in condenser by using the applying device for applying the condenser applying device disclosed by an embodiment of the invention, equal space among condensation pipes and rapid adhesion of an adhesive tape can be realized; the condensation pipes are tightly adhered on a side plate; and the efficiency can be improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Detector for sheet class media with foreign bodies stuck to surfaces

ActiveCN104802514AQuick pasteQuick identificationPaper-money testing devicesMaterial analysis by electric/magnetic meansEngineeringForeign body

The embodiment of the invention provides a detector for sheet class media with foreign bodies stuck to the surfaces, and aims to rapidly recognize to-be-detected media with foreign bodies stuck to the surfaces. The detector is characterized by comprising an electrostatic supply part for providing electrostatic charge, a media transporting part for transporting the to-be-detected media and an electrostatic induction recognizing part; the media transporting part comprises an electrostatic receiving unit and an electrostatic absorbing unit which are connected in sequence; the electrostatic receiving unit is connected with the electrostatic supply part; the electrostatic absorbing unit is connected with the electrostatic induction recognizing part; the electrostatic receiving unit is used for transferring electrostatic charge obtained from the electrostatic supply part to the to-be-detected media; the electrostatic absorbing unit is used for absorbing the electrostatic charge of the to-be-detected media; the electrostatic induction recognizing part is used for judging whether foreign bodies are stuck to the surfaces of the to-be-detected media or not according to a received electrostatic pattern of the to-be-detected media.

Owner:GRG BAKING EQUIP CO LTD

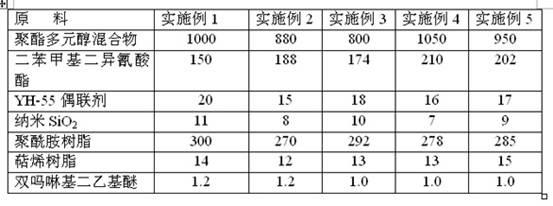

Polyurethane moisture-curable hot-melt edge sealing adhesive, and preparation method and application thereof

InactiveCN102690625AImprove material utilizationLow shrinkagePolyureas/polyurethane adhesivesPolyesterAdhesive cement

The invention belongs to the technical field of chemical adhesives, and relates to a polyurethane moisture-curable hot-melt edge sealing adhesive and a preparation method thereof. Based on weight part, the polyurethane moisture-curable hot-melt edge sealing adhesive comprises the following components: a polyester polyol mixture, diphenylmethyl diisocyanate, a plasticizer, a chain extender and a tackifying resin, wherein the polyester polyol mixture has the relative molecular weight of 1,000-7,000 and is one or more of PHL-1600, PH-2000, CMA-1044 and CMA-44; and the polyurethane moisture-curable hot-melt edge sealing adhesive does not contain any organic solvent, has the solid content of 100 percent, is short in positioning time, quickly and accurately adhere between a decorative film and a to-be-decorated base material, has high adhesive strength and high peel strength, can prevent the influence of water and other adverse environmental factors, has a flexible and elastic adhesive layer and can resist mechanical impact of edge parts in the subsequent polishing decoration process.

Owner:舒跃辉

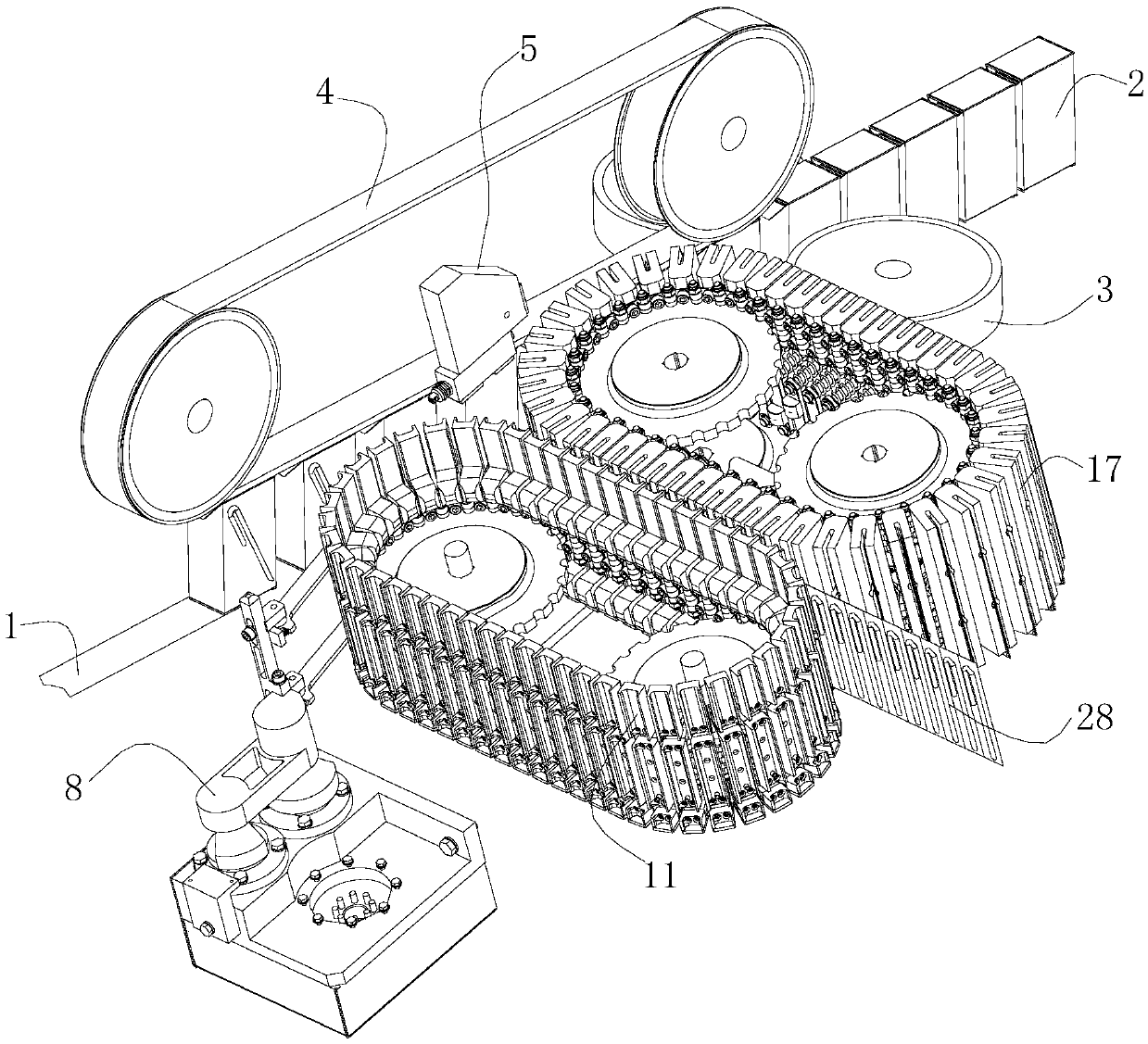

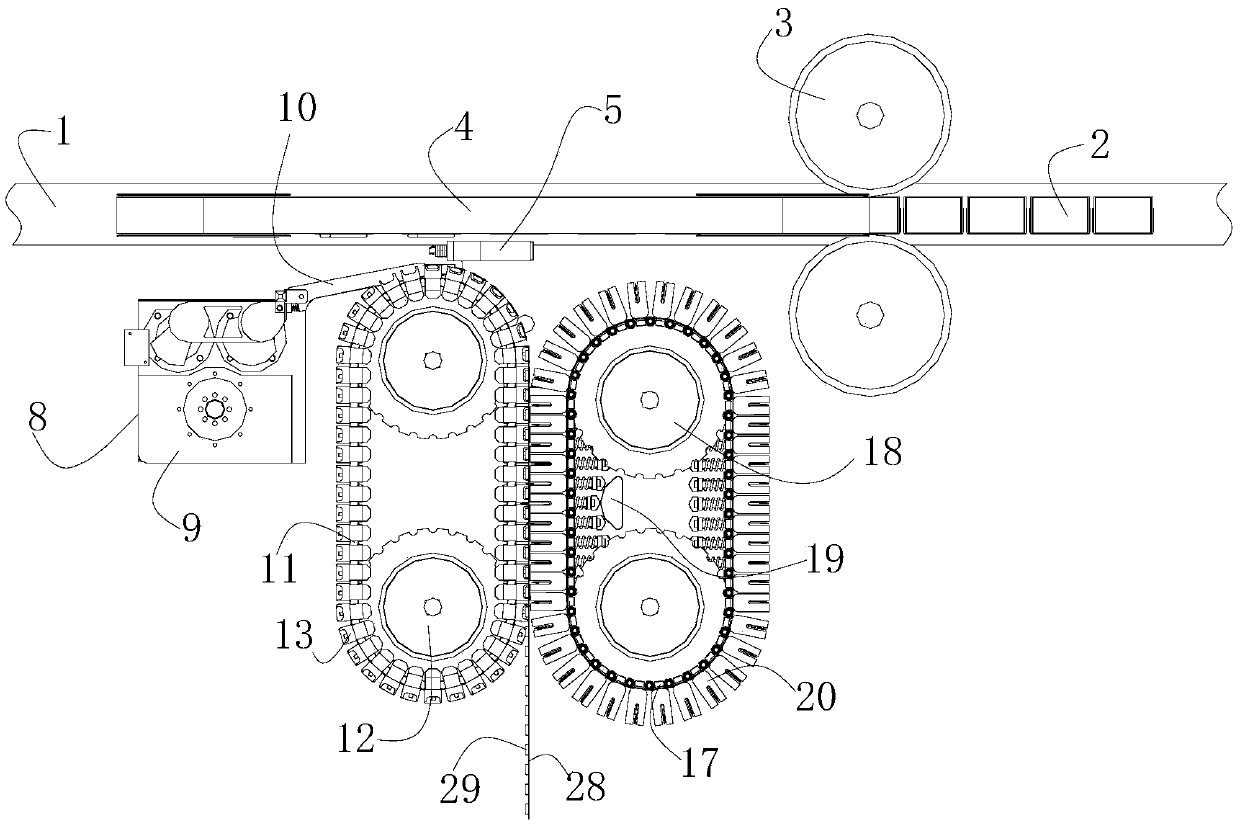

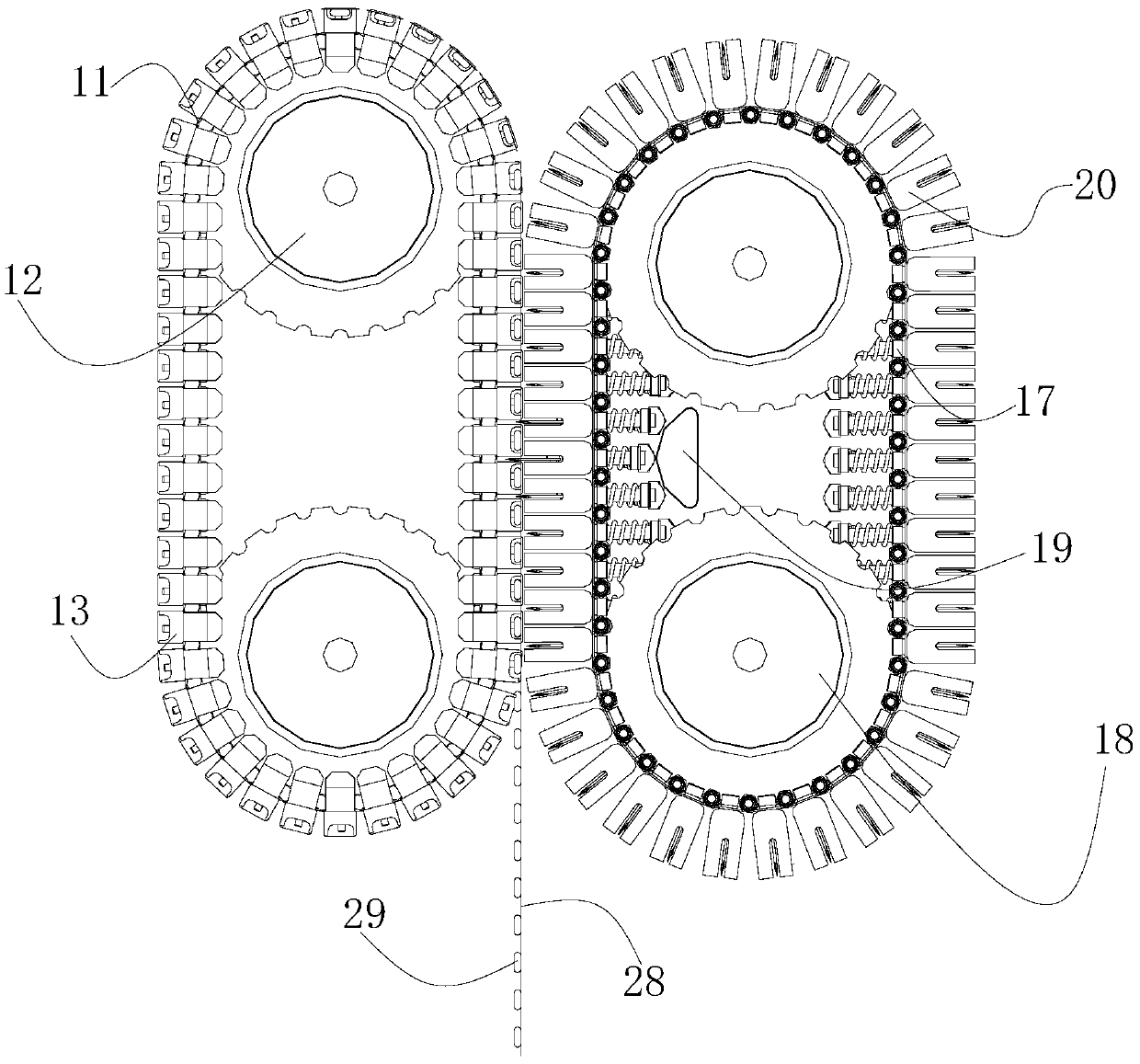

Tableware pasting device

ActiveCN105501561AAchieve separationRealize the retract functionLiquid surface applicatorsPackagingEngineeringMechanical engineering

The invention discloses a tableware pasting device used for pasting tableware to products. The tableware pasting device comprises a product conveying chain, a tableware bin chain belt adjacent to the product conveying chain, a cutting cutter assembly chain belt, a pulling and grabbing assembly and a glue gun assembly. The tableware pasting device can be used for fast pasting the tableware to the corresponding positions of the products, pasting missing or manual damage can be avoided, the production efficiency is high, the manual cost is saved, the structure is simple, and the production cost is relatively low.

Owner:广州市铭慧机械股份有限公司

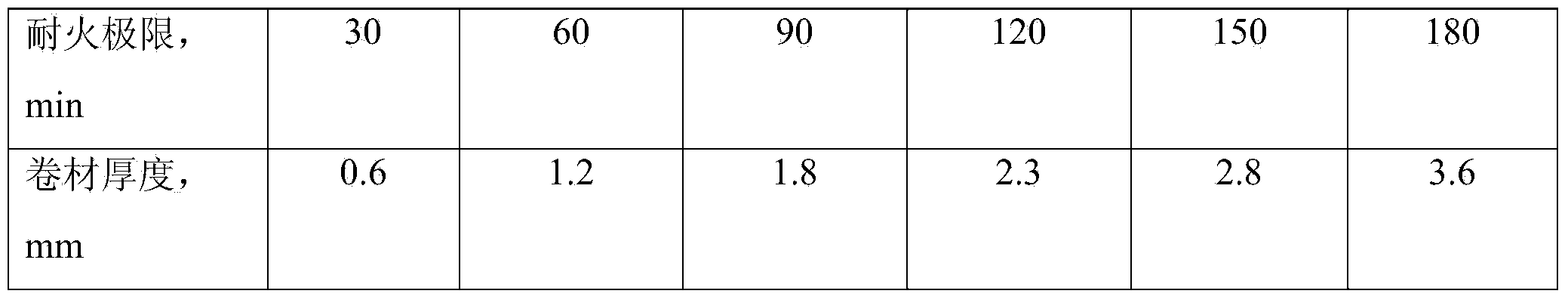

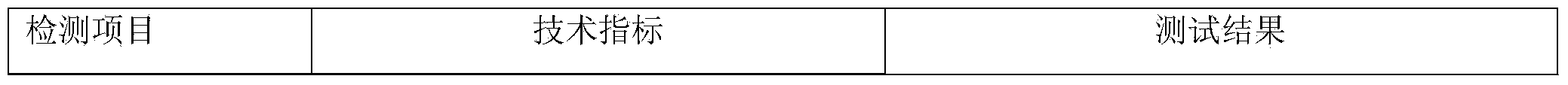

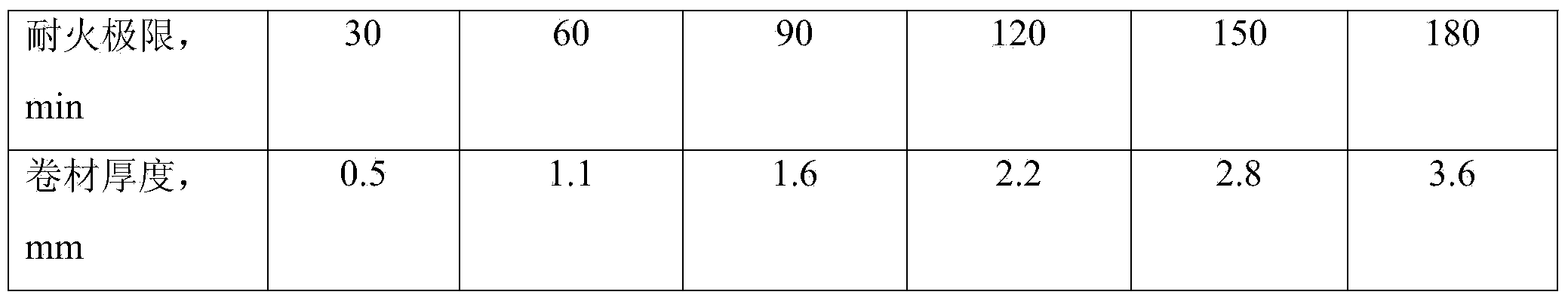

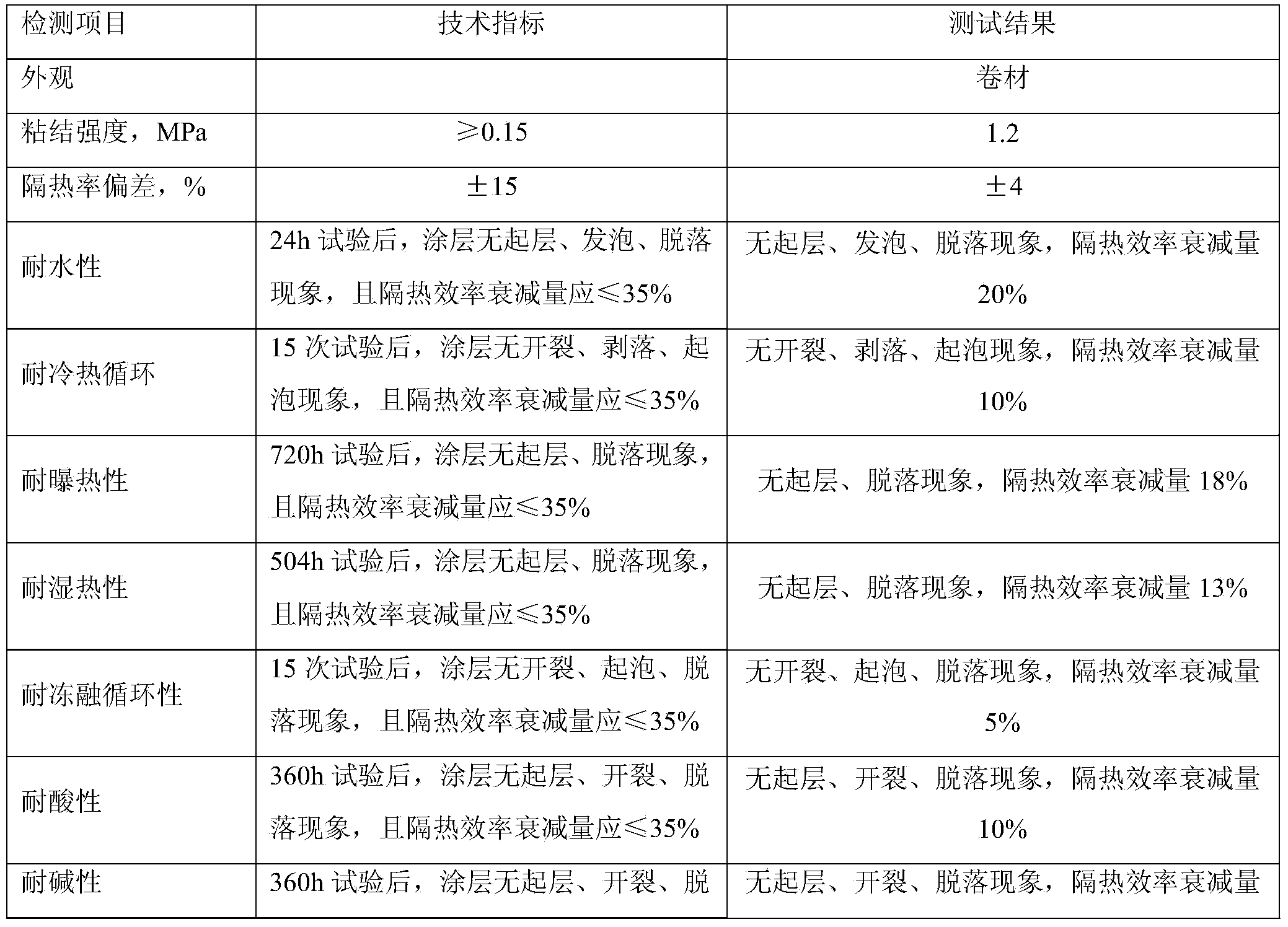

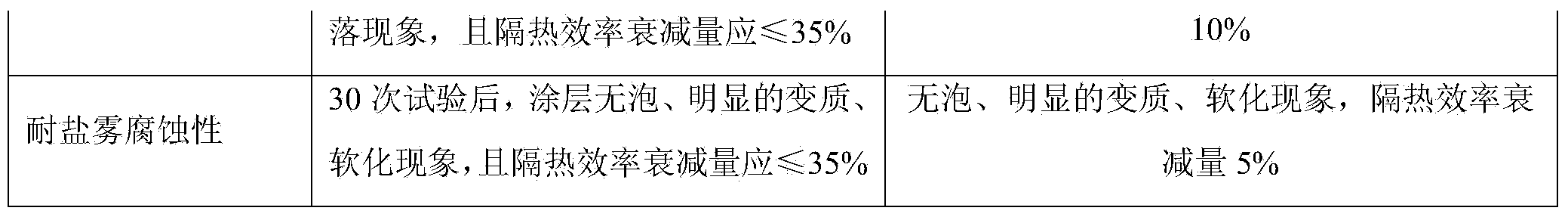

Steel structure fireproof coiled material with function layer and preparing method thereof

InactiveCN103953127AExcellent physical and chemical propertiesProduction safety and environmental protectionSynthetic resin layered productsFire proofingProduction lineWastewater

The invention relates to a steel structure fireproof coiled material with a function layer and a preparing method of the steel structure fireproof coiled material, and belongs to the field of fireproof materials. The fireproof coiled material consists of a fireproof layer and a function layer, wherein the fireproof layer consists of high molecular solid resin, expansion type fire retardants, dispersion auxiliary agents and enhancing auxiliary agents, the function layer is manufactured by additionally adding functional filling materials on the basis of the materials of the fireproof layer, and the two layers are respectively subjected to mixing, extrusion pelleting, casting tabletting, re-compounding casting and coiling into coiled materials. The steel structure fireproof coiled material can be continuously produced on a production line, the materials are processed into the coiled materials with the required thickness in one step, the production efficiency is high, the equipment is simple, the production process is safe and environment-friendly, industrial pollution such as waste water and waste gas do not exist, the fireproof coiled material can be used for producing sheet materials with different thickness according fireproof design requirements, and fireproof design requirements under different conditions can be met. The coiled material can be fast pasted on the surface of a steel structure in the use process, the fireproof design thickness can be realized through one-step pasting, the multi-time repeated brushing and coating is not needed, the work efficiency is high, the work procedures are simple, and the construction is environment-friendly and convenient.

Owner:天津宝宸恒远科技有限公司

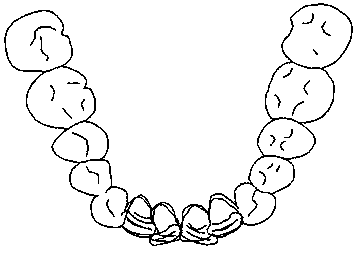

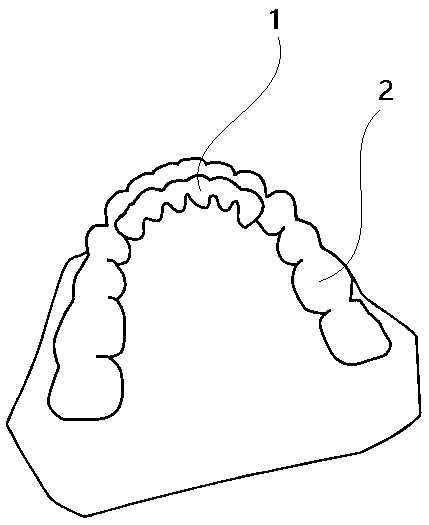

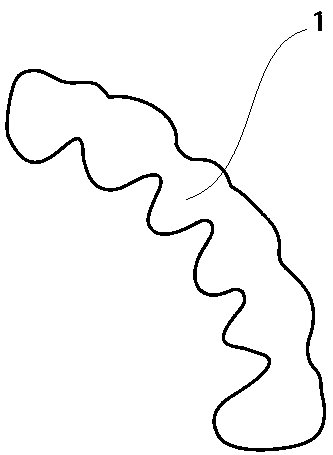

Customized lingual side fixed retainer and preparation method thereof

InactiveCN107837121AQuick pasteReduce difficulty and intensityAdditive manufacturing apparatusBracketsPatient treatmentBiomedical engineering

The invention discloses a customized lingual side fixed retainer which can provide continuous and stable retentiveness, shorten a patient treatment cycle and realize personalized treatment, and a preparation method thereof; the customized lingual side fixed retainer includes a fixed retainer main body which is molded by one time through three-dimensional stereoscopic printing, and the fixed retainer main body is made of an alloy material, and is pasted and fixed with patient teeth through resin. The invention provides the customized lingual side fixed retainer and the preparation method thereof; the customized lingual side fixed retainer made of the alloy material having a shape memory function has a personalized shape matched with arraying of patient own teeth; through self positioning with a fixed retaining structure which is safely fitted to the hook shape of the surface of each tooth, fast pasting is achieved, an indirect pasting guide plate for positioning has no need of additional design, and the difficulty and intensity of doctor clinical operation are reduced.

Owner:云艺生物科技(长春)有限公司

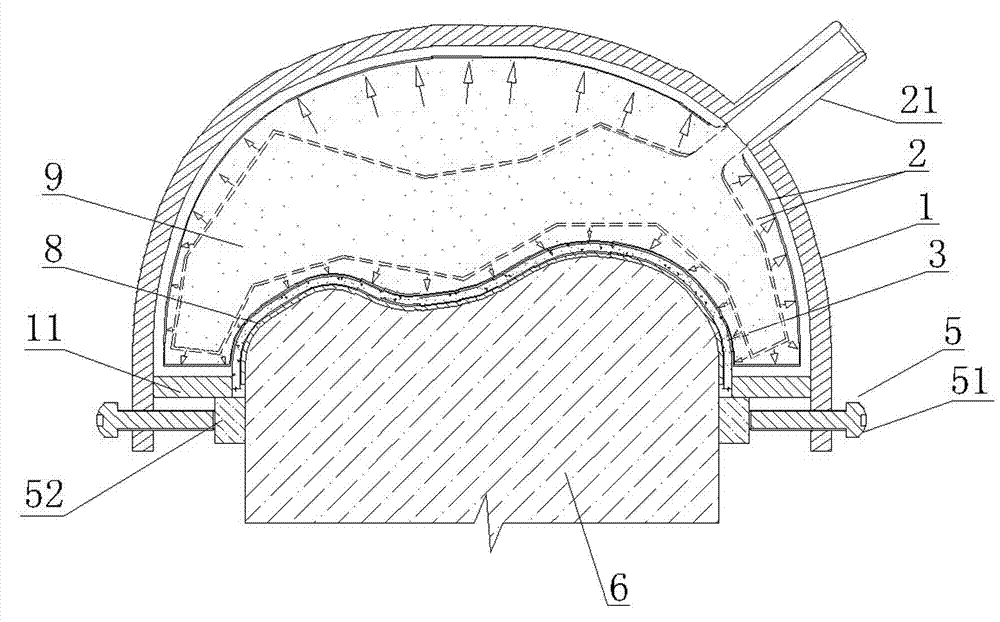

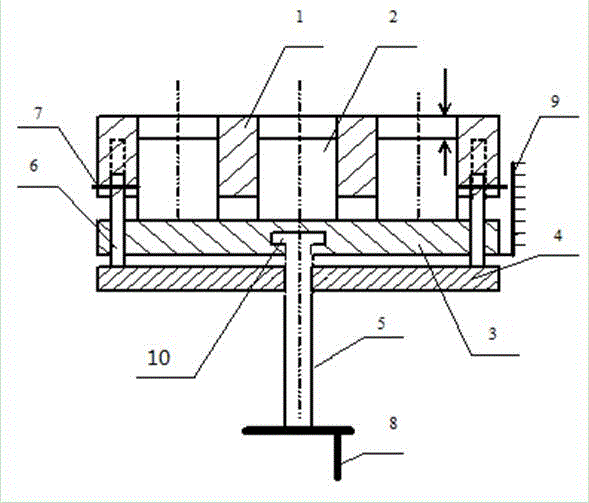

Flexible die hot pressing furniture edge sealing device and furniture heteromorphous component edge sealing technique

The invention relates to a flexible die hot pressing furniture edge sealing device and a furniture heteromorphous component edge sealing technique. The edge sealing device comprises an outer casing boy with a lower mounting opening, an inflatable bag arranged in the outer casing, a flexible heat pipe located below the inflatable bag, an insufflation port extending out of the outer casing is formed in the inflatable bag, and the capacity of air in the inflatable bag is larger than the volume of the outer casing. According to the invention, the flexible die hot pressing edge furniture edge sealing device formed by the outer casing, a flexible die inflatable bag arranged in the outer casing, the flexible heat pipe and the like are adopted, so that when in use, the flexible die hot pressing furniture edge sealing device to inflate and pressurize the inflatable bag to achieve pressurization of the flexible heat pipe and enable a sealing edge strip rubberizing surface to quick shape and solidify, so that an edge sealing strip is quickly and efficiently clung to the edge of a heteromorphous component, and the pressed and shaped furniture heteromorphous component edge sealing has enough strength, good stability, and a product surely cannot degum and crack in case of humidity change. The flexible die hot pressing furniture edge sealing device and the furniture heteromorphous component edge sealing technique can be widely applicable to the field of furniture.

Owner:梅州市汇胜木制品有限公司 +1

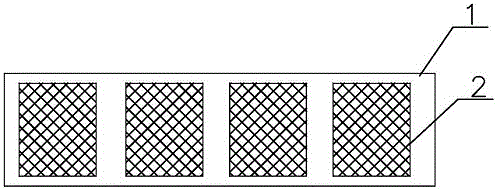

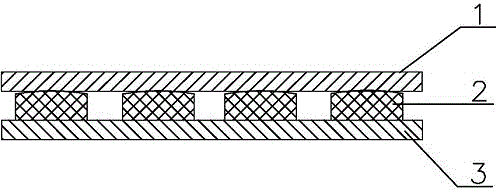

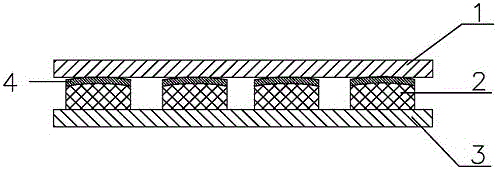

Improved substrate-free tape

InactiveCN106833405APrevent overflowAvoid cleaning inconvenienceFilm/foil adhesivesHydrogenEngineering

The invention discloses an improved substrate-free tape. The improved substrate-free tape sequentially comprises a first release layer, a pressure-sensitive adhesive layer and a second release layer, wherein the release force of the first release layer is less than that of the second release layer; both the first release layer and the second release layer are of a ribbon structure; the pressure-sensitive adhesive layer is a plurality of rectangular blocks uniformly distributed along the first release paper layer of the ribbon structure; the distance between every two adjacent rectangular blocks is 0.5-10mm; and the distance from the edge of the pressure-sensitive adhesive layer to the edge of the first release paper layer is 0.5-3mm.The improved substrate-free tape has the advantages of high viscosity, convenient use, no sticking after component bonding, easy tear-off and the like. According to the invention, a mixture of sodium hydrogen carbonate particles and carbon powder is added, so that the heat dissipation manner inside the pressure-sensitive adhesive layer can be effectively improved, the heat dissipation effect can obviously enhanced, thereby providing a novel improved substrate-free tape with a favorable heat dissipation function.

Owner:WUHU HONGSHENG TECH

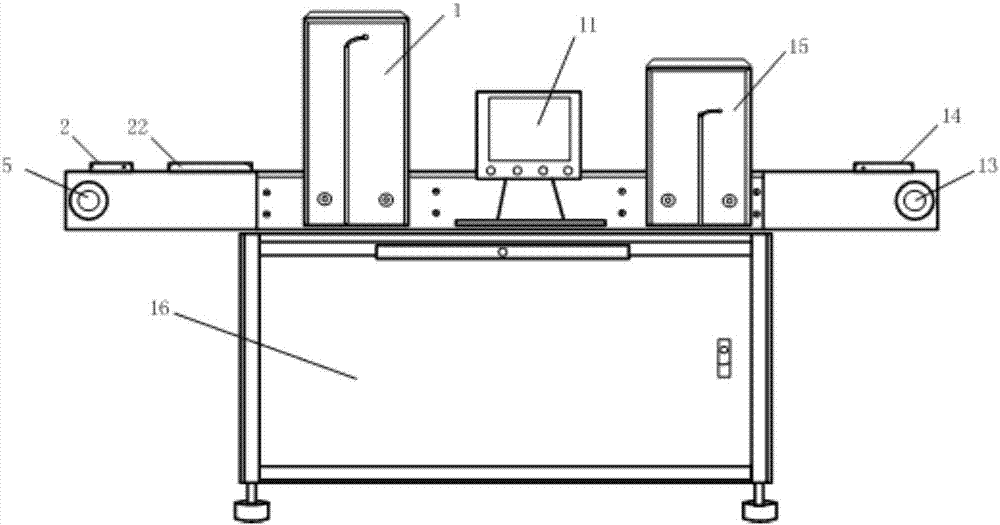

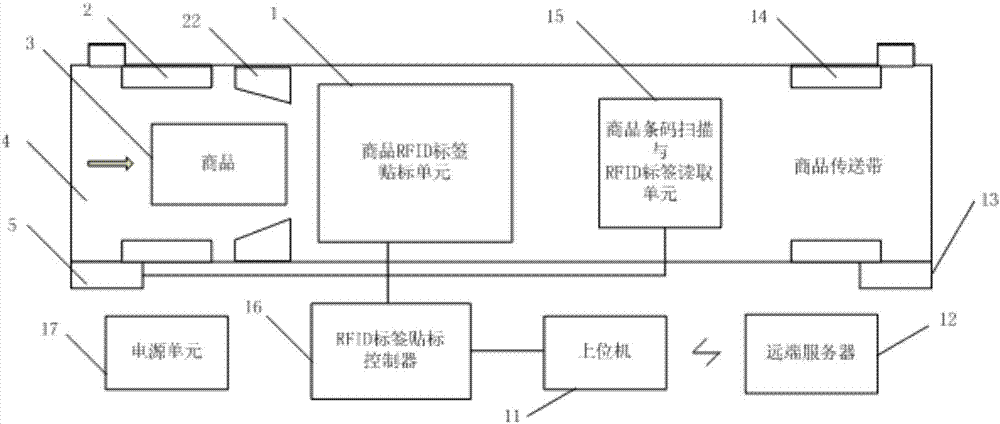

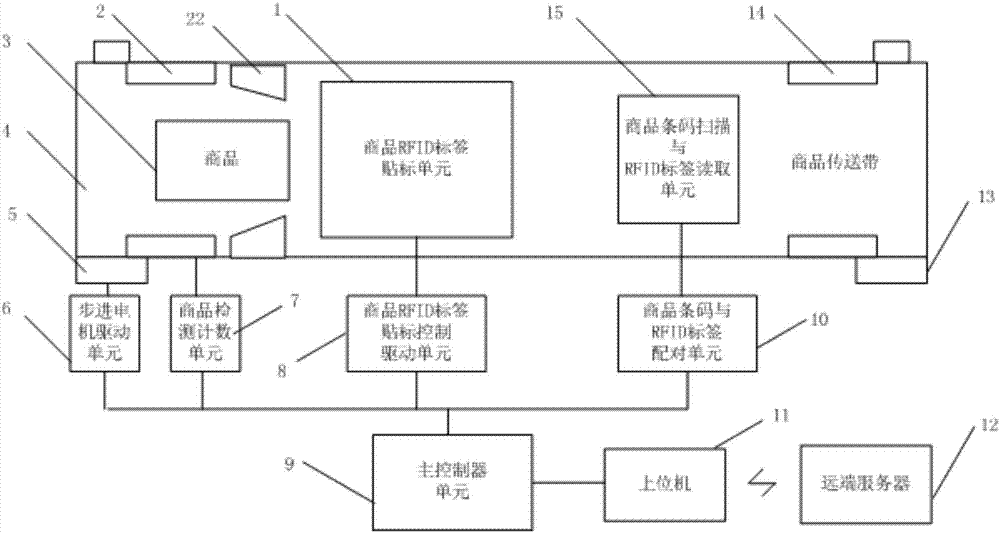

Barcode and RFID labeling machine

PendingCN107344644AQuick pasteImprove the level of intelligent managementCo-operative working arrangementsCommerceBarcodeLogistic management

The invention discloses a barcode and RFID labeling machine, and relates to the field of factory production, self-service, logistics management and cargo packing. The labeling machine comprises a commodity RFID labeling unit, a left-end infrared commodity inspection unit, a right-end infrared commodity inspection unit, a commodity conveyor belt, a commodity conveyor belt driving device, a commodity guide device, commodity conveyor belt guide wheels, a RFID labeling controller, an upper computer, remote servers, a barcode scanning and RFID label reading unit and a power unit; and the upper computer is connected to the remote servers through a network, and the power unit is connected to the upper computer, the RFID labeling controller, the commodity conveyor belt driving device and the barcode scanning and RFID label reading unit. According to the labeling machine disclosed by the invention, the intelligent management degree of commodities or cargoes is improved greatly, and the manpower cost is reduced; and the management efficiency is improved.

Owner:浙江行雨网络科技有限公司

Quick mounting method of velocity/acceleration sensor

InactiveCN104655867AExtended operating temperature rangeIncrease support weightSpeed/acceleration/shock instrument detailsEngineeringShort terms

The invention provides a quick mounting method of a velocity / acceleration sensor, used for structural testing of bridges, buildings and the like. The method can guarantee rapid mounting at the top and bottom, and on side surfaces of a structure, can rapidly conduct dismounting and cleaning, and is effective on various surfaces, such as the surfaces of novel concrete structures, old concrete structures, steel structures and wood structures, as well as the common paving structures. According to the actual condition of a mounting site, the method is suitable for short-term or long-term tests, is further suitable for sticking at complex positions (horizontal sticking, lateral sticking and upward sticking), avoids temporary fixing, can realize instant adhesion after pasting, and can realize the fact that the strength is reached a moment later; quick sticking powders with different setting times and different water-cement ratios added during mixing are selected, so as to control the viscosity and setting times, and the requirements of quick sticking, large-scale sticking, sticking at special positions and the like are satisfied; the mounted sensor has the advantages of being wide in application occasions, wide in frequency response ranges, wide in application temperature ranges, high in supporting weight, convenient to dismount and clean up and the like.

Owner:TSINGHUA UNIV

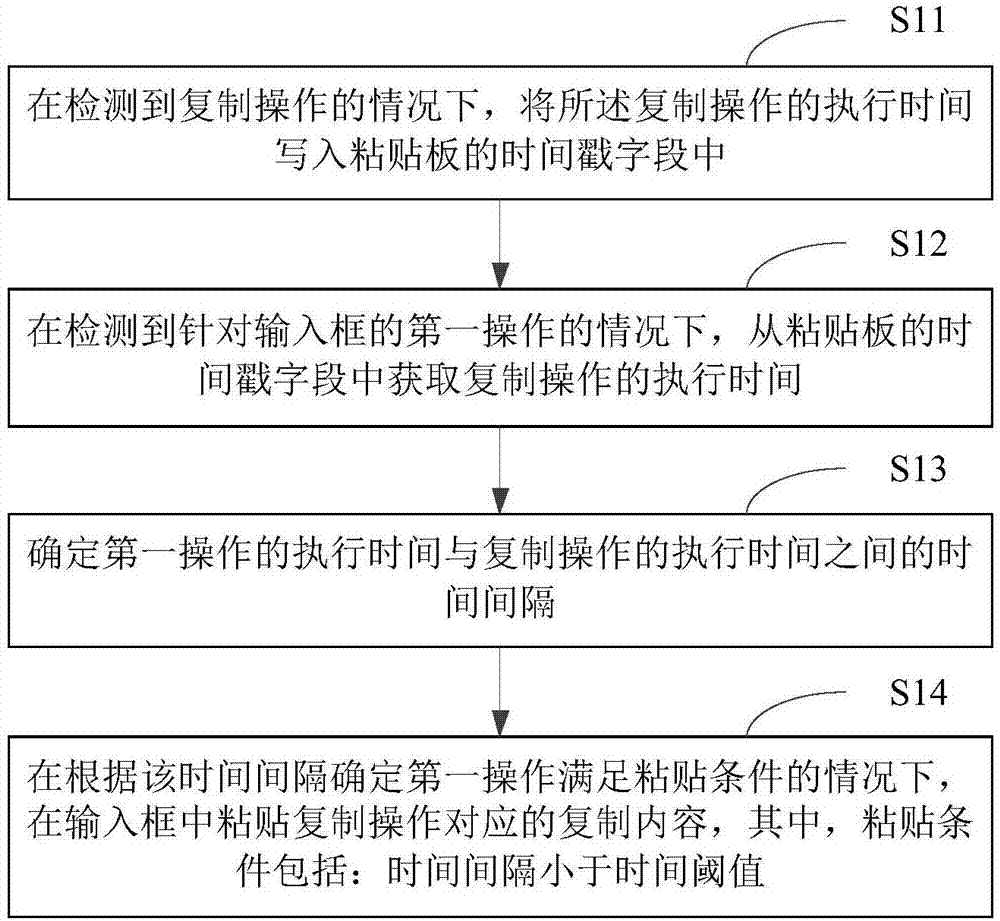

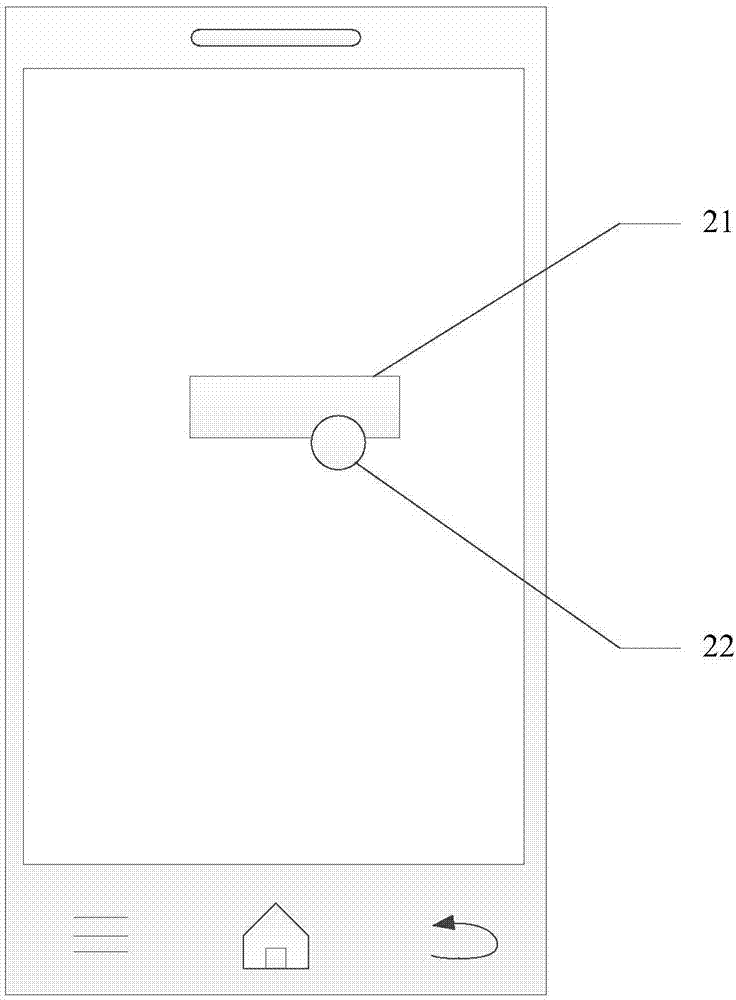

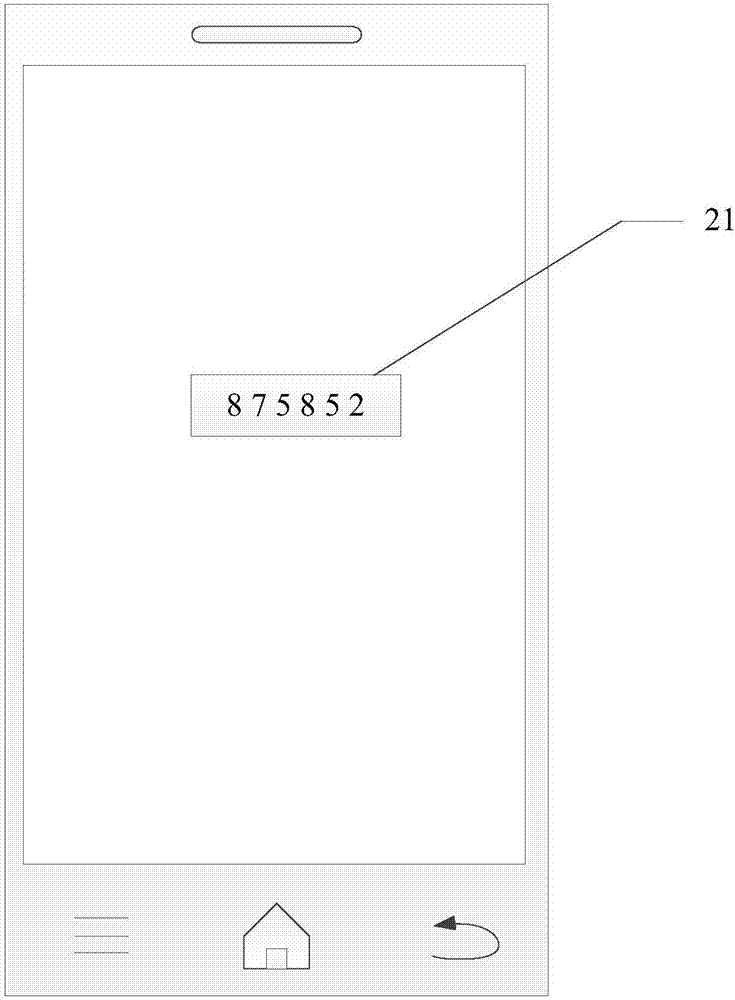

Paste method and device

ActiveCN107239351ASimplify the pasting processImprove operational convenienceInterprogram communicationInput/output processes for data processingTimestampComputer science

The invention relates to a paste method and device. The method comprises the steps that under the condition that copy operation is detected, the execution time of the copy operation is written in a timestamp field of a pasteboard; under the condition that first operation for an input box is detected, the execution time of the copy operation is obtained in the timestamp field of the pasteboard; the time interval between the execution time of the first operation and the execution time of the copy operation is determined; under the condition that it is determined that the first operation meets the paste condition according to the time interval, the copy content corresponding to the copy operation is pasted in the input box, wherein the paste condition comprises the condition that the time interval is smaller than a time threshold. By means of the paste method and device, the paste process can be simplified, the operation convenience of the paste operation can be greatly improved, and quick paste is achieved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

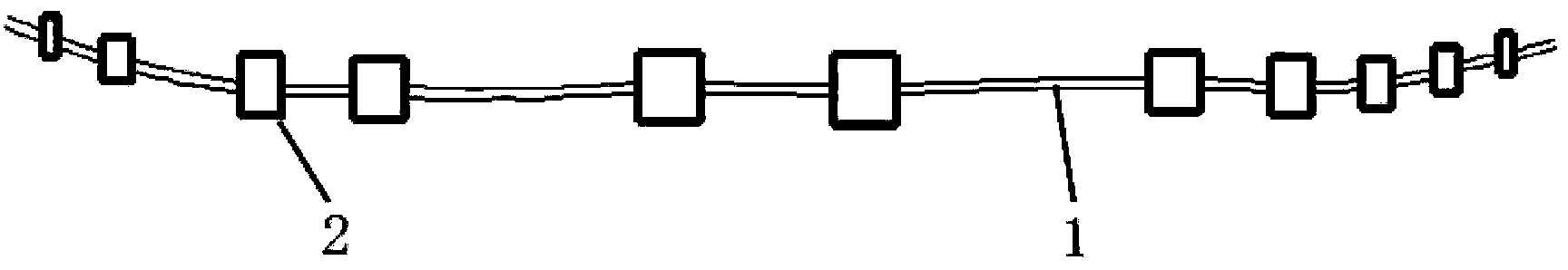

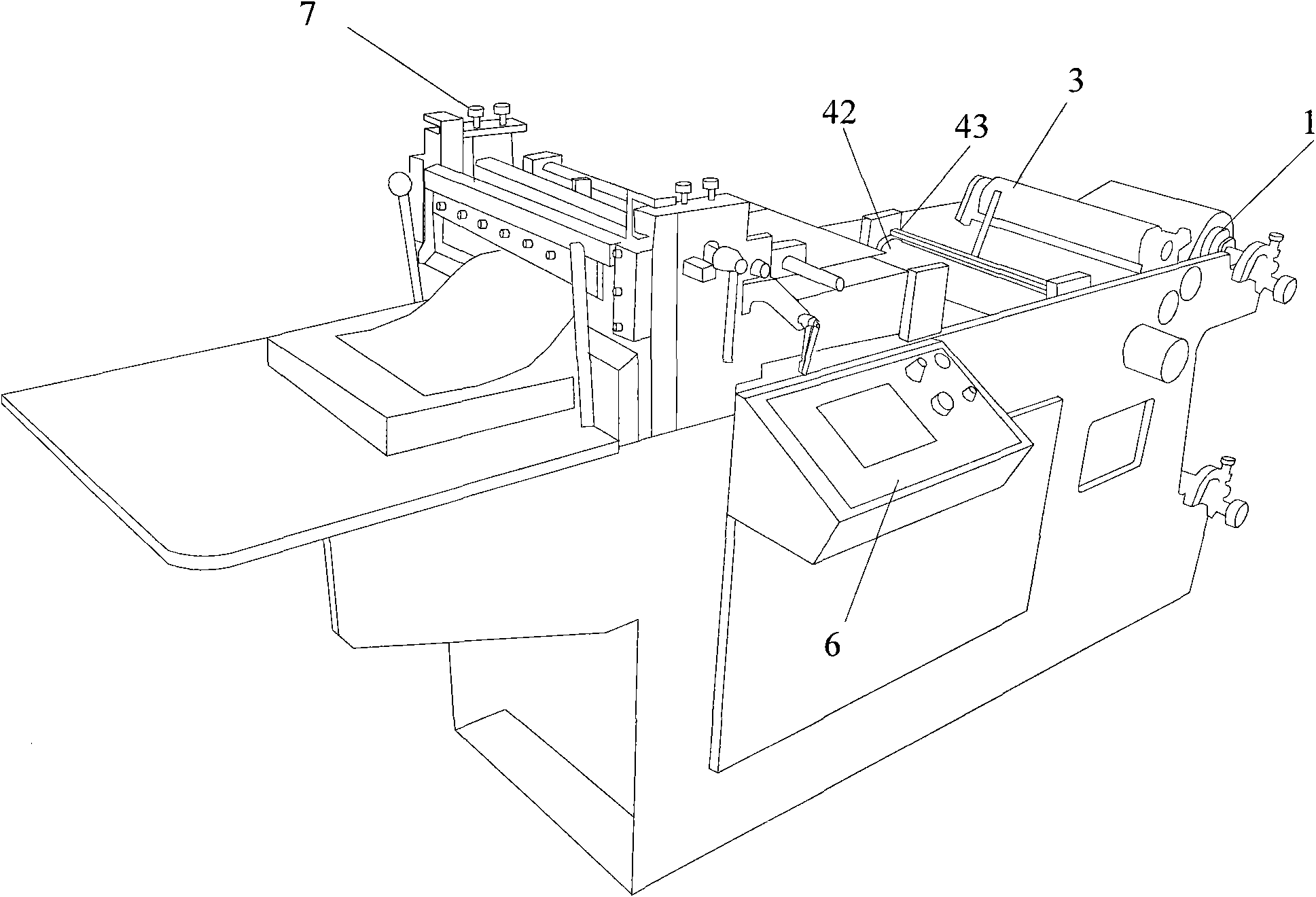

Linear glue spreading machine and linear composite glue flake spreading machine

The invention discloses a linear glue spreading machine and a linear composite glue flake spreading machine. The linear glue spreading machine is characterized in that a motor in a rack drives a spindle winding round a first polyester film to rotate via two transmission gears and drives a spindle winding round a second polyester film to rotate via another two transmission gears; the first polyester film passes above a glue box; a spindle is arranged above the glue box and drives a glue spreading wheel on the spindle to rotate by rotating; the glue water in the glue box is spread on the first polyester film contacted with the glue spreading wheel; the first polyester film on which the glue water is spread is stuck to the second polyester film, and the two films pass between a roller and a compression roller and are firmly stuck after being compacted; and the rotating speeds of each transmission gear, the spindle with the glue spreading wheel, the roller and the compression roller are accurately and synchronously controlled by a PLC control servo motor. The linear glue spreading machine is used for sticking the polyester films efficiently to prepare composite flakes. The linear composite glue flake spreading machine is used for cutting the stuck composite flakes into individual composite flake in a size required by the users.

Owner:李小杰

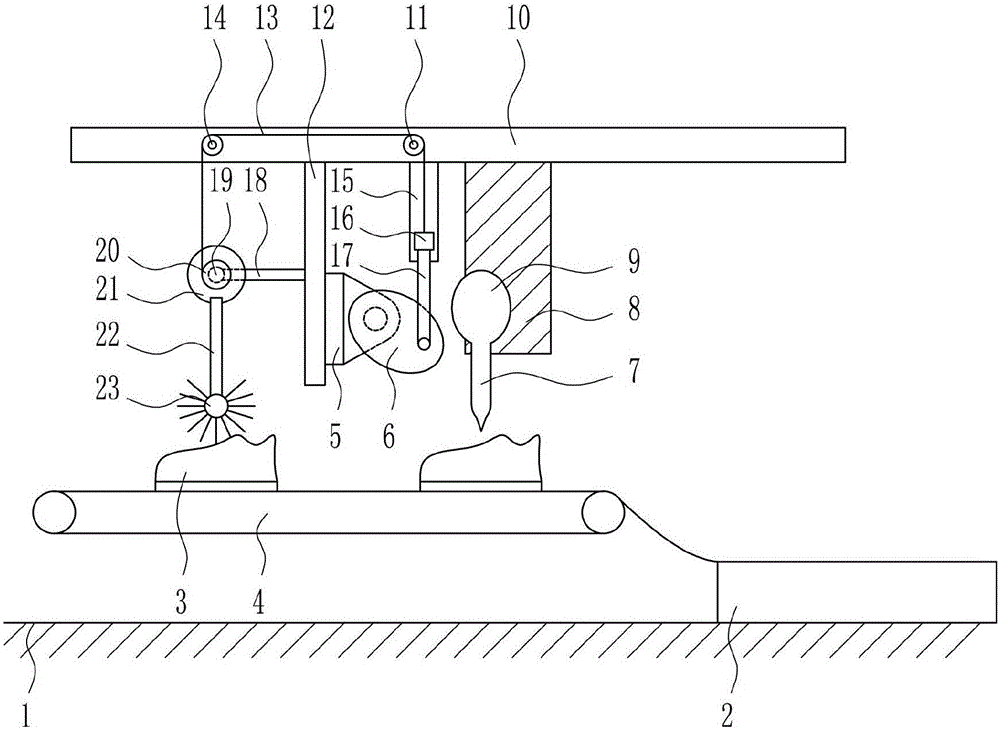

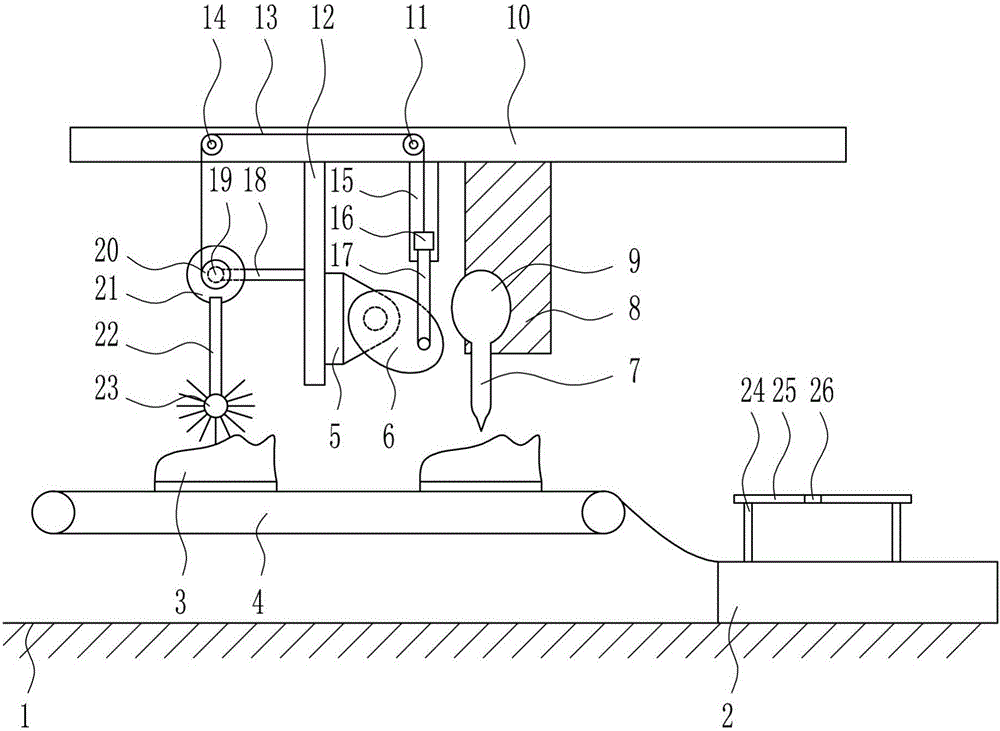

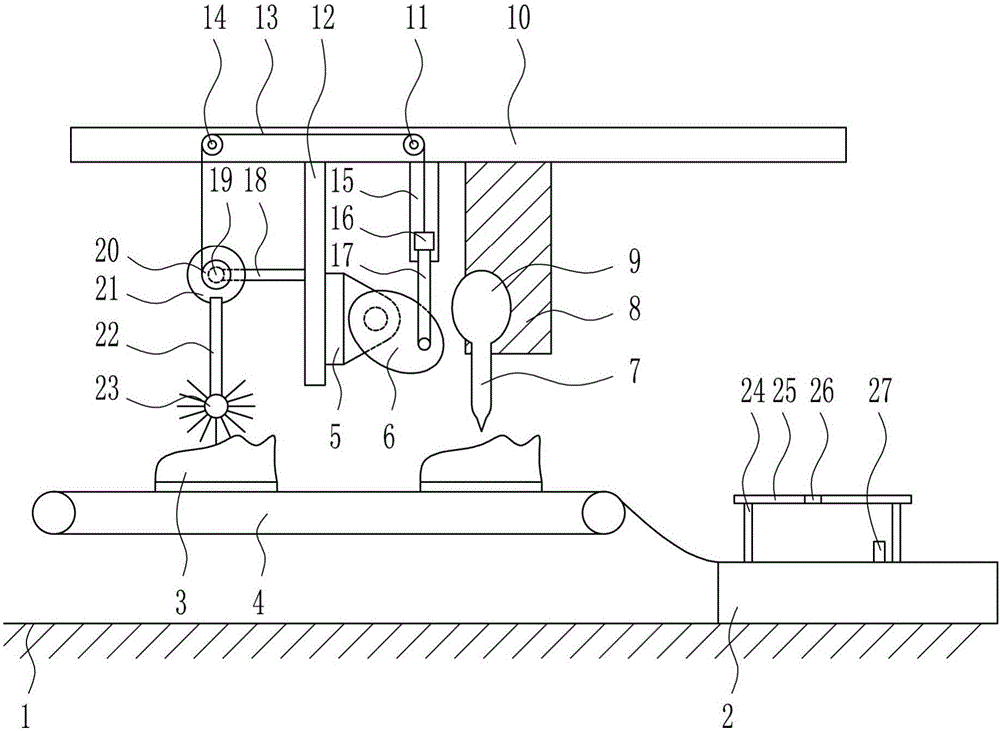

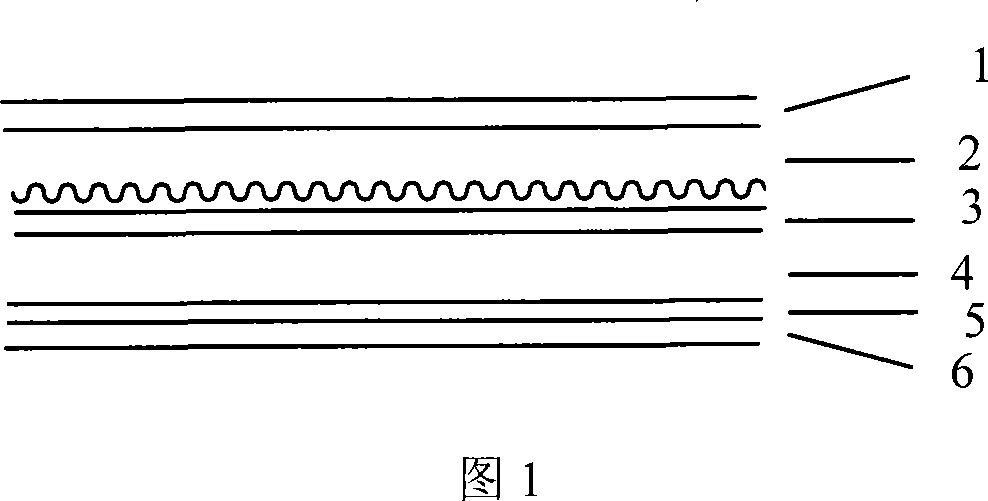

Ornament adhesion device for shoe making

The invention relates to an ornament adhesion device and especially relates to an ornament adhesion device for shoe making. The technical problem to be solved by the invention is to provide the ornament adhesion device for the shoe making, wherein adhesion efficiency is high and ornament adhesion is accurate. In order to solve the technical problem, the invention provides the ornament adhesion device for the shoe making. The device comprises a working table, a transmission device, a sway base, an ellipsoid cam, an adhesive dripping bottle, a fixation trough, an adhesive cap, a top plate, a second fixed pulley, a fixation plate, a pull wire, a first fixed pulley, a slide rail, a slide block, a connecting rod, a first strut, an electric motor, a winding wheel, a round disk, a sway rod and a duster, wherein the transmission device and the working table are disposed on the ground, and the transmission device is located above the left part of the working table. According to the invention, ornaments can be adhered on a shoe rapidly; by a limiting block, a second strut and a positioning plate, the ornaments can be adhered on the shoe more easily; and ornament adhesion positions are more accurate.

Owner:广东亮丰达实业有限公司

Precoating glue table tennis bat series glue and manufacturing method thereof

The invention discloses a pregummed table-tennis rubber sheets and a manufacturing method, which comprises the sequential connected rubber protecting film, the rubber, the adhesive layer and the spongy layer, and also comprises the pressure sensitive sub connected with the profile material layer, the pressure sensitive sub connected with the spongy layer and the profile material layer sticking on the pressure sensitive sub. During the preparation, coating the sponge of the traditional table-tennis rubber sheets making from the rubber, the spongy layer and the adhesive layer with the pressure sensitive glue, and utilizing the profile materials sticking on the pressure sensitive sub to protect the pressure sensitive sub; the pressure sensitive sub is the pressure sensitive glue of rubber styles, the pressure sensitive glue of the acrylic ester or the thermal pressure sensitive glue. The invention has the advantages of repeated sticking and stripping after once gelatinizing, the good elasticity, the convenient use and taking and nontoxic, and overcomes the sticking shortage of the traditional table-tennis rubber sheets, which use toxic organic solvent glue or use the water glue with slow dryness.

Owner:SOUTH CHINA UNIV OF TECH

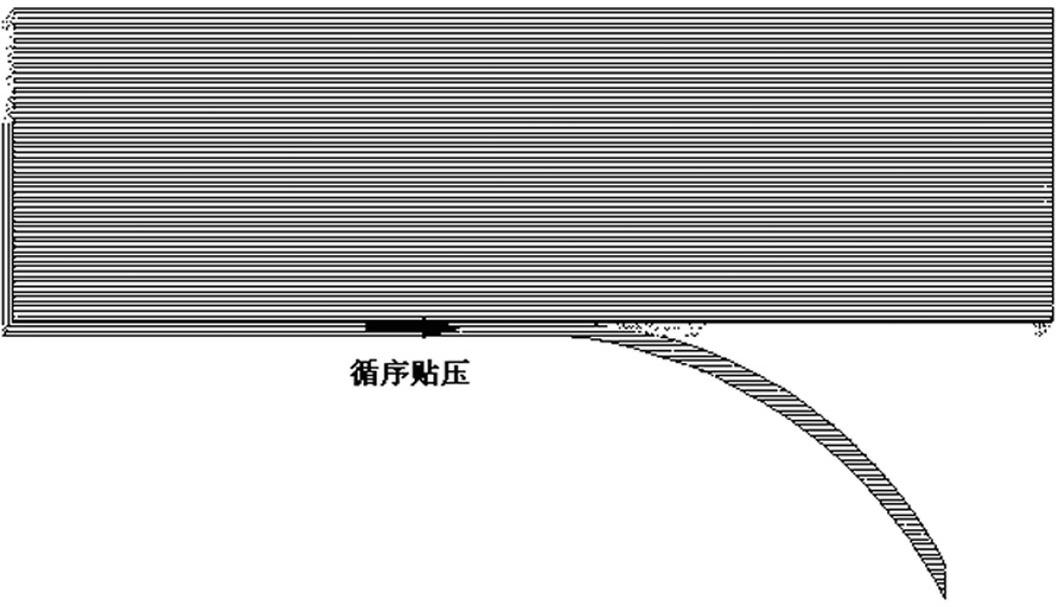

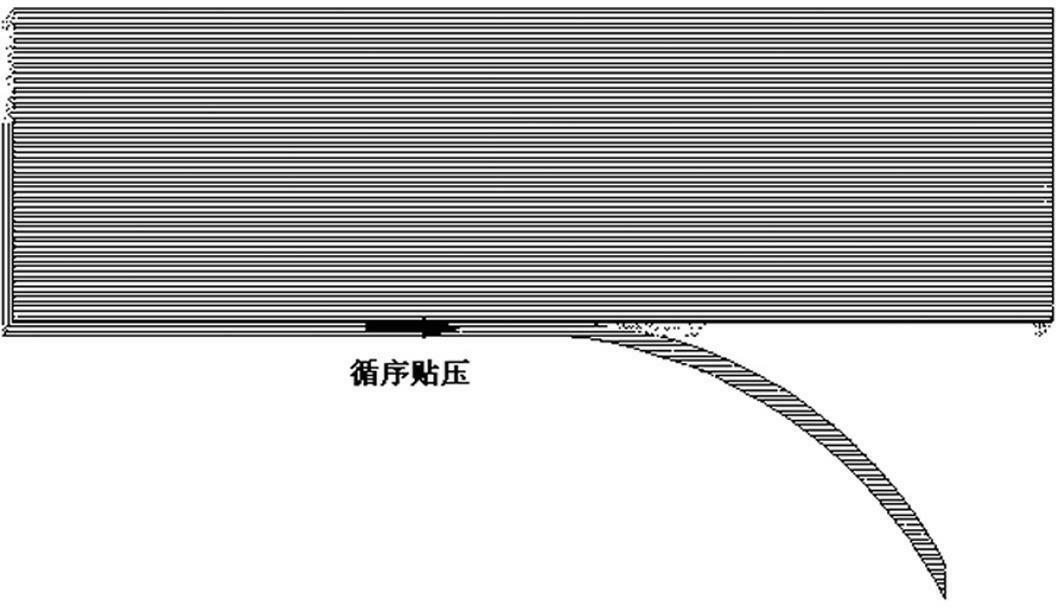

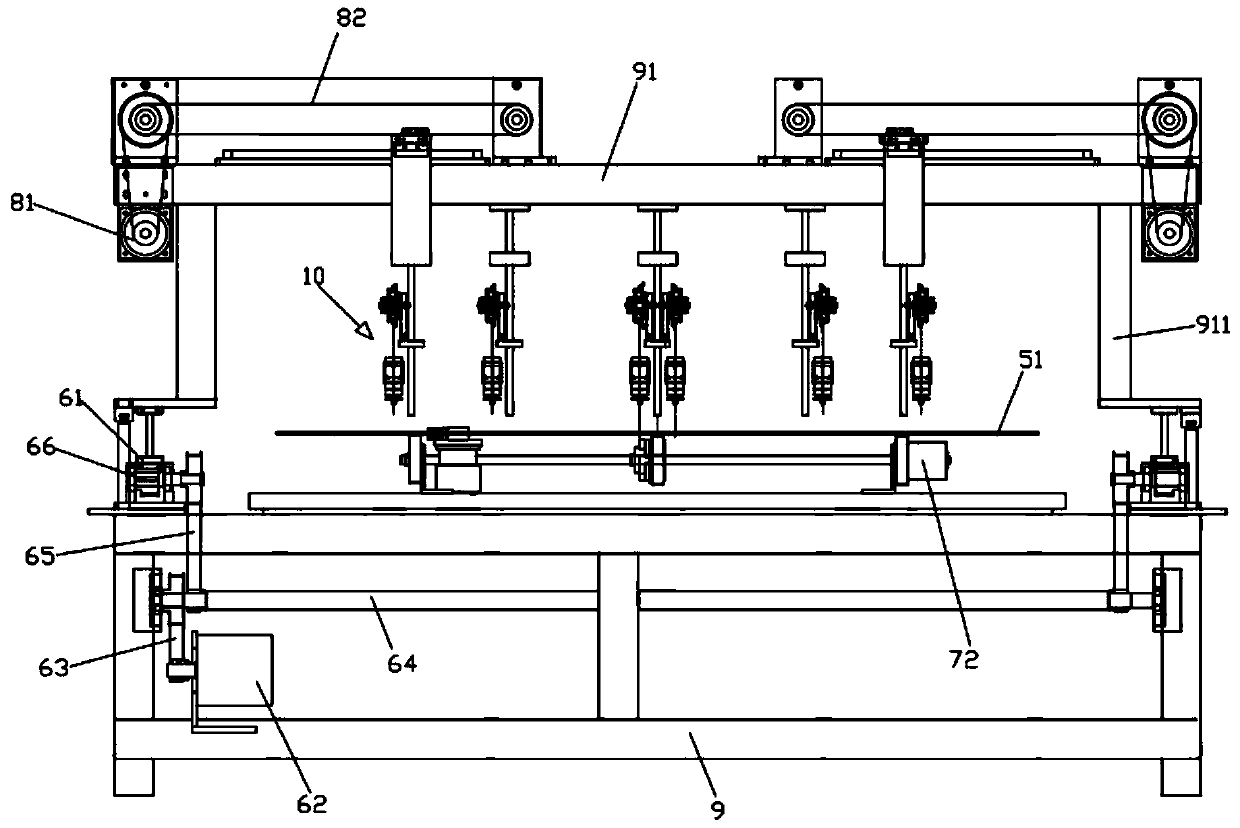

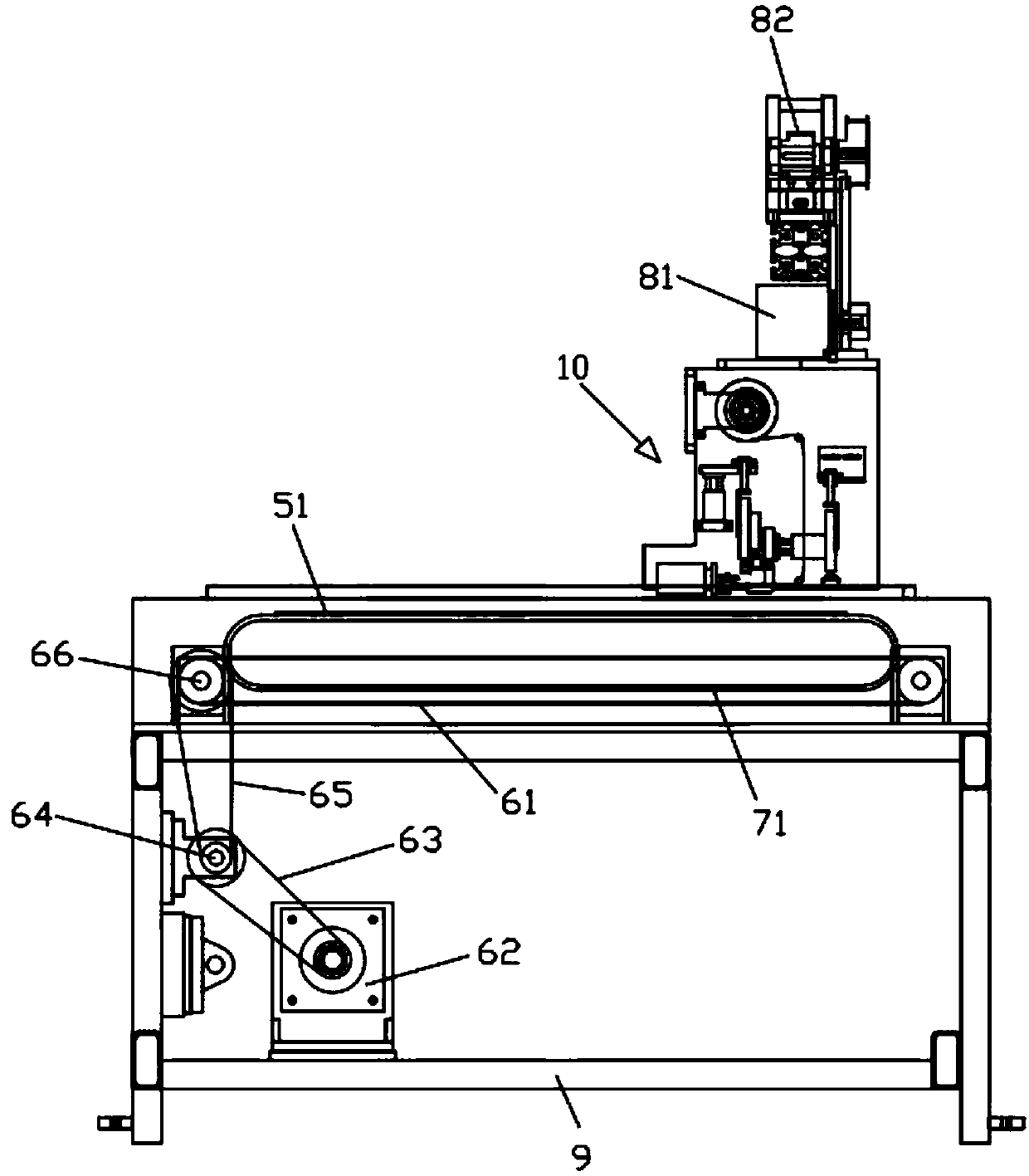

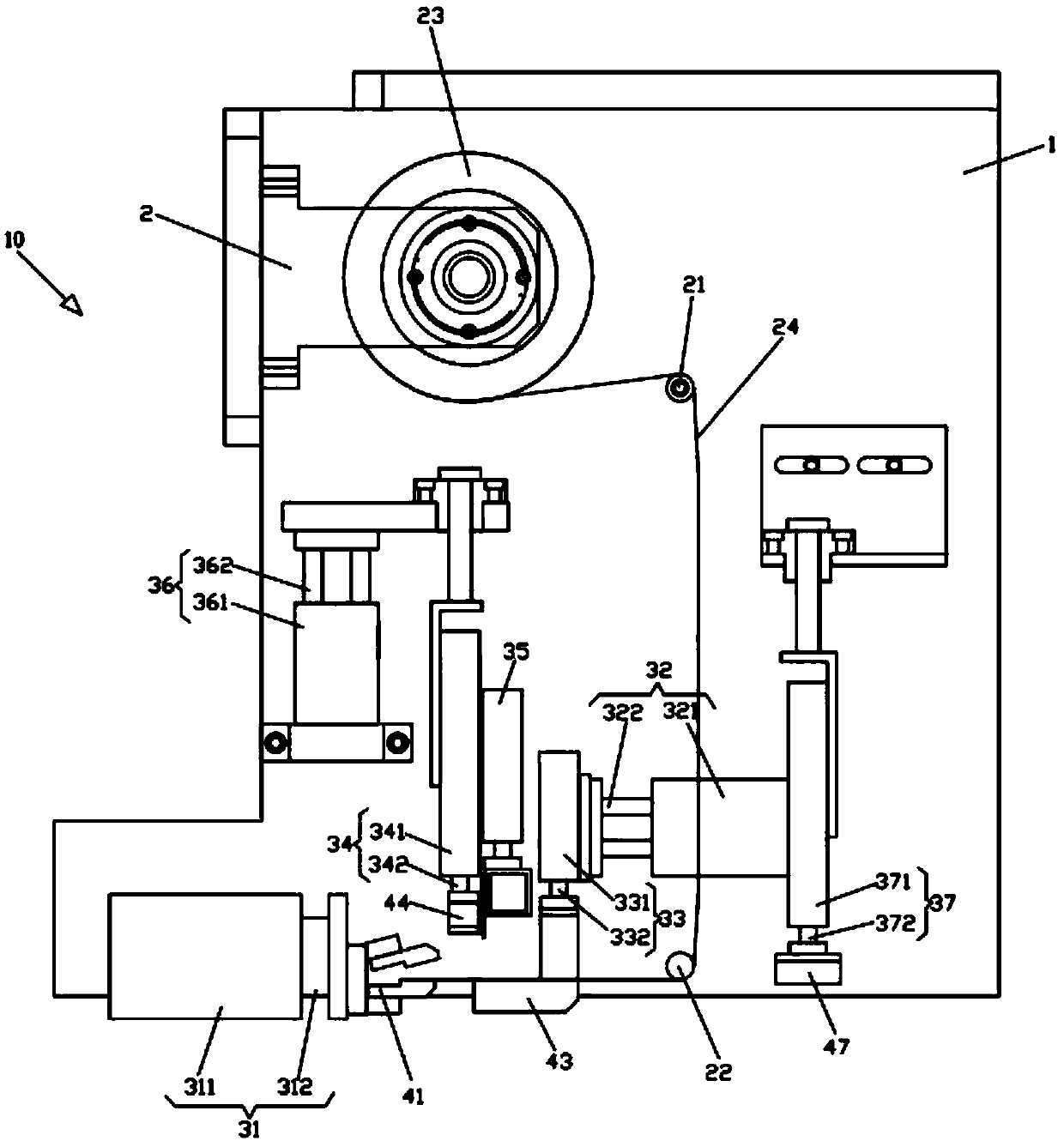

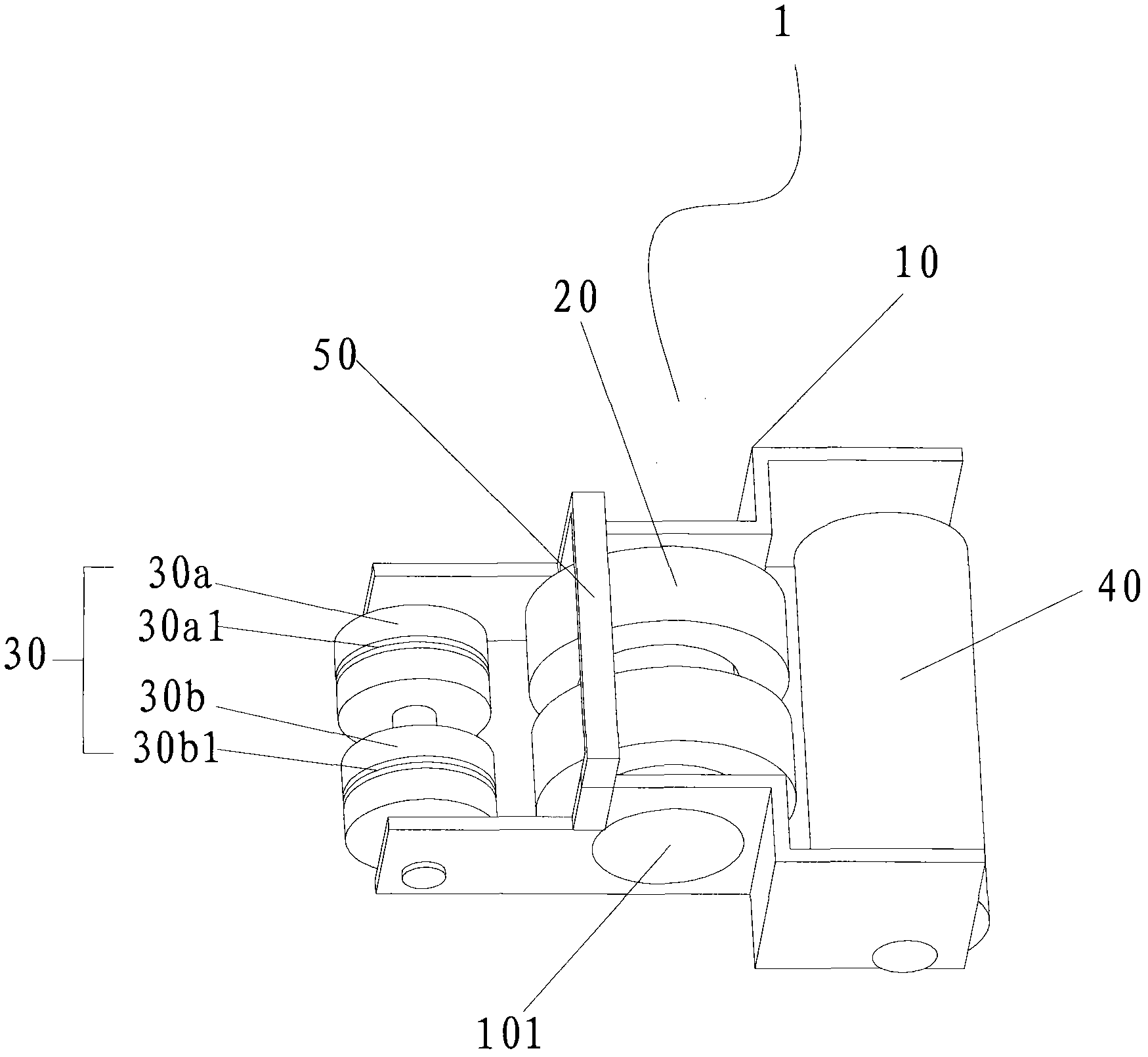

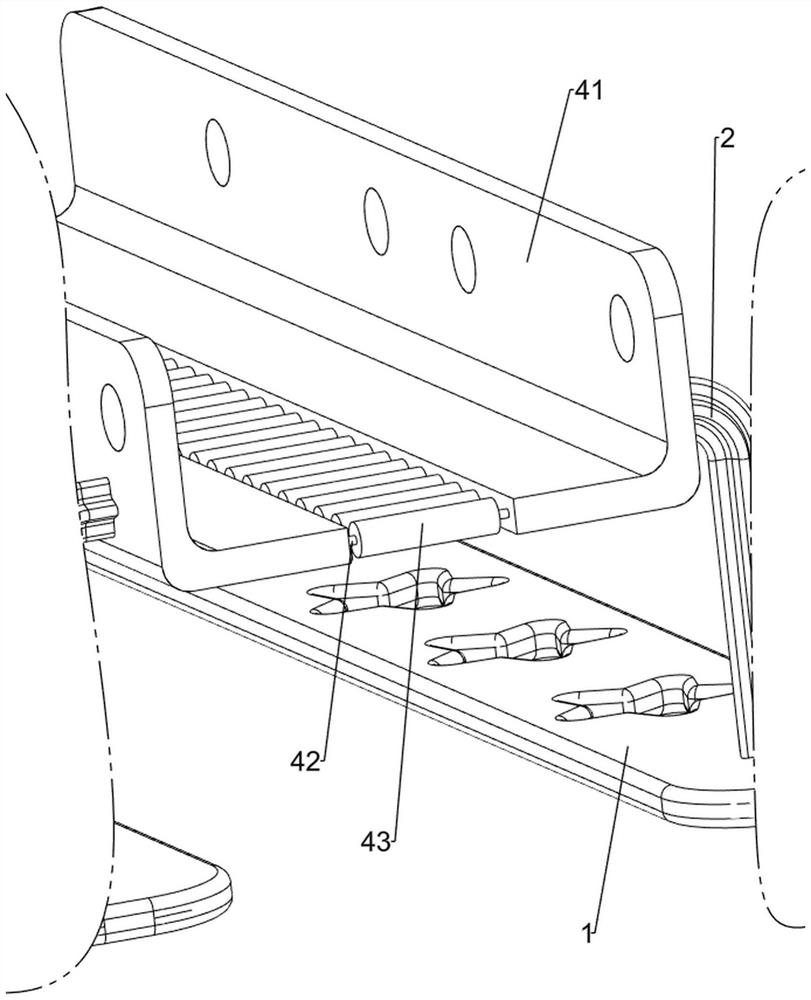

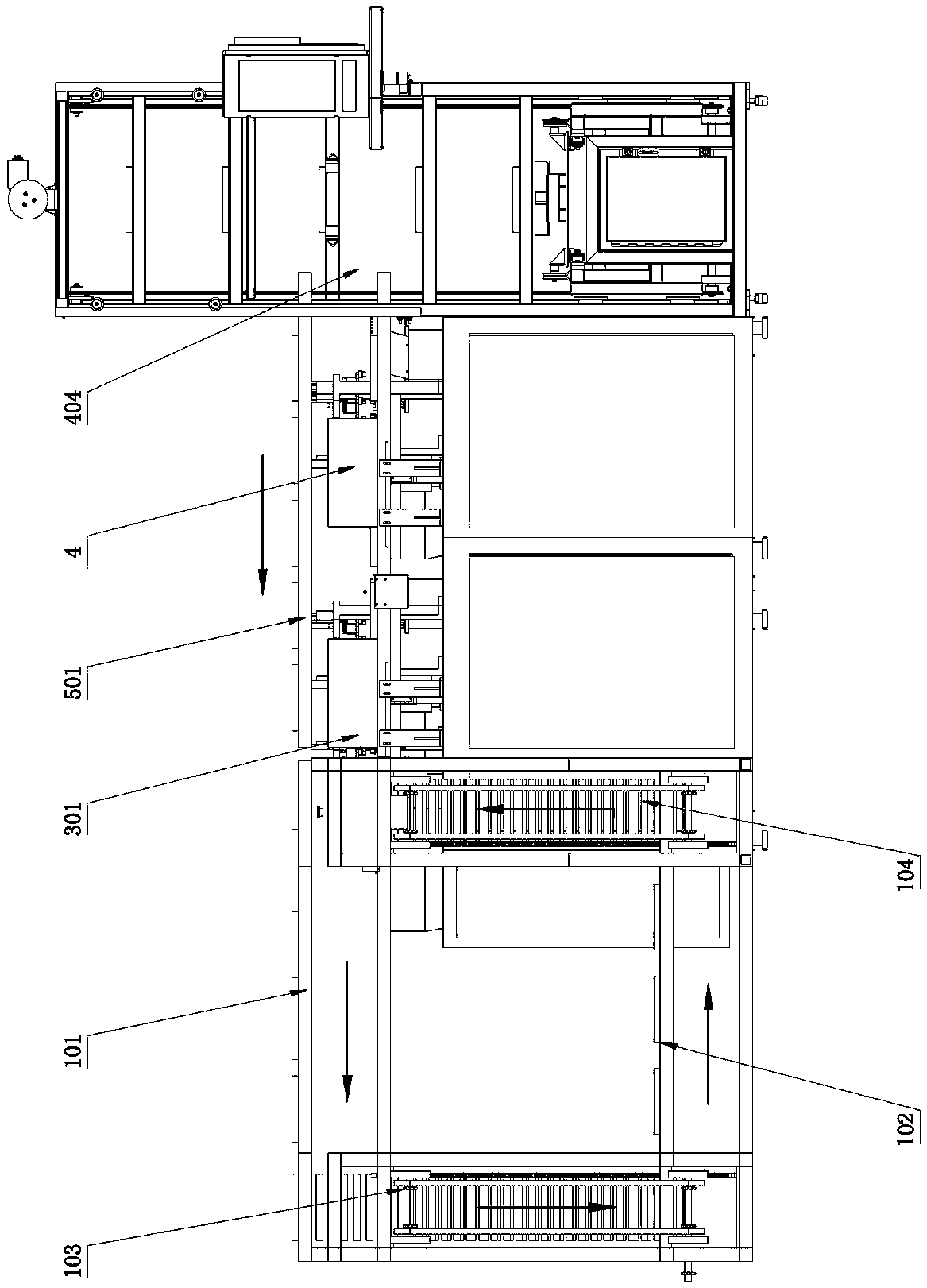

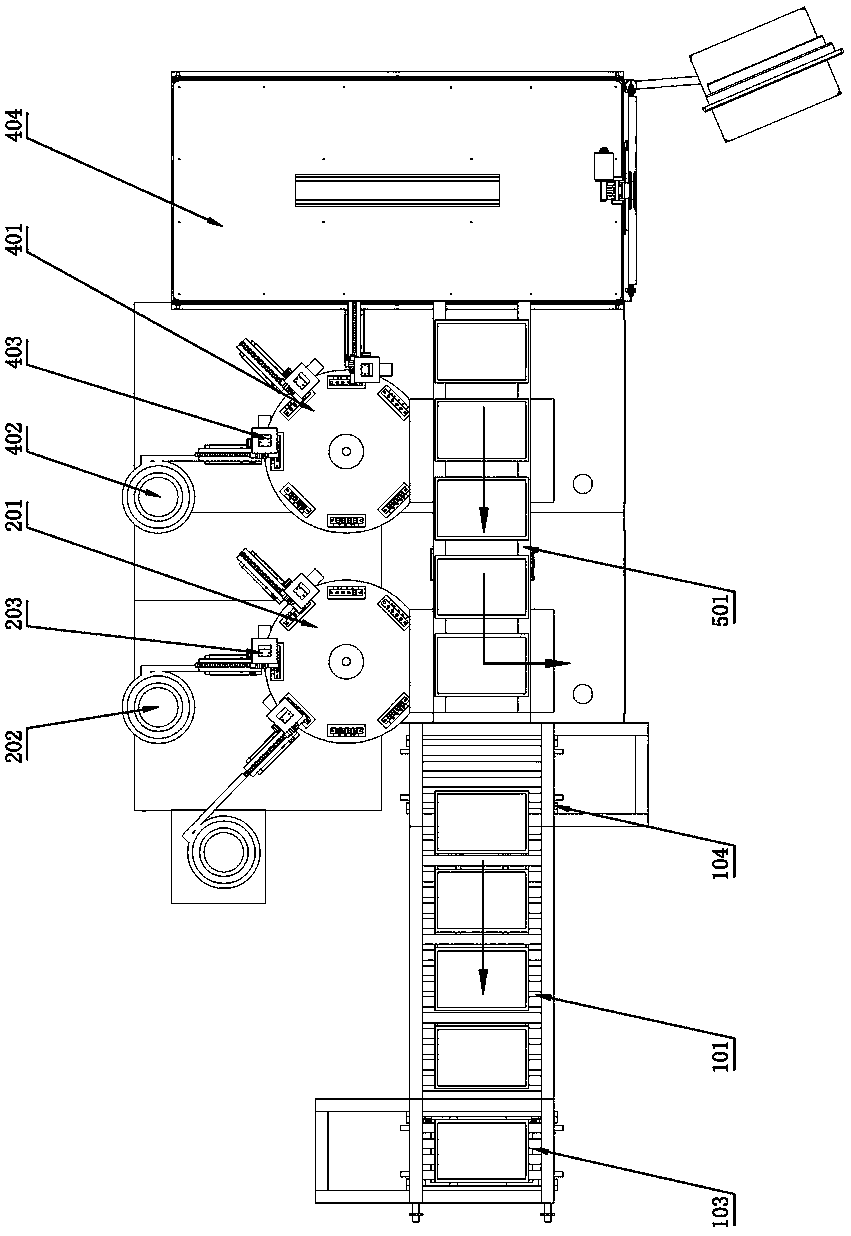

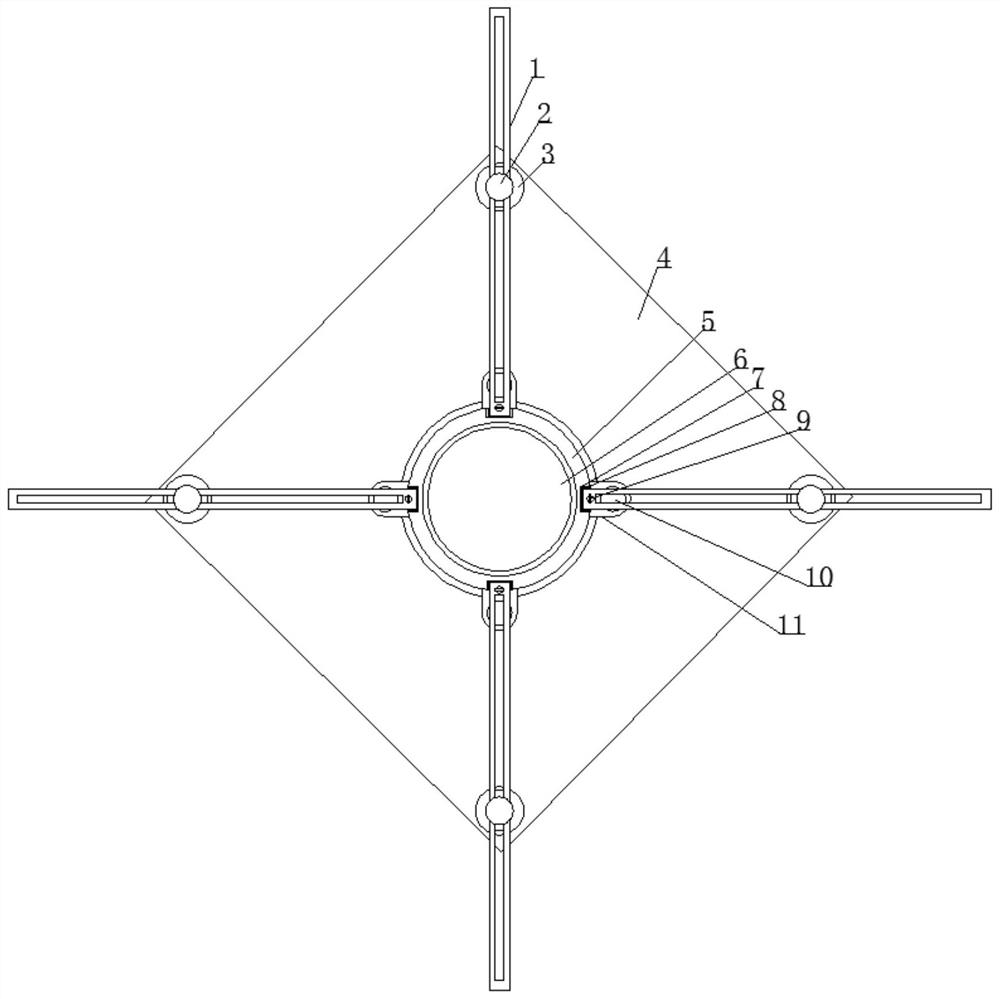

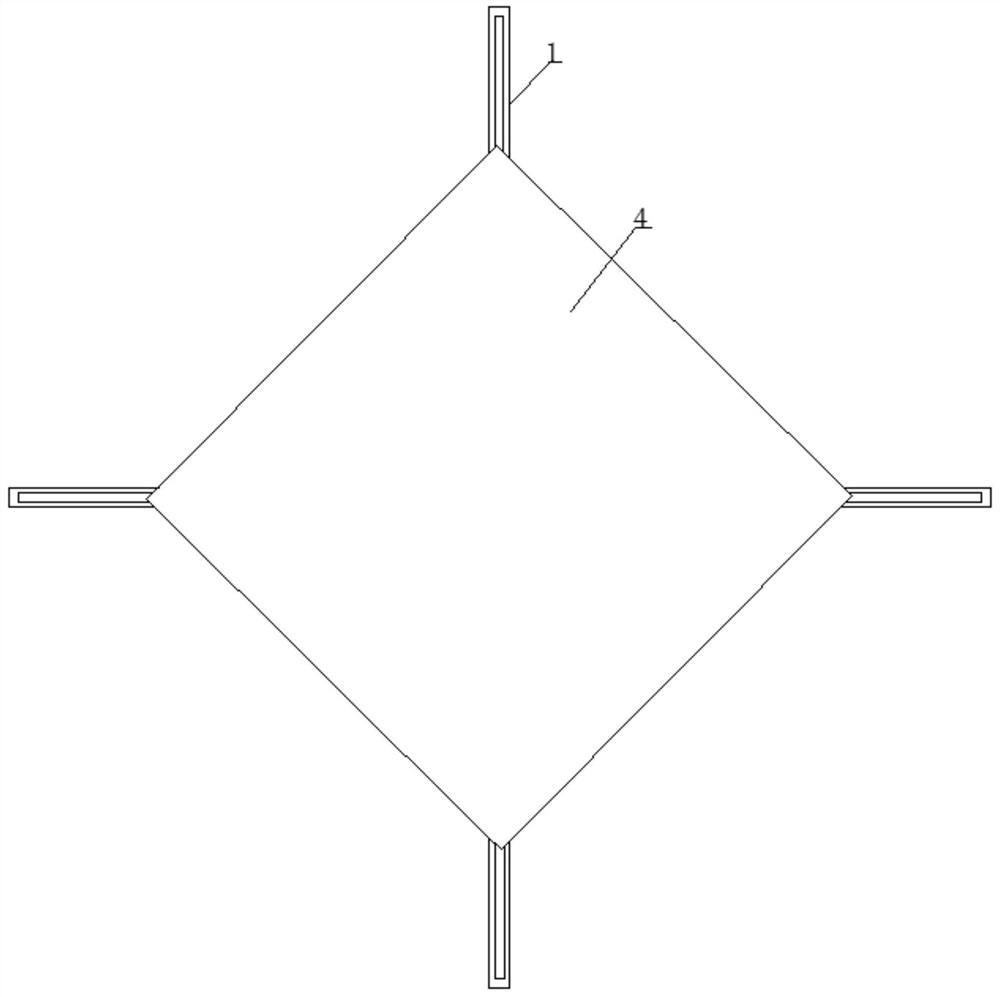

Photovoltaic cell piece tape pasting machine

PendingCN109552932APaste in orderQuick pasteLabelling machinesArticle deliveryEngineeringElectrical and Electronics engineering

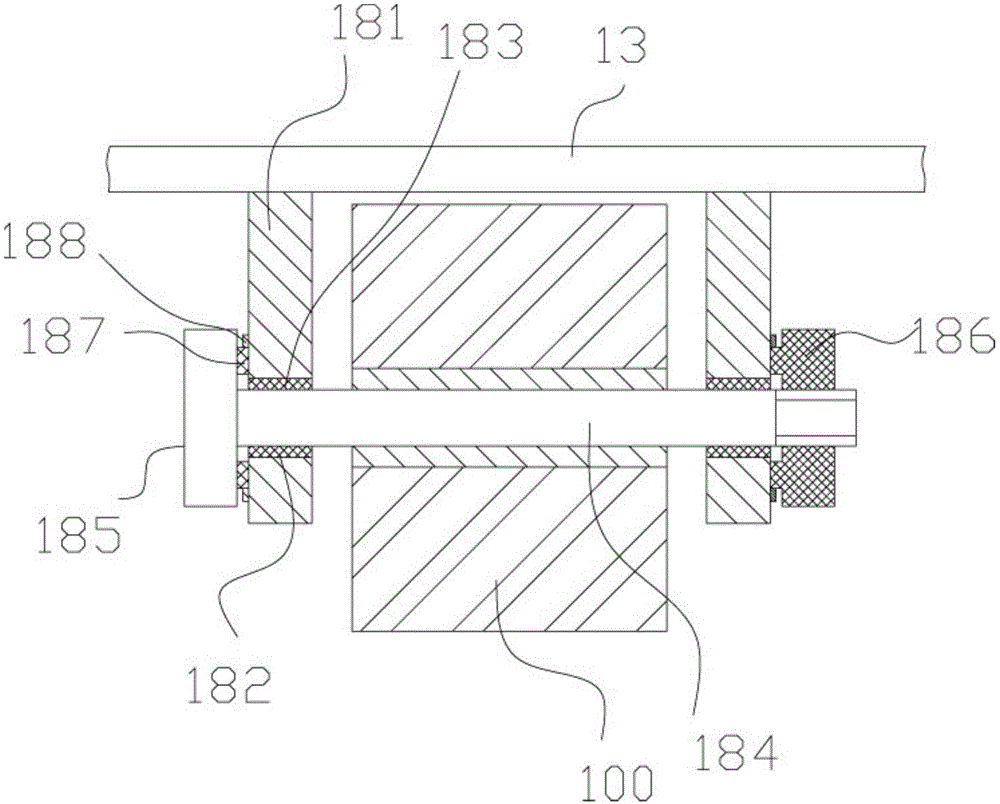

The invention provides a photovoltaic cell piece tape pasting machine. The photovoltaic cell piece tape pasting machine comprises a supporting piece, a plurality of photovoltaic cell pieces arranged on the supporting piece, a cross beam positioned above the supporting piece, a first driving mechanism for driving the cross beam to move back and forth, and a plurality of tape pasting heads installedon the cross beam. According to the photovoltaic cell piece tape pasting machine, through the cooperative action of the first driving mechanism, a second driving mechanism and a third driving mechanism, the tape pasting heads can sequentially and rapidly paste tape strips on the adjacent photovoltaic cell pieces, so that the photovoltaic cell pieces tape pasting work can be automatically completed, the bonding is firm and high, the working efficiency is improved, and the working cost is reduced.

Owner:WUXI JINGDIAN TECH CO LTD

Applying device for applying condenser and production process of built-in condenser

The invention discloses a process for producing a built-in condenser by using an applying device for applying a condenser, which comprises the following steps: A, putting condenser pipes on a side plate; B, clamping the condenser pipes to correct distances between adjacent condenser pipes by using a groove of a pinch roller of the applying device; C, pasting the condenser pipes on the side plate by using a metal adhesive tape roll on the applying device; D, pushing forward the applying device along the longitudinal direction so as to fold the metal adhesive tape roll and meanwhile roll the metal adhesive tape through the roller; and repeating the above steps B-D. According to the process for producing the built-in condenser by using the applying device for applying the condenser applying device disclosed by an embodiment of the invention, equal space among condensation pipes and rapid adhesion of an adhesive tape can be realized; the condensation pipes are tightly adhered on a side plate; and the efficiency can be improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Steel structure fireproof coiled material and preparation method thereof

InactiveCN103951893AEfficient fire resistanceExcellent physical and chemical propertiesProduction lineFire protection

The invention relates to a steel structure fireproof coiled material and a preparation method thereof and belongs to the field of fireproof materials. The steel structure fireproof coiled material is composed of macromolecule solid resin, an inrumescent flame retardant, a dispersing auxiliary and a reinforcing auxiliary and is prepared by mixing, extrusion pelletizing, flattening into pieces and rolling into a coiled material, wherein the inrumescent flame retardant is formed by taking phosphate as an acid source, an amine compound as a gas source and polyol as a carbon source. The steel structure fireproof coiled material can be continuously produced on a production line, a coiled material with the required thickness is processed once, production efficiency is high, equipment is simple, a production process is safe and environmental friendly, and industrial pollution such as waste water and waste gas is not produced; the steel structure fireproof coiled material can be used for producing sheets with different thicknesses according to the fire protection design requirement, and different fire protection design requirements can be met; The steel structure fireproof coiled material can be rapidly pasted on the surface of a steel structure when being used, the fire protection design thickness can be realized in once pasting, repeated brushing is not needed, working efficiency is high, working procedures are simple, and construction is environmental friendly and convenient.

Owner:JINGTAN ALBERT BEIJING TECH

Automatic stocking winding structure for stocking packaging

InactiveCN108569450ACurl fastReduce manual finishing timeLabelling deformable materialsLabelling machinesConductor CoilManufacturing line

The invention provides an automatic stocking winding structure for stocking packaging. The automatic stocking winding structure is arranged on a stocking packaging production line, and is characterized in that the stocking packaging production line comprises a first conveyor belt and a second conveyor belt, wherein the first conveyor belt and the second conveyor belt are parallel to each other andhave gaps. The automatic stocking winding structure also comprises a curling mechanism for curling both ends of a stocking at the same time and a labeling mechanism for sticking a label on the stocking to fix a curled shape of the stocking, and the curling mechanism is positioned above the first conveyor belt and the second conveyor belt; and the labeling mechanism is located below the curling mechanism.

Owner:海宁威尔斯针织股份有限公司

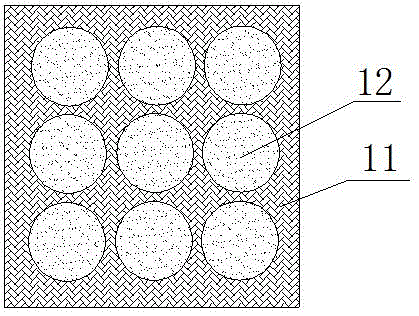

Method and mould for preparing pavement combined adhering block

The invention discloses a method and mould for preparing a pavement combined adhering block. The mould comprises a template, a plurality of mould cores, a fixed plate, a bottom plate, a screw and a connecting rod; the template is located above the fixed plate, a plurality of through mould holes are formed in the template, one ends of the mould cores are formed in the fixed plate while the other ends extend into the mould holes; the bottom plate is located below the fixed plate and is provided with a threaded hole, one end of the screw penetrates through the threaded hole and the screw sleeves a bearing, the bearing is embedded into the lower portion of the fixed plate, and the screw is in screw-thread fit with the threaded hole of the bottom plate; a through hole is formed in the fixed plate, and one end of the connecting rod is connected to the bottom plate while the other end of the connecting rod penetrates through the through hole and is connected to the template. The mould can prepare a plurality of brick blocks at one time and the brick blocks are connected as a whole through a linking layer, so that the pavement combined adhering block is obtained. As two adjacent brick blocks are separated from a certain distance, pavement damage caused by thermal expansion can be avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

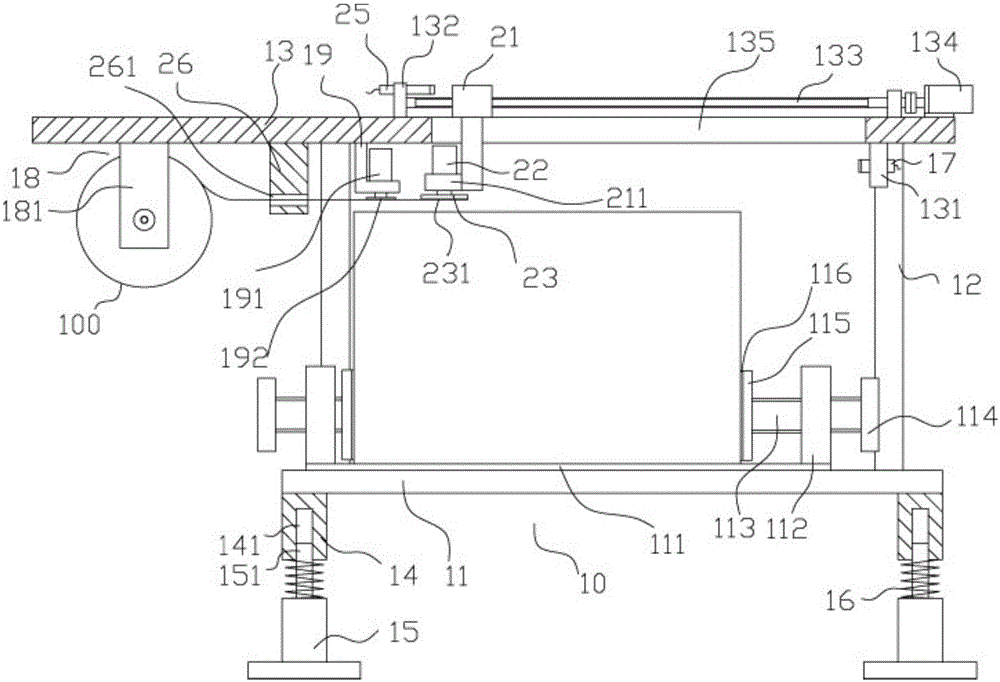

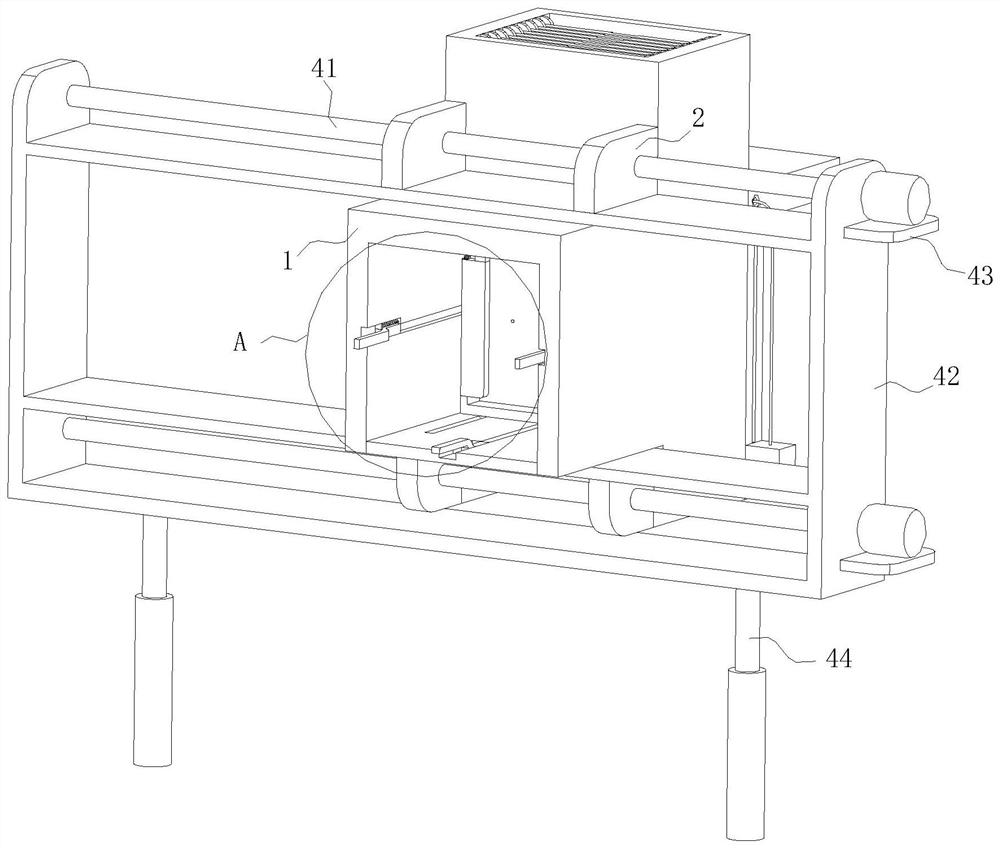

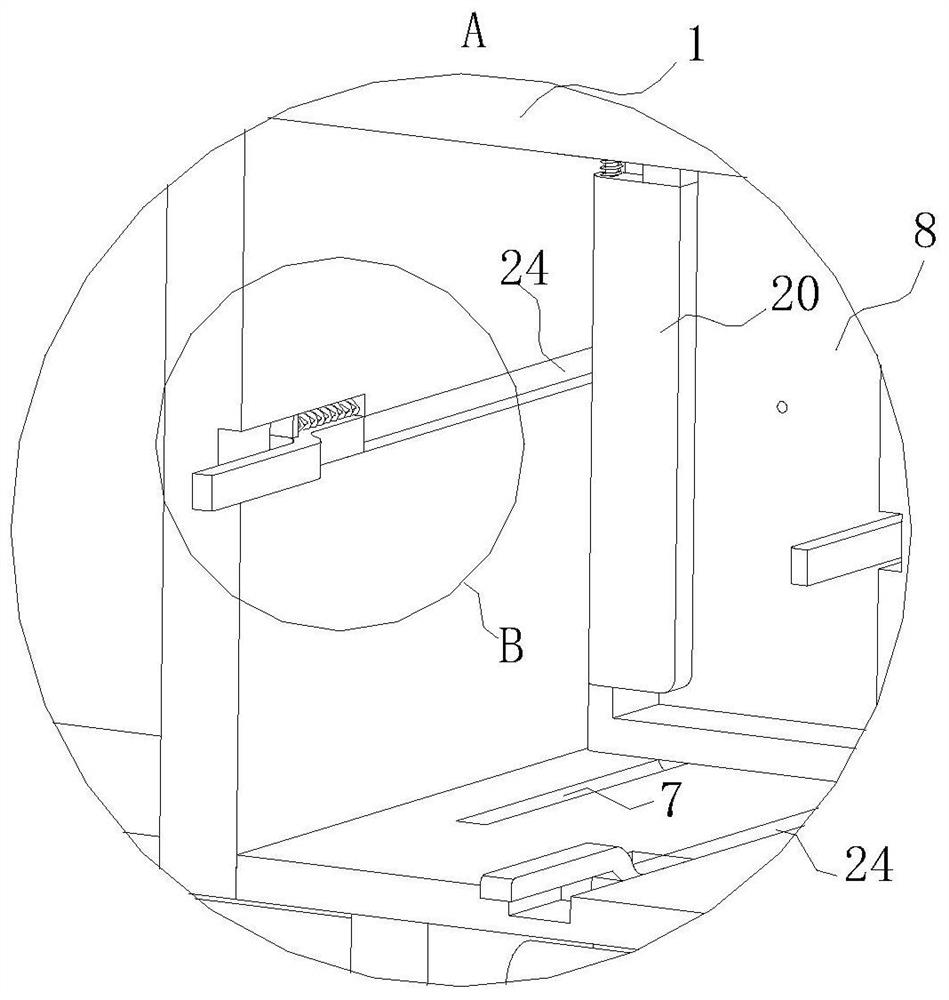

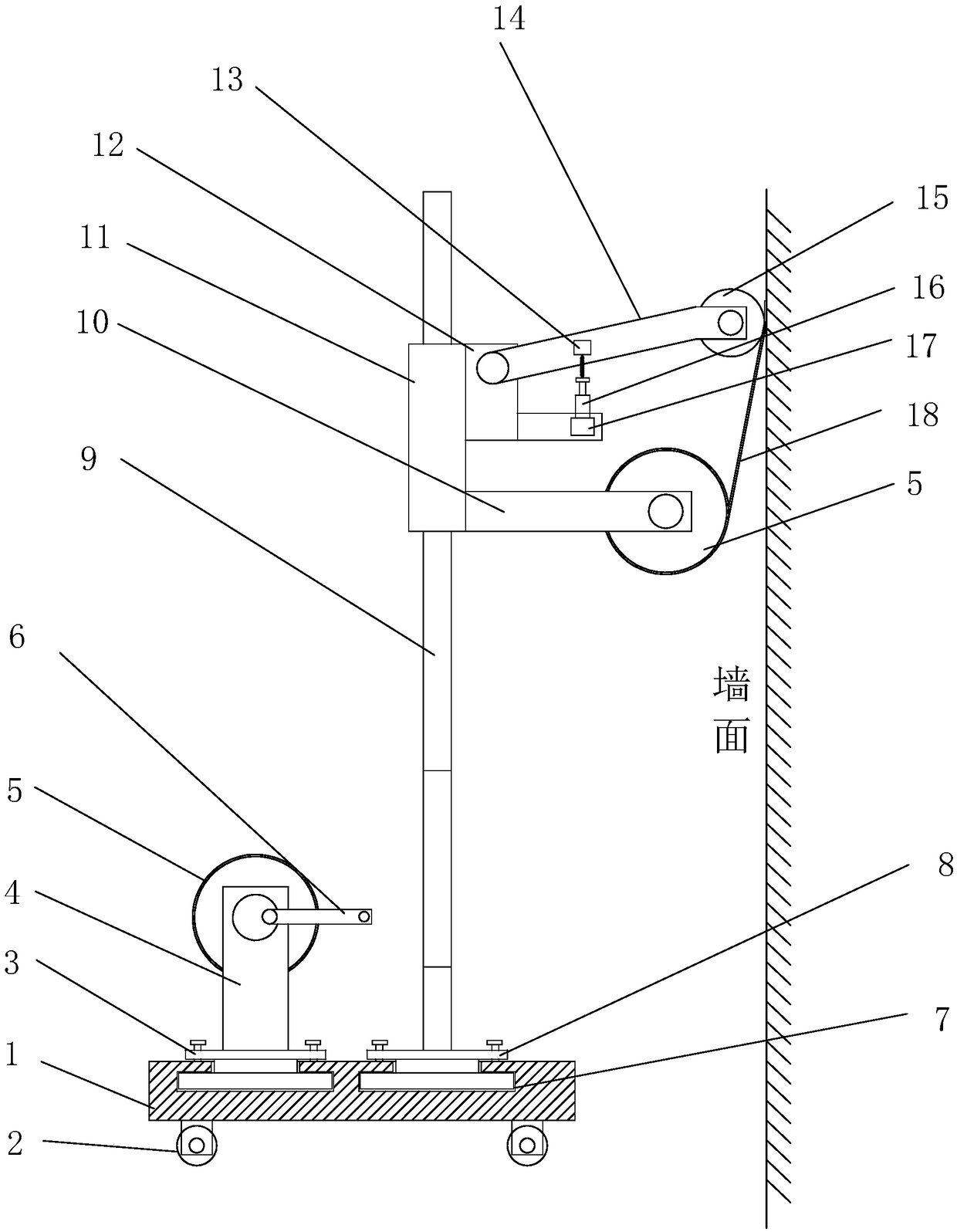

Anti-seismic reinforcement construction device and method for house building outer wall heat preservation layer

ActiveCN112360119AAvoid paste work efficiency reductionAvoid loss of pasting work qualityBuilding constructionsEarthquake resistantHouse building

The invention discloses an anti-seismic reinforcement construction device and method for a house building outer wall heat preservation layer, and belongs to the technical field of anti-seismic reinforcement construction devices for house building outer wall heat preservation layers. The anti-seismic reinforcement construction device comprises a mounting frame, four connecting plates are fixedly connected to the side face of the mounting frame, and the connecting plates are connected with a power unit for driving the whole device to move. According to the anti-seismic reinforcement constructiondevice and method, by arranging a positioning conveying unit, firstly, a heat preservation plate is limited in a framework composed of a bearing frame and a first limiting plate, coarse positioning of the heat preservation plate is achieved, a rectangular block drives the heat preservation plate to make contact with the side faces of three special-shaped limiting plates, and the heat preservationplate is limited in a space formed by the surfaces of the three special-shaped limiting plates, so that accurate positioning of the heat preservation plate is achieved, then the heat preservation plate can be rapidly and accurately pasted onto the wall surface, automation of the heat preservation board pasting process is achieved through the process, and meanwhile the problems that due to manualpasting, the pasting work efficiency is reduced, and the pasting work quality is reduced are solved.

Owner:浙江东冶建设有限公司

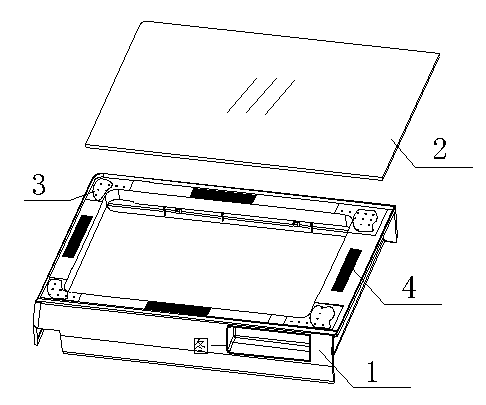

Pasting method of microwave oven glass door

InactiveCN102997302AIncrease productivityQuick pasteDoors for stoves/rangesPressure sensitiveMicrowave oven

The invention provides a pasting method of a microwave oven glass door. The method comprises the following steps: (1) coating a single component silica gel on four corners of a door cover surface to be pasted with glass; (2) pasting pressure rapid-adhesion pressure sensitive tapes on four edges of the door cover surface to be pasted with the glass; and (3) pasting the glass door onto a paste penal of the door cover. Door cover subjected to the method provided by the invention can directly enter into a production flow line; and the method meets the paste requirements, as well as greatly improves production efficiency.

Owner:WHIRLPOOL CHINA

Label pasting device for logistics packaging

ActiveCN112407512AImprove labeling efficiencyHigh speedLabelling machinesLogistics managementSupport plane

The invention relates to a label pasting device, and specifically relates to a label pasting device for logistics packaging. The label pasting device for logistics packaging is high in label pasting efficiency, firm in pasting and capable of achieving automatic discharging. The label pasting device for logistics packaging comprises base plates and first supporting frames, a conveying mechanism, apressing mechanism and a cylinder, the two base plates are provided with four first supporting frames, the conveying mechanism is arranged on the four first supporting frames, the pressing mechanism is arranged on the conveying mechanism, and the cylinder is mounted on the pressing mechanism. According to the device, the effect of improving the labeling efficiency of express boxes is achieved, theexpress boxes are conveyed through the conveying mechanism, labels can be rapidly pasted to the express boxes through the pressing mechanism, the labeling speed of the express boxes can be increased,and through the cooperation of a discharging mechanism and a reciprocating mechanism, the express boxes can be automatically discharged and moved.

Owner:江西恒和物流有限公司

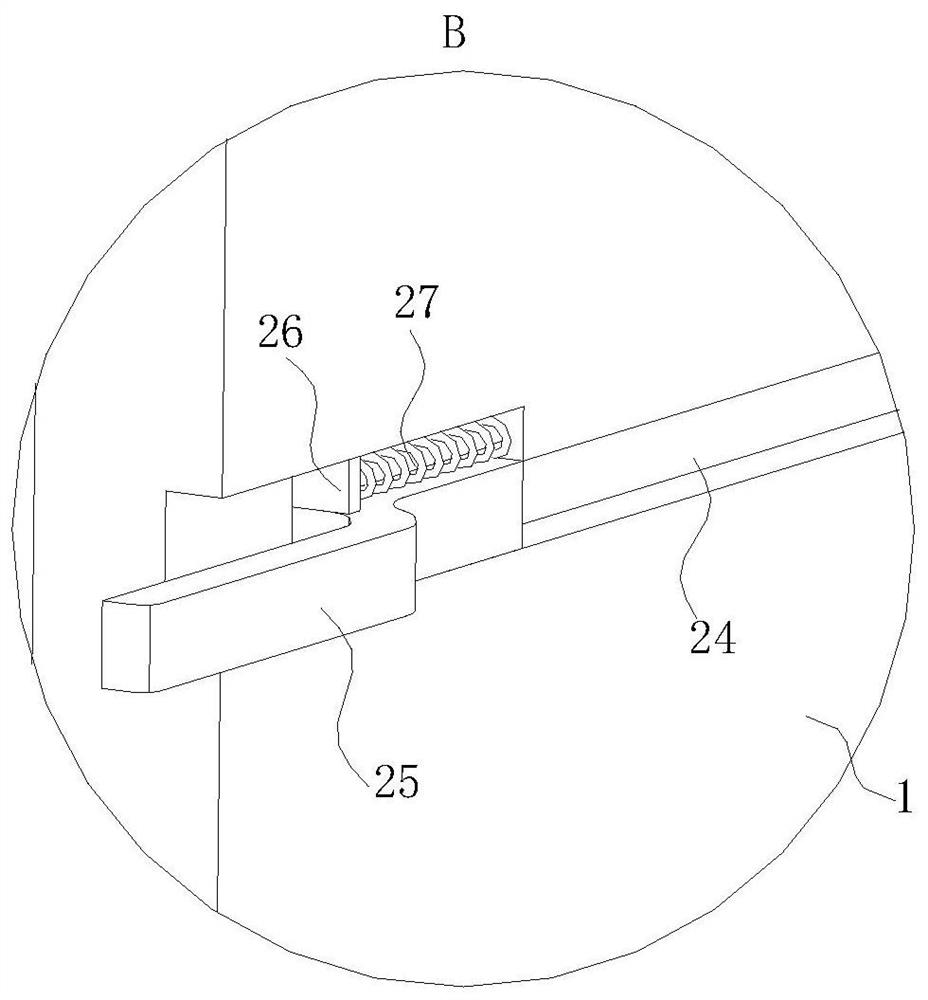

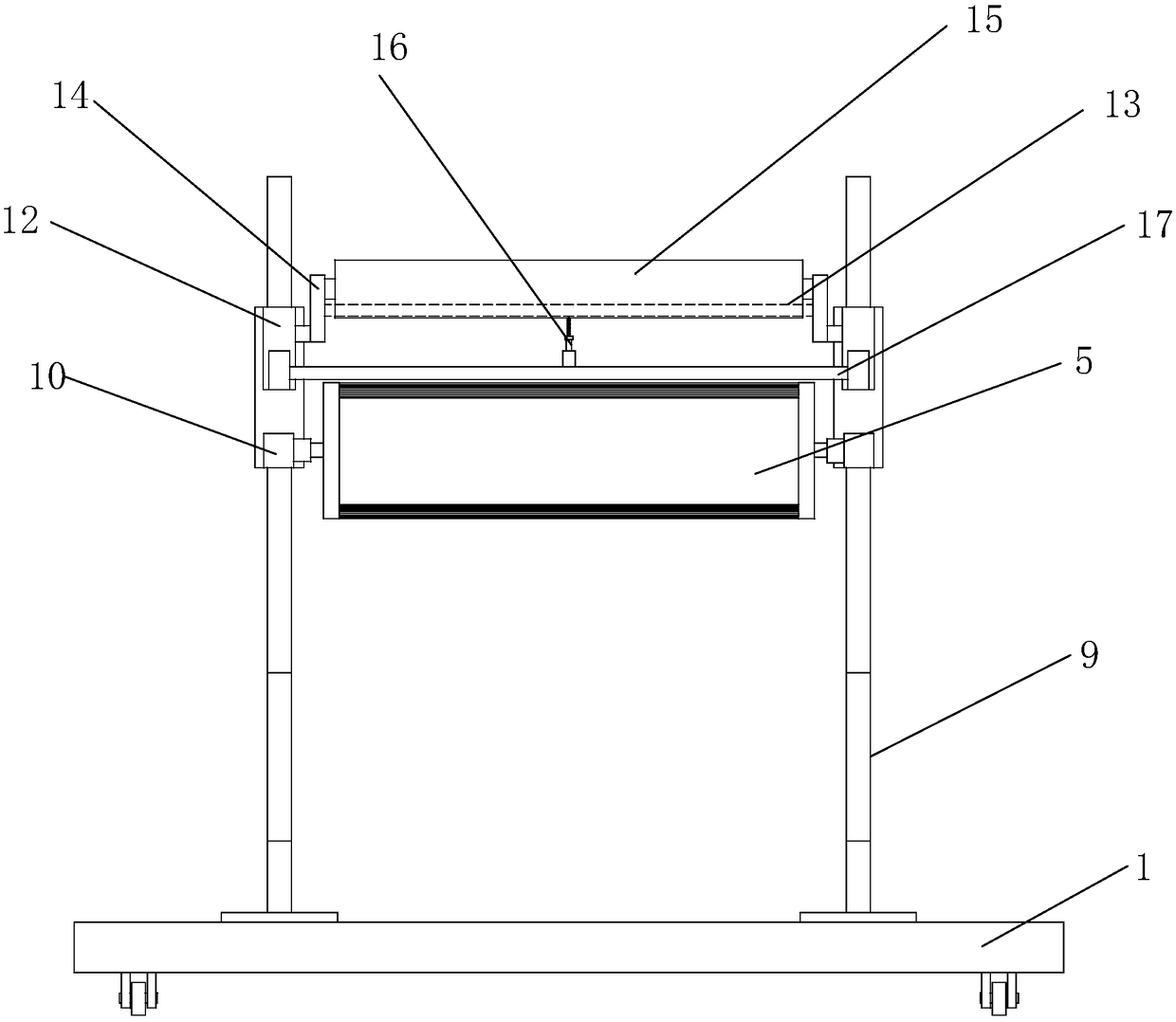

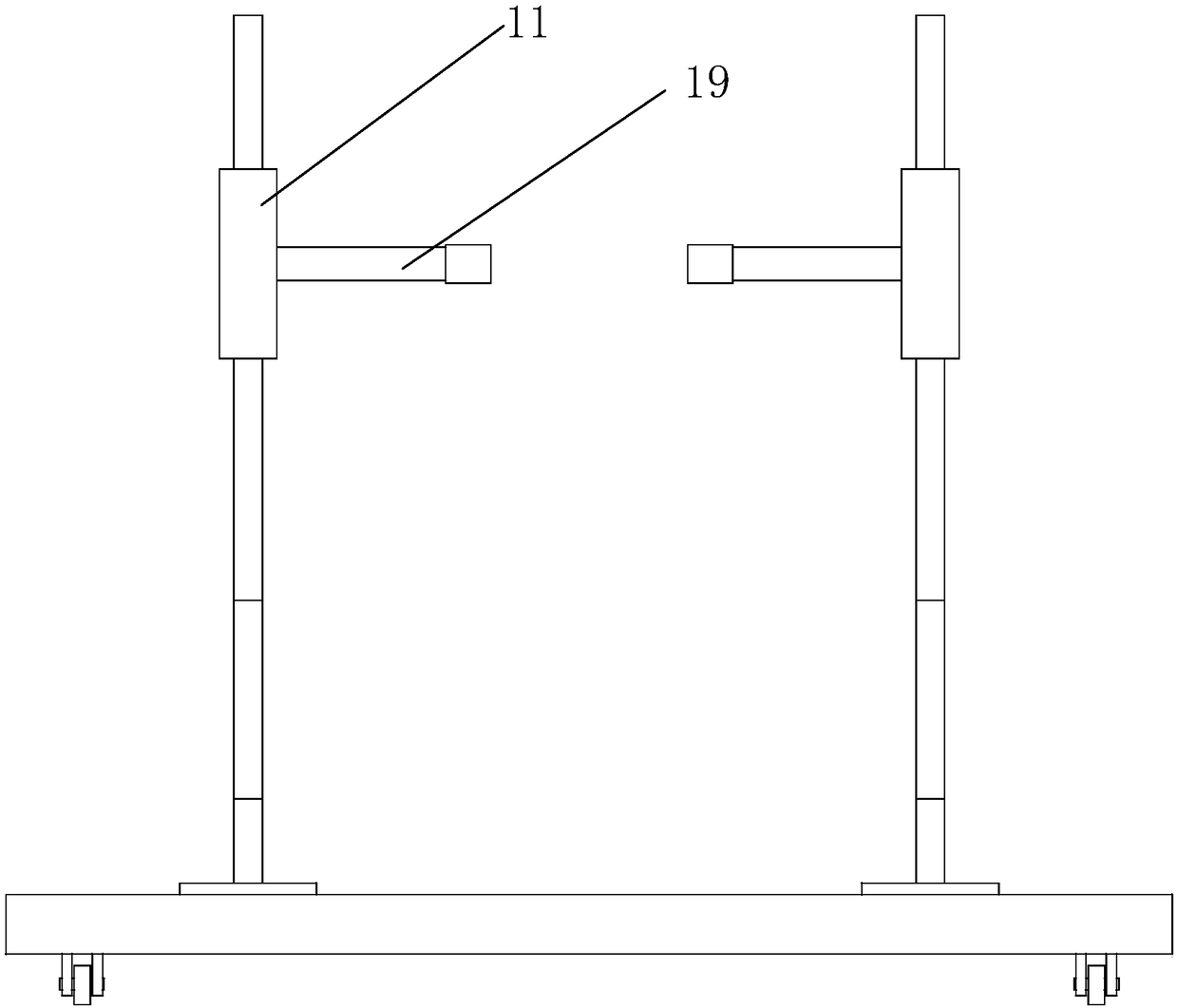

Split mounting type wallpaper laminator

The invention provides a split mounting type wallpaper laminator. The split mounting type wallpaper laminator comprises a base. Wheels capable of being locked are arranged under the base, a primary supporting assembly is arranged on the base, the primary supporting assembly comprises two vertically arranged vertical columns, each column is composed of multiple sections of steel tubes which are spliced, a mounting plate is arranged at the bottom of each column, and the mounting plate can slide and can be locked on the base to adjust the distance between the two vertical columns; a lifting assembly is arranged on the columns, a lifting and locking mechanism is arranged on the lifting assembly, a wallpaper paving assembly is also arranged on the lifting assembly, a wallpaper compression assembly is arranged above the wallpaper paving assembly, and a compression force adjusting mechanism is arranged below the wallpaper compression assembly. Debugging equipment can be assembled quickly by way of site splicing, so that the split mounting type wallpaper laminator is extremely convenient to carry and use, can fit wallpaper of nearly all width dimensions, and is high in universality.

Owner:黄山市亿华装饰材料有限公司

Chip radiator pasting mechanism

InactiveCN108520860AImprove work efficiency and product qualification rateQuick pasteSemiconductor/solid-state device manufacturingEmbedded systemIntegrated circuit

The invention discloses a chip radiator pasting mechanism. The mechanism comprises an integrated circuit board feeding mechanism, a radiator feeding mechanism, a pasting mechanism, a static pressing mechanism and an unloading mechanism; the pasting mechanism pastes radiators outputted by the radiator feeding mechanism onto a plurality of chips on an integrated circuit board; the static pressing mechanism arranges static pressing blocks on the radiators that have been pasted on the chips; and the unloading mechanism outputs the integrated circuit board onto which the radiators have been pasted.The whole chip radiator pasting process of the chip radiator pasting mechanism of the invention includes integrated circuit board feeding, radiator feeding, pasting, static pressing and unloading which are all automatically completed by a pasting machine; one person can operate the pasting mechanism so as to complete the pasting of the radiators quickly and accurately; and therefore, work efficiency and the yield of production can be significantly improved.

Owner:JIANGSU BVM INTELLIGENT TECH

Fabricated wallboard structure of painting room

The invention discloses a fabricated wallboard structure of a painting room. The existing problem that the wall surface of the painting room is difficult to replace is solved. The fabricated wallboardstructure of the painting room comprises wallboards, bonding layers are fixedly installed in the middles of the wallboards, connecting rings are arranged on the outer sides of the bonding layers, andconnecting buckles are uniformly installed on the periphery of the connecting rings. Third fastening screws are installed between the connecting buckles and the wallboards, rotating frames evenly sleeve with the side walls of the connecting rings, the rotating frames sleeve guide frames, rotating shafts are installed between the guide frames and the rotating frames, second fastening screws are installed between the guide frames and the connecting rings, cushion blocks are evenly installed on the peripheries of the surfaces of the wallboards, and first fastening screws are installed between the cushion blocks and the guide frames. By reasonably adjusting the flexible wallboards and stretching the wallboards, the fabricated wallboard structure of the painting room can be suitable for wall surfaces of different sizes, is convenient to assemble, and meets the use requirement of the painting room wallboards.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Cover layer seal film for strain gauge, and production method and using method thereof

InactiveCN107933003ASolve the problem of poor positioning consistencyRealize self-sealingLamination ancillary operationsMeasurement devicesEngineeringStrain gauge

The invention discloses a cover layer seal film for a strain gauge, and a production method and a using method thereof. The cover layer seal film comprises a strain gauge cover layer, the seal layer surface of the strain gauge cover layer is provided with an adhesive layer, and the adhesive layer is adhered with cover layer release paper, wherein the strain gauge cover layer is provided with a plurality of marking points, and positions, corresponding to strain gauge bonding pads, of the strain gauge cover layer, are hollow-out; and the cover layer seal film is used for sealing the whole straingauge. The cover layer seal film can realize the automatic sealing of the whole gauge strain, especially special-shaped pattern sealing which cannot be realized through a conventional technology, allows the alignment precision to be 3 times higher than that the manual alignment precision, improves the sealing efficiency by 5 times or more, and completely solves the problems of low efficiency, unstable quality and poor product consistence of existing artificial production.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com