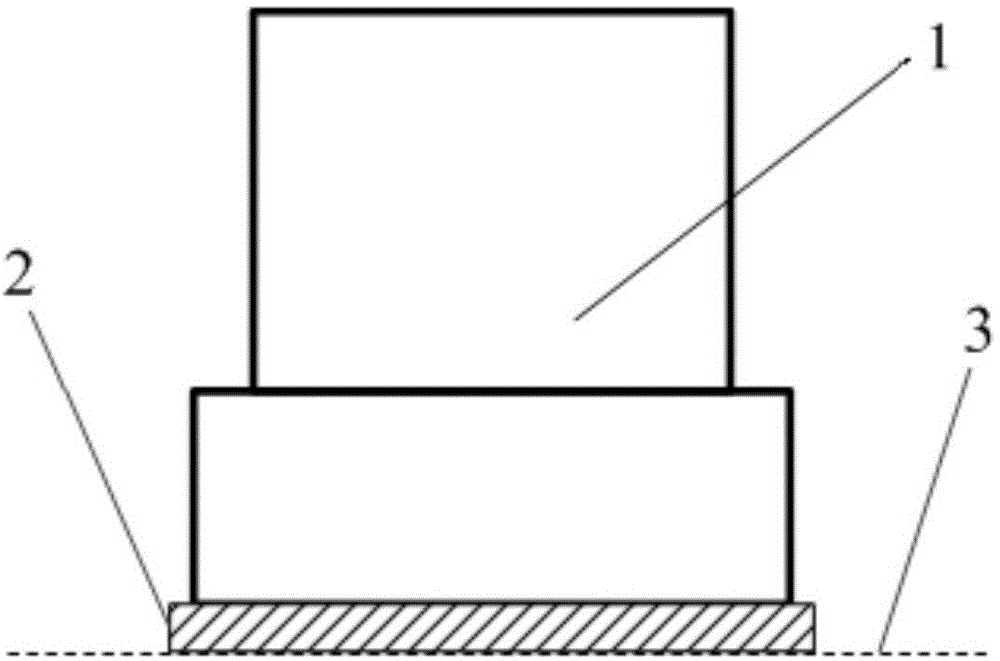

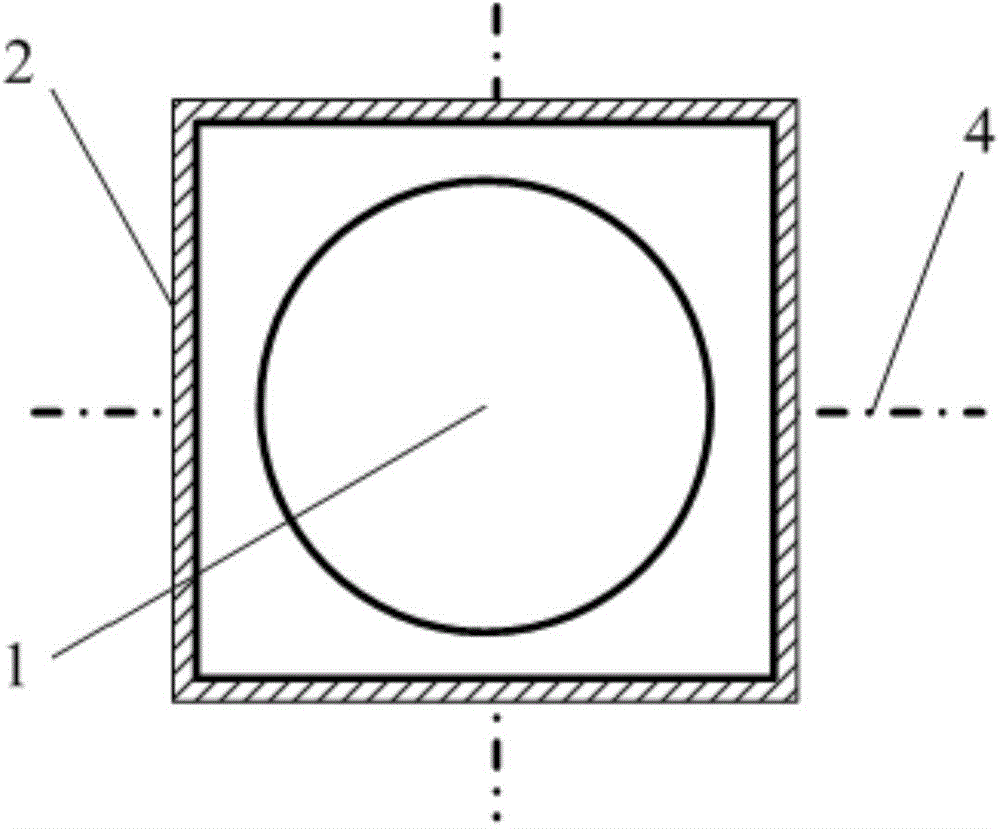

Quick mounting method of velocity/acceleration sensor

A technology of acceleration sensor and installation method, which is applied in the direction of speed/acceleration/shock measurement, speed/acceleration/electric shock meter details, instruments, etc. It can solve the problems of sensor displacement, unstable installation quality, low installation efficiency and quality, etc. Achieve the effect of wide temperature range, easy disassembly and cleaning, and heavy support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Before further describing the present invention, it should be understood that the present invention is not limited to the following specific embodiments of the invention. At the same time, it should also be understood that the terminology used herein is only used to describe specific implementations, and is not used to limit the scope of protection claimed in the present application.

[0048] In order to avoid punching holes on the surface of the object to be measured and install the accelerometer with bolts, it is necessary to consider the use of adhesives. If the surface of the structural material is not easy to punch holes, or the surface is uneven, then mechanical installation (such as punching) will bring some randomness to the installation quality. At this time, it is the best choice to install the accelerometer with adhesive.

[0049] At the same time, factors such as construction conditions, installation methods, site environment, and sensor parameters play a ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com