Patents

Literature

196results about How to "Avoid cleaning inconvenience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

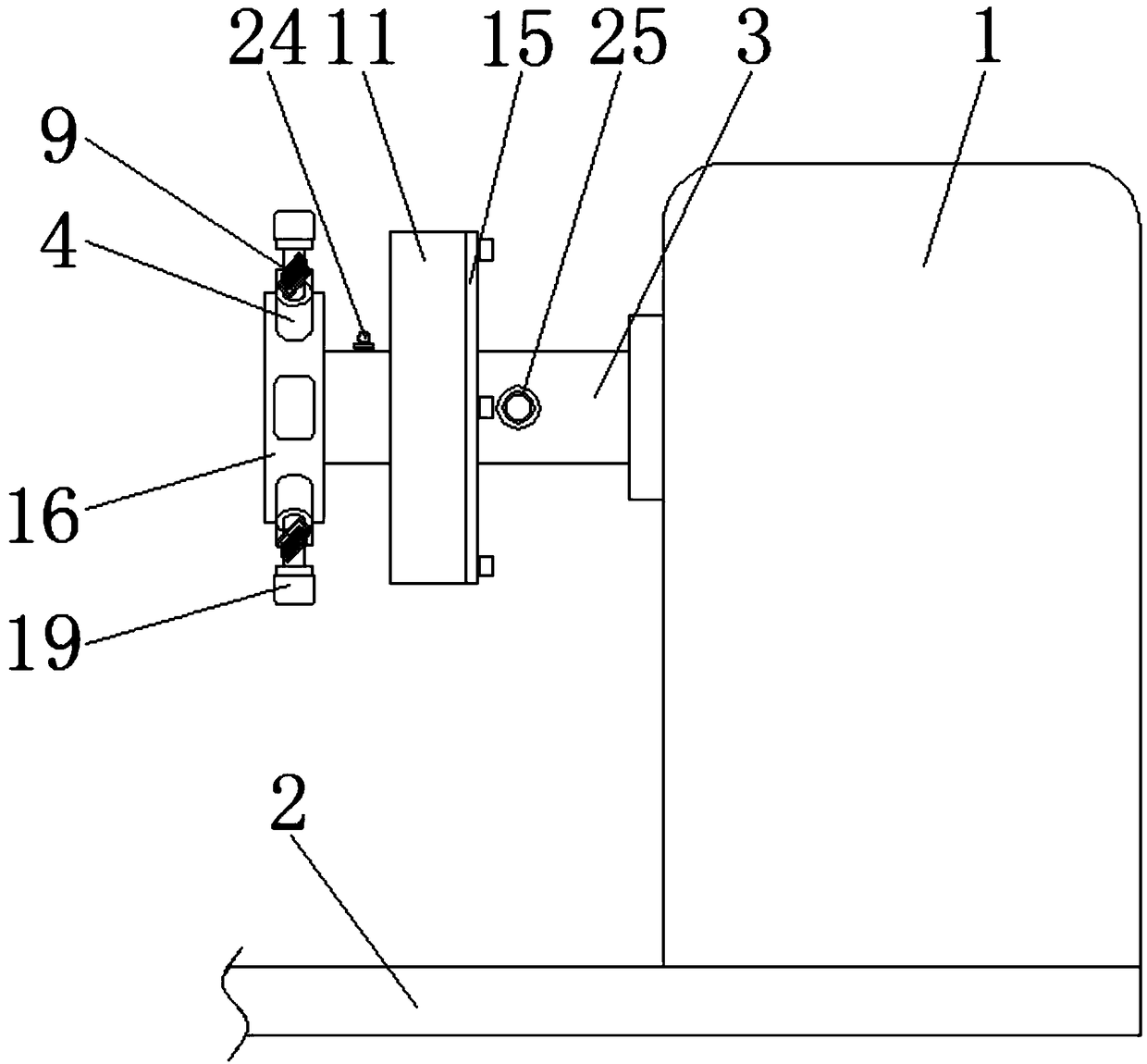

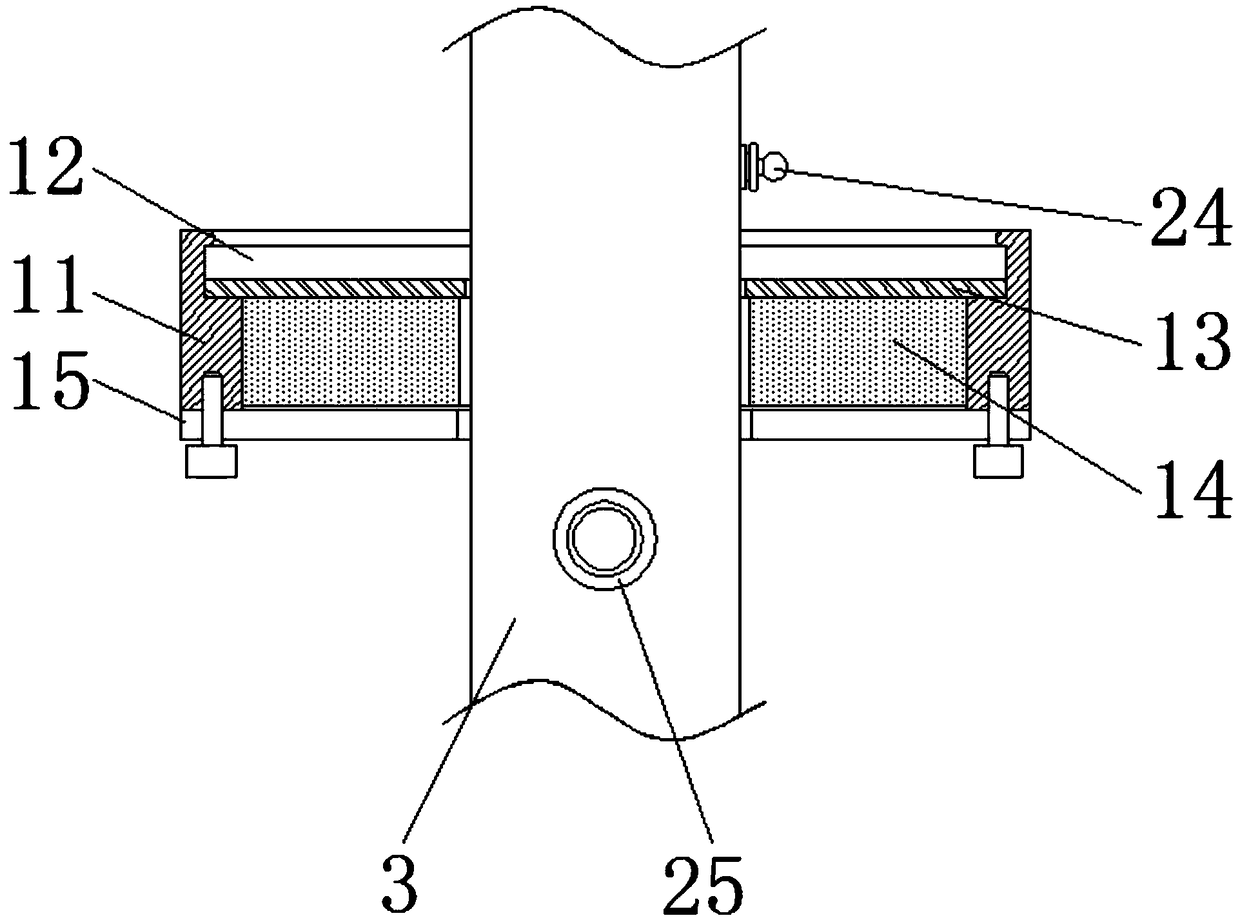

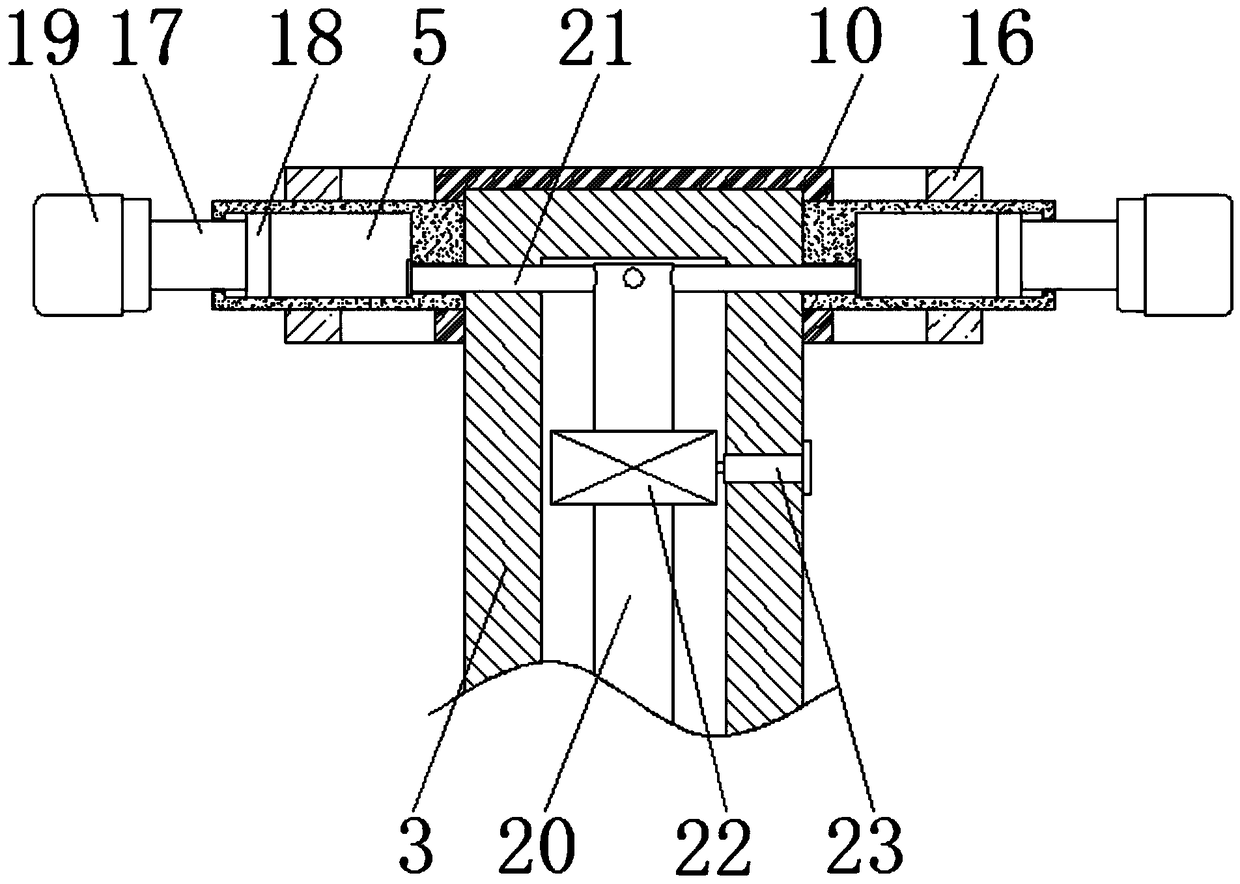

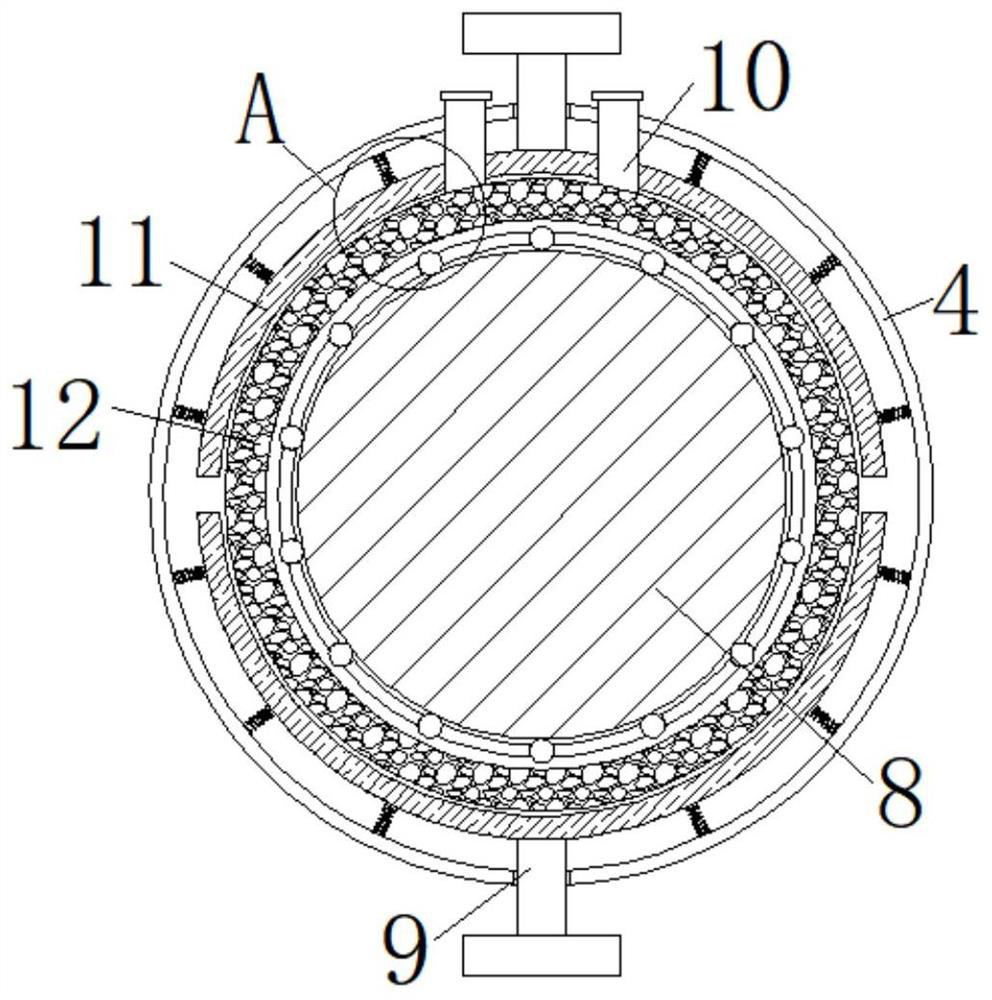

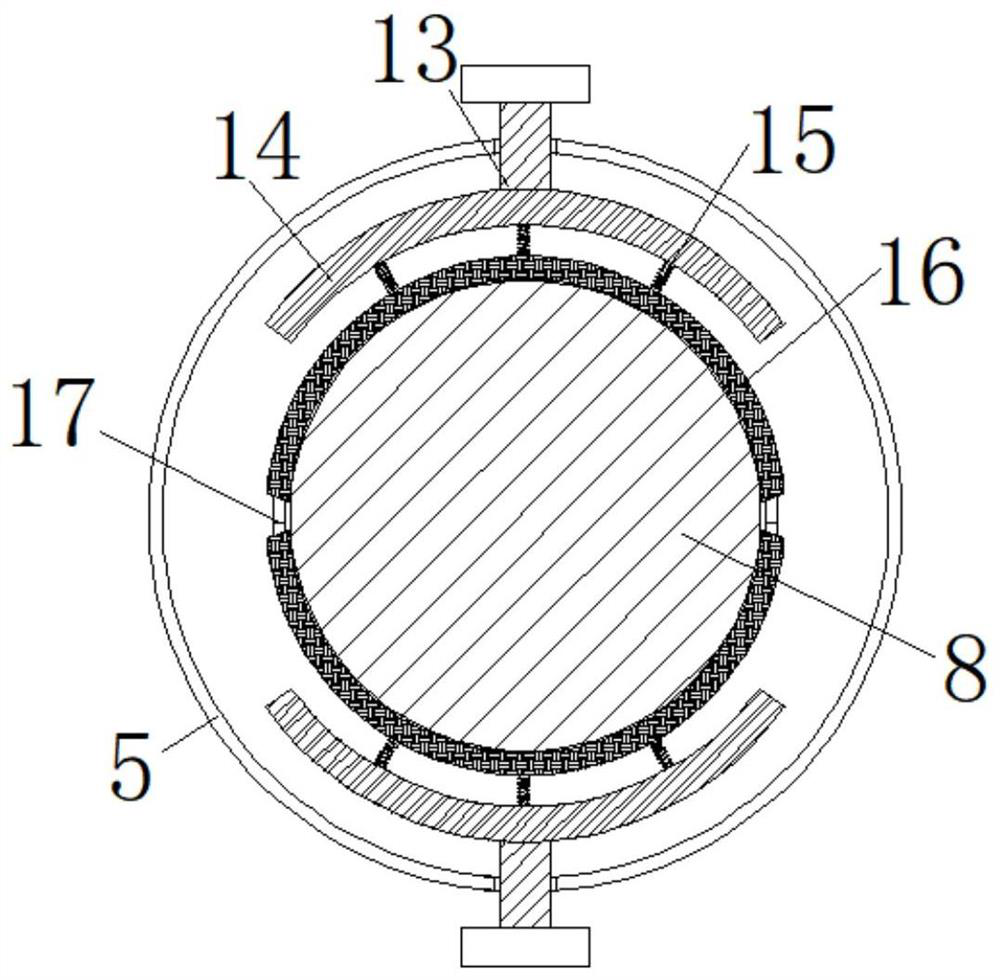

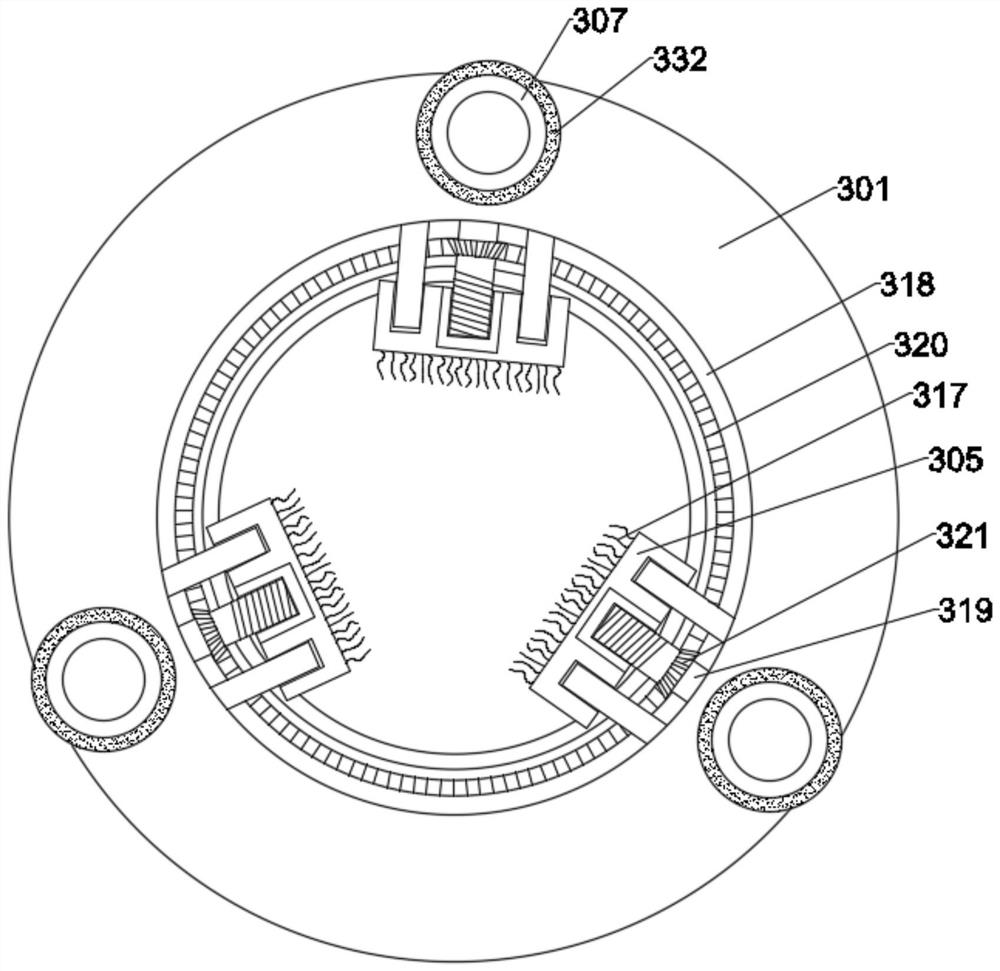

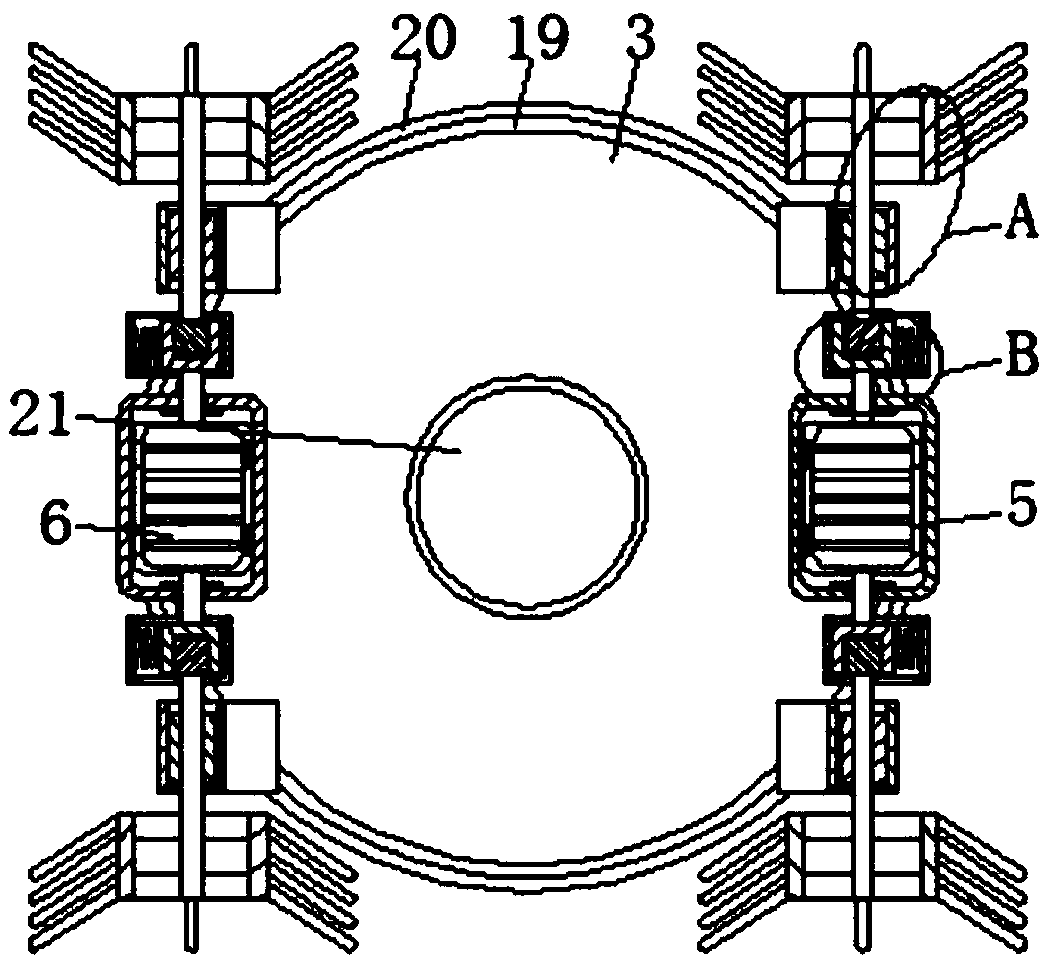

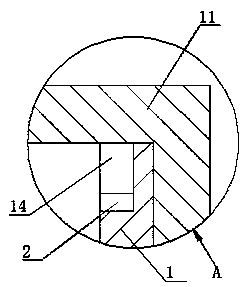

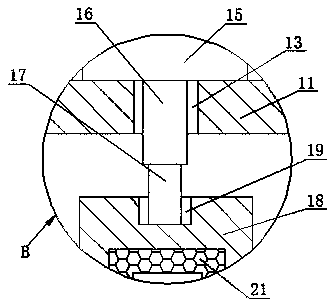

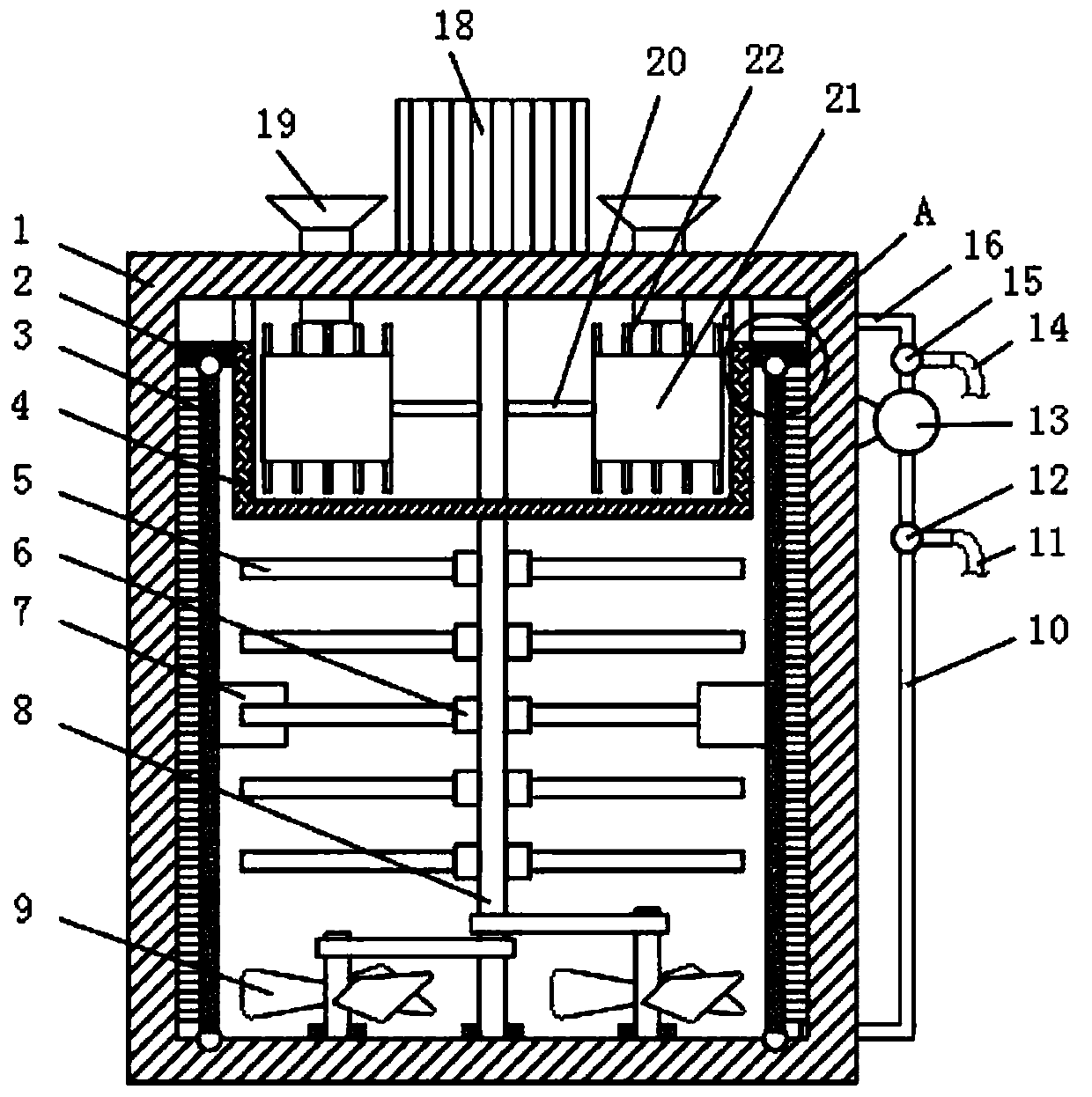

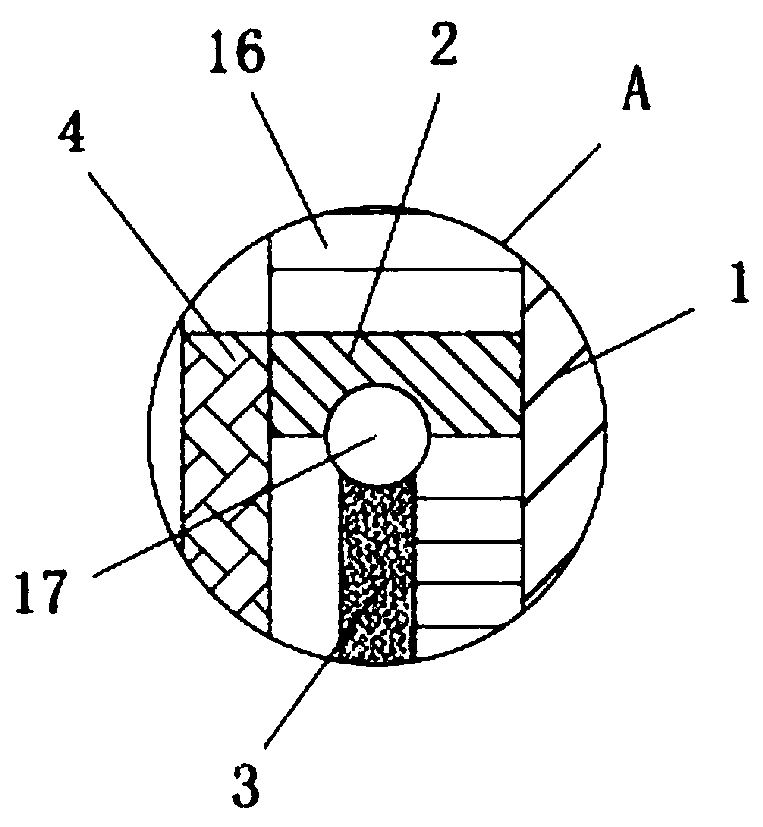

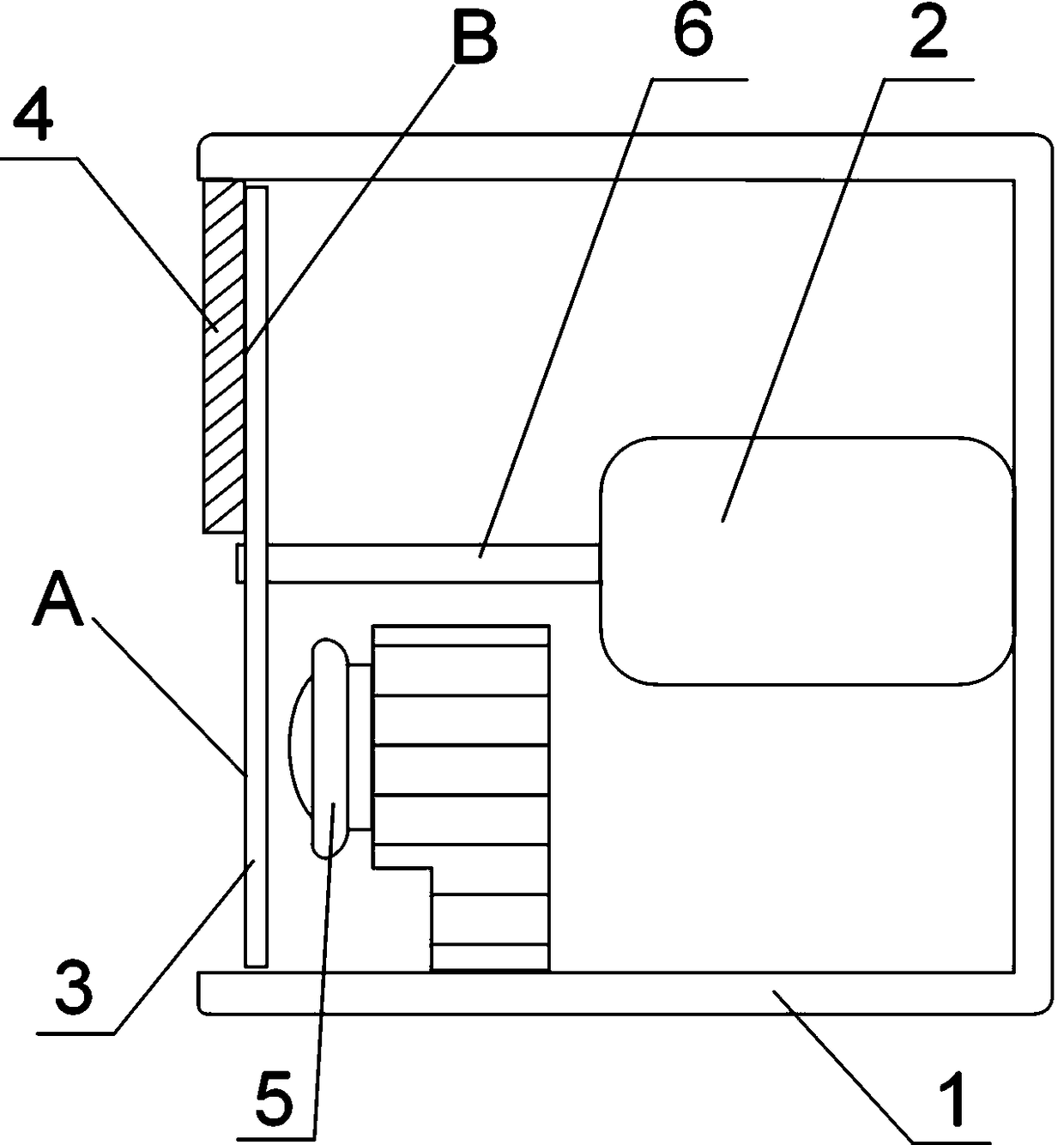

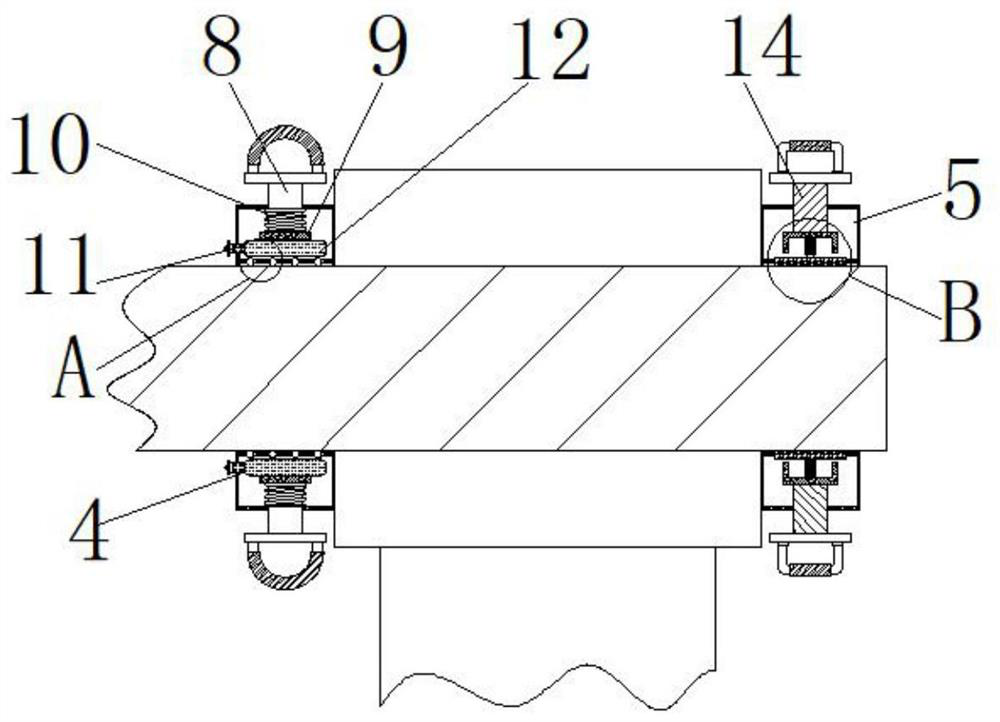

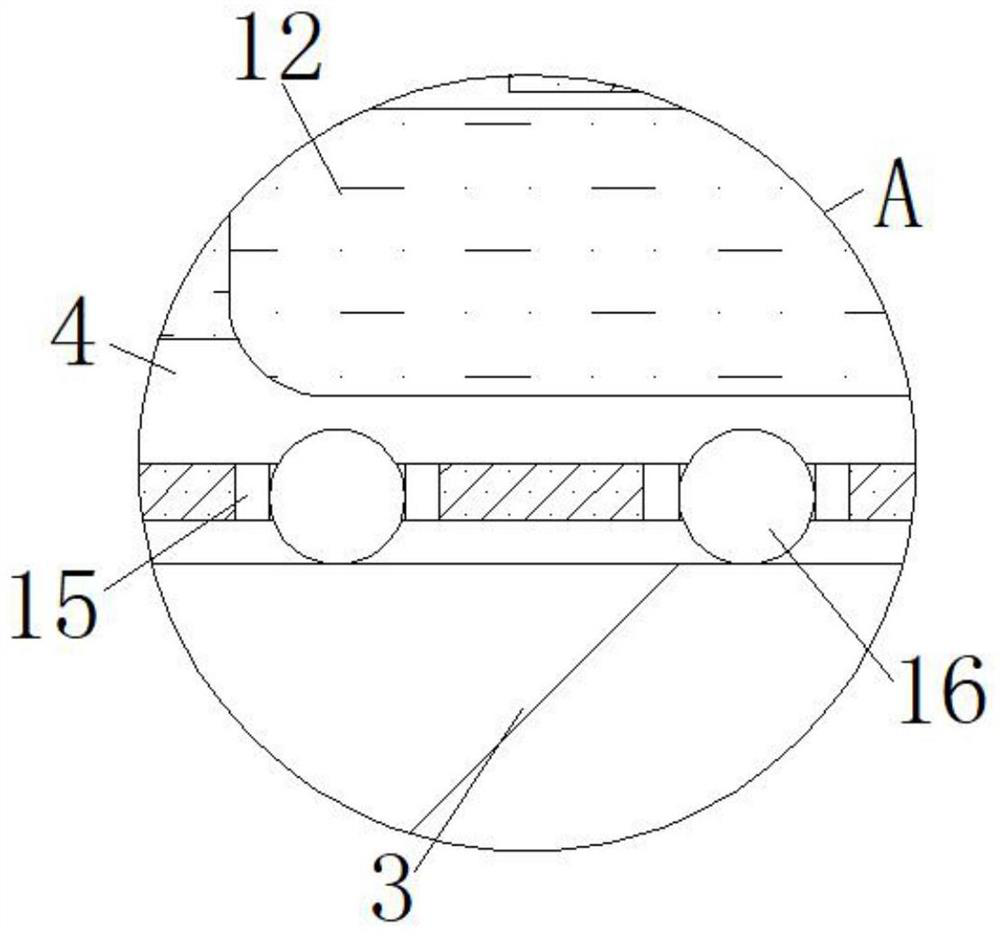

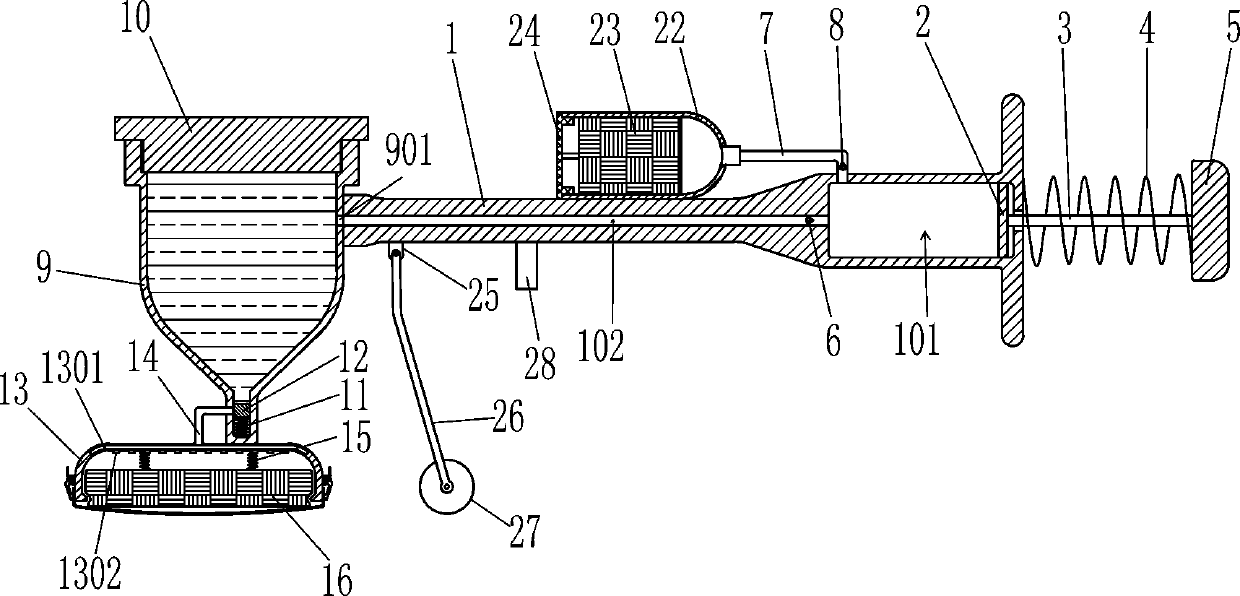

Polishing equipment for bearing inner roller way machining

InactiveCN109202621AImprove grinding efficiencyEven by forceGrinding machine componentsGrinding machinesEngineeringPiston

The invention discloses polishing equipment for bearing inner roller way machining, and relates to the technical field of bearing machining equipment. The polishing equipment comprises a mainframe box; the bottom of the mainframe box is fixedly connected with a base, and the left side of the mainframe box is rotationally connected with a hollow rotation shaft; the left end of the surface of the hollow rotation shaft communicates with telescopic sleeves and piston cylinders; and the ends, away from the hollow rotation shaft, of the telescopic sleeves are provided with hairbrush rods in a penetrating mode. According to the polishing equipment for bearing inner roller way machining, hairbrush heads are arranged between polishing structures and made to be tightly attached to the surface of a bearing inner roller way through elastic force of springs, and during rotation, scrap iron generated after the surface of the bearing inner roller way is polished is removed; the hairbrush heads are obliquely arranged, the scrap iron can be swept out rightwards, moreover, the scrap iron is attracted to the surface of an iron sheet through magnetism of a magnetic ring so as to be collected, and thesituation that the scrap iron flies all around and is inconvenient to remove can be avoided; and the scrap iron is removed in time, influence on the machining surface is avoided, and cutting fluid issaved.

Owner:湖北优尔特轴承科技有限公司

Corrugated pipe machining method

ActiveCN110202630AAvoid cleaning inconvenienceMetal working apparatusTubular articlesLiquid stateDesiccant

The invention discloses a corrugated pipe machining method. The corrugated pipe machining method comprises the following steps of a, feeding, specifically, putting raw materials into a vacuum feedingmachine, and enabling the raw materials to be fully mixed in the feeding machine; b, drying, specifically, putting the mixed raw materials into a drying agent, and drying the raw materials in a hot air drying mode; c, plasticizing, specifically, heating and plasticizing the mixed raw materials in a plasticizing machine, enabling the raw materials to be in a liquid state, and extruding the liquid raw materials according to the required shape through mutual cooperation of an extruding machine and an extruding mould; d, forming; e, cooling, specifically, introducing a corrugated pipe into a spraying water tank, carrying out spraying treatment on the surface of the corrugated pipe, and enabling the surface of the corrugated pipe to be in a room temperature state; f, blow-drying, specifically,blowing air to the surface of the corrugated pipe through a fan, and drying the water on the corrugated pipe; g, cutting, specifically, introducing the corrugated pipe into a cutting machine, and cutting the corrugated pipe into a required length according to requirements; and h, checking and warehousing, specifically, checking various indexes of the corrugated pipe, removing defective products inthe corrugated pipes, and packaging and warehousing finished corrugated pipes.

Owner:浙江蔚福科技股份有限公司

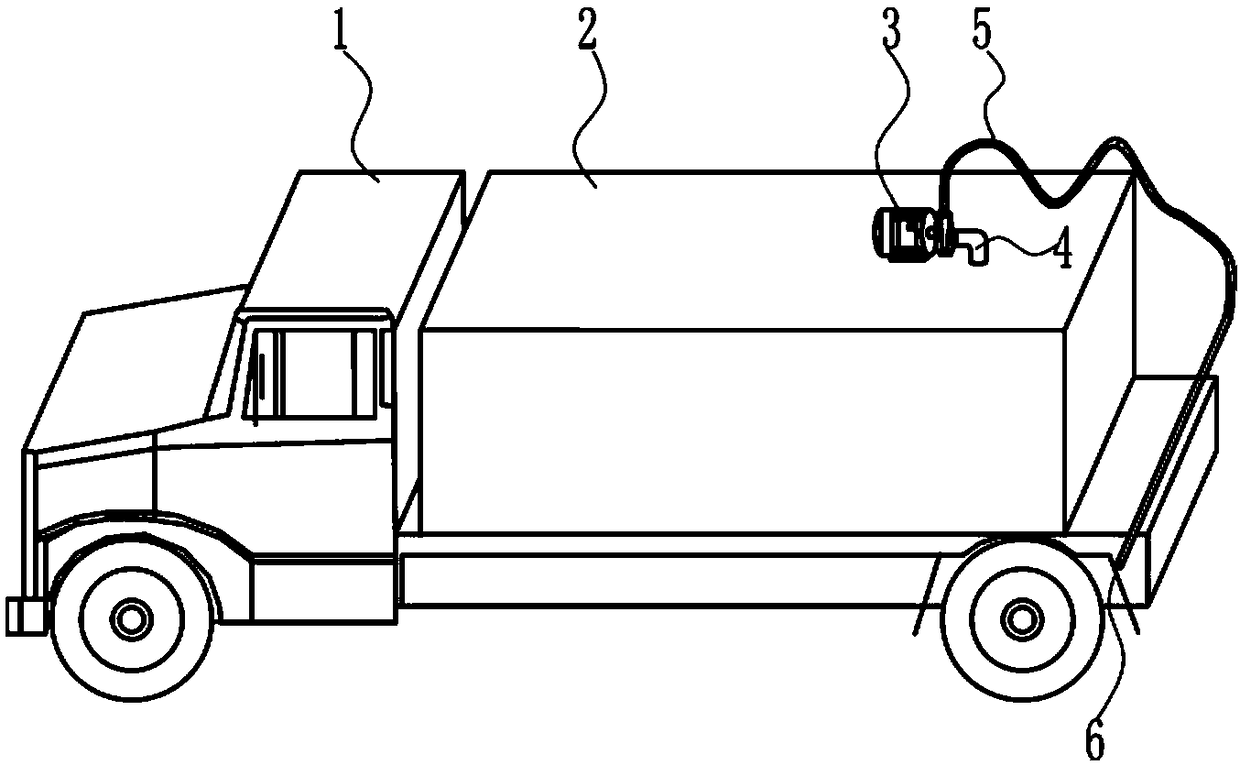

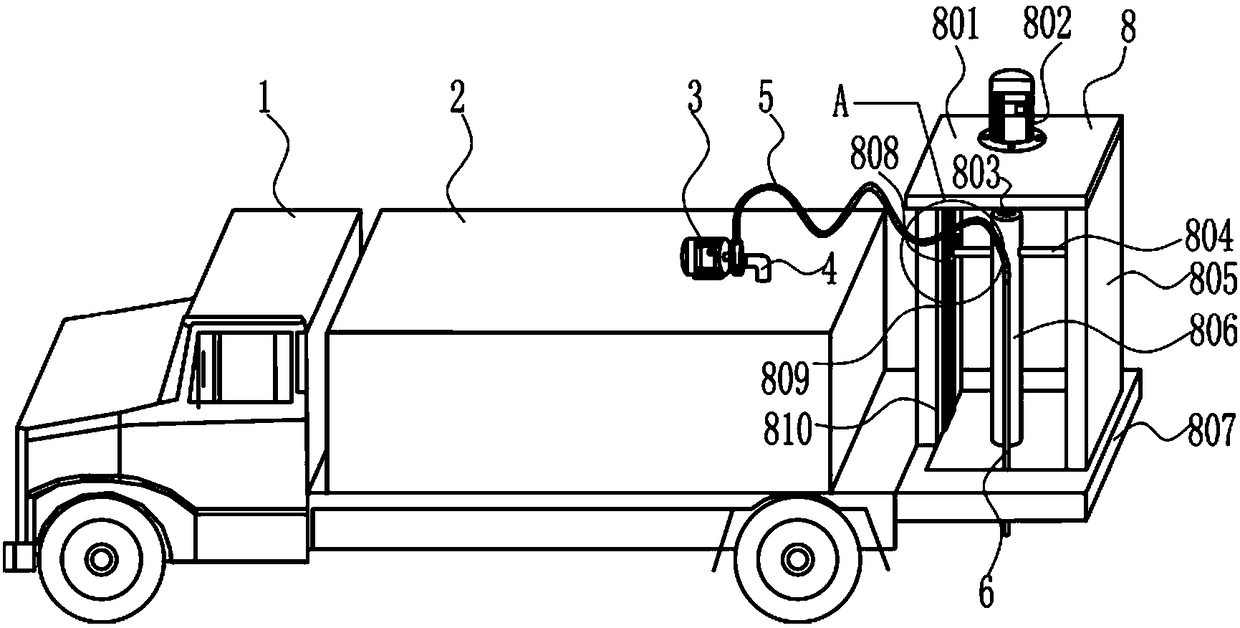

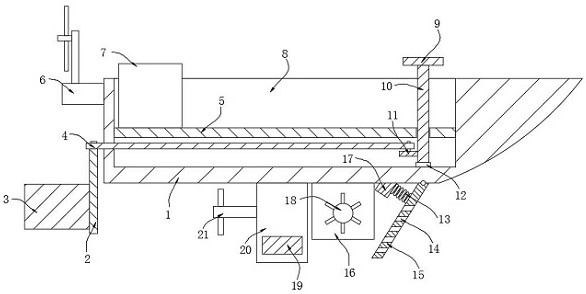

Municipal sanitary-sewer-manhole high-efficiency desilting vehicle

The invention relates to a desilting vehicle, in particular to a municipal sanitary-sewer-manhole high-efficiency desilting vehicle. The technical aims that the municipal sanitary-sewer-manhole high-efficiency desilting vehicle is convenient to clean, capable of cleaning sludge caking and comprehensive in function are achieved. The municipal sanitary-sewer-manhole high-efficiency desilting vehiclecomprises a vehicle body and the like; a silt storage box is arranged on the vehicle body, a silt absorption pump is arranged at the top of the silt storage box, a connecting pipe is connected between the silt absorption pump and the silt storage box, a silt feeding flexible pipe is arranged at the top of the silt absorption pump, a silt absorption pipe is connected to the right end of the silt absorption pump, and is put on the vehicle body, and the back side of the silt storage box is in thread fit with a first threaded cover. According to the municipal sanitary-sewer-manhole high-efficiency desilting vehicle, the effects of being convenient to clean, capable of cleaning sludge caking and comprehensive in function are achieved, a lifting device can conveniently move the silt absorptionpipe to the suitable position, and silt is conveniently absorbed.

Owner:杭州君呈贸易有限公司

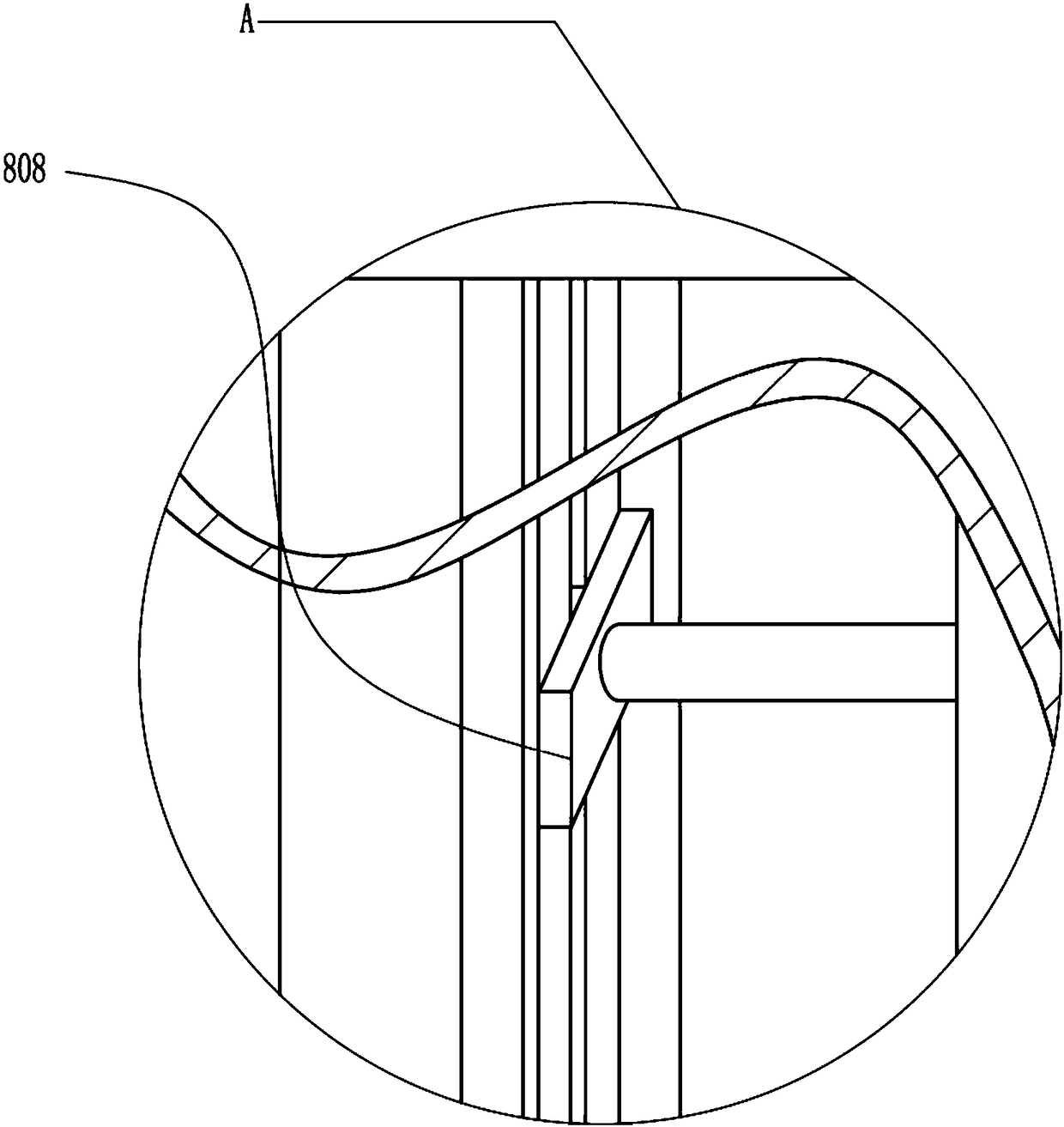

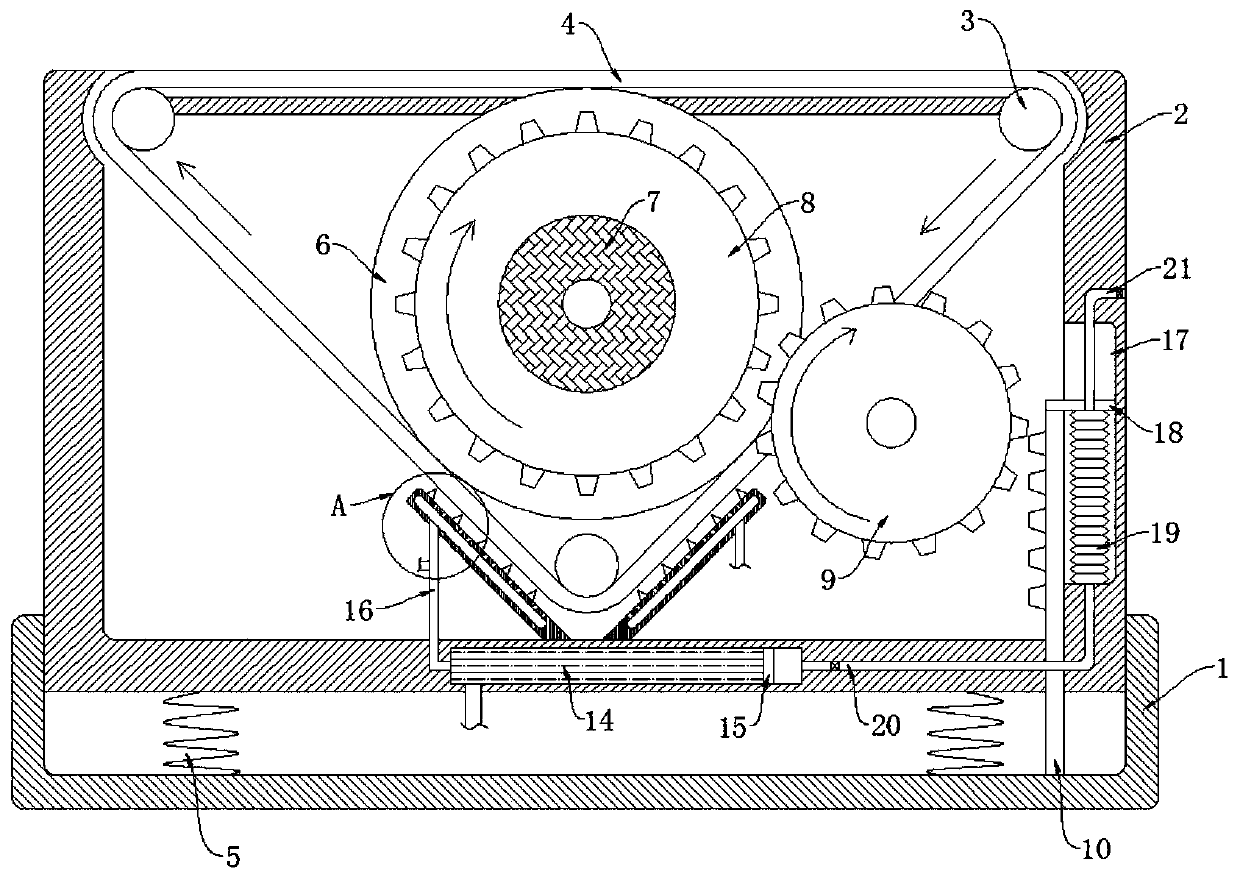

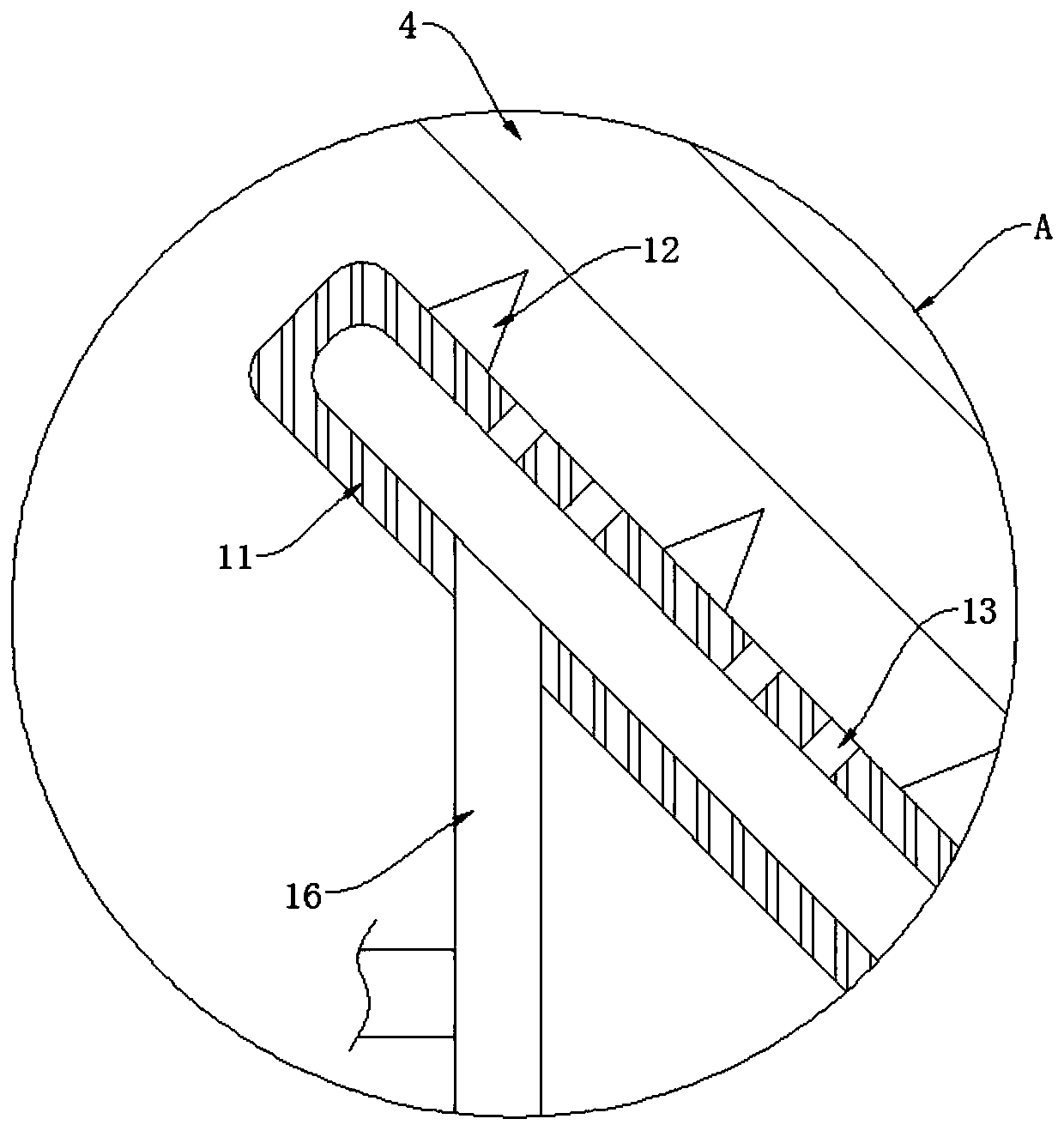

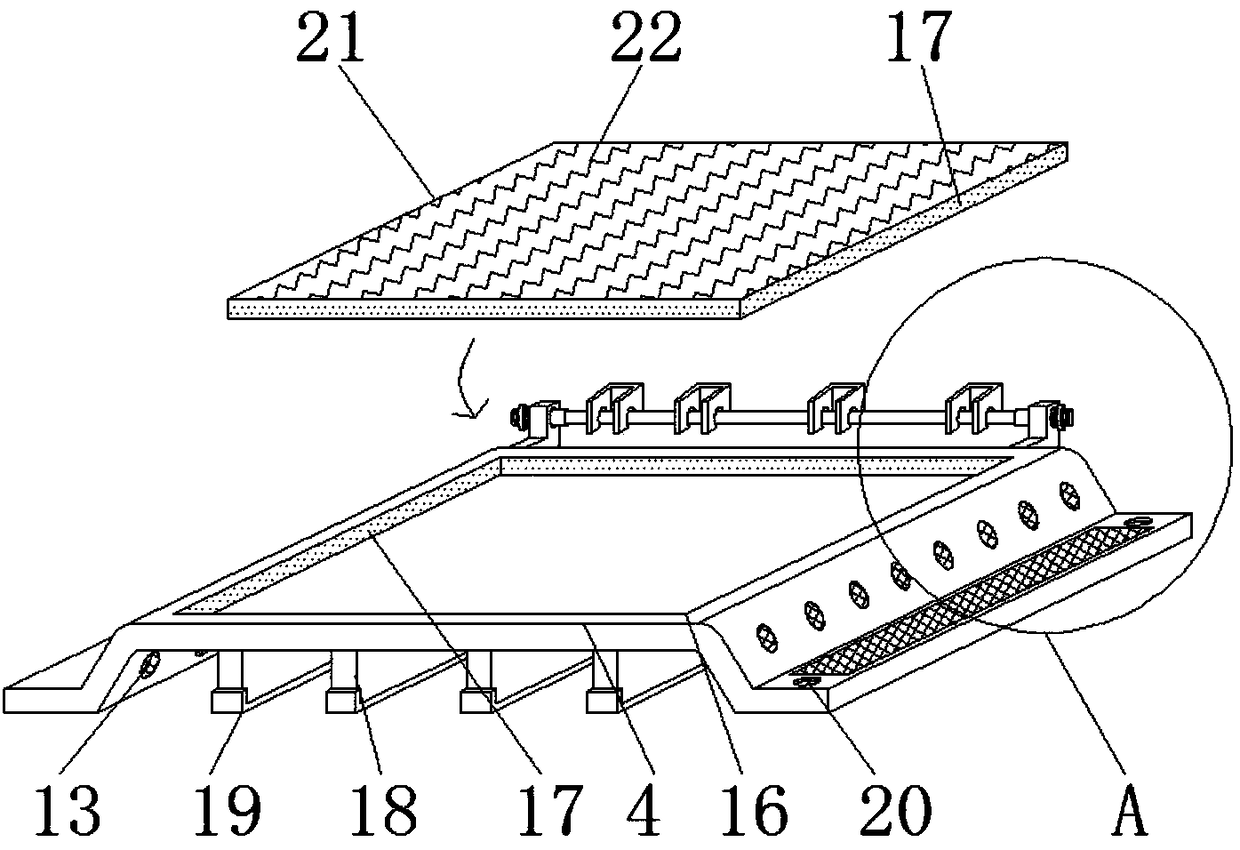

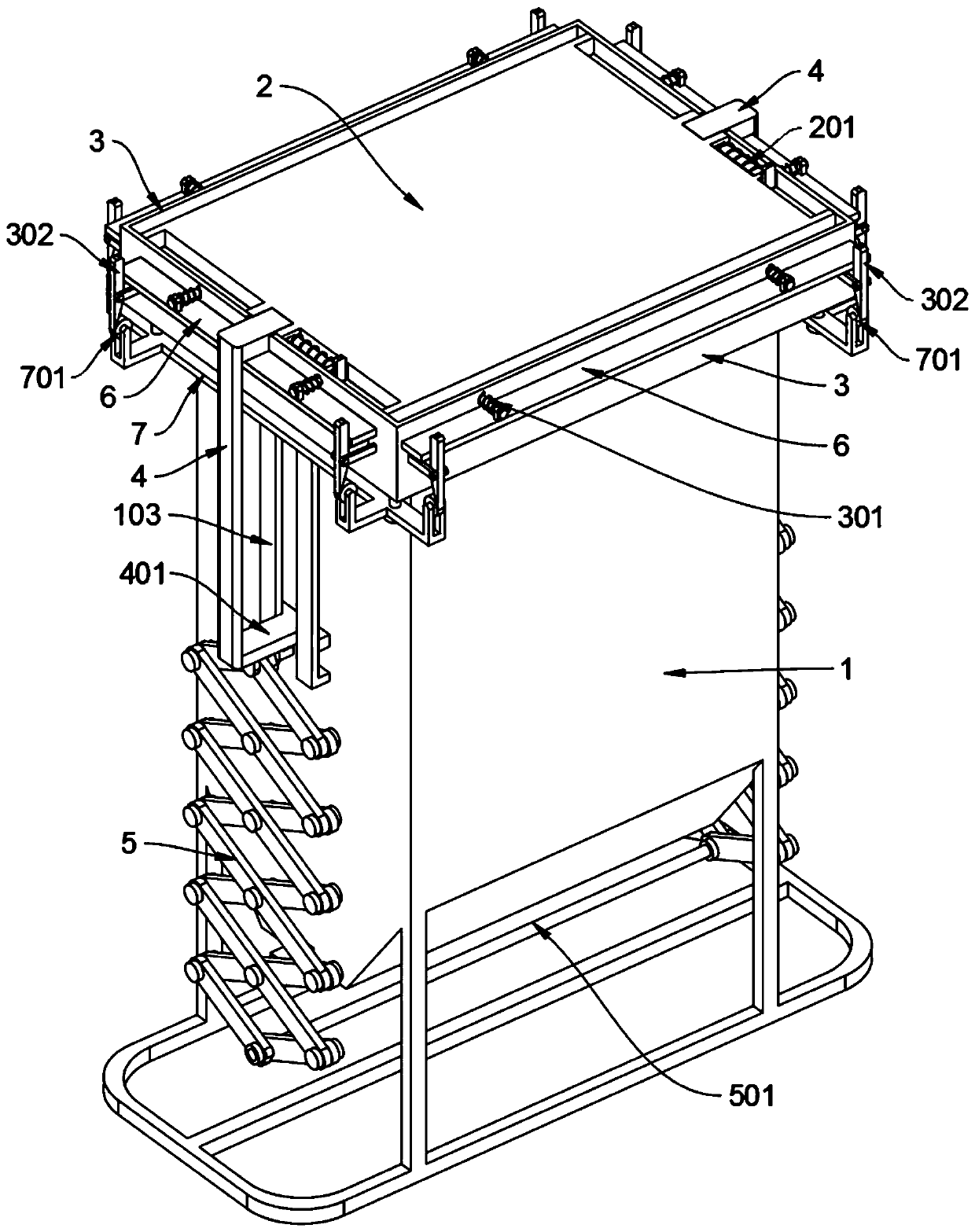

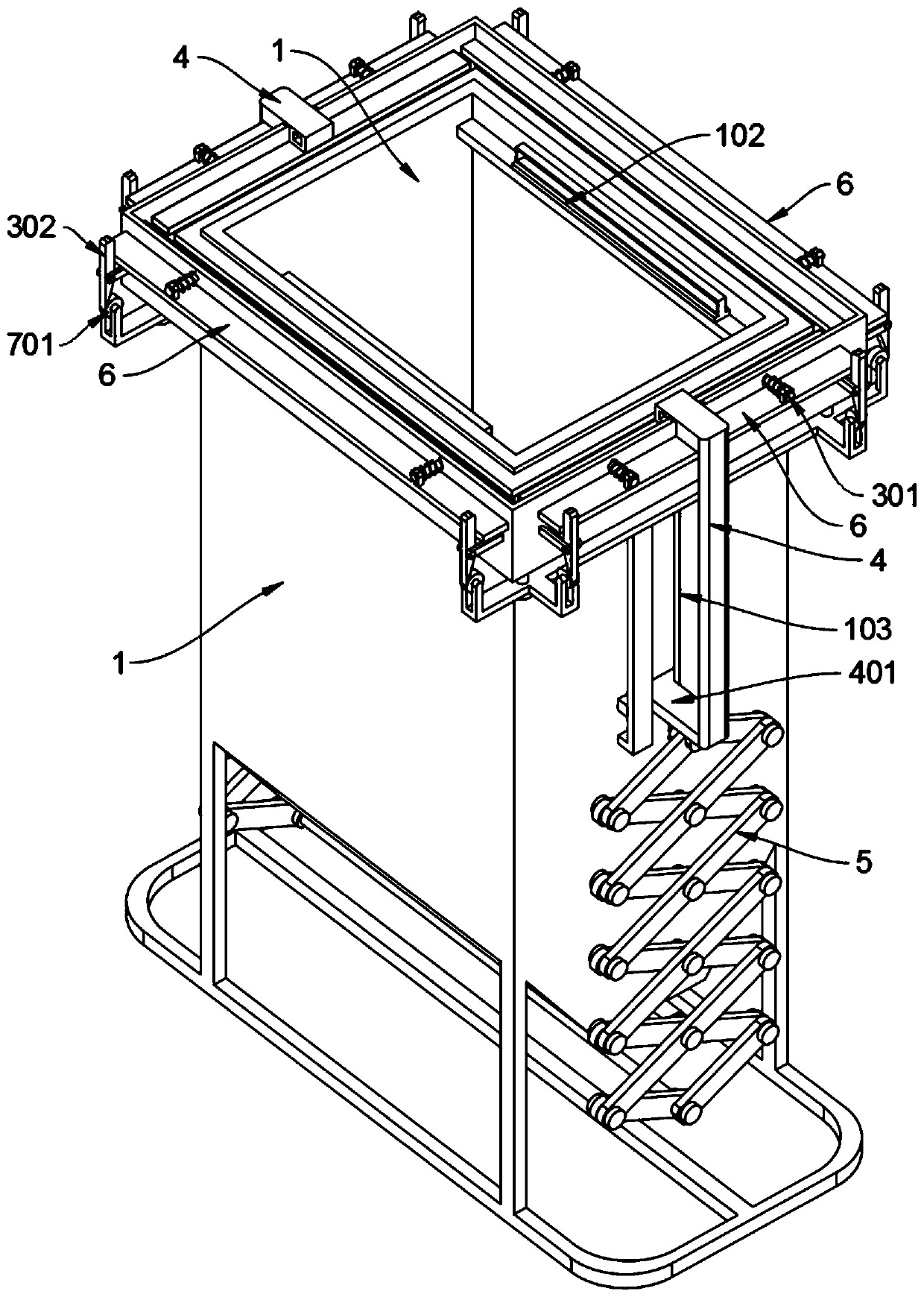

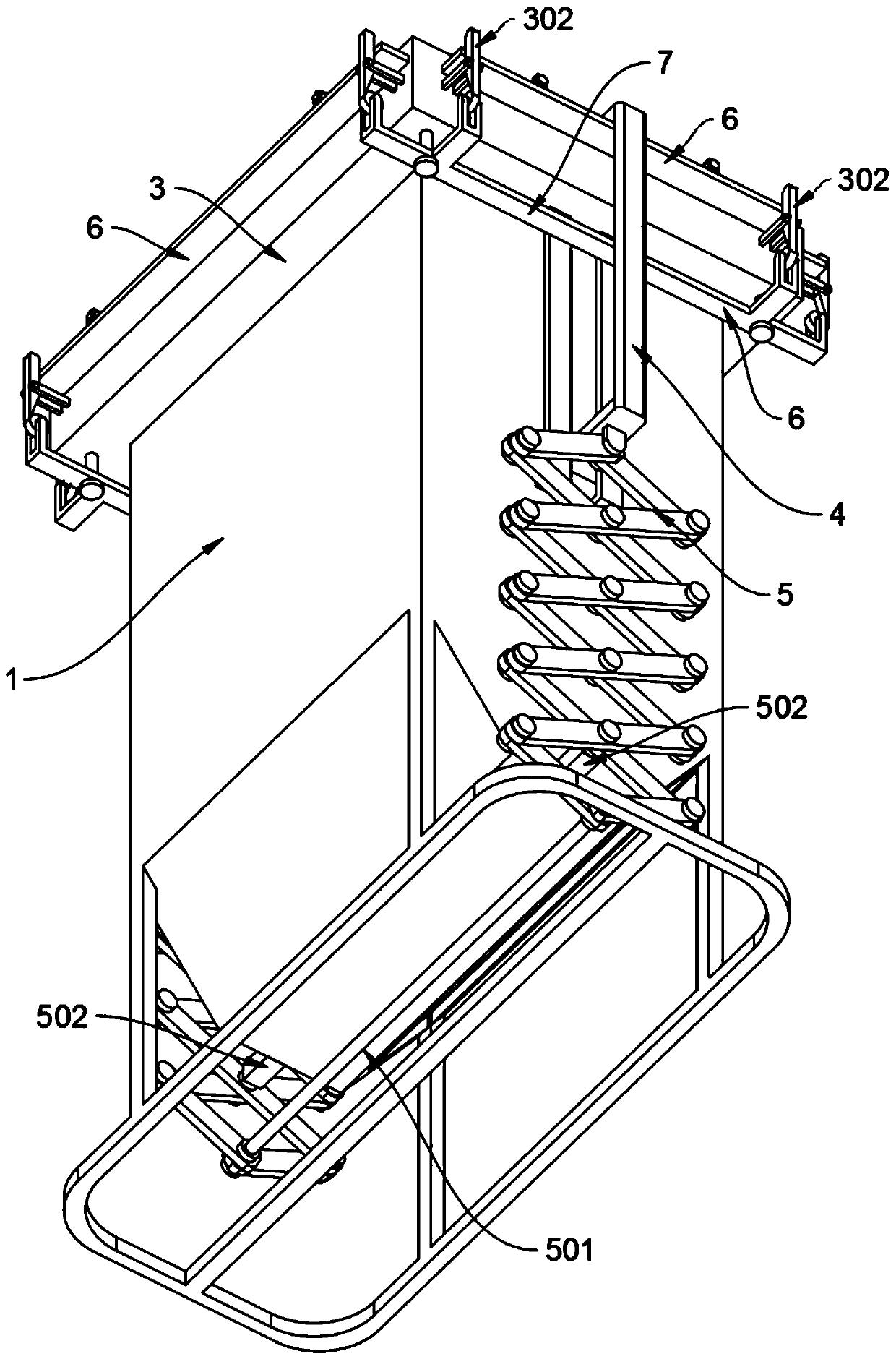

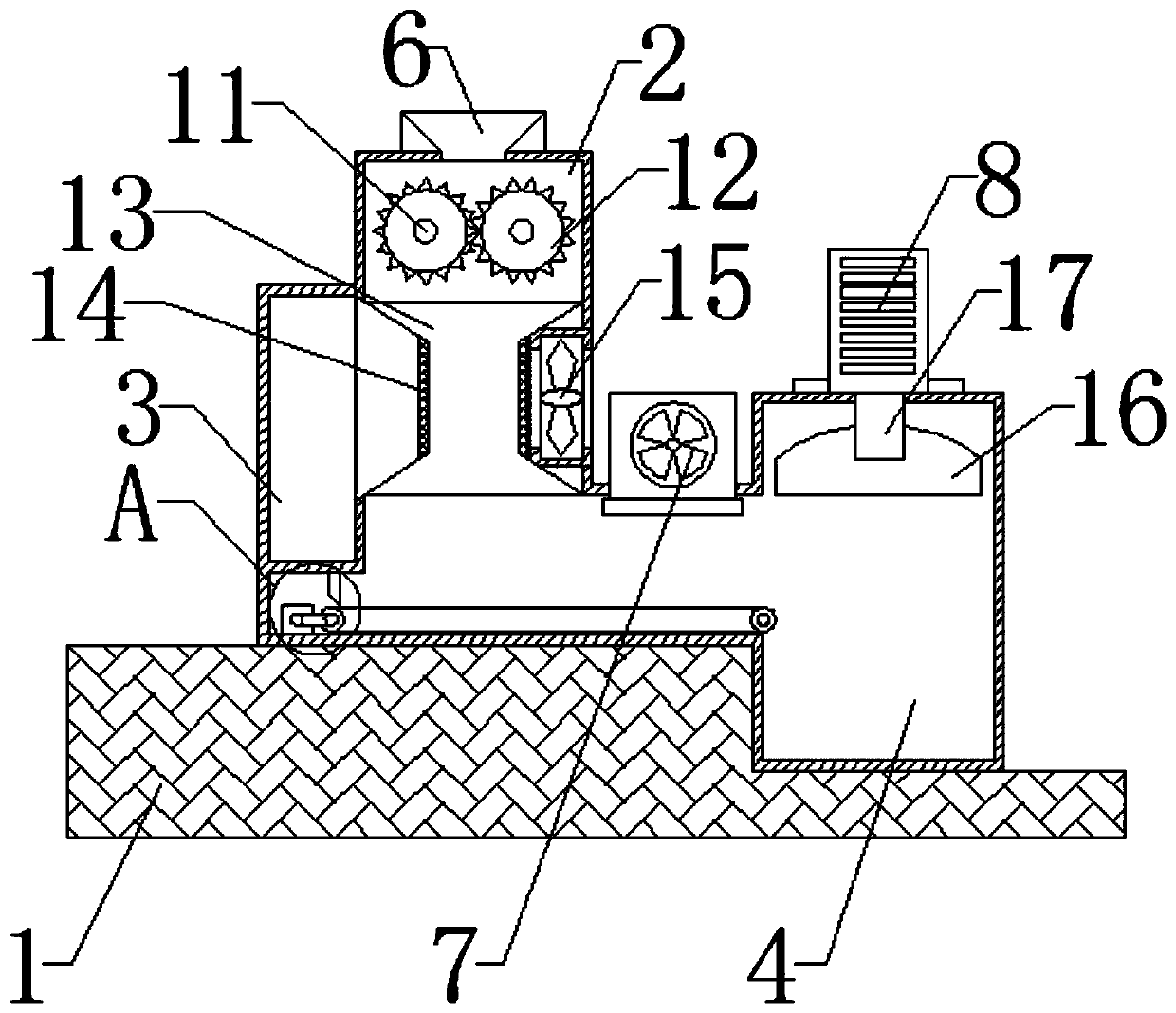

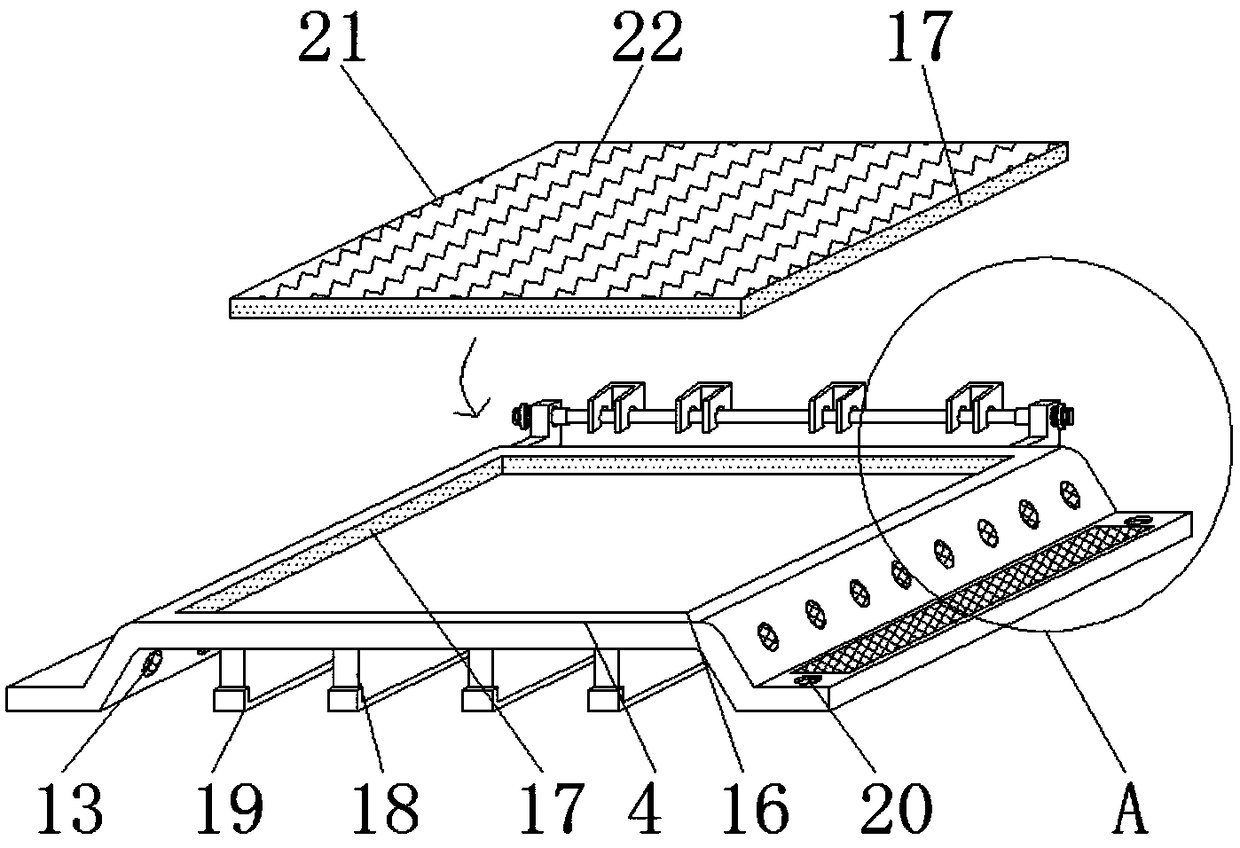

Mechanical self-cleaning device for entrance carpet of smart home

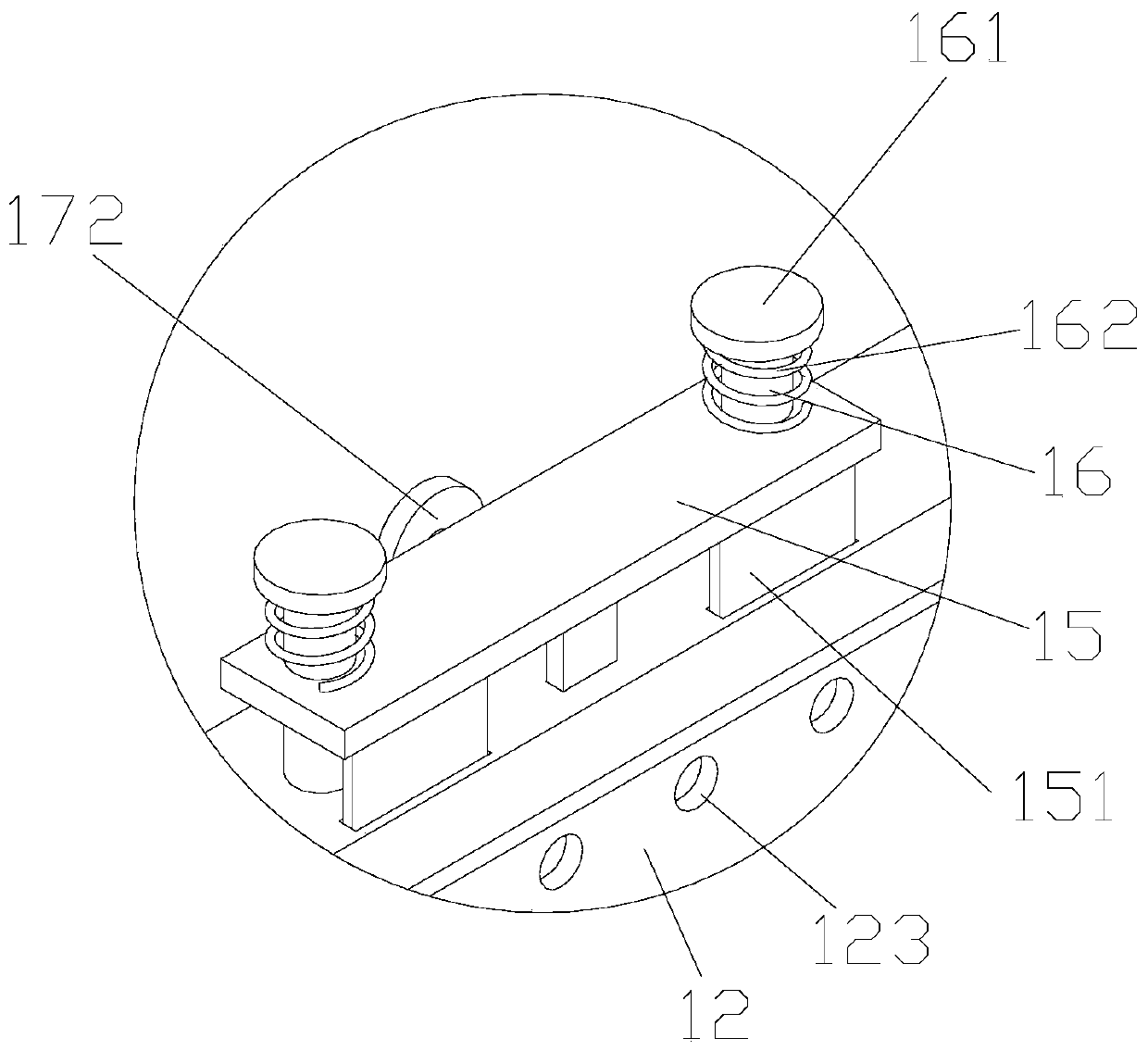

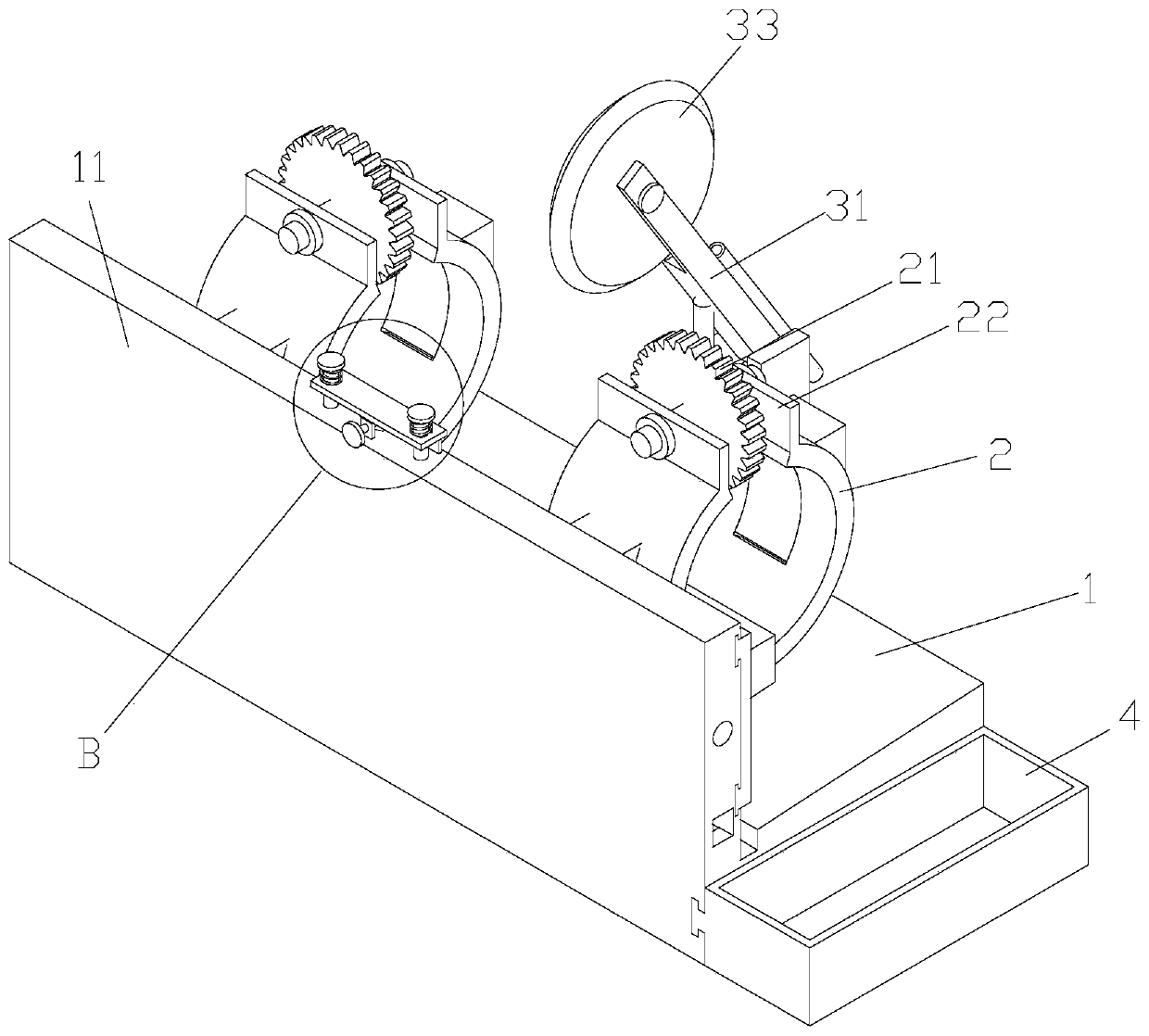

PendingCN110934556AImprove the living environmentAvoid cleaningFootwear cleanersGear wheelClassical mechanics

The invention discloses a mechanical self-cleaning device for an entrance carpet of a smart home, and the mechanical self-cleaning device comprises a box body with an opening formed in the upper end;a friction wheel is rotatably connected to the inner wall of a movable box through a rotating shaft, and a driving device for driving the friction wheel to rotate is installed on the movable box. Thearrangement of a rack, a first gear, a second gear, a one-way bearing and the friction wheel enables the friction wheel to rotate only when people leave the carpet body, and therefore, the carpet bodyrotates on the driving roller; when the movable box moves downwards, tthe rack drives a sliding plate to slide upwards in a groove; an elastic corrugated pipe performs air suction extension throughaone-way air suction pipe; when the movable box moves upwards, the rack drives the sliding plate to slide downwards in the groove to compress the elastic corrugated pipe, so gas in the elastic corrugated pipe enters a sliding plug cavity through a one-way gas inlet cavity, cleaning liquid in the sliding plug cavity is sprayed out from liquid spraying holes, and dirt on the moving carpet body is cleaned under the action of scraping teeth.

Owner:何明来

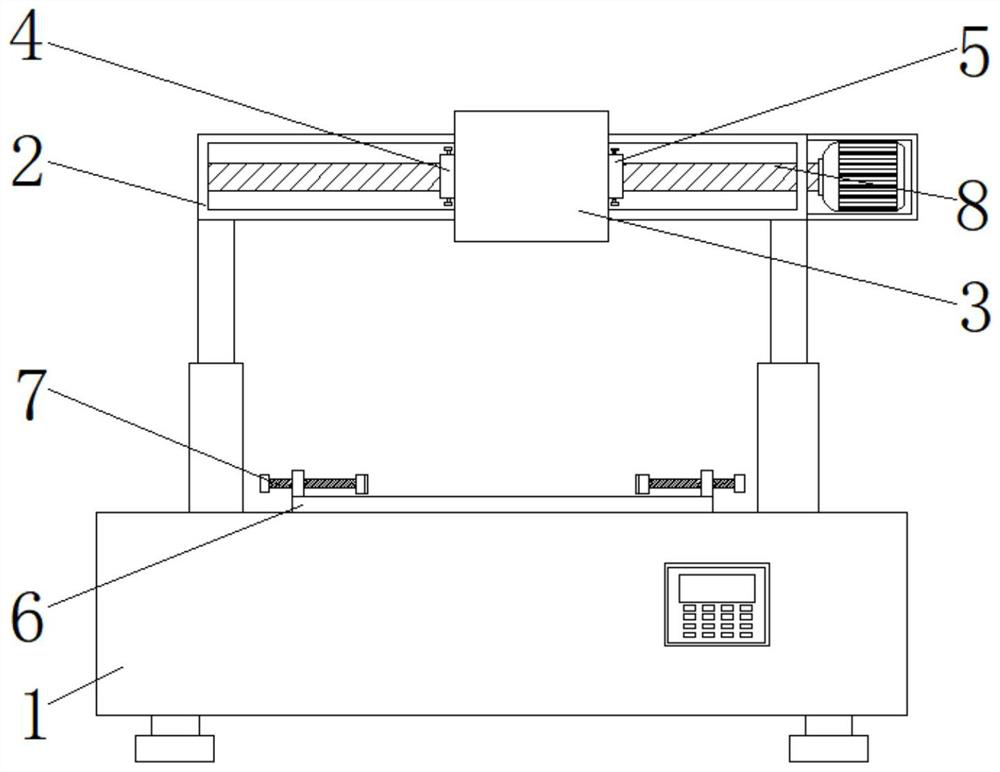

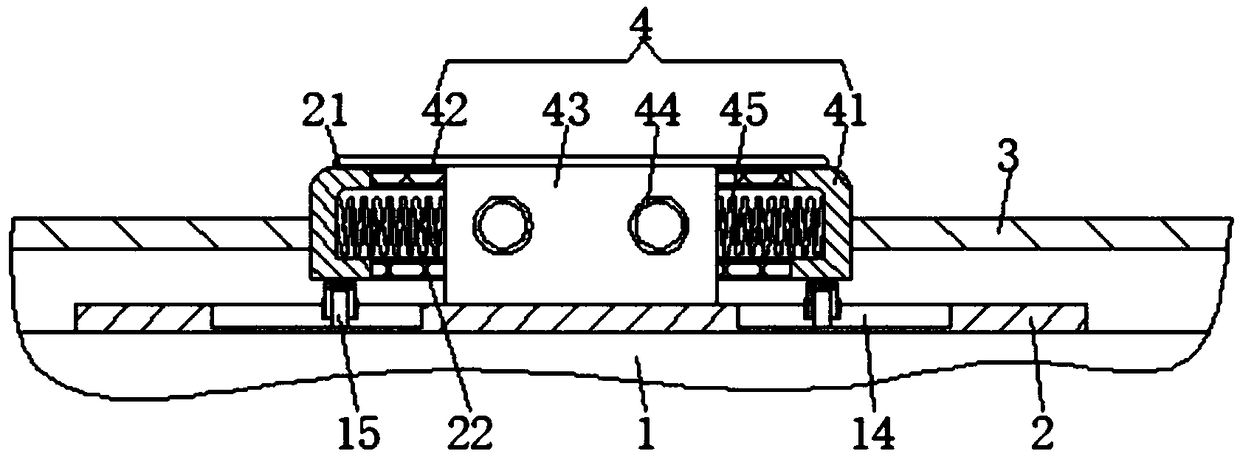

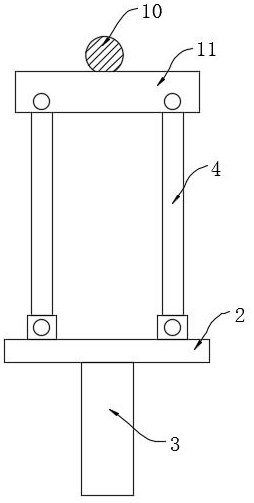

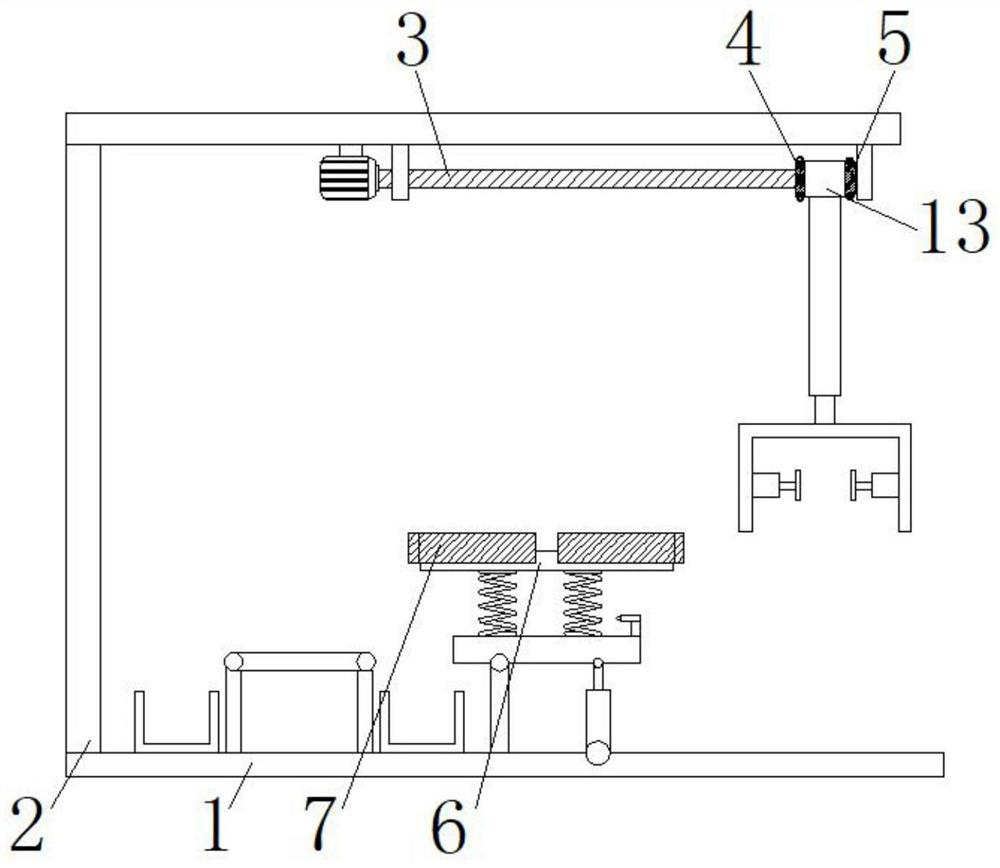

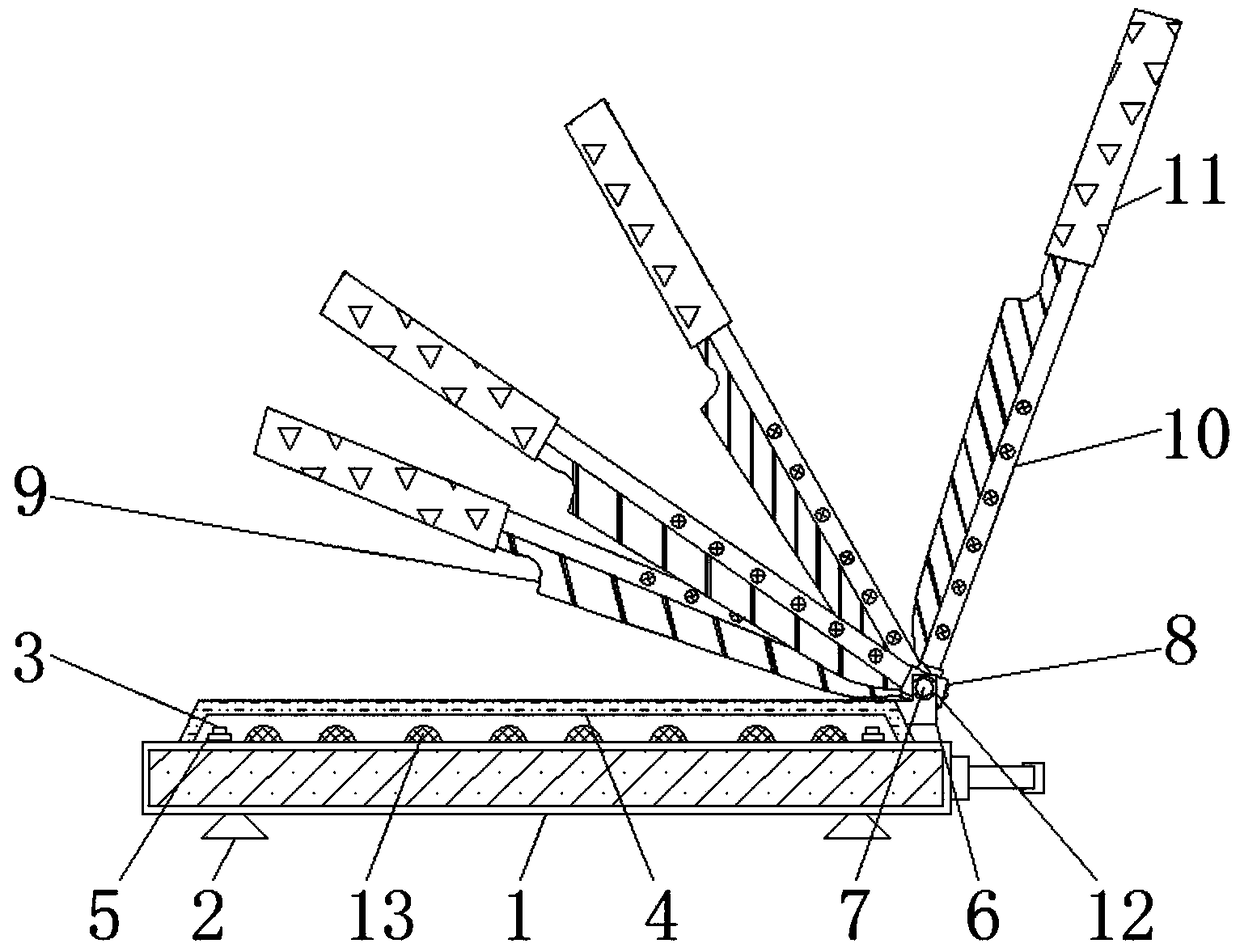

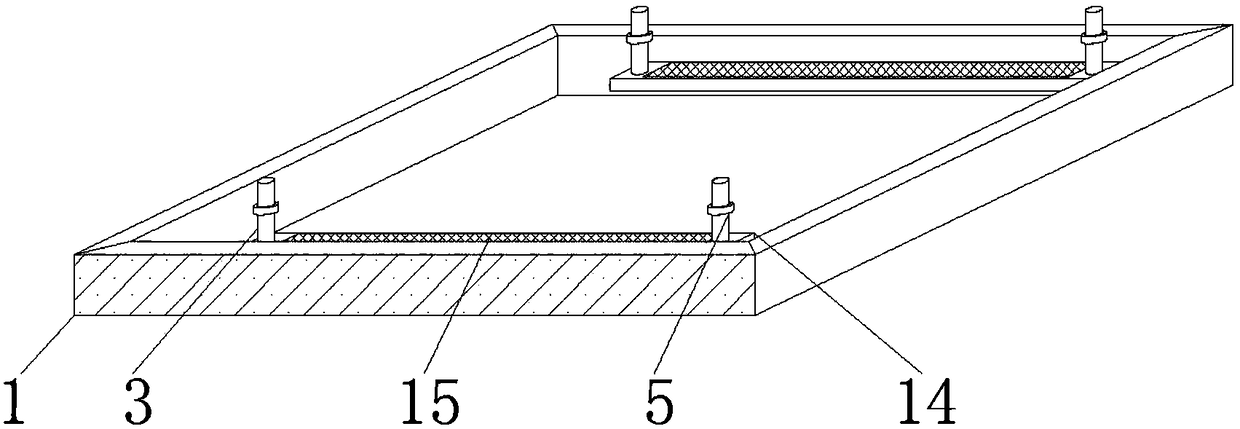

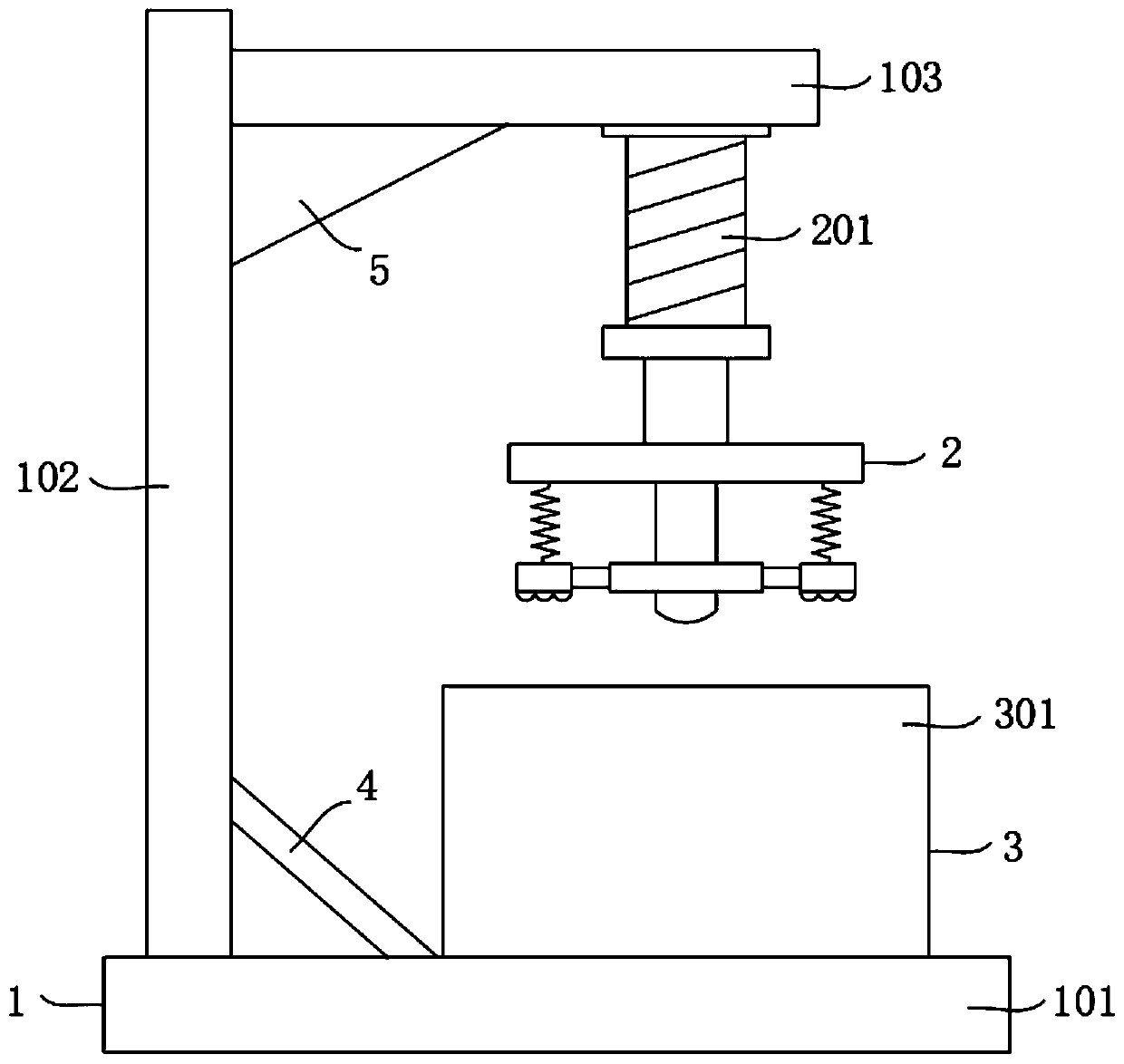

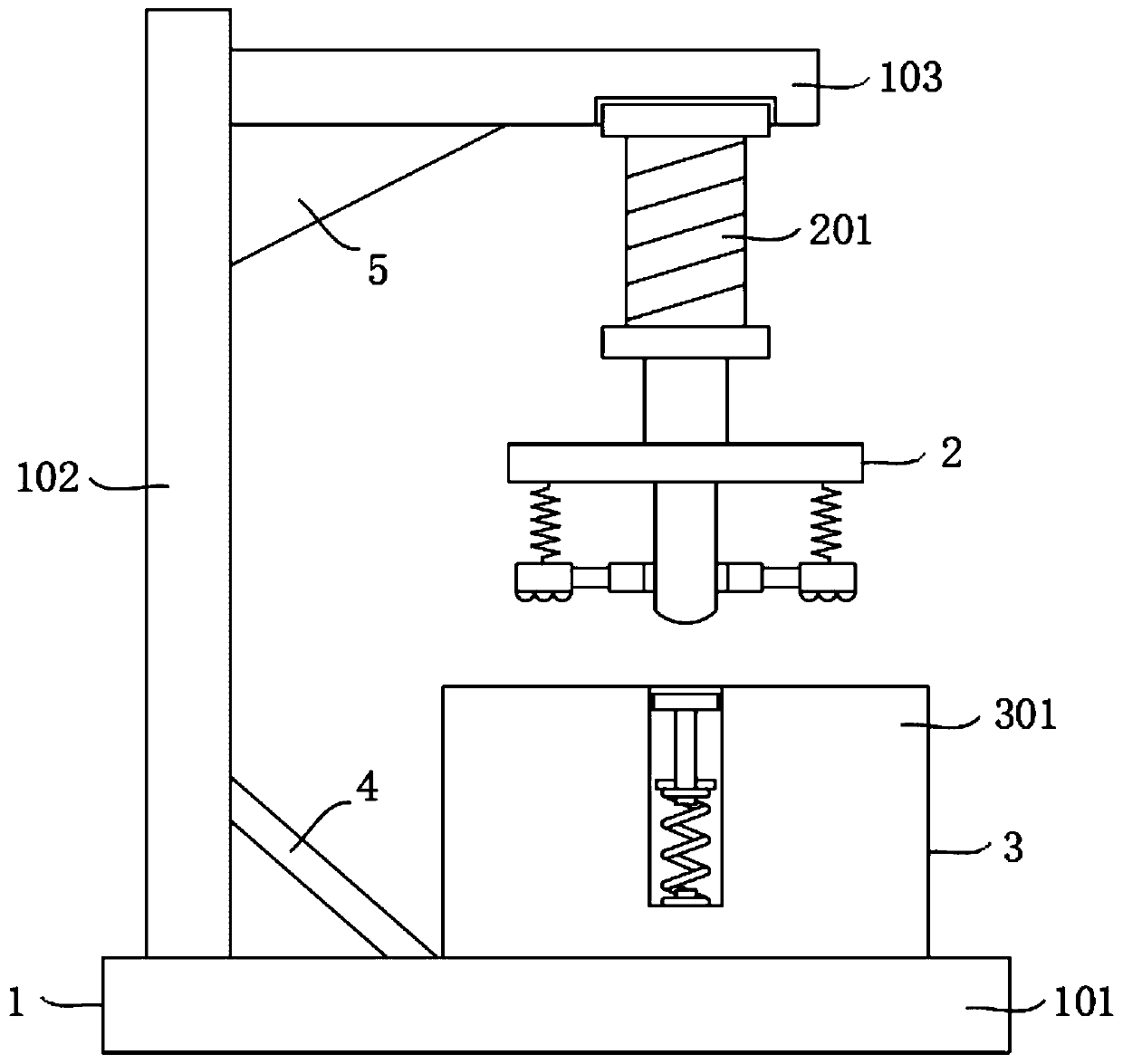

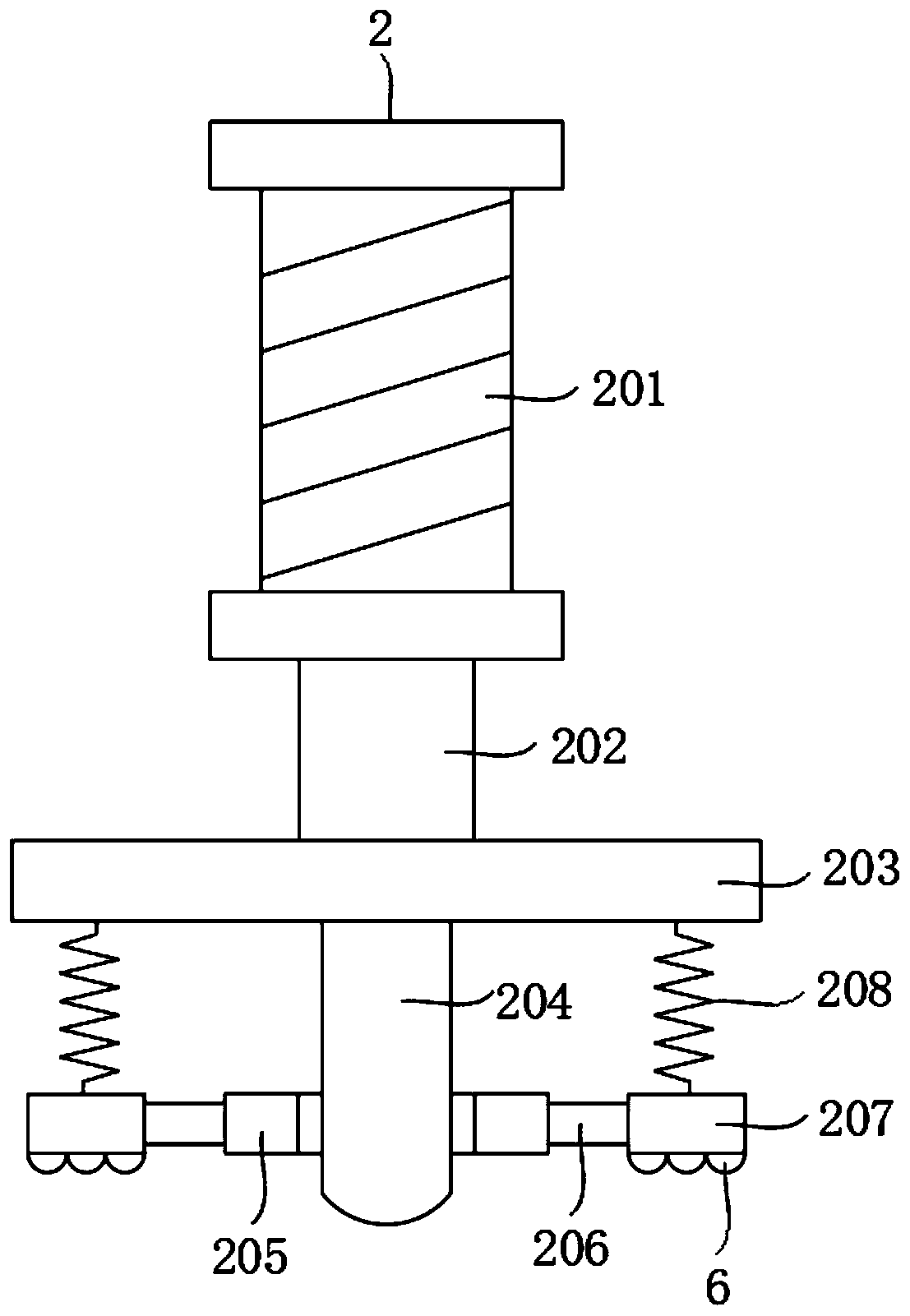

Repairing device applied to multi-main-grid photovoltaic module

ActiveCN111755573AAvoid problems that reduce the efficiency of screw driveAvoid transmission efficiency problemsFinal product manufacturePhotovoltaic energy generationElectric machineScrew thread

The invention discloses a repairing device applied to a multi-main-grid photovoltaic module, which comprises a base, wherein a cross beam is supported and fixed on the surface of the top end of the base, a motor is fixed to the surface of one side of the cross beam, an output shaft of the motor is rotationally connected with a lead screw, one end of the lead screw penetrates through the cross beamand extends into an inner cavity of the cross beam, a threaded moving block is connected to a bearing of the lead screw in a sleeving mode, and an infrared welding lamp box is fixed to the front surface of the threaded moving block; and a lubricating sleeve and a cleaning sleeve are sequentially fixed to the surfaces of the two sides of the threaded moving block from left to right and rotationally connected to the outer wall of the lead screw in a sleeving mode. By arranging the lubricating sleeve, the surface of the lead screw can be conveniently and efficiently lubricated, and the working efficiency of the device is improved; through the arrangement of the cleaning sleeve, the surface of the lead screw can be conveniently and rapidly cleaned; and through the arrangement of the screw, the multi-main-grid photovoltaic module can be conveniently and efficiently clamped and fixed.

Owner:江苏悦阳光伏科技有限公司

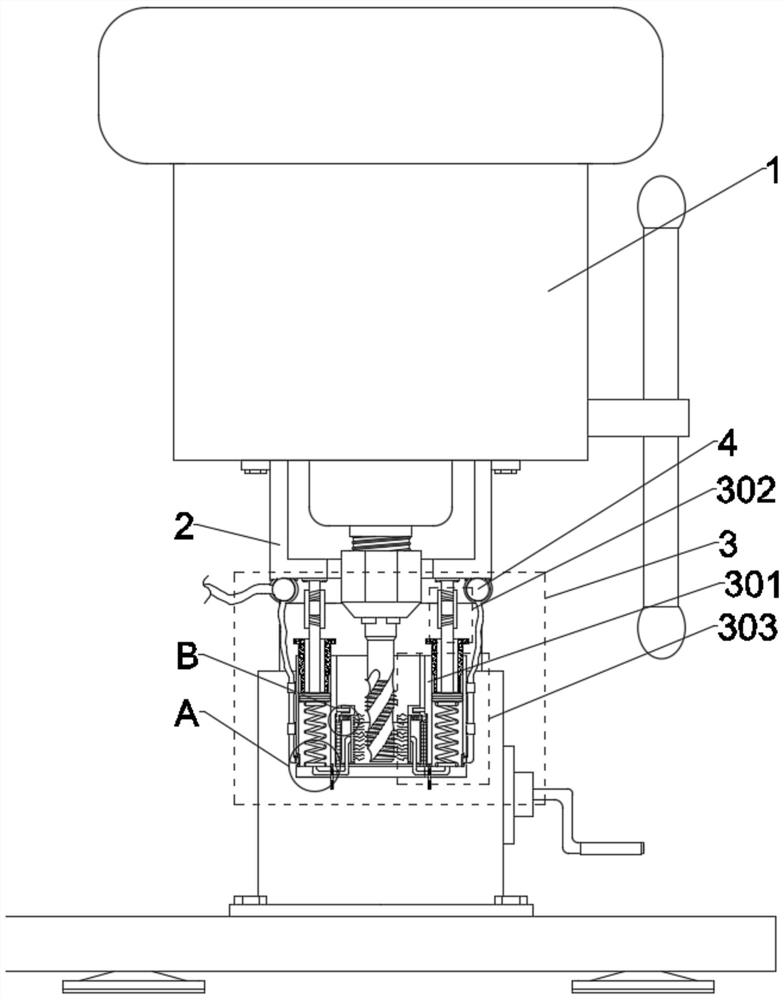

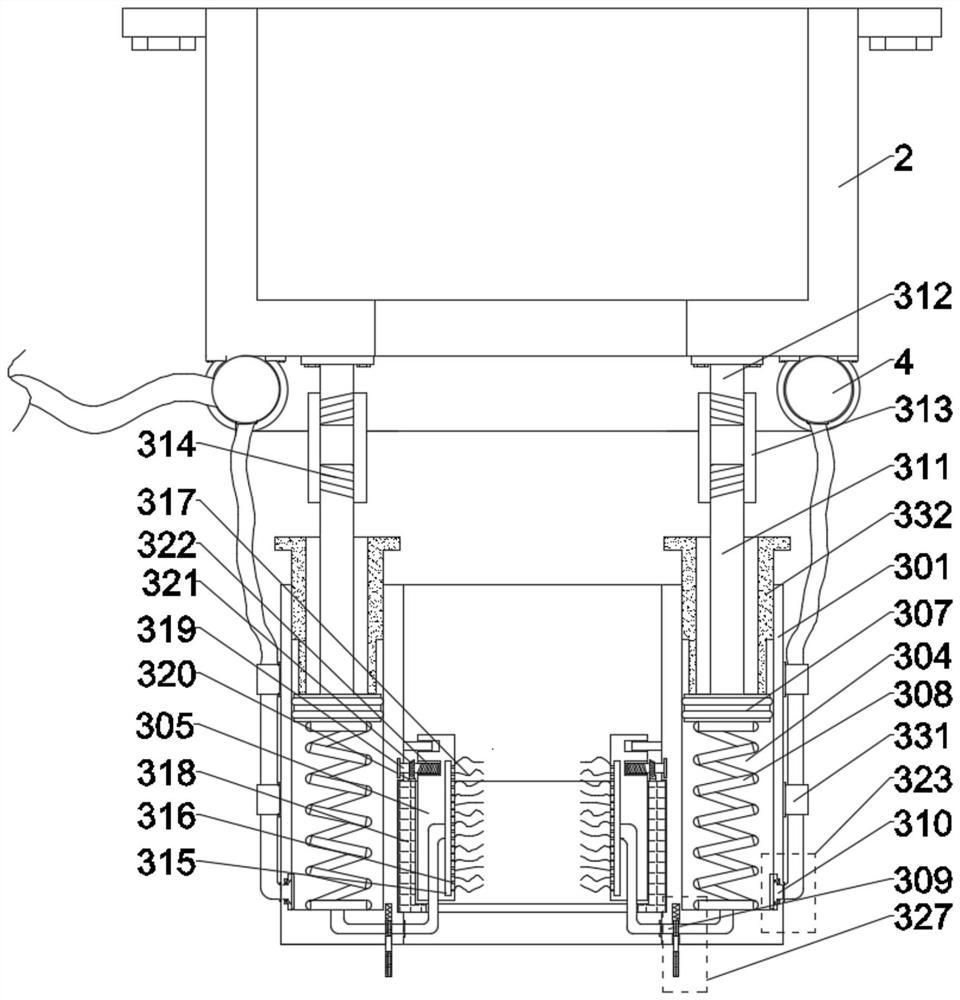

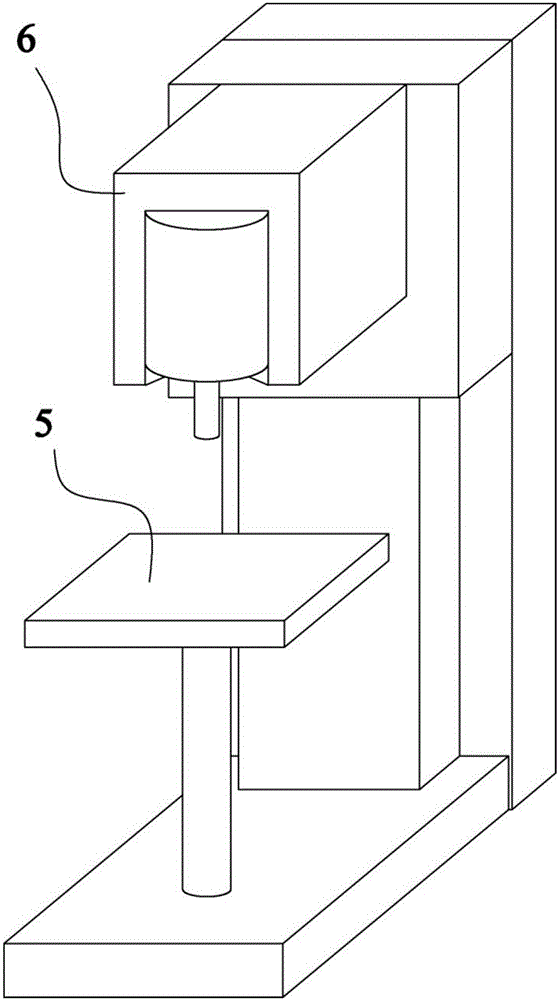

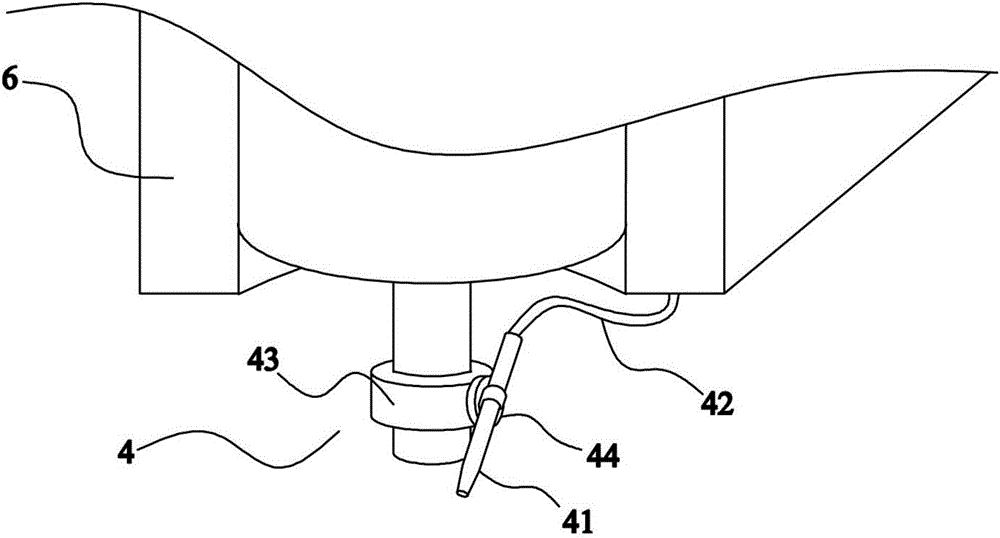

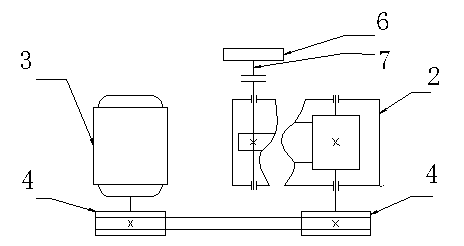

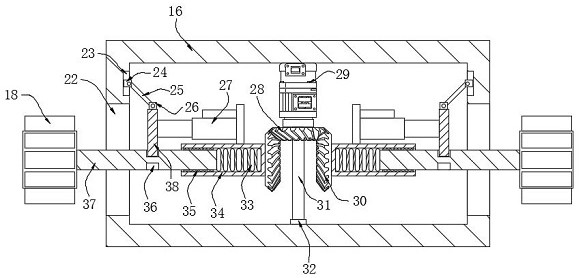

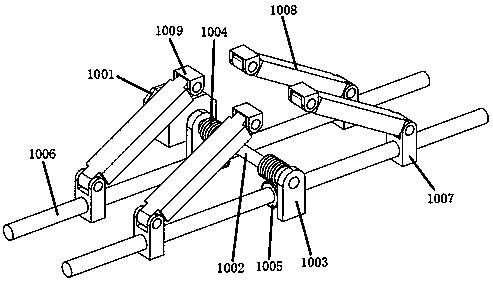

Automatic synchronizing device and lubricating method for lubricating and tapping big data connecting piece

ActiveCN111922453AApply evenlyAvoid uneven applicationThread cutting machinesMaintainance and safety accessoriesData connectionControl engineering

The embodiment of the invention discloses an automatic synchronizing device for lubricating and tapping of a big data connecting piece. The automatic synchronizing device comprises a drilling machine,a mounting frame is sleeved on a main shaft of the drilling machine, a lubricating assembly for lubricating a screw tap is fixedly mounted below the mounting frame, an annular oil pipe used for providing lubricating oil for the lubricating assembly is further arranged below the mounting frame, and the annular oil pipe is connected with an external oil tank through a hose; and the lubricating method comprises the steps that the lubricating device is mounted on the drilling machine, and connection between the lubricating device and the external oil tank is completed; then the position of an oilbrushing block is adjusted according to the diameter and the end position of the screw tap, tapping is started for tapping, the lubricating oil is extruded out of the oil storage tank, and oil brushing of the screw tap is completed through a brush on the oil brushing block. In use, when the tapping machine descends, a piston block can be pressed downwards to extrude the lubricating oil onto the oil brushing block; and therefore, when the screw tap rotates, uniform coating can be realized, and the problem of non-uniform coating can be avoided.

Owner:韶关市志通达信息科技有限公司

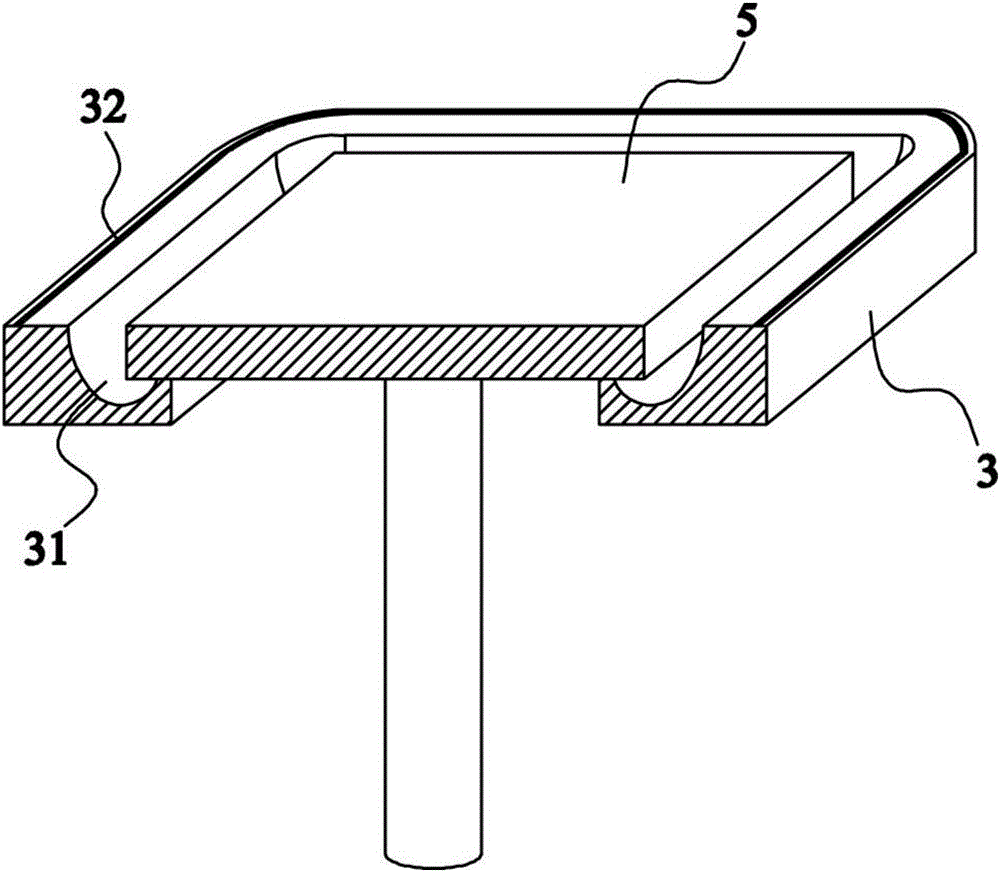

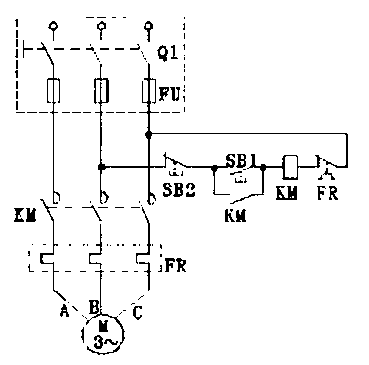

Drilling machine with metal filling cleaning device

InactiveCN106624980AAvoid inconvenient cleaningAvoid abrasion damageMaintainance and safety accessoriesMetalDrilling machines

The invention discloses a drilling machine with a metal filling cleaning device. The drilling machine comprises a drill part and a working table part; the working table part is provided with a working table top; and the metal filling cleaning device used for adsorbing metal fillings is arranged on the periphery of the working table top. The metal filling cleaning device used for adsorbing the metal fillings is arranged on the drilling machine, so that in the process that operating personnel conduct drilling on metal boards, the situation that the metal fillings extruded during drilling scatter on the ground and cleaning is not convenient can be avoided, and by means of the timely collecting capacity of the metal filling cleaning device, abrasion and damage to the upper and lower surfaces of the metal boards caused by the metal fillings during the drilling process can be avoided.

Owner:深圳市诚瑞丰科技股份有限公司

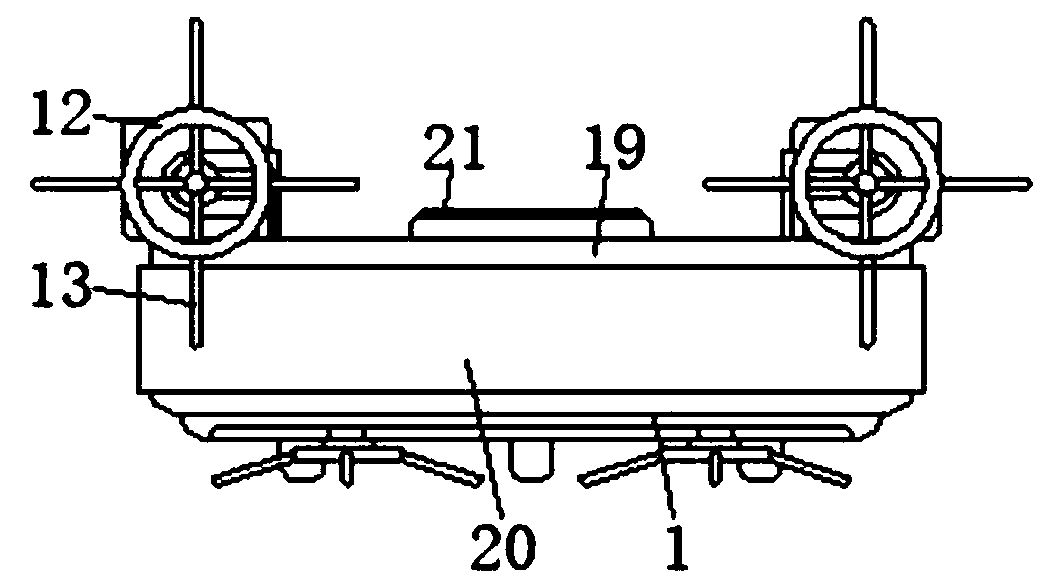

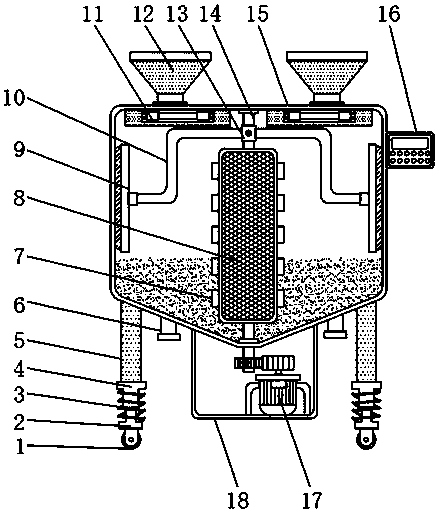

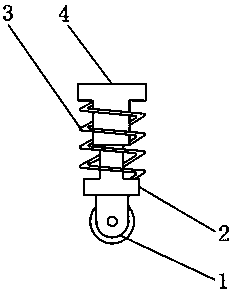

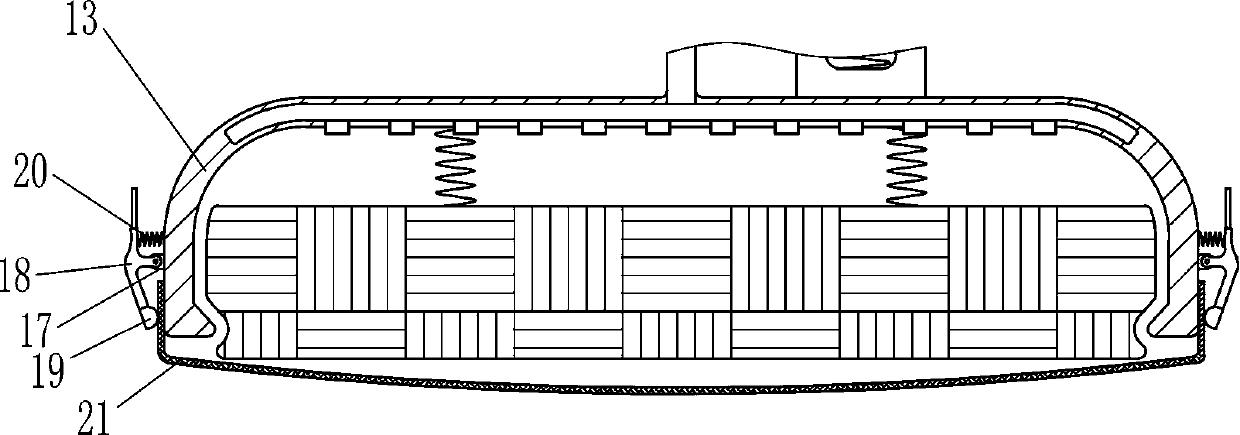

Cleaning mechanism of intelligent floor-sweeping robot

InactiveCN109497892AImprove practicalityEasy to cleanCarpet cleanersFloor cleanersBristleMotor drive

The invention discloses a cleaning mechanism of an intelligent floor-sweeping robot. The cleaning mechanism comprises a floor-sweeping robot body, wherein the top of the floor-sweeping robot body is fixedly connected with a base plate, the top of the base plate is movably provided with a top plate, a damping mechanism is arranged between the top plate and the base plate, two sides of the top plateare both fixedly connected with connecting boxes, and the bottoms of the inner walls of the connecting boxes are fixedly connected with double-shaft motors. The double-shaft motors drive a connectingrod to rotate, the connecting rod drives a supporting rod to rotate through a square sleeve and a square metal plate, the supporting rod drives a bristle brush to brush and clean a wall face and corners through a brush sleeve, accordingly the cleaning mechanism has the advantages of being capable of cleaning the bottom and corners of the wall face and good in cleaning effect, the problem is solved that the intelligent floor-sweeping robot can only clean the surface of a floor, cannot clean the bottom and corners of the wall face and is good in cleaning effect, the practicability of the intelligent floor-sweeping robot is improved, and convenience is provided for a user to use.

Owner:宁波金汤科技服务有限公司

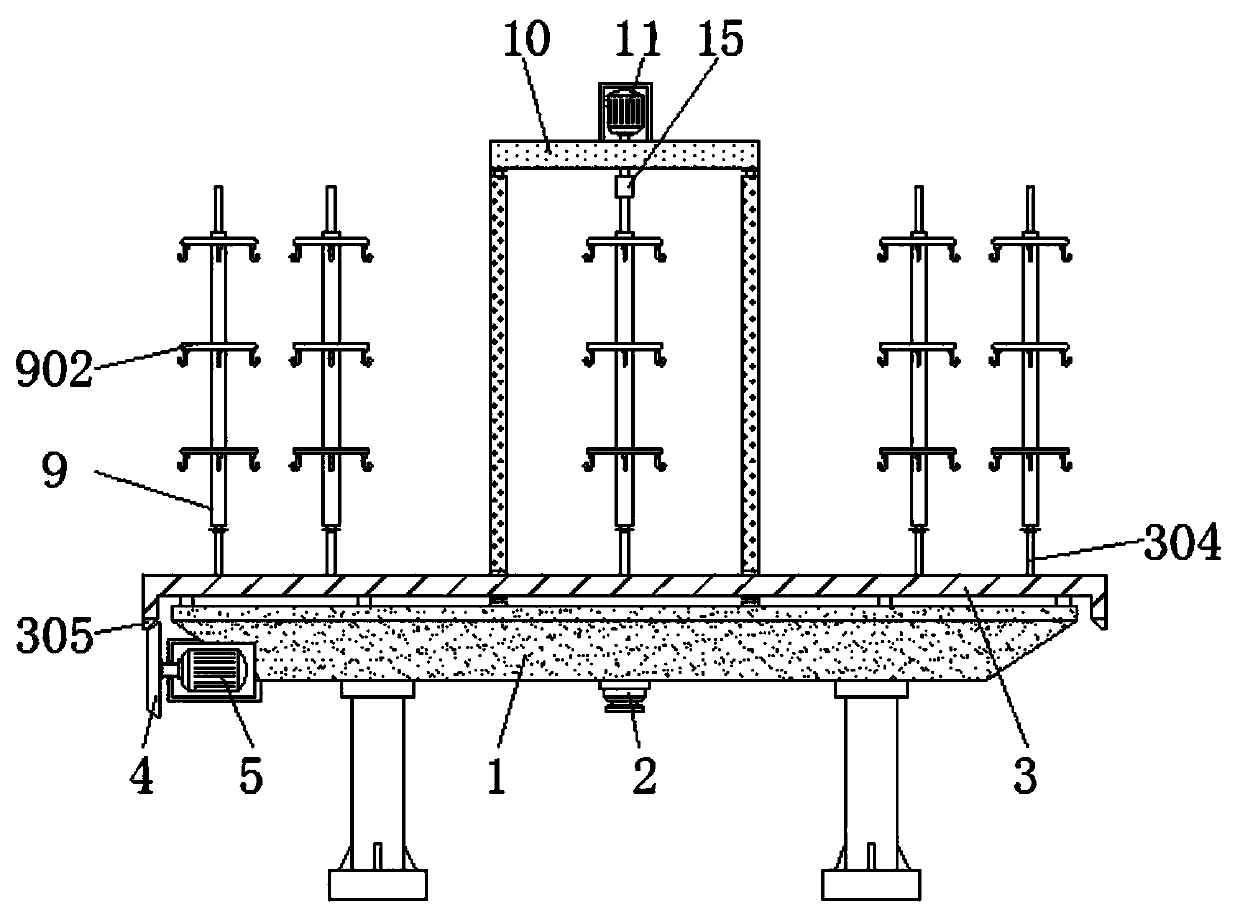

Baking device for pressed spicy salted duck processing convenient for centralized loading and unloading

ActiveCN109832307AConvenient centralized loading and unloadingEasy accessCharging/discharging ovensSpecial goods bakingDrive wheelGear wheel

The present invention discloses a baking device for pressed spicy salted duck processing convenient for centralized loading and unloading. The baking device comprises a supporting bracket, a first motor, a second motor and baking lamps, a material discharge opening is formed in a lower side of the supporting bracket, besides, a drive plate is arranged at an upper side of the supporting bracket, abevel gear is arranged a left side of the supporting bracket, connecting grooves are formed in the supporting bracket, besides, insides of the connecting grooves are provided with connecting rings, vertical shafts are arranged under driving wheels, besides, the vertical shafts are located inside a baking oven, besides, lower sides of the vertical shafts are connected with clamping pieces, the baking lamps are located inside the baking oven, and besides, the baking oven is provided with oven doors. The baking device for the pressed spicy salted duck processing convenient for the centralized loading and unloading can hang pressed spicy salted ducks needing to be baked in batches on baking brackets, thus is convenient for the drive plate to drive the pressed spicy salted ducks on the baking brackets successively into the baking oven to be baked, reduces labor intensity of workers and at the same time can also prevent the workers from being harmed by high temperatures in the baking oven during the work process.

Owner:HUNAN UNIV OF ARTS & SCI

Working method of cutting board kitchen knife combination device for kitchen

ActiveCN108392111AAvoid inconvenient cleaningTo collect sapKitchen equipmentMetal working apparatusWater flowAgricultural engineering

The invention discloses a working method of a cutting board kitchen knife combination device for a kitchen. The device comprises a water collecting tank and a limit device, a sucker is arranged on thelower portion of the water collecting tank , a connecting block mounted on one side of a cutting board sleeve is connected with a connecting sheet through an extension shaft, a bolt sleeve is mountedon the extension shaft, draining holes are formed in the front surface of the cutting board sleeve, connecting plates are symmetrically arranged on the inner left side and the inner right side of thewater collecting tank , through holes are reserved in the left side and the right side of the cutting board sleeve, the limit device is connected with a connecting shaft, the left end and the right end of the connecting shaft are mounted on the connecting block through extension shafts, and a bottom groove is formed in the bottom of the water collecting tank . According to the cutting board kitchen knife combination device for the kitchen, fruit and vegetable juice can be collected by the aid of the water collecting tank , inconvenience in cleaning caused by flowing of water towards a placement plane is avoided, the cutting board sleeve can be connected with the connecting sheet through the connecting shaft, so that a kitchen knife can be connected onto the cutting board sleeve, and a kitchen knife blade can be stored when not in use.

Owner:合肥源康信息科技有限公司

Intelligent kitchen equipment-kitchen garbage treatment equipment

The invention discloses intelligent kitchen equipment-kitchen garbage treatment equipment, relates to the technical field of garbage cans, and solves the problems that existing kitchen garbage treatment equipment is poor in garbage can sealing performance, easy to cause the escape of peculiar smell and poor in odor-proof effect and cannot meet the modern intelligent kitchen application standard. The equipment comprises a can body and a scissors mechanism, wherein the can body is integrally arranged in a rectangular shape, the can cover is integrally arranged in a rectangular shape, the can body is inserted into the opening of the top end of the can cover, a square water groove is welded to the top end portion of the can body in a welded mode, insertion baffle plates are inserted in the upper half parts of the side walls of the periphery of the water groove in a penetrating mode, and sliding sleeves of two pushing mechanisms are hoisted on the bottom plates on the left side and the right side of the water groove. According to the equipment, the surrounding insertion baffle plates and a peripheral frame are combined for use, so that the water groove can be covered and enclosed, and sealing water inside the water groove is prevented from flushing out when the can cover is inserted and reset on the opening of the can body.

Owner:宋洪涛

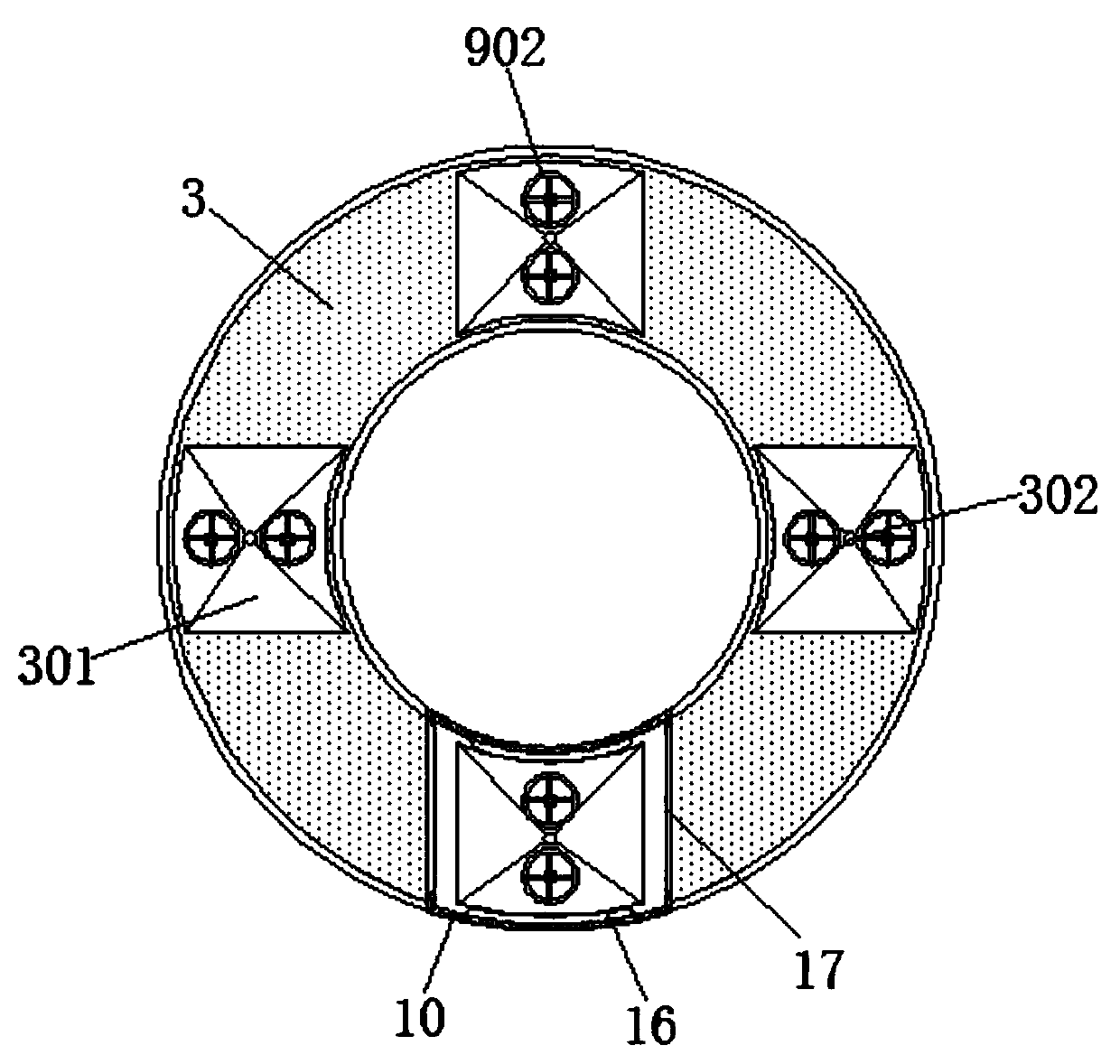

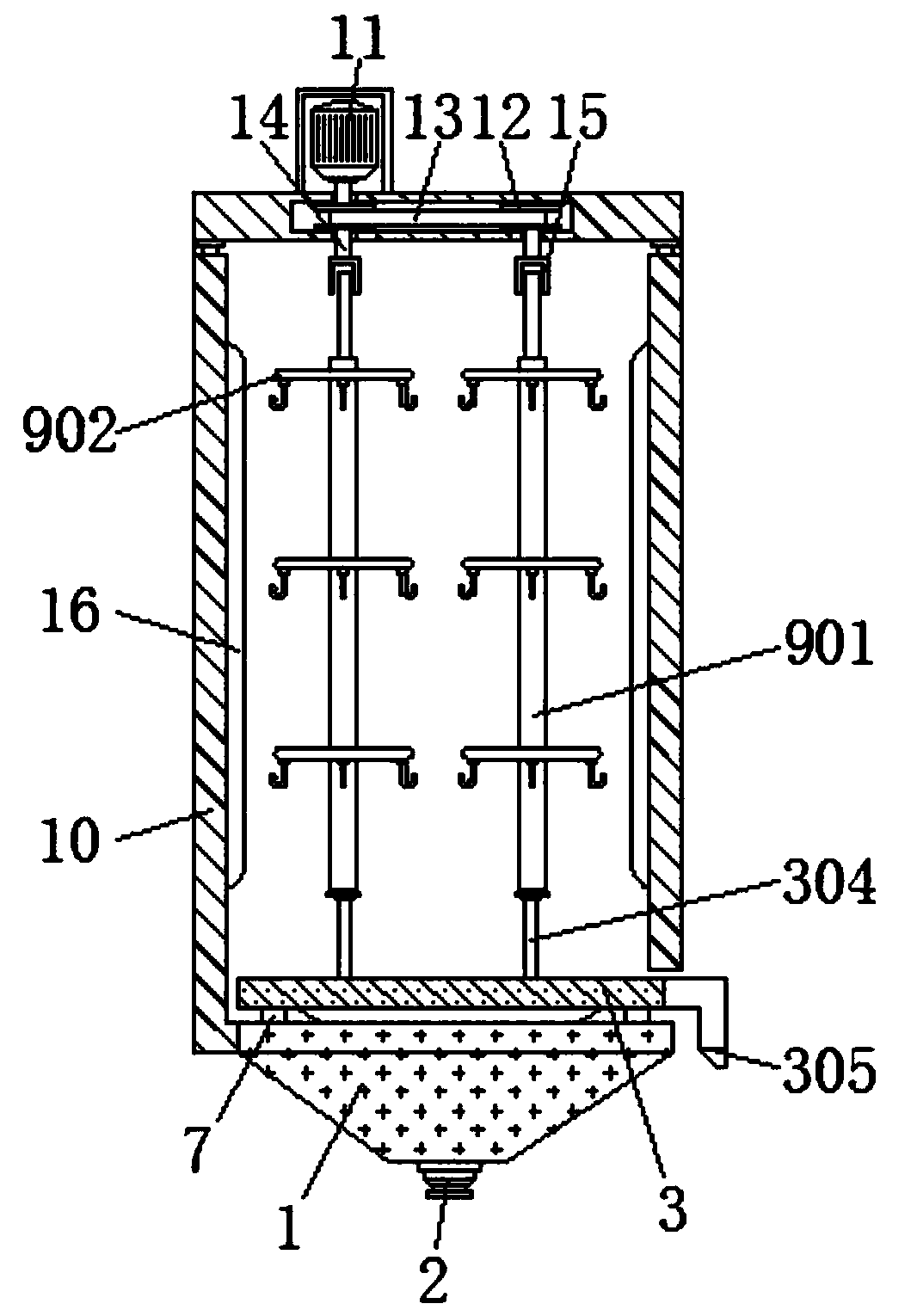

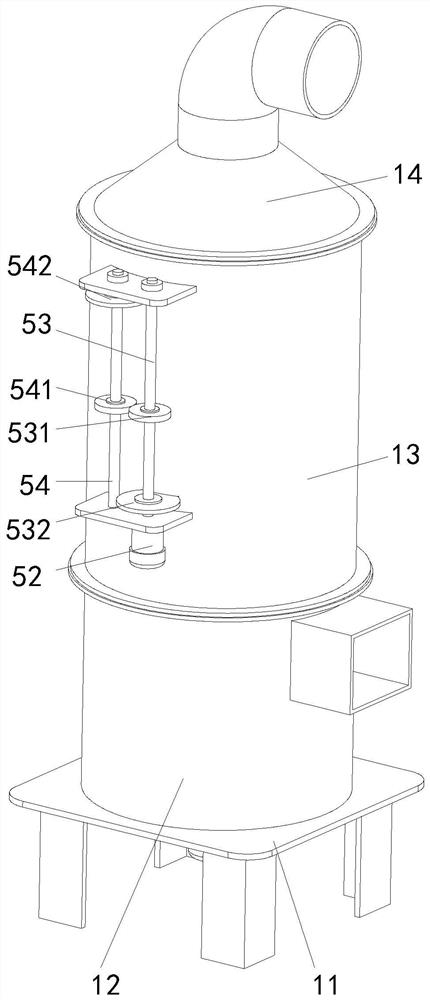

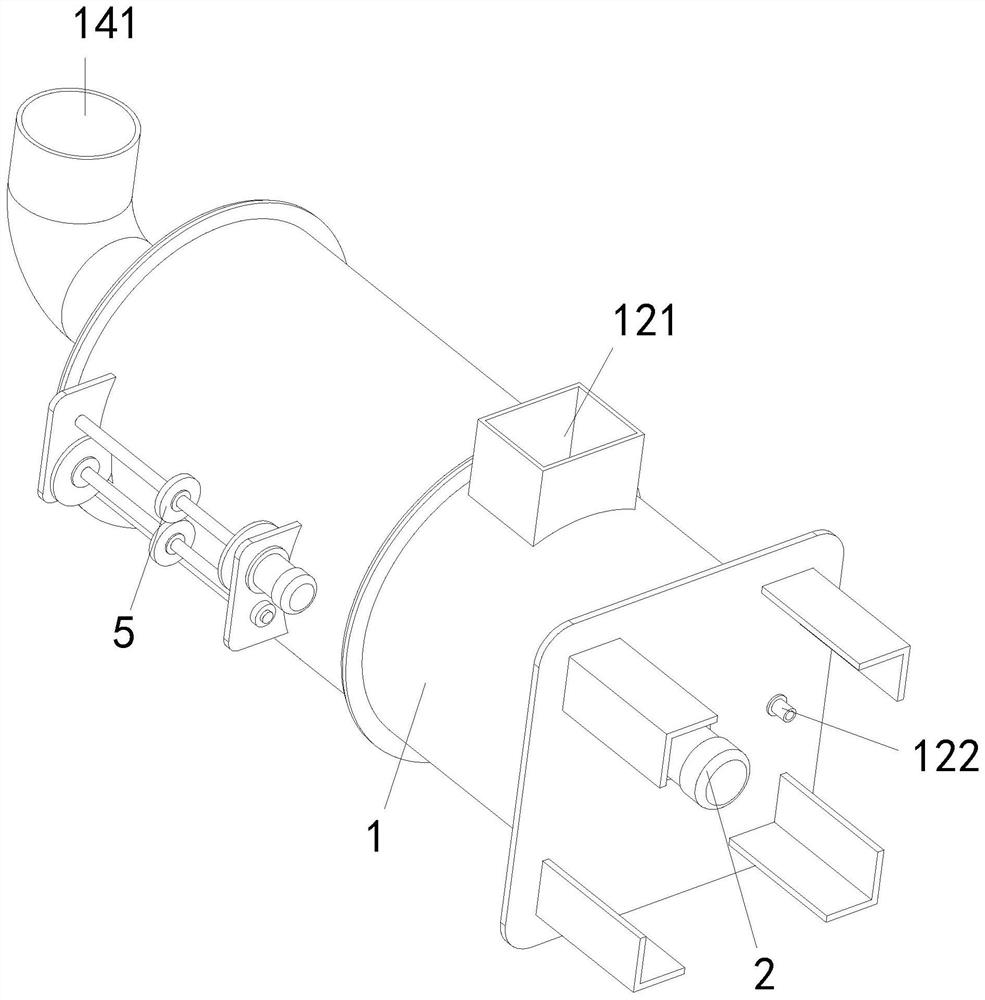

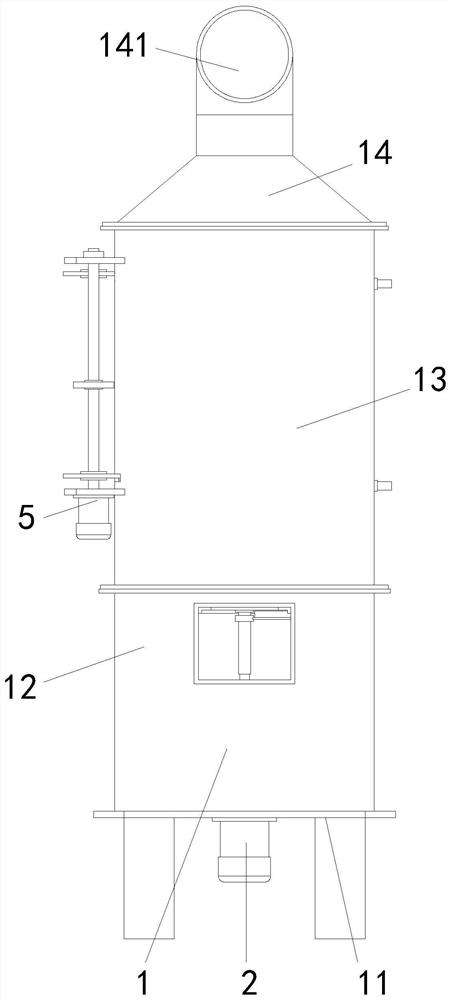

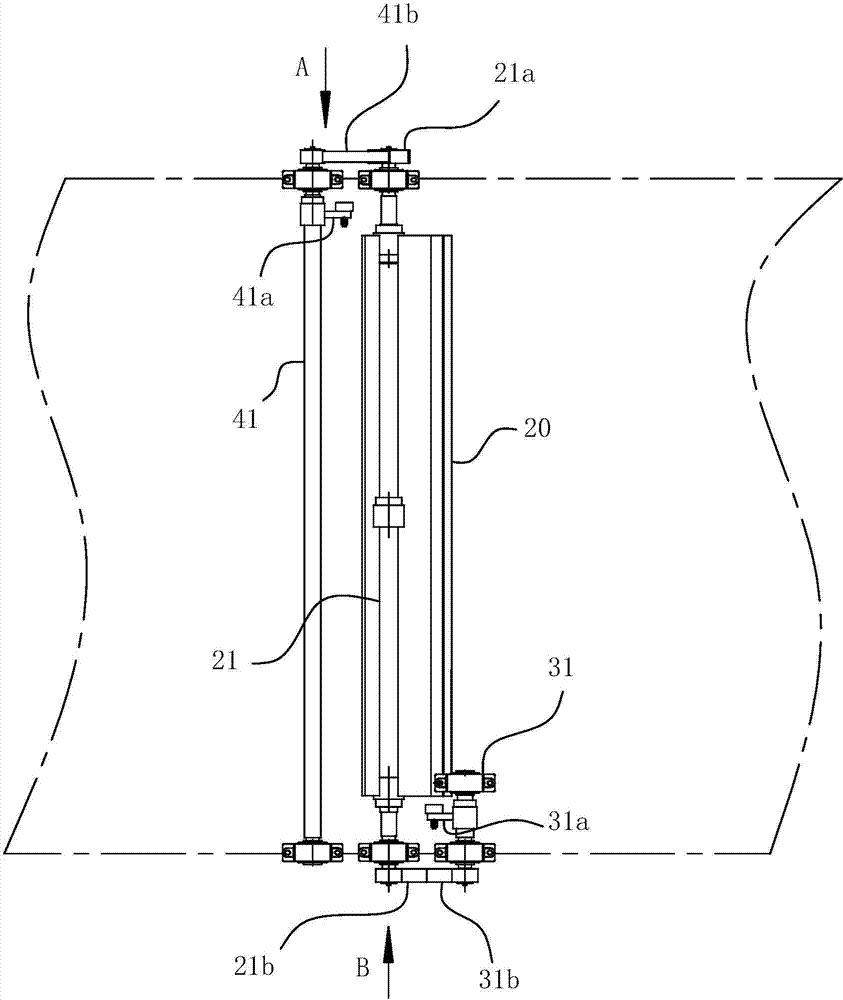

Circulating spray absorption tower for flue gas purification treatment

InactiveCN111821817AEvenly distributedAvoid formingGas treatmentDispersed particle separationFlue gasEngineering

The invention relates to a circulating spray absorption tower for flue gas purification treatment. The absorption tower comprises a cylindrical liquid storage tower body and a cylindrical spray towerbody connected with the top end of the liquid storage tower body; a cleaning and scraping mechanism is arranged on the liquid storage tower body; two spraying pipeline assemblies capable of horizontally rotating are vertically arranged in the spray tower body; and a rotation driving mechanism used for driving the two spraying pipeline assemblies to rotate is arranged on the outer side wall of thespray tower body. According to the absorption tower provided by the invention, a spraying medium liquid can be uniformly and widely distributed in the spraying space, so that flue gas flowing upwardscan be in contact exchange with the spraying medium liquid at equal probability, and the spraying absorption effect can be improved and guaranteed; in addition, solid precipitates can be continuouslyscraped off, and formation and accumulation of a precipitation layer are avoided.

Owner:杭州亿航环保科技有限公司

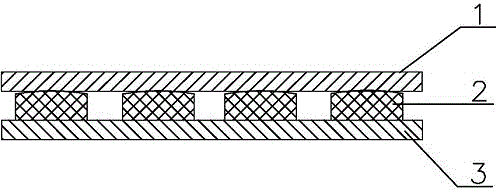

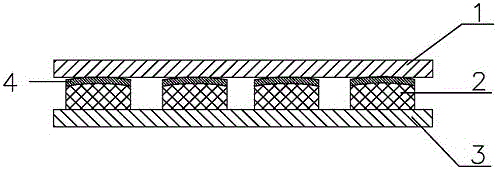

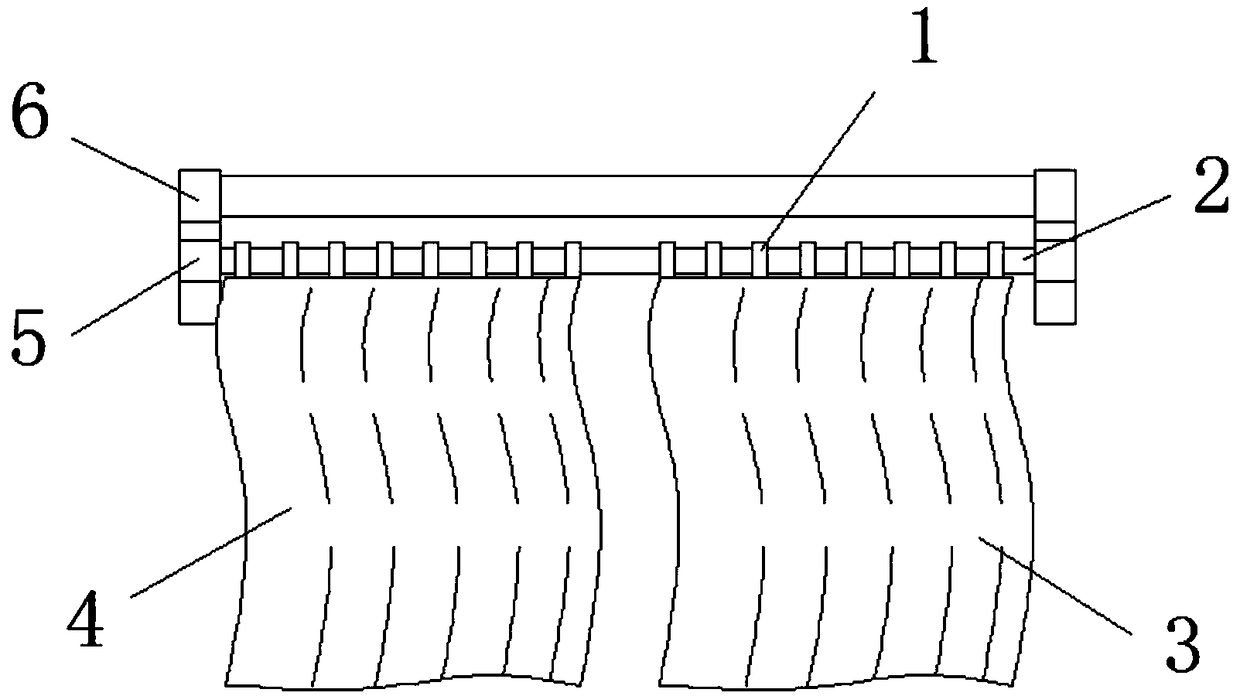

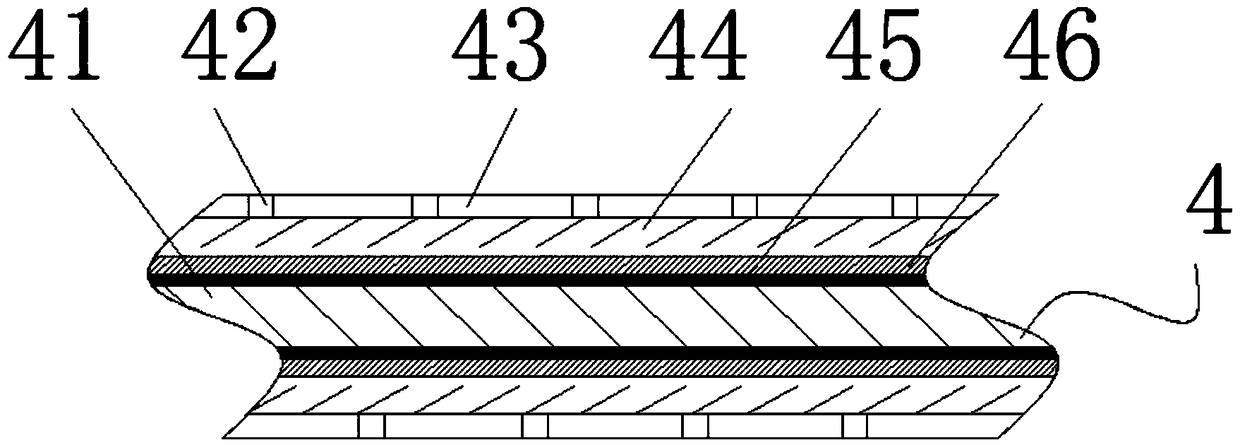

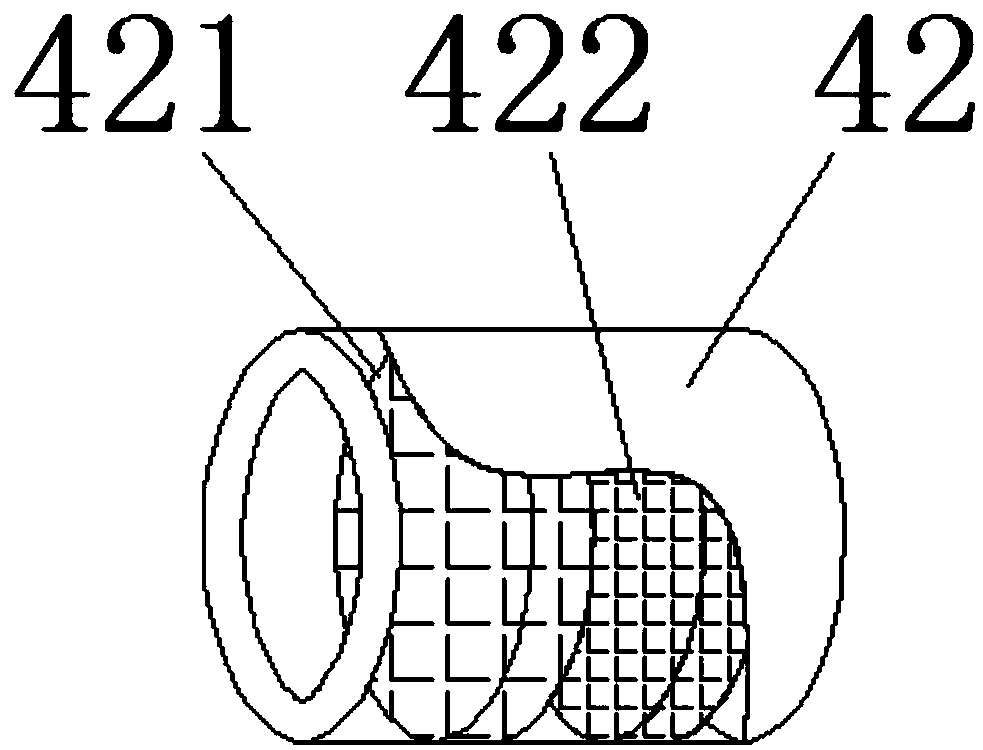

Improved substrate-free tape

InactiveCN106833405APrevent overflowAvoid cleaning inconvenienceFilm/foil adhesivesHydrogenEngineering

The invention discloses an improved substrate-free tape. The improved substrate-free tape sequentially comprises a first release layer, a pressure-sensitive adhesive layer and a second release layer, wherein the release force of the first release layer is less than that of the second release layer; both the first release layer and the second release layer are of a ribbon structure; the pressure-sensitive adhesive layer is a plurality of rectangular blocks uniformly distributed along the first release paper layer of the ribbon structure; the distance between every two adjacent rectangular blocks is 0.5-10mm; and the distance from the edge of the pressure-sensitive adhesive layer to the edge of the first release paper layer is 0.5-3mm.The improved substrate-free tape has the advantages of high viscosity, convenient use, no sticking after component bonding, easy tear-off and the like. According to the invention, a mixture of sodium hydrogen carbonate particles and carbon powder is added, so that the heat dissipation manner inside the pressure-sensitive adhesive layer can be effectively improved, the heat dissipation effect can obviously enhanced, thereby providing a novel improved substrate-free tape with a favorable heat dissipation function.

Owner:WUHU HONGSHENG TECH

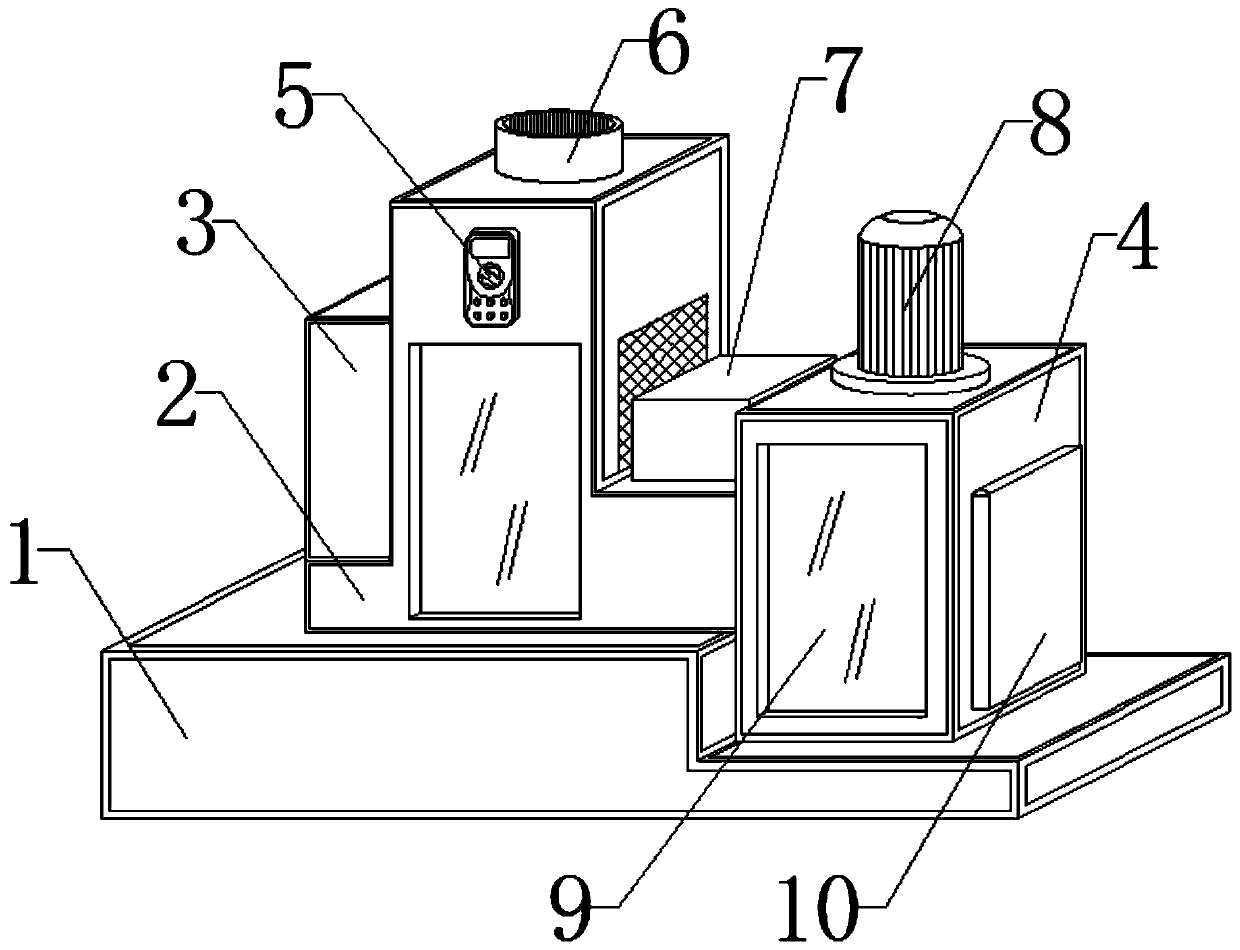

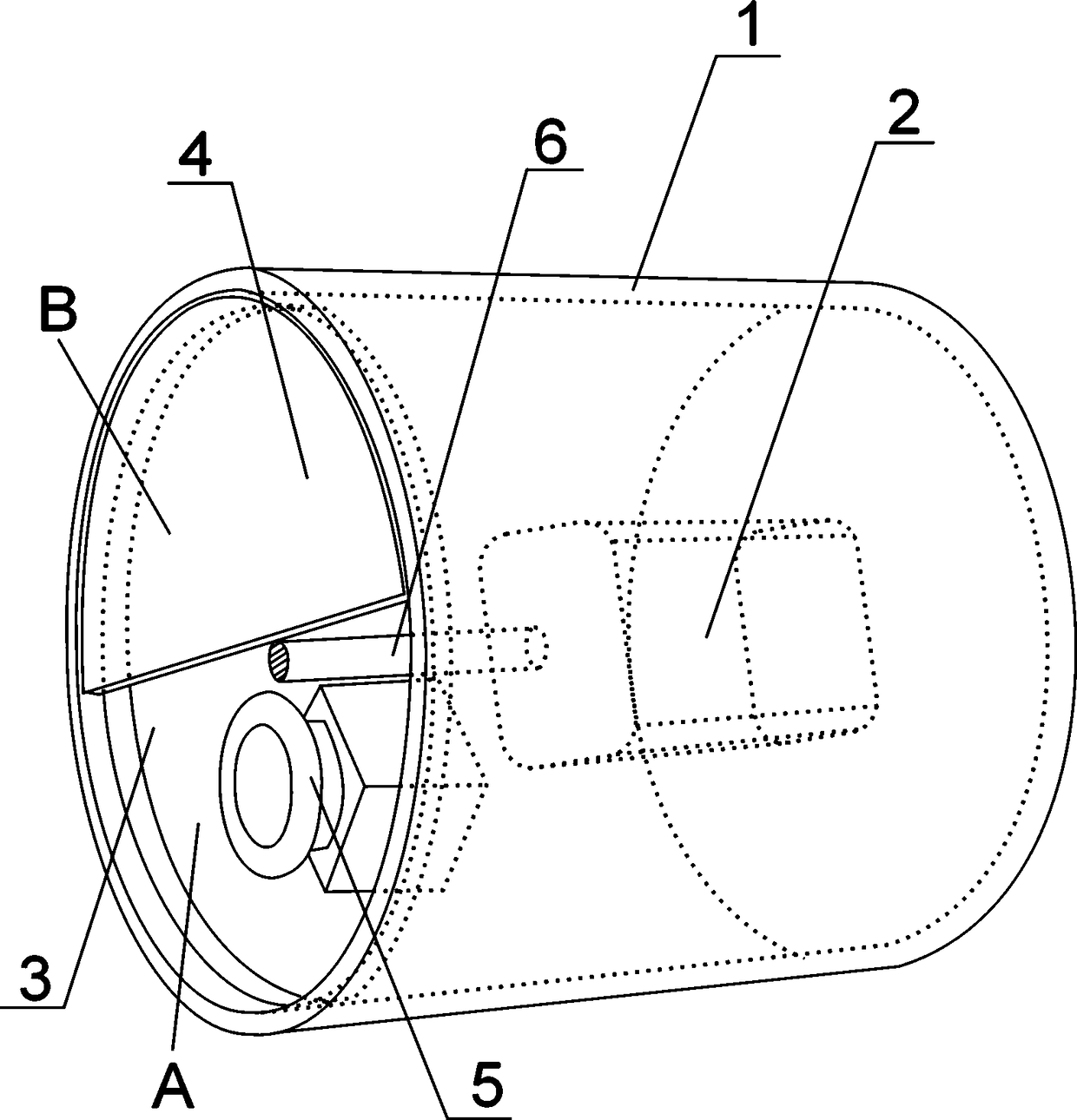

Ultrasonic cleaning machine used for edible vegetable oil production

InactiveCN107671066AHigh purityHarm reductionNon-rotating vibration suppressionHollow article cleaningMegasonic cleaningUv disinfection

The invention discloses an ultrasonic cleaning machine for edible vegetable oil production, which comprises a main body of the ultrasonic cleaning machine and a bracket. An ultraviolet disinfection lamp is arranged at a position close to the rotating shaft at the top of the main body of the ultrasonic cleaning machine, and the inside of the main body of the ultrasonic cleaning machine is A sleeve is sleeved close to the outside of the rotating shaft, a roller is sleeved outside the rotating shaft close to the lower part of the sleeve, a telescopic rod is embedded in the bottom end of the support rod, and a spring is sleeved outside the support rod, A magnetite is arranged on one side of the drum. The present invention can facilitate users to absorb and remove metal impurities by arranging rollers and magnets, thereby improving the purity of vegetable oil, and arranging telescopic rods and springs can make the pulleys have a shock-absorbing effect during the moving process and improve the efficiency of ultrasonic cleaning. The safety performance of the machine body during the movement process, the ultraviolet disinfection lamp is set, can sterilize the materials to be cleaned, and improve the pass rate of the materials.

Owner:江苏金阳光粮油工业有限公司

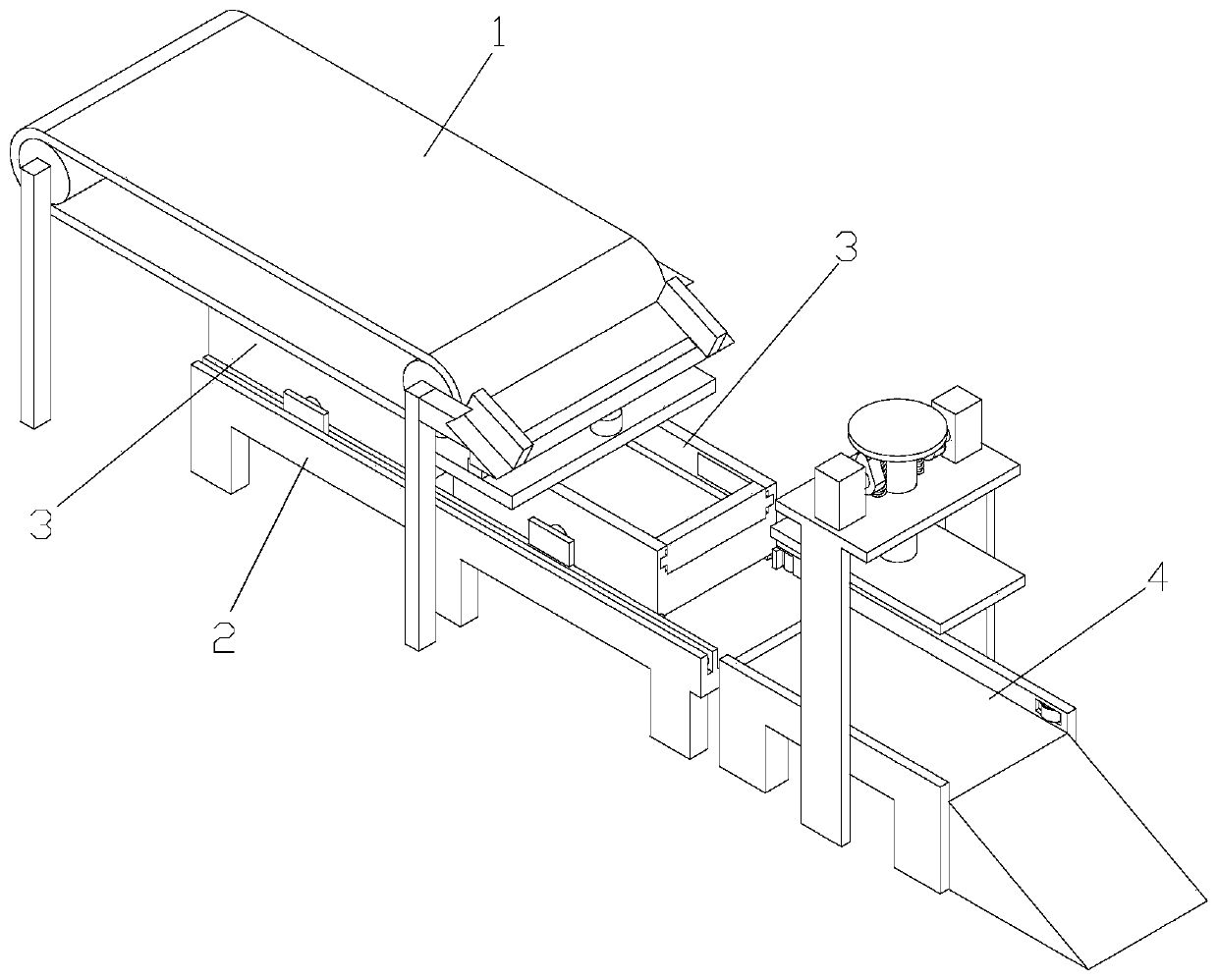

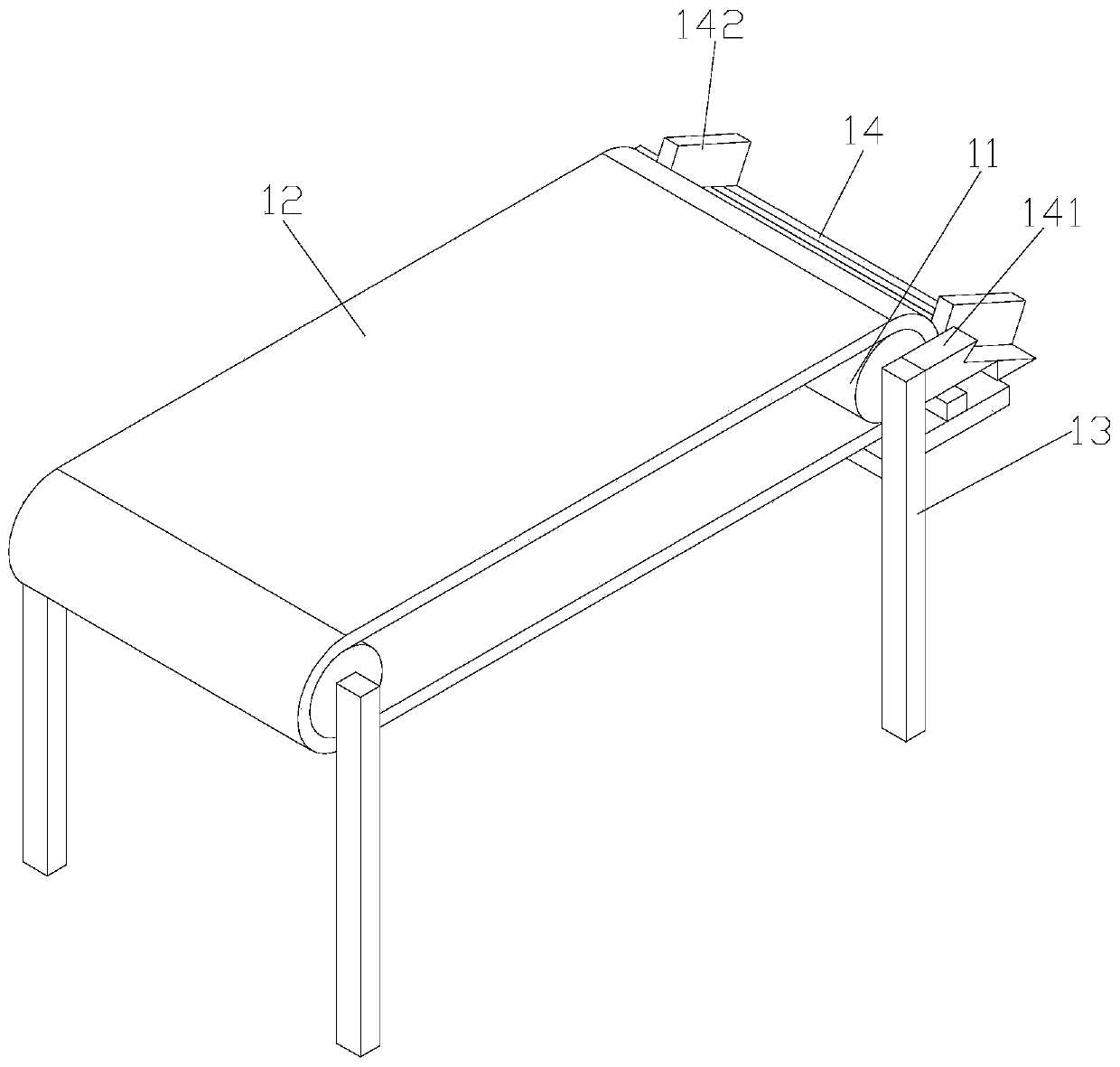

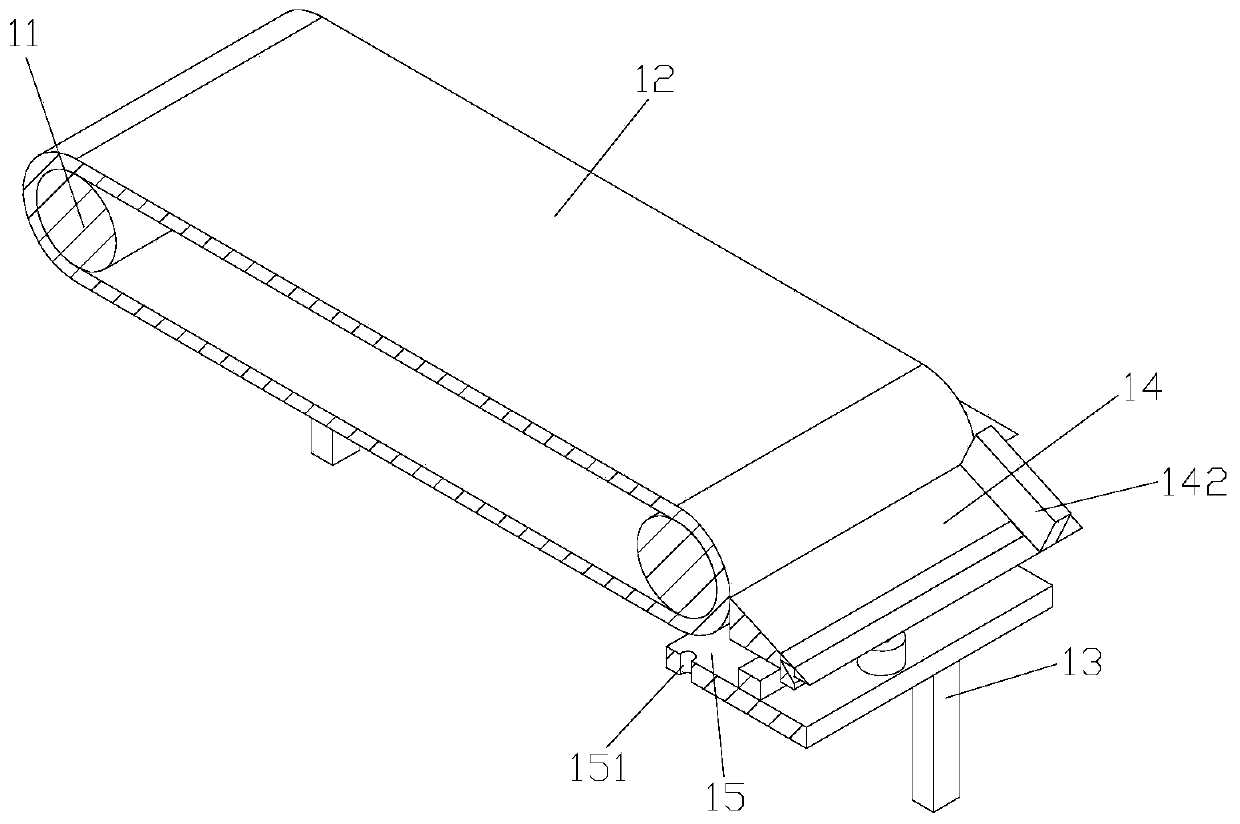

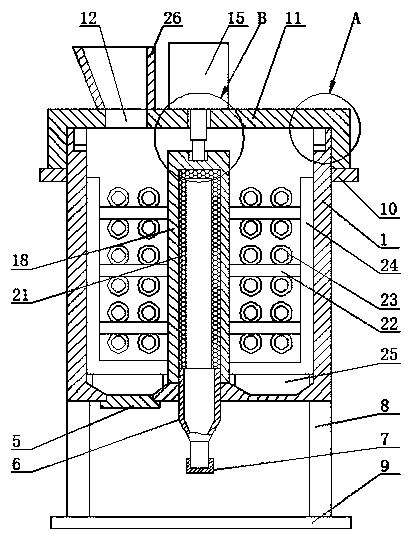

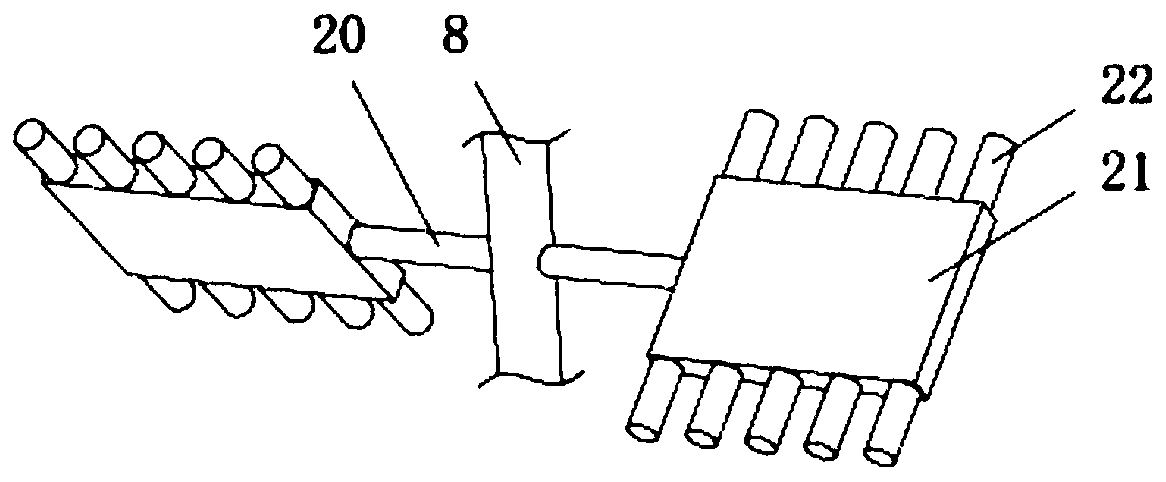

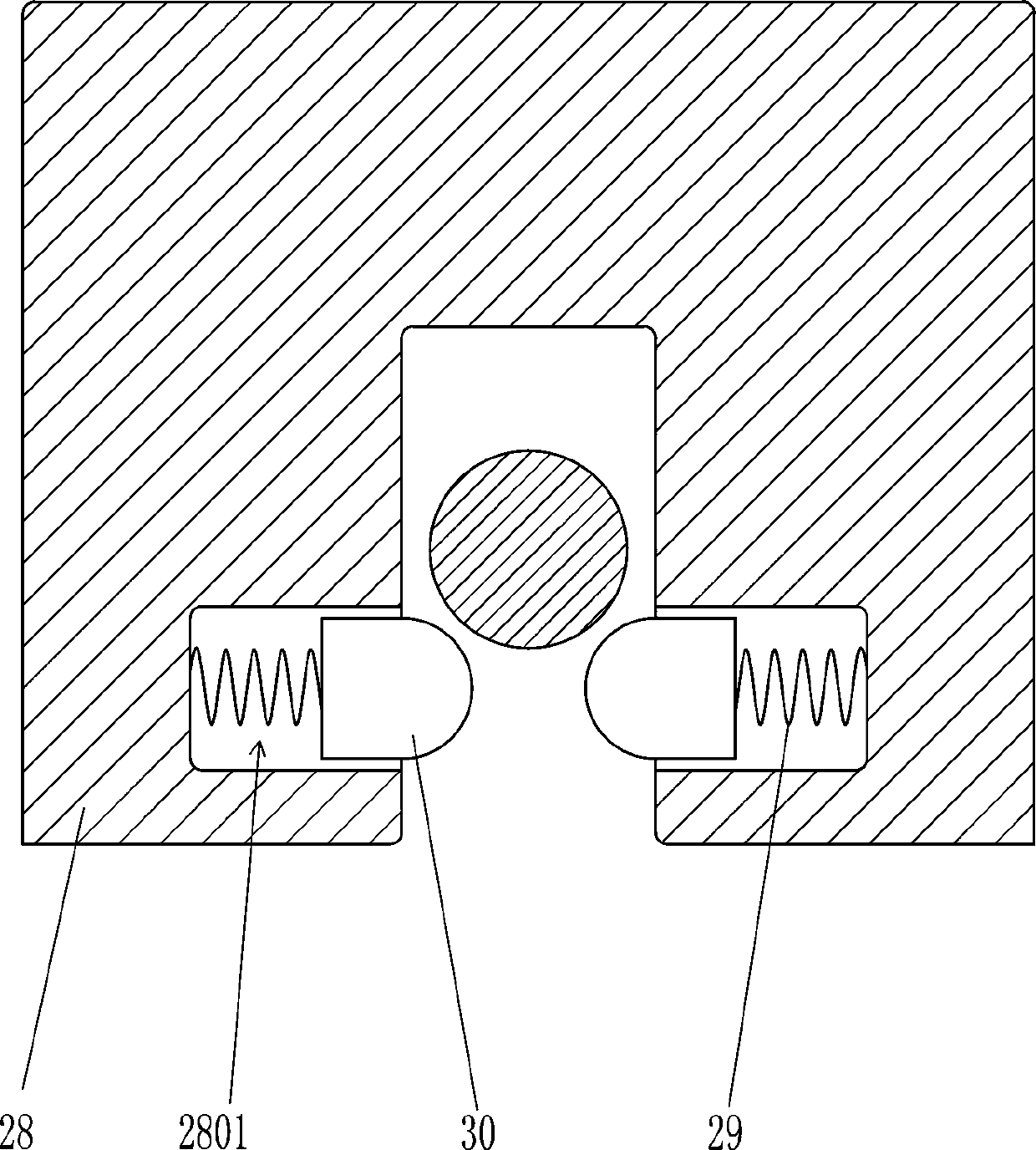

Scrap iron compaction system capable of working continuously

ActiveCN110789169APrevent fallingAvoid cleaning inconveniencePressesMining engineeringTransmission belt

The invention discloses a scrap iron compaction system capable of working continuously. The scrap iron compaction system comprises a material conveying device, material receiving devices, a transporter and a compaction device. The material conveying device comprises first transmission rollers, a first conveying belt arranged on the first transmission rollers in a sleeving manner and first supporting feet arranged on the two sides of the first transmission rollers. The transporter is arranged below the first conveying belt. The material receiving devices are arranged on the transporter. Fifth connecting rods are arranged on the first supporting feet. A scraping plate is arranged on the fifth connecting rods and is provided with a through cavity, and a ninth baffle capable of doing lifting motion is arranged in the through cavity in a penetrating manner. When the material receiving devices move to the position of the compaction device and the material receiving devices are not replaced,the ninth baffle rises in the through cavity, a stop function is achieved on scrap iron on the scraping plate under the action of the ninth baffle, the scrap iron is prevented from continuously falling down, part of scrap iron stays on the scraping plate temporarily, and the situation that the scrap iron directly falls off to cause clearing inconvenience is avoided.

Owner:浙江阳力钢结构股份有限公司

Kneading seasoning stirrer capable of filtering and collecting grease of meat products

InactiveCN110141987AEasy to disassembleEasy maintenance workTransportation and packagingRotary stirring mixersEngineeringRaw material

The invention discloses a kneading seasoning stirrer capable of filtering and collecting grease of meat products. The kneading seasoning stirrer comprises a box body; limiting grooves are symmetrically formed in the upper end of the box body; an annular groove is formed in the lower end of the interior of the box body; a collecting cylinder is fixedly connected at the bottom of the box body in a sleeve mode; the lower end of the collecting cylinder is connected with an end cover through threads; a box cover is clamped at the upper end of the box body; and a motor is fixedly connected to the upper end of the box cover. The kneading seasoning stirrer is assembled by a mode that the box cover sleeves the box body, so that disassembly is convenient, and maintenance work is facilitated. In addition, a built-in filter cartridge and filter screen can filter grease in the raw materials, and the grease is collected through the collecting cylinder; the annular groove is formed in the bottom of the box body and is matched with a scraping strip and a scraping plate, so that material feeding is facilitated; and the scraping plate and the scraping strip can prevent the raw materials from being attached to the inner wall of the box body during working, so that inconvenient cleaning is avoided.

Owner:QINGYUAN CHUQU INTELLIGENT TECH CO LTD

Agricultural fertilizer dissolving device

InactiveCN111036119ASpeed up the flowFor quick outflowFlow mixersTransportation and packagingAgricultural engineeringDrive motor

The invention discloses an agricultural fertilizer dissolving device, which comprises a dissolving box and a dissolving assembly arranged in the dissolving box, wherein the dissolving assembly comprises a filter cylinder and a stirring plate, wherein a driving motor is fixed at the top of the dissolving box, the filter cylinder is fixedly mounted on the inner wall of the top of the dissolving box,a stirring shaft is fixedly mounted at the output end of the driving motor, the stirring plate is fixedly mounted on the stirring shaft through a connecting rod, a water pump is fixedly mounted on the dissolving box, the water inlet end of the water pump is communicated with the bottom of the dissolving box through a liquid outlet pipe, a first three-way valve is arranged on the liquid outlet pipe and is communicated with a water inlet hose, the water outlet end of the water pump is communicated with the filter cylinder through a liquid inlet pipe, and a stirring assembly and an inner wall cleaning assembly are further arranged in the dissolving box. The fertilizer dissolving device has the advantages that the fertilizer dissolving speed is high, the dissolving efficiency is high, the dissolved fertilizer liquid is uniform, and the problem that the small fertilizer particles are attached to the inner wall of the dissolving box and are inconvenient to clean is solved by arranging a brush.

Owner:蔡方

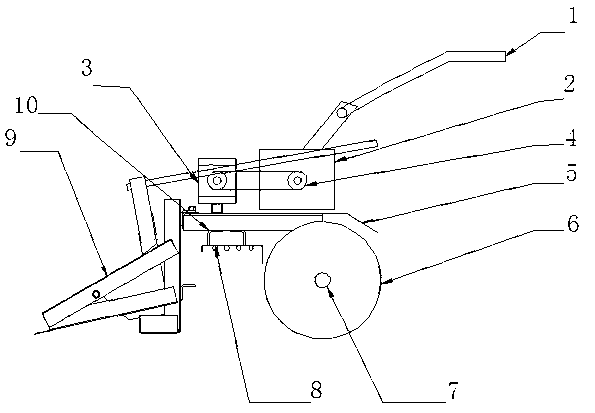

Self-propelled cleaning method and self-propelled cleaning device for manures in dairy farm

The invention discloses a self-propelled cleaning method and a self-propelled cleaning device for manures in a dairy farm. The self-propelled cleaning method is characterized in that a motor is used as a power source, and is connected with a transmission assembly by belt pulleys, the transmission assembly provides power for wheels connected onto a support, accordingly, the support advances, and the manures in the dairy farm are shoveled by a shovel loader arranged at the front end of the support, and are cleaned in a self-propelled manner. The self-propelled cleaning method and the self-propelled cleaning device have the advantages that an advancing mode and an operation mode of a mini-tiller suitable for a site of the dairy farm are adopted, a manure cleaning machine is small in size and flexible in operation, and inconvenience in cleaning due to activity of cattle can be effectively prevented; the motor is used as the power source, so that working noise of the manure cleaning machine is reduced, and is prevented from injuring and scaring the cattle during operation; the motor is connected with the transmission assembly by the belt pulleys, and accordingly the problem of oil leakage when an existing motor is connected with an existing transmission assembly by splines is solved; various shortcomings such as large sizes, heavy weight and loud noise of an existing manure cleaning machine are overcome, and the self-propelled cleaning device is simple in structure, reasonable in function and flexible in operation.

Owner:贵州众智恒生态科技有限公司

Wind power electric landing boat with good seakeeping performance

PendingCN113071618AImprove seakeepingExtended service lifeWind energy with electric storagePropulsion power plantsWind drivenImpeller

The invention discloses a wind power electric landing boat with the good seakeeping performance, which comprises a boat body; a first groove is formed in the upper surface of the boat body, a base plate is welded in the first groove, a storage battery is fixedly connected to the upper surface of the base plate, and a wind driven generator is installed on one side of the boat body. The electric output end of the wind driven generator is electrically connected with the electric input end of the storage battery through a wire, a first rotating rod is arranged on one side of the upper surface of the base plate, and a first fixed plate is welded to the top of the first rotating rod; when the landing boat is used, a third plate body drives a third rod body to slide front and back, so that a third fixed plate and a sleeve pipe slide front and back; a third spring is extruded through the sleeve pipe, and therefore the third plate body is adjusted, and fluctuation of water on the side face of the boat body is buffered; with an impeller, the service life of the boat body is greatly prolonged.

Owner:上海贸迎新能源科技有限公司

Improved molding method of ETPU (expanded thermoplastic polyurethane) foaming body

ActiveCN109762197AThere is no problem of taking up a lot of storage costsReduce manufacturing costWater vaporThermoplastic polyurethane

The invention discloses an improved molding method of an ETPU (expanded thermoplastic polyurethane) foaming body. The method comprises following steps: 1, TPU (thermoplastic polyurethane) particles are impregnated in high-pressure fluid, dissolution equilibrium of the high-pressure fluid in the TPU particles is realized, pressure of the high-pressure fluid is 70 MPa or lower, and temperature of the high-pressure fluid is 70 DEG C or lower; 2, the TPU particles reaching the dissolution equilibrium are refrigerated in a refrigeration storage, so that the high-pressure fluid in the TPU particlesis still retained in the TPU particles; 3, a certain quantity of TPU particles reaching the dissolution equilibrium are taken out from the refrigeration storage according to actual demands and subjected to molding in a steam foaming or die pressing foaming mode, and the ETPU foaming body is obtained. The improved molding method has the characteristics of better connectivity of the adjacent particles and low production cost.

Owner:晋江国盛新材料科技有限公司

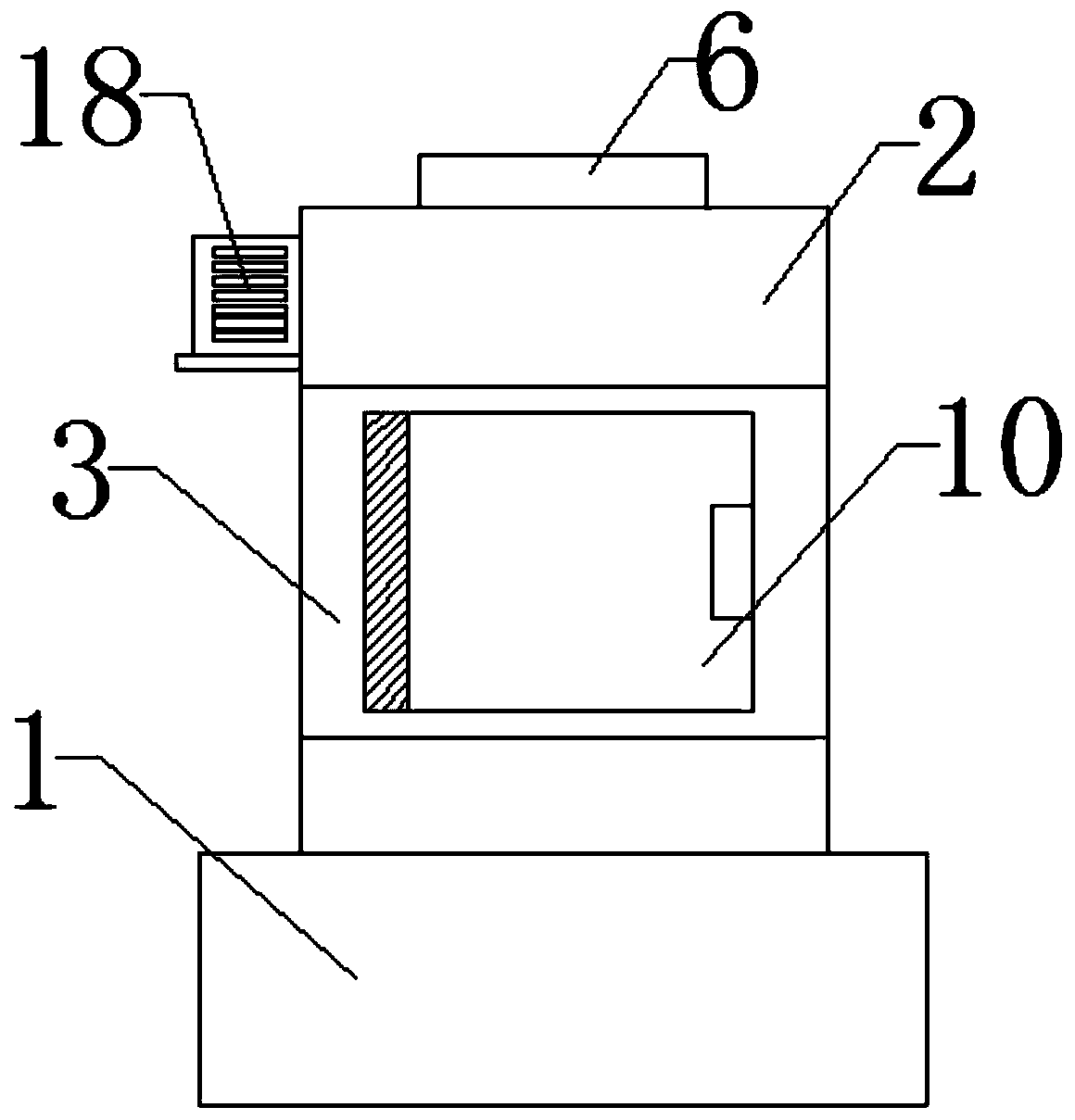

Pulverizer for recovery of paper products

InactiveCN110975984AAvoid cleaning inconvenienceAvoid situations that take up a lot of storage spaceGrain treatmentsPressesElectric machineryProcess engineering

The invention discloses a pulverizer for the recovery of paper products, and belongs to the technical field of pulverizers. The pulverizer comprises a machine base, a machine body, a heater, an air cylinder, a fan, a first motor and a second motor, wherein the machine body is fixed at the top of the machine base, a chip collecting chamber is fixed on one side of the machine body, an operating table is installed above the outer surface of the machine body, the first motor is installed above the back of the machine body, the output end of the first motor is connected with a first rotating shaftpenetrating into the machine body, the outer surface of the first rotating shaft is provided with a paper shredding roller in a sleeved mode, and a feeding port penetrating through the top of the machine body is installed above the paper shredding roller. According to the pulverizer for the recovery of the paper products, after paper is shredded, the paper can enter a paper falling channel, meanwhile, the fan is started by a worker, the fan and the chip collecting chamber are located at the same height, so that chips in the paper can be blown into the chip collecting chamber through air blowing of the fan, then the chips cannot fly at will, and the situation that the chips are inconvenient to clear is avoided.

Owner:湖南湘衡彩印有限公司

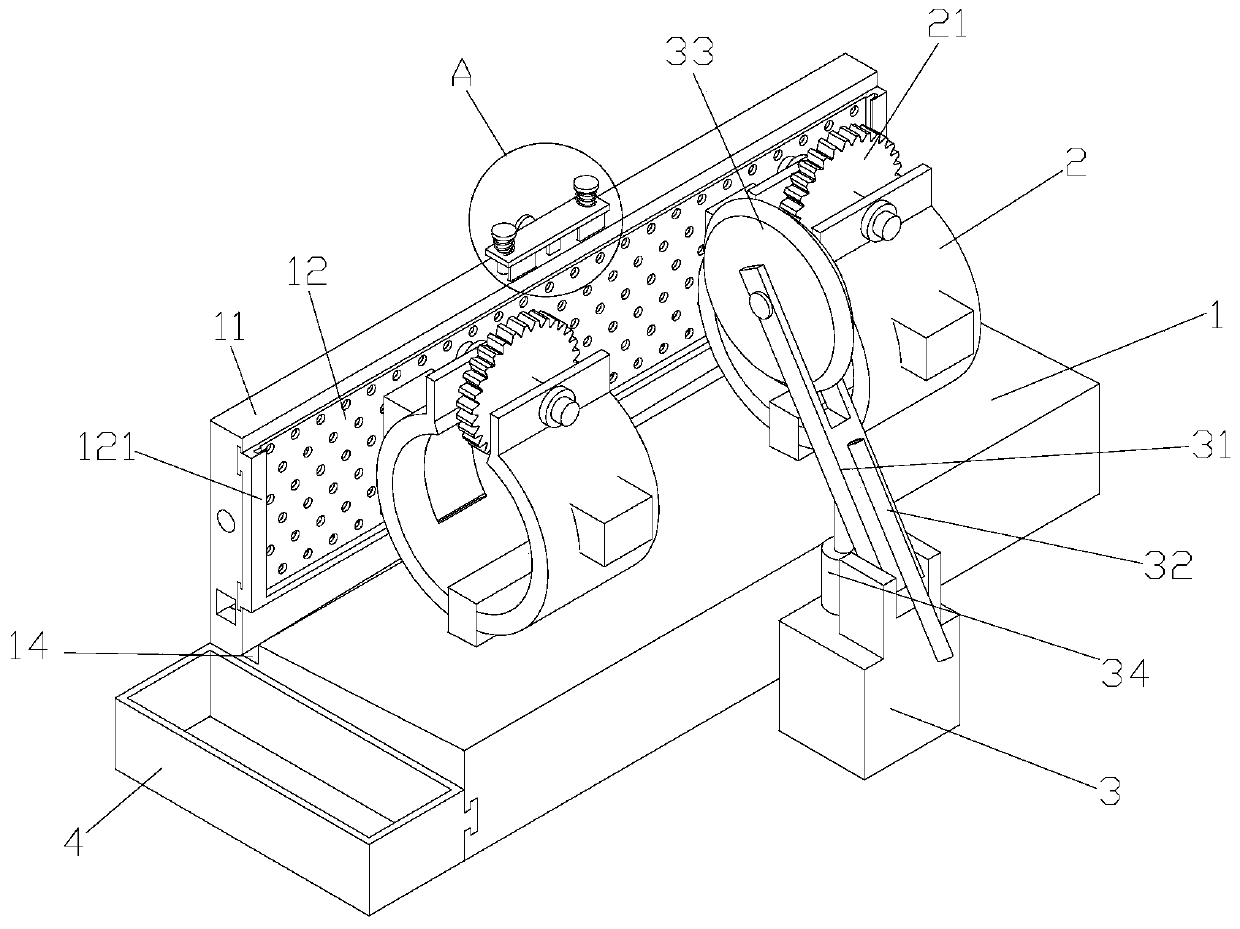

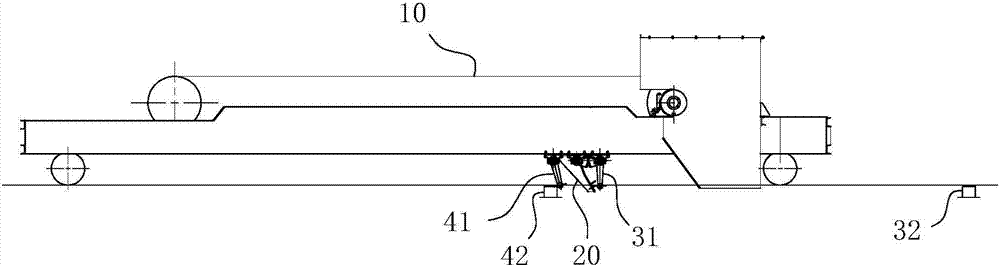

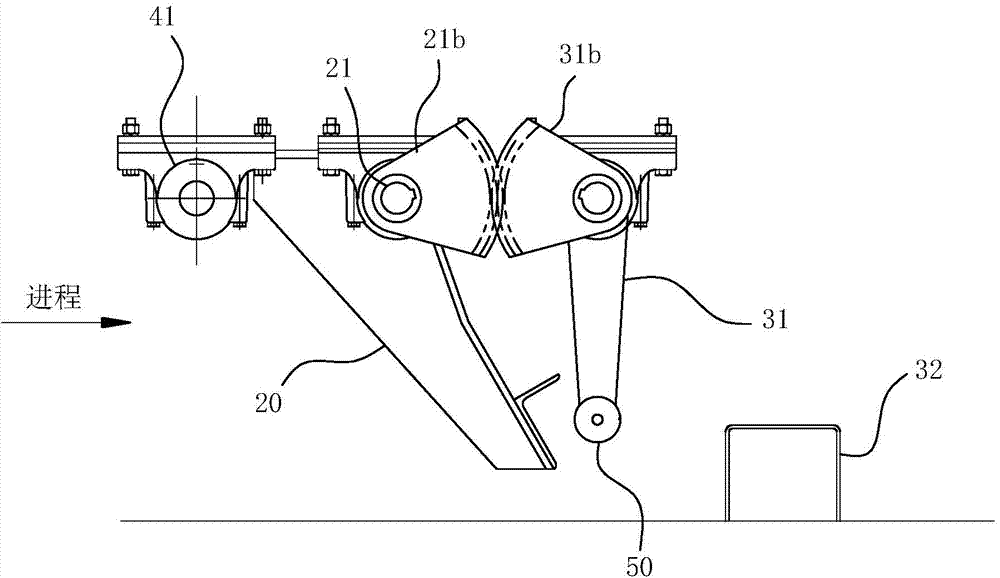

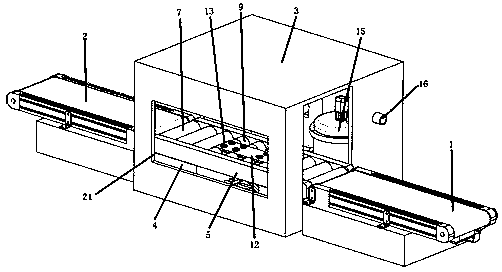

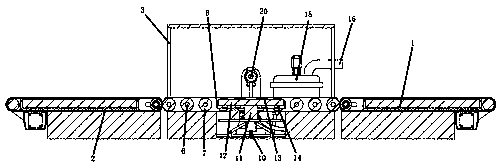

Automatic ground sweeper for belt conveyers

ActiveCN104495298AAchieve eradication effectAvoid cleaning inconvenienceCleaningEngineeringBelt conveyor

The invention relates to the field of ground sweeping equipment for conveyers, in particular to an automatic ground sweeper for belt conveyers. The automatic ground sweeper comprises a travelling trolley, a front scraper is fixedly connected below the travelling trolley, a spindle is fixedly connected to the front scraper, the automatic ground sweeper further comprises a front scraper lifting unit and a front scraper resetting unit, the front scraper lifting unit comprises a first impact rod and a first stopper, the first impact rod provided with a gear portion is in gear meshing fit with the spindle, the front scraper resetting unit comprises a second impact rod, a ratchet wheel portion is concentrically disposed on the spindle, a pawl portion in ratchet and pawl fit with the ratchet wheel portion is coaxially disposed on the second impact rod, the front scraper resetting unit further comprises a second stopper, the pawl portion of the second impact rod has a one-way limiting direction relative to the ratchet wheel portion on the spindle, and the one-way limiting direction is opposite to a stirring direction in which the first impact rod stirs the spindle after the first impact rod impacts on the first stopper. The automatic ground sweeper is capable of quickly, efficiently and automatically sweeping material accumulating on the ground from the conveyers.

Owner:TONGLING MIRACLE MECHANICAL EQUIP

Monitor lens capable of automatically cleaning in real time

InactiveCN108377321AAvoid cleaning inconvenienceReduce labor costsTelevision system detailsColor television detailsCamera lensEngineering

The invention discloses a monitor lens capable of automatically cleaning in real time. The monitor lens comprises a shell, an electric motor, dustproof glass, a cleaning plate, and a camera; the electric motor is started when needing to clean the monitor lens, a motor rotating shaft drives the dustproof glass to rotate, the blinded glass surface can be cleaned when the dustproof passes through thecleaning plate due to the wiping effect on the glass surface by the cleaning plate, the camera at the other side of the dustproof glass maintains the performing the camera surveillance through the cleaned glass region all along, the monitor lens can be automatically and continuously cleaned in real time without artificially using cleaning appliances, the cleaning is convenient and quick, and themanpower cost is saved.

Owner:青岛福鼎数码科技有限公司

Efficient sorting device based on logistics information scanning recognition

InactiveCN112013092AGood lubricationImprove work efficiencyGearingGear lubrication/coolingStructural engineeringManufacturing engineering

The invention discloses an efficient sorting device based on logistics information scanning recognition. The device comprises a bottom plate. A support is fixed to the top end of the bottom plate, a lead screw is rotationally arranged at the top end of the support, and a ball nut rotationally sleeves the outer wall of the lead screw in a connection mode. A fixing block fixedly sleeves the outer surface of the ball nut in a connection mode, and a lubricating sleeve and a cleaning sleeve are fixed to the surfaces of the two sides of the fixing block respectively. Two push rods symmetrically andmovably penetrate through the outer wall of the lubricating sleeve, the push rods extend into a cavity of the lubricating sleeve, and an extrusion plate is fixed to the tail end of each push rod. Extrusion springs are fixed at the joint of the extrusion plates and the cavity of the lubricating sleeve and surround the outer surfaces of the push rods. Due to the arranged lubricating sleeve, the surface of the lead screw can be conveniently, rapidly and efficiently lubricated; due to the arranged cleaning sleeve, the surface of the lead screw can be conveniently and rapidly cleaned; and due to arranged protective baffles, the protective baffles can be conveniently and rapidly installed and disassembled, and objects can be conveniently protected.

Owner:上海贵蓉国际物流有限公司

Cutting board and kitchen knife combined device for kitchen

ActiveCN108371496AAvoid inconvenient cleaningTo collect sapKitchen equipmentMetal working apparatusFruit juiceWater flow

The invention discloses a cutting board and kitchen knife combined device for a kitchen. The cutting board and kitchen knife combined device comprises a water collecting tank and a limiting device, wherein the lower part of the water collecting tank is provided with suckers; a connecting block mounted on one side of a cutting board sleeve is connected with a connecting piece through an extension shaft; the extension shaft is provided with a bolt sleeve; the front surface of the cutting board sleeve is provided with water drain holes; the left and right sides of the interior of the water collecting tank are symmetrically provided with connecting plates; the left and right sides of the cutting board sleeve are provided with through holes in a reservation manner; the limiting device is mutually connected with a connecting shaft; further, the left and right ends of the connecting shaft are mounted on the connecting block through the extension shaft; the bottom of the water collecting tankis provided with bottom tanks. The cutting board and kitchen knife combined device for the kitchen can be used for achieving the purpose of collecting vegetable and fruit juice through the setting ofthe water collecting tank, and is used for avoiding the condition that water flows to a placement plane and cleaning is inconvenient to perform; meanwhile, the cutting board sleeve can be connected with the connecting piece through the connecting shaft; thus, a kitchen knife can be connected onto the cutting board sleeve, and kitchen knife blades can be stored when not in use.

Owner:惠安多殿起优信息科技有限公司

Dustproof and intelligent smart home curtain

ActiveCN108720532AImprove the protective effectPracticalDispersed particle filtrationTransportation and packagingAirflowEngineering

The invention discloses a dustproof and intelligent smart home curtain which comprises a second curtain and a supporting frame. Control boxes are symmetrically arranged on the left side and the rightside of the supporting, the two control boxes are fixedly connected through a guide rail, a slide block is arranged outside the guide rail, a first curtain is arranged on one side of the lower portionof the guide rail, and a second curtain is arranged on the other side of the lower portion of the guide rail. A bonding layer of the curtain is an organic silicon coating and has water repellency andair permeability, and the problem is avoided that moisture seeps into the curtain to cause separation of internal materials. A hollow layer can achieve timely heat dissipation and has the effects ofsun blocking, ventilation and prevention of exposure in the blazing sun. A coarse filter screen can preliminarily filter dust in airflow, a fine filter screen further adsorbs dust which is not filtered and meanwhile can absorb water and other pollutants, the protective effect of a dustproof layer is improved, the dustproof cloth design is not adopted, the problem is avoided that curtains of a villa or a duplex house are inconvenient to clean, and the practicability is good.

Owner:LIANYUNGANG SUNLIGHT QUARTZ CERAMICS CO LTD

Hand-pressing type applicator

The invention relates to an applicator, in particular to a hand-pressing type applicator. The hand-pressing type applicator aims at achieving the technical purposes that the smearing area is larger, liquid medicine is more uniformly smeared, and air can be filtered. According to the technical scheme, the hand-pressing type applicator comprises a handle rod, a piston, a push rod, a first spring, apressing plate, a first valve, an air suction pipe, a second valve, a medicine bottle, a bottle cap, a second spring, a sprue, a medicine smearing shell and the like. A first cavity and a through holeare formed in the handle rod, the first cavity is located in the right side of the through hole, the first cavity is communicated with the through hole, the piston is slidingly arranged in the firstcavity, the push rod is arranged in the middle of the right side of the piston, the pressing plate is arranged at the right end of the push rod, and the left side of the pressing plate is connected with the first spring. Compared with a cotton swab, the smearing area of a medical sponge is larger, the smearing frequency of people is reduced, repeated smearing is not needed, the workload of smearing staff is relieved, and smearing of people is facilitated.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

Numerical control machine tool convenient to use

InactiveCN110976617AEasy to useImprove work efficiencyMetal-working feeding devicesStripping-off devicesNumerical controlPunching

The invention discloses a numerical control machine tool convenient to use. The numerical control machine tool comprises a rack, a punching mechanism and a holding mechanism. The punching mechanism isfixedly installed at the top of the rack. The holding mechanism is arranged below the punching mechanism. The rack comprises a base, a support frame and a transverse frame. The bottom of the supportframe is fixedly installed on the left side of the top of the base. The transverse frame is fixedly installed at the top of the right side of the support frame. The punching mechanism comprises a driving cylinder, a driving rod, an installation plate, a punching head, a sliding sleeve, a connection rod, a connection block and a connection spring. Through mutual matching of the rack, the punching mechanism and the holding mechanism, the numerical control machine tool convenient to use is achieved, waste adhering to the punching head can be removed in time, waste removed from a punching hole canbe ejected out, inconvenience brought by cleaning done by a worker is avoided, normal use of the machine tool is facilitated, and therefore, work efficiency of the machine tool is improved greatly.

Owner:义乌市千智机械设备有限公司

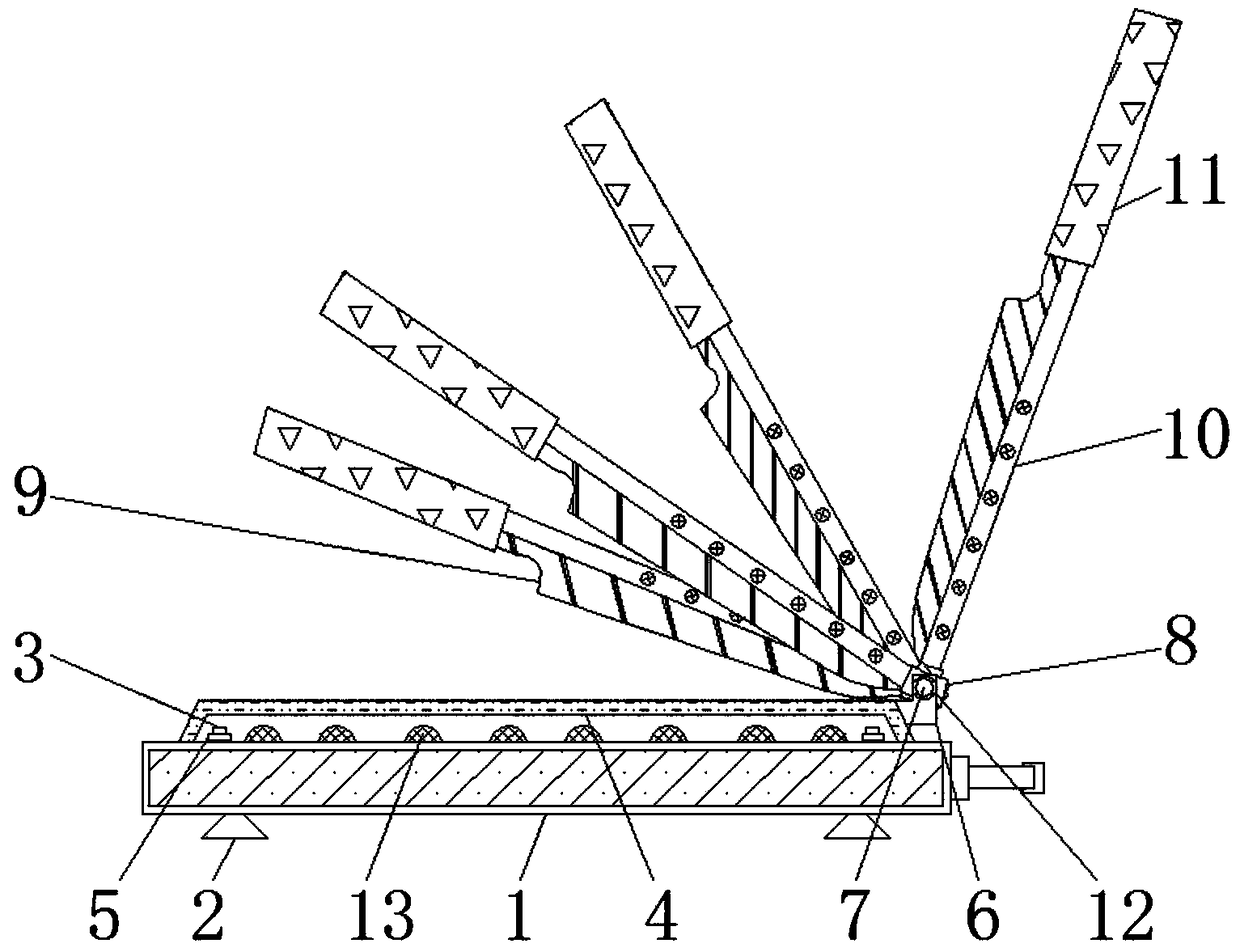

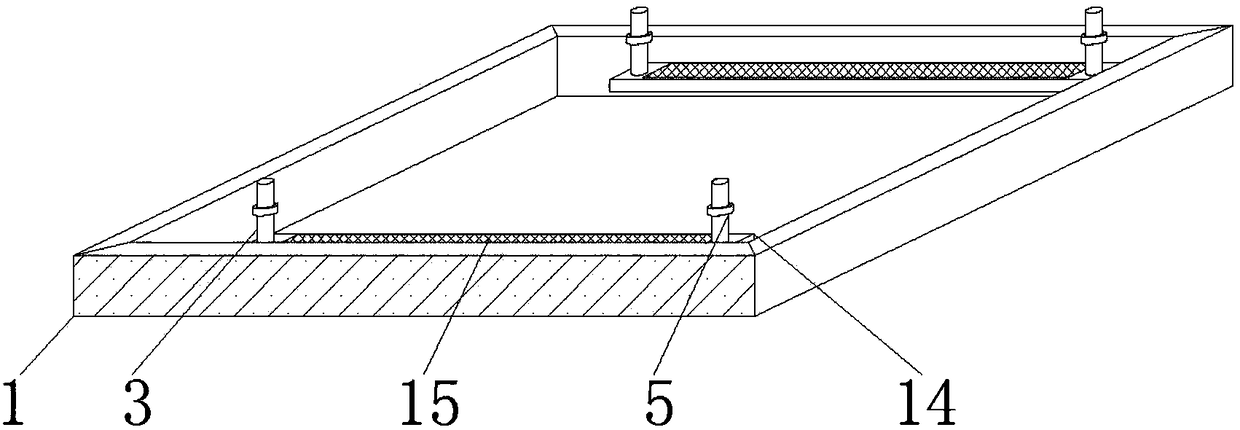

Full-automatic efficient furniture assembly line

InactiveCN111250308APrevent dumpingAvoid cleaning inconvenienceSpraying apparatusRobot handStructural engineering

The invention relates to the technical field of furniture production, in particular to a full-automatic efficient furniture assembly line. The full-automatic efficient furniture assembly line comprises a feeding conveying belt assembly, a discharging conveying belt assembly is arranged on one side of the feeding conveying belt assembly, and a spraying room is fixedly arranged between the discharging conveying belt assembly and the feeding conveying belt assembly and is fixedly provided with a U-shaped drive base. A mounting frame is arranged between two baffles, multiple drive rollers are symmetrically and rotationally connected to the mounting frame at equal distance. A lifting device is fixedly arranged on the U-shaped drive base and is fixedly provided with an angle adjusting device. The spraying room is fixedly provided with a stirring device. A spraying mechanical arm is arranged on one side of the U-shaped drive base. According to the full-automatic efficient furniture assembly line, on the basis of a common assembly line, the lifting device, the angle adjusting device and the stirring device are arranged, the spraying effect and efficiency are improved, wide market prospectsare achieved, and the assembly line is suitable for popularization.

Owner:惠州市九生宸家具有限公司

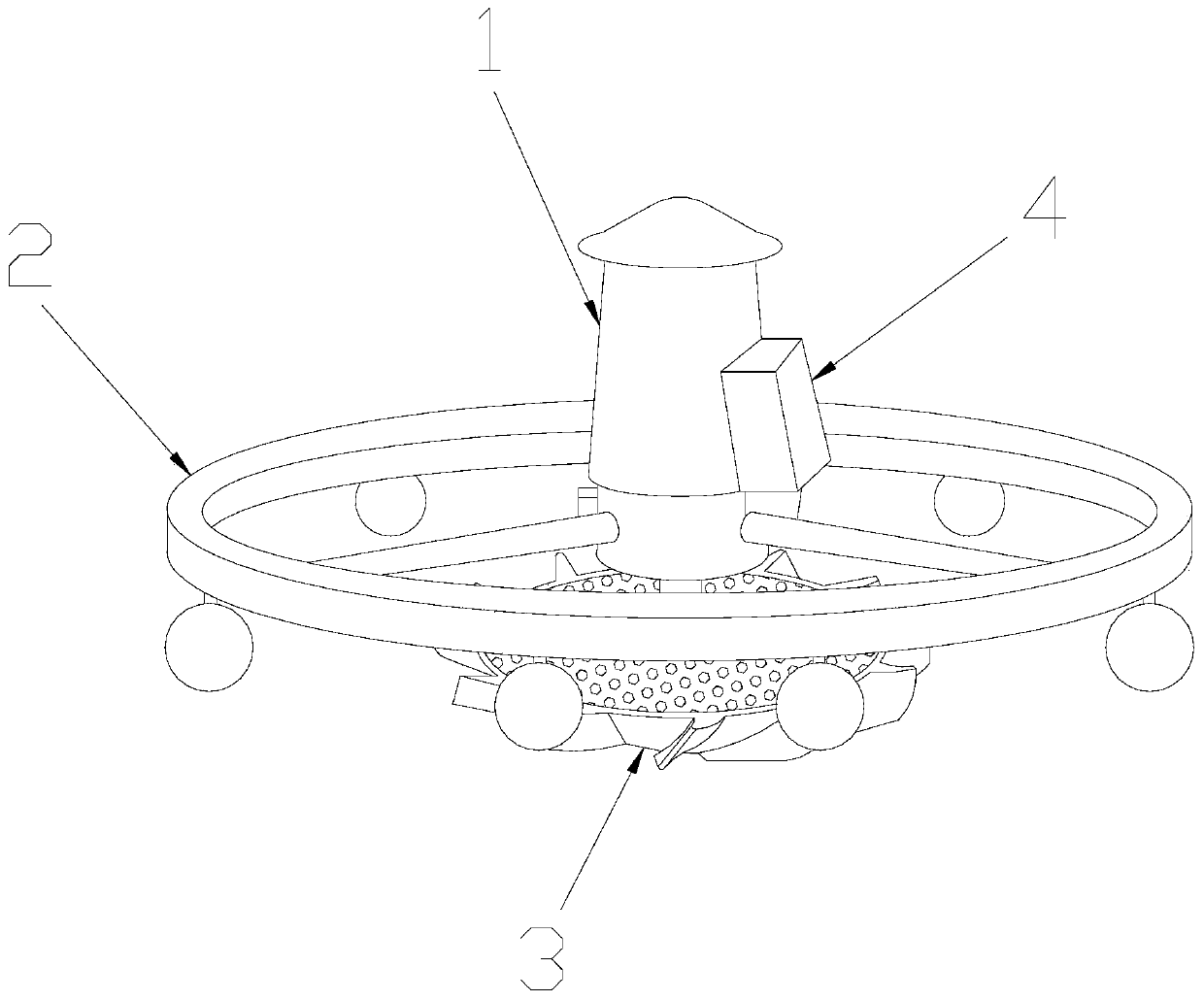

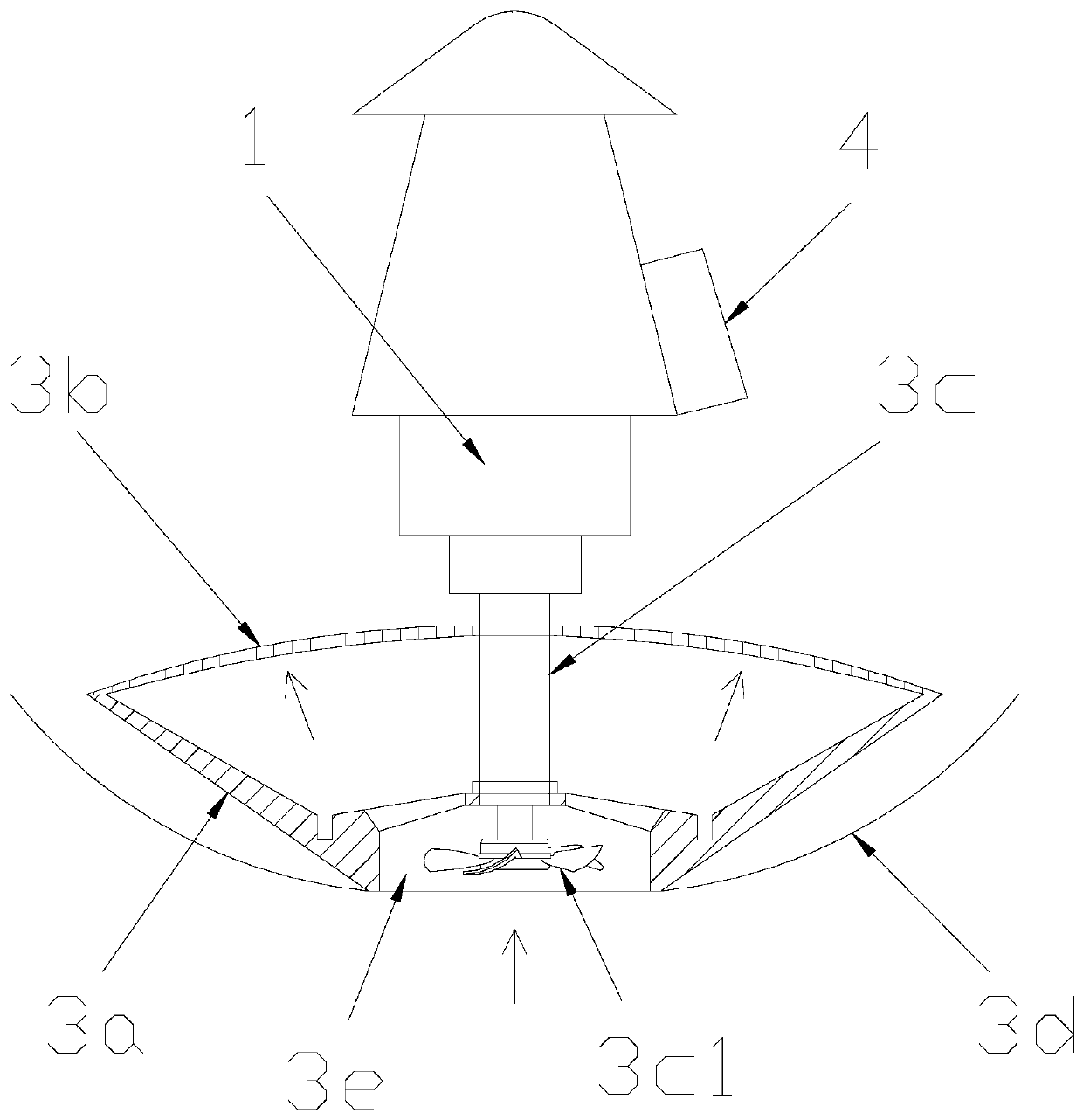

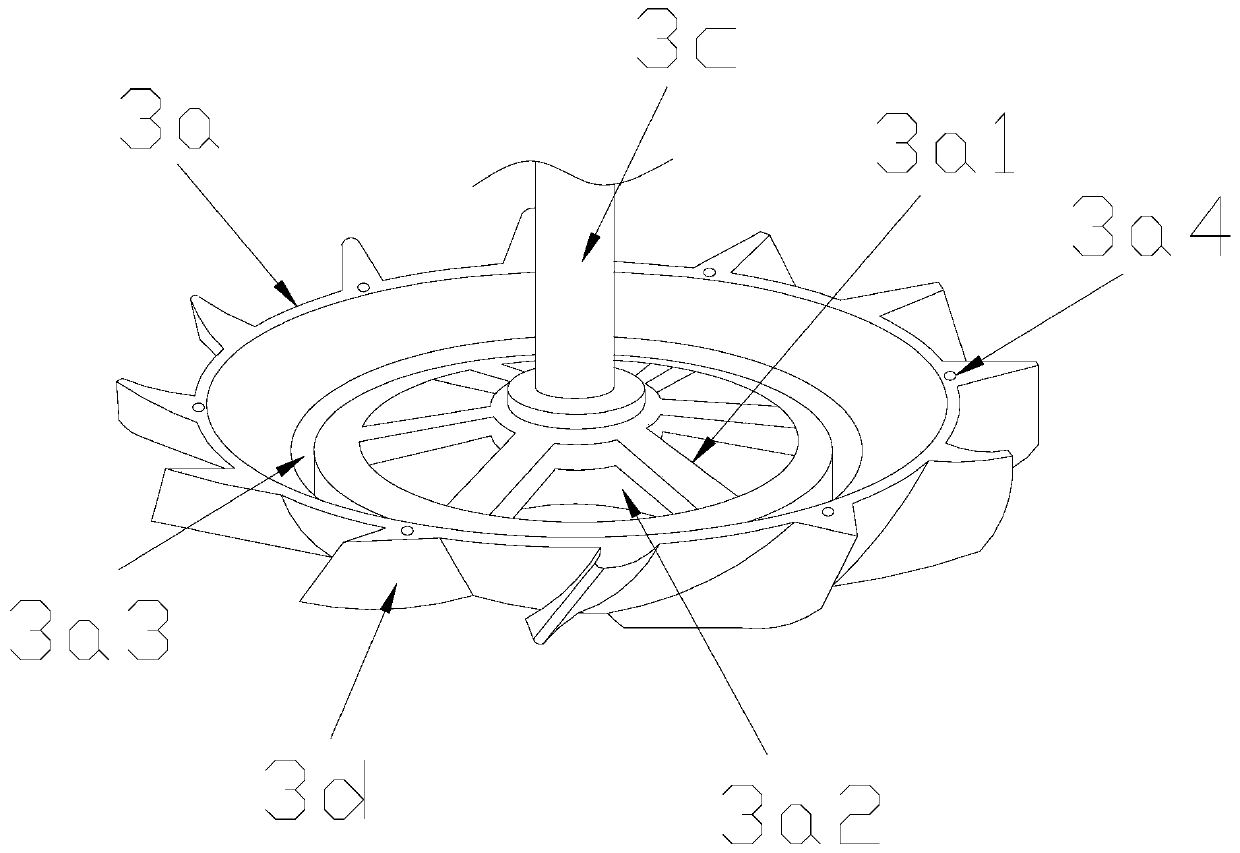

Overwater self-moving oxygenation device

The invention discloses an overwater self-moving oxygenation device which structurally comprises an electric motor, a floater, an oxygenation mechanism and a storage battery. The oxygenation mechanismconsists of a storage shell, a net cover body, a transmission shaft, an impeller and a water inlet groove, the electric motor is driven by electric energy provided by the storage battery, the whole device can float on water to move by the floater, and the floater can effectively prevent a protective support ring from being collided or overturned by an anti-collision rubber strip. The impeller anda negative pressure fan are controlled by the transmission shaft to introduce surrounding air into water, so that the oxygen in the water is supplemented, the oxygenation effect is improved, collected garbage is centralized by the storage shell through a storage tank, the sucked water is filtered by the net cover body, and inconvenient cleaning caused by diffusion of some floating garbage in a fishpond is avoided.

Owner:陈劲毅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com