Liquid-state paste for dye printing and preparation method and application of liquid-state paste

A paste and printing technology, which is applied in the field of liquid paste for dye printing and its preparation, can solve the problems of hard hand feeling and environmental pollution caused by paste, and achieve the effect of uniform color, high color yield and clear printing edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

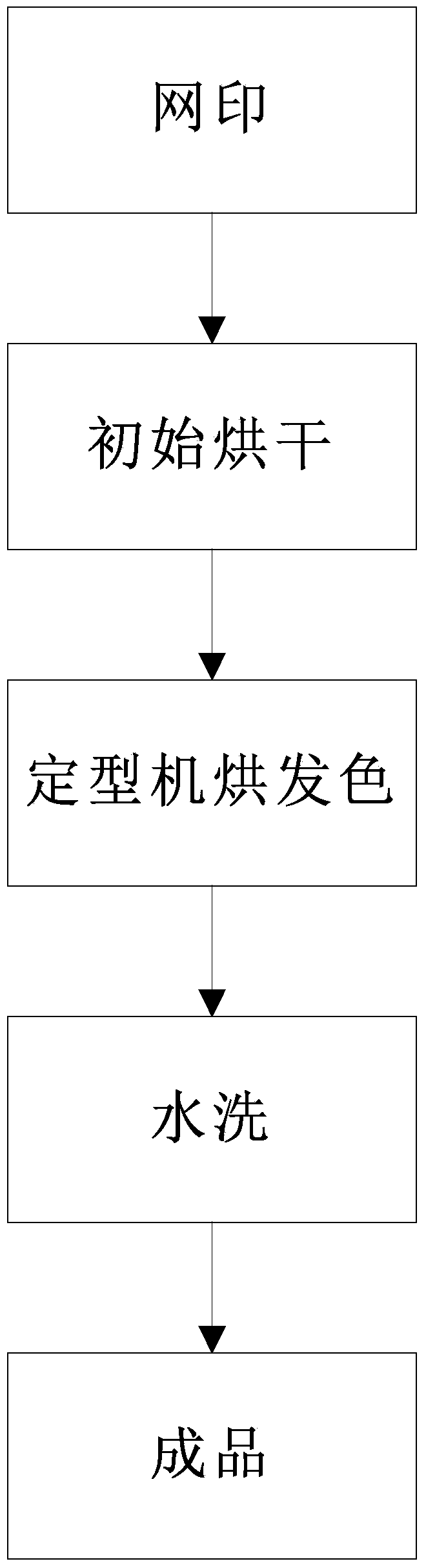

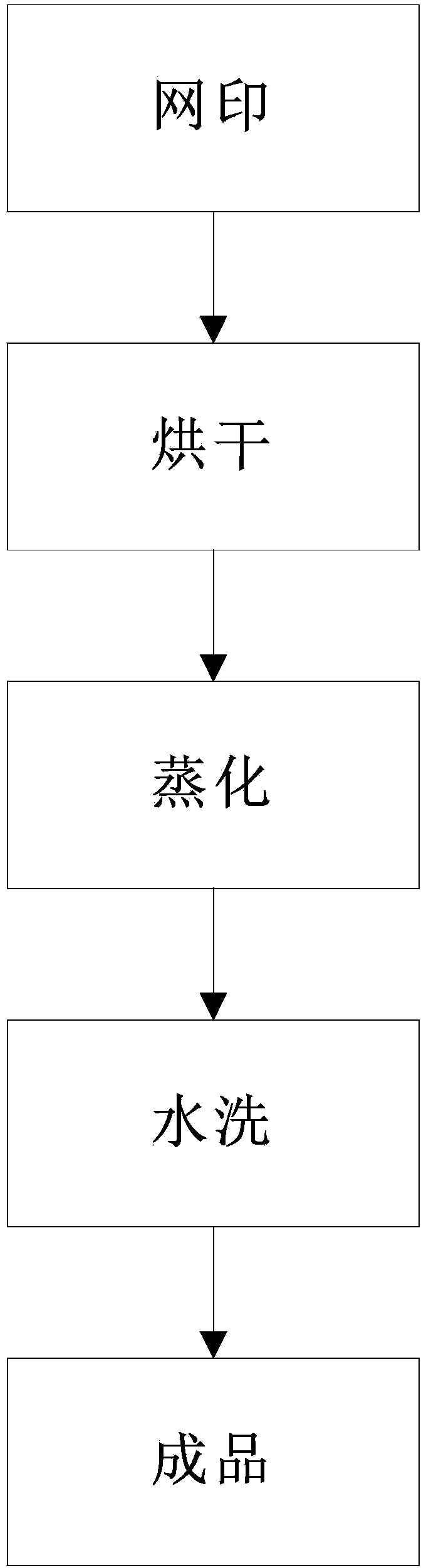

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1 The preparation of liquid paste for dye printing

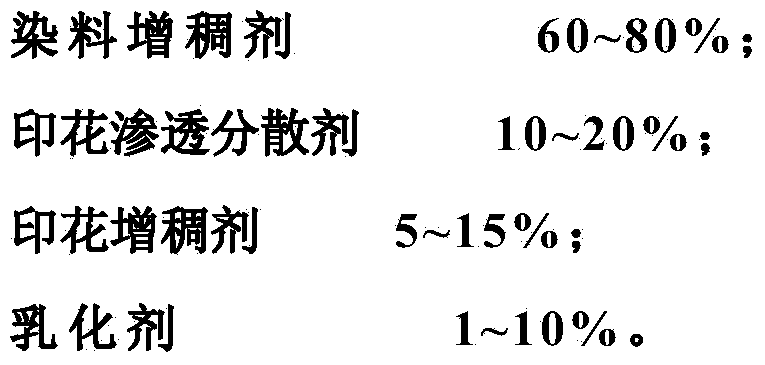

[0059] The raw materials and formulas adopted are as follows:

[0060]

[0061] Among them, PUP-82 thickener was purchased from Dongguan Changlian New Material Technology Co., Ltd.; printing penetrating dispersant JN-301 and printing thickener JH-1260 were purchased from Suzhou Jiahe Textile Auxiliary Factory; emulsifier AEO-15 was market conventional products.

[0062] The preparation method is as follows:

[0063] Preparation method of liquid paste:

[0064] First, mix the dye thickener PUP-82 at a low speed of 200 rpm for 5 minutes, then at a medium speed of 1450 rpm, add all the printing penetrating and dispersing agents in proportion within 10 minutes, and continue at a medium speed of 1450 rpm , within 5 minutes, add all the printing thickeners according to the proportion, and finally add the emulsifier at a high speed of 2850 rpm within 5 minutes, and then add the emulsifier at a high speed of ...

Embodiment 2

[0068] Embodiment 2 The preparation of liquid paste for dye printing

[0069] The raw materials and formulas adopted are as follows:

[0070]

[0071] Among them, PUP-82 thickener was purchased from Dongguan Changlian New Material Technology Co., Ltd.; printing penetrating dispersant JN-301 and printing thickener JH-1260 were purchased from Suzhou Jiahe Textile Auxiliary Factory; emulsifier AEO-15 was market conventional products.

[0072] The preparation method is as follows:

[0073] Preparation method of liquid paste:

[0074] First, mix the dye thickener PUP-82 at a low speed of 200 rpm for 5 minutes, then at a medium speed of 1450 rpm, add all the printing penetrating and dispersing agents in proportion within 10 minutes, and continue at a medium speed of 1450 rpm , within 5 minutes, add all the printing thickeners according to the proportion, and finally add the emulsifier at a high speed of 2850 rpm within 5 minutes, and then add the emulsifier at a high speed of ...

Embodiment 3

[0078] Embodiment 3 The preparation of liquid paste for dye printing

[0079] The raw materials and formulas adopted are as follows:

[0080]

[0081] Among them, PUP-82 thickener was purchased from Dongguan Changlian New Material Technology Co., Ltd.; printing penetrating dispersant JN-301 and printing thickener JH-1260 were purchased from Suzhou Jiahe Textile Auxiliary Factory; emulsifier AEO-15 was market conventional products.

[0082] The preparation method is as follows:

[0083] Preparation method of liquid paste:

[0084] Stir the dye thickener PUP-82 slowly at a low speed of 200 rpm for 5 minutes, then at a medium speed of 1450 rpm, add all the printing penetrating and dispersing agents in proportion within 10 minutes, continue at 1450 rpm for 5 minutes Add all the printing thickeners according to the proportion, and finally add the emulsifier at a high speed of 2850 rpm within 5 minutes, and then add the emulsifier at a high speed of 2850 rpm for 3 minutes to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com