Treatment method for dry acrylic fiber production wastewater

A treatment method and technology for producing wastewater, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. Long and other problems, to achieve the effect of good water effluent effect, easy operation and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

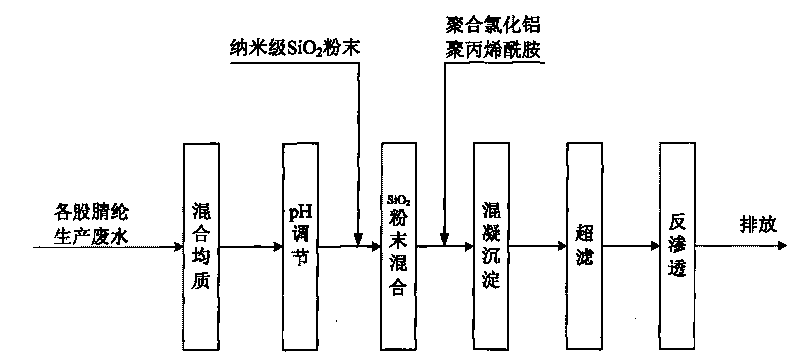

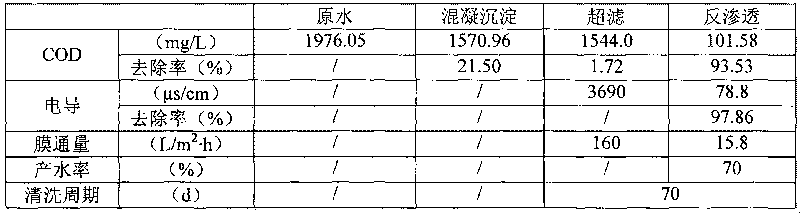

[0027] Each strand of dry acrylic fiber production wastewater in a factory first enters the mixing homogenization tank for mixing, and adjusts the pH to 6.5 with a 25% NaOH solution, and then enters the powder SiO 2 Dosing tank, add powder SiO with a particle size of 80nm 2 , The concentration is 100mg / L, then enter the coagulation sedimentation tank, add polyaluminum chloride and anionic polyacrylamide successively, the concentrations of which are 200mg / L and 10mg / L respectively, the sedimentation time is 30min, the effluent of the sedimentation tank enters the ultrafiltration device For treatment, the ultrafiltration effluent enters the reverse osmosis device for further processing, and the reverse osmosis effluent is discharged.

[0028] The ultrafiltration membrane adopts polyethersulfone (PES) membrane, the membrane structure is flat plate, the membrane pore size is 0.05μm, and the molecular weight cutoff is 5000. The operating pressure is 0.03MPa, and the membrane flux is 16...

Embodiment 2

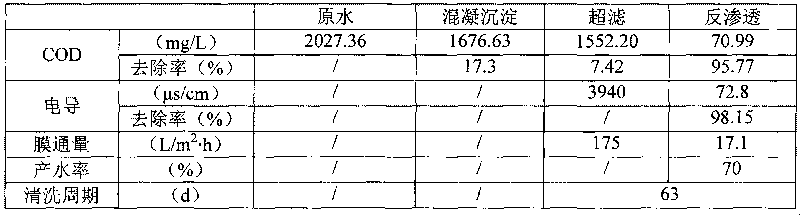

[0033] The same treatment process as in Example 1 was used for the wastewater produced by the dry-process acrylic fiber production in a certain factory.

[0034] In the operating parameters, the mixing and homogenizing pool is adjusted to pH 7.0 with 25% NaOH solution, powder SiO 2 (The particle size is 60nm), the concentrations of polyaluminum chloride and polyacrylamide are 75mg / L, 140mg / L and 8mg / L, respectively.

[0035] The operating pressure of ultrafiltration treatment is: 0.04MPa, the membrane flux is: 175L / (m 2 ·H), the operating pressure of reverse osmosis treatment is: 0.8MPa, the membrane flux is: 17.1L / (m 2 H), other operating conditions are the same as in Example 1. The treatment results are shown in Table 2.

[0036] Table 2

[0037]

Embodiment 3

[0039] The same treatment process as in Example 1 was used for the wastewater produced by the dry-process acrylic fiber production in a certain factory.

[0040] In the operating parameters, the mixing and homogenizing pool is adjusted to pH 6.7 with 25% NaOH solution, powder SiO 2 (The particle size is 50nm), the concentrations of polyaluminum chloride and polyacrylamide are 50mg / L, 100mg / L and 6mg / L, respectively. The operating pressure of ultrafiltration treatment is: 0.045MPa, the membrane flux is: 181L / (m 2 ·H), the operating pressure of reverse osmosis treatment: 1.3MPa, membrane flux: 19.6L / (m 2 H), other operating conditions are the same as in Example 1. The treatment results are shown in Table 3.

[0041] table 3

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com