Improved substrate-free tape

A technology without substrate and tape, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of poor heat insulation, poor heat dissipation, failure of electronic components, etc., to reduce poor adhesion , fast paste, paste firmly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

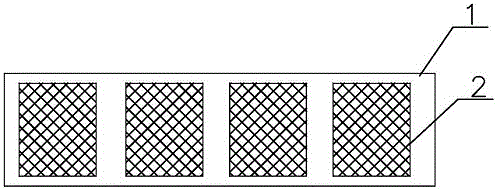

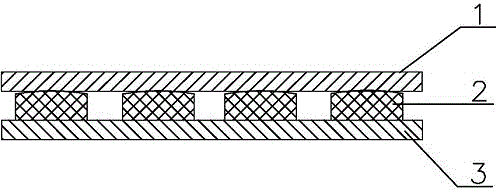

[0028] Such as figure 1 and figure 2 Shown, a kind of improved non-substrate adhesive tape, comprise first release layer 1, pressure-sensitive adhesive layer 2 and second release layer 3 successively, wherein the peeling force of first release layer 1 is less than the second release layer The peel force of 3, the first release layer 1 and the second release layer 3 are both strip-shaped structures, and the pressure-sensitive adhesive layer 2 is a plurality of rectangular blocks evenly distributed along the first release layer of the strip structure. The distance between adjacent rectangular blocks is 3mm (the value can also be other values between 0.5mm-10mm, no need to tear off and remove the adhesive layer a little bit, easy to use); the edge distance of the pressure-sensitive adhesive layer 2 is the first distance The edge of the type paper layer is 2mm (the value can also be other values between 0.5-3mm, which can ensure that there will be no glue overflow during p...

Embodiment 2

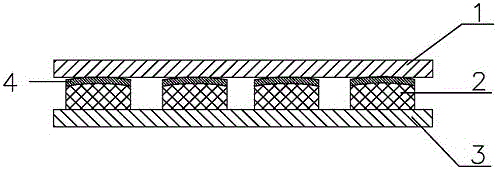

[0033] Such as figure 1 and image 3 Shown, a kind of improved non-substrate adhesive tape, comprise first release layer 1, pressure-sensitive adhesive layer 2 and second release layer 3 successively, wherein the peeling force of first release layer 1 is less than the second release layer The peel force of 3, the first release layer 1 and the second release layer 3 are both strip-shaped structures, and the pressure-sensitive adhesive layer 2 is a plurality of rectangular blocks evenly distributed along the first release layer of the strip structure. The distance between adjacent rectangular blocks is 5mm (the value can also be other values between 0.5mm-10mm, no need to tear off and remove the adhesive layer a little bit, easy to use); the edge distance of the pressure-sensitive adhesive layer 2 is the first distance The edge of the type paper layer is 1mm (the value can also be other values between 0.5-3mm, which can ensure that there will be no glue overflow during pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com