Scrap iron compaction system capable of working continuously

A technology of iron filings and compacting device, applied in the field of parts processing, can solve the problems of unsustainable addition of new iron filings, scattering of iron filings, inconvenience in finishing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

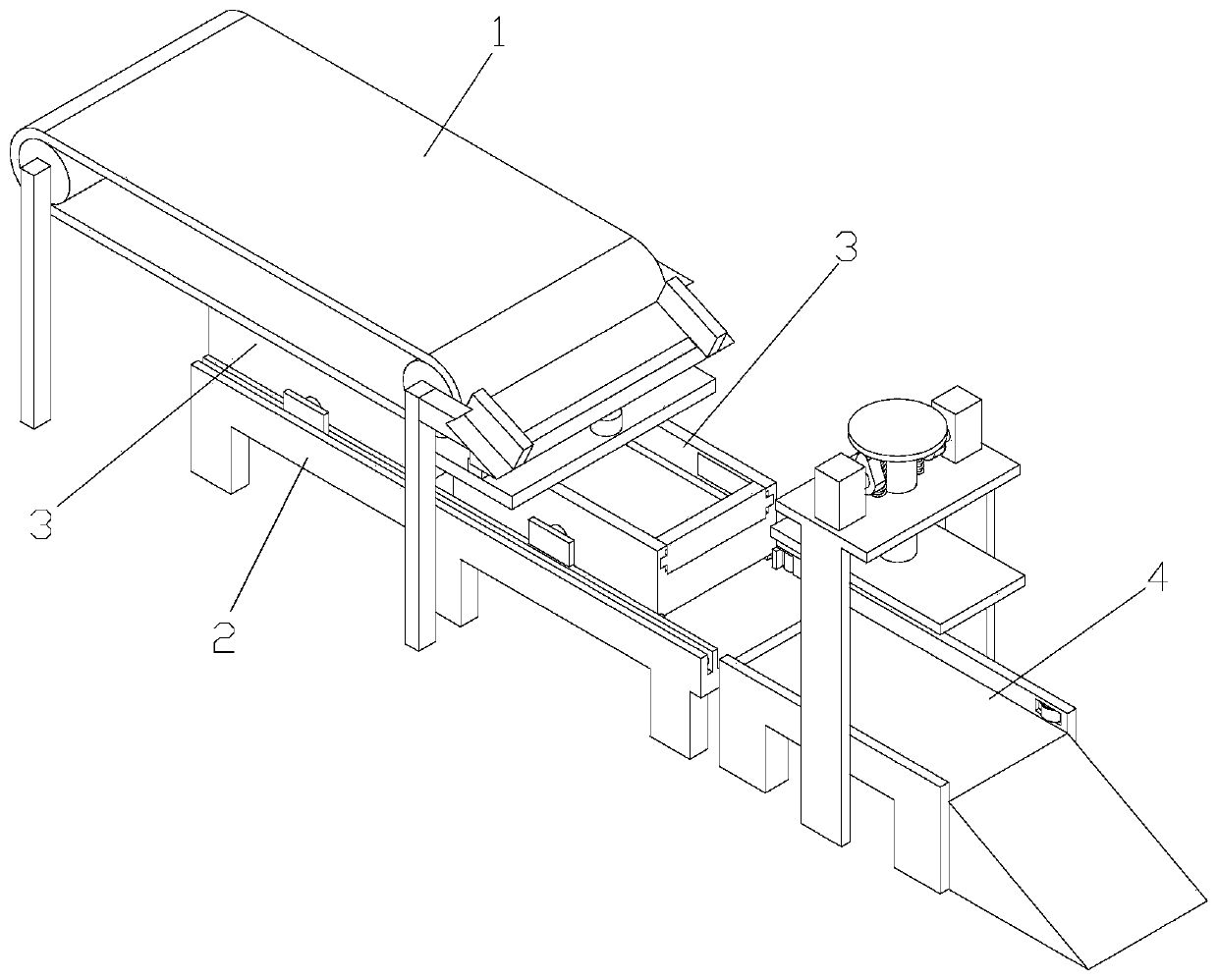

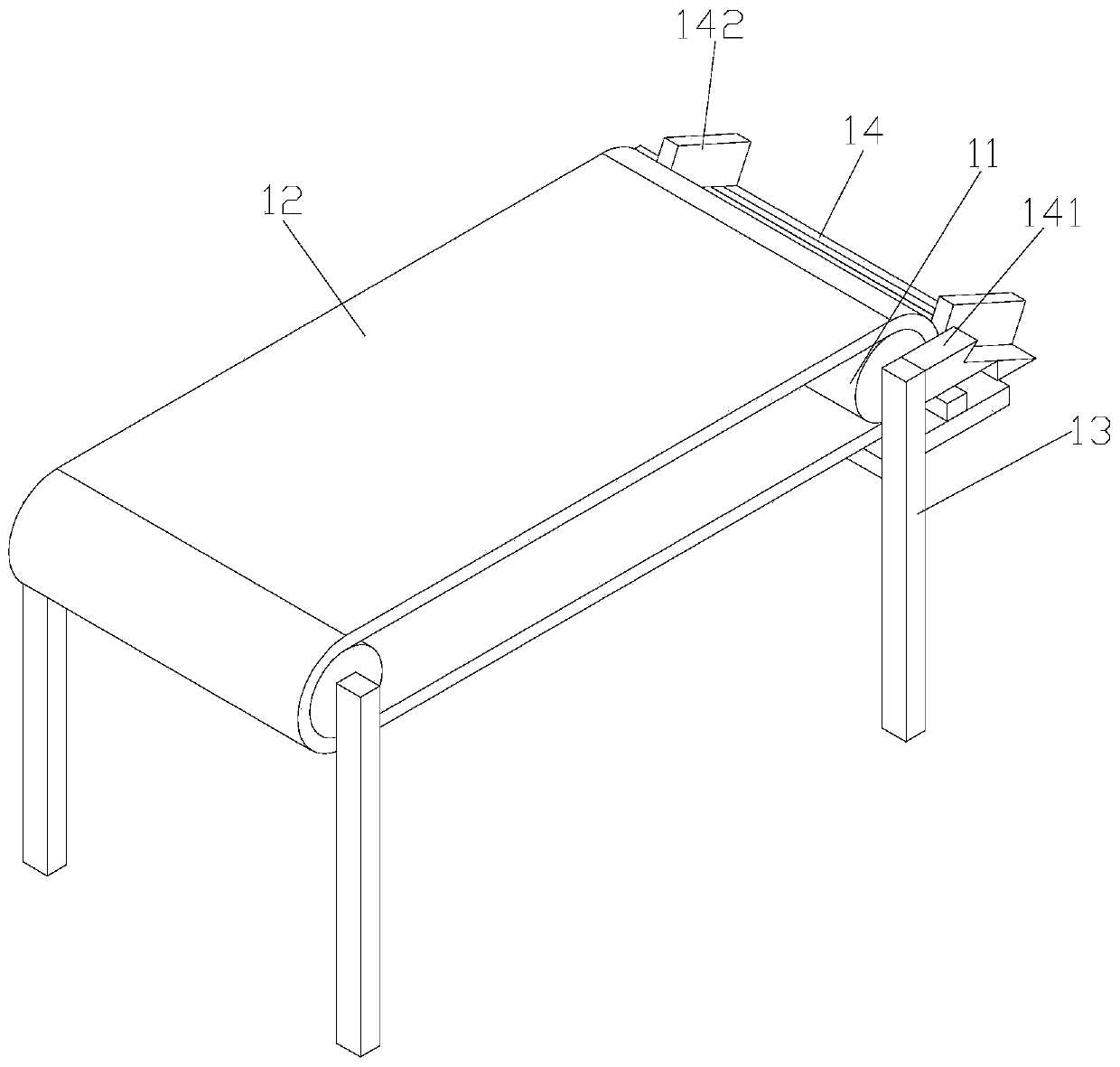

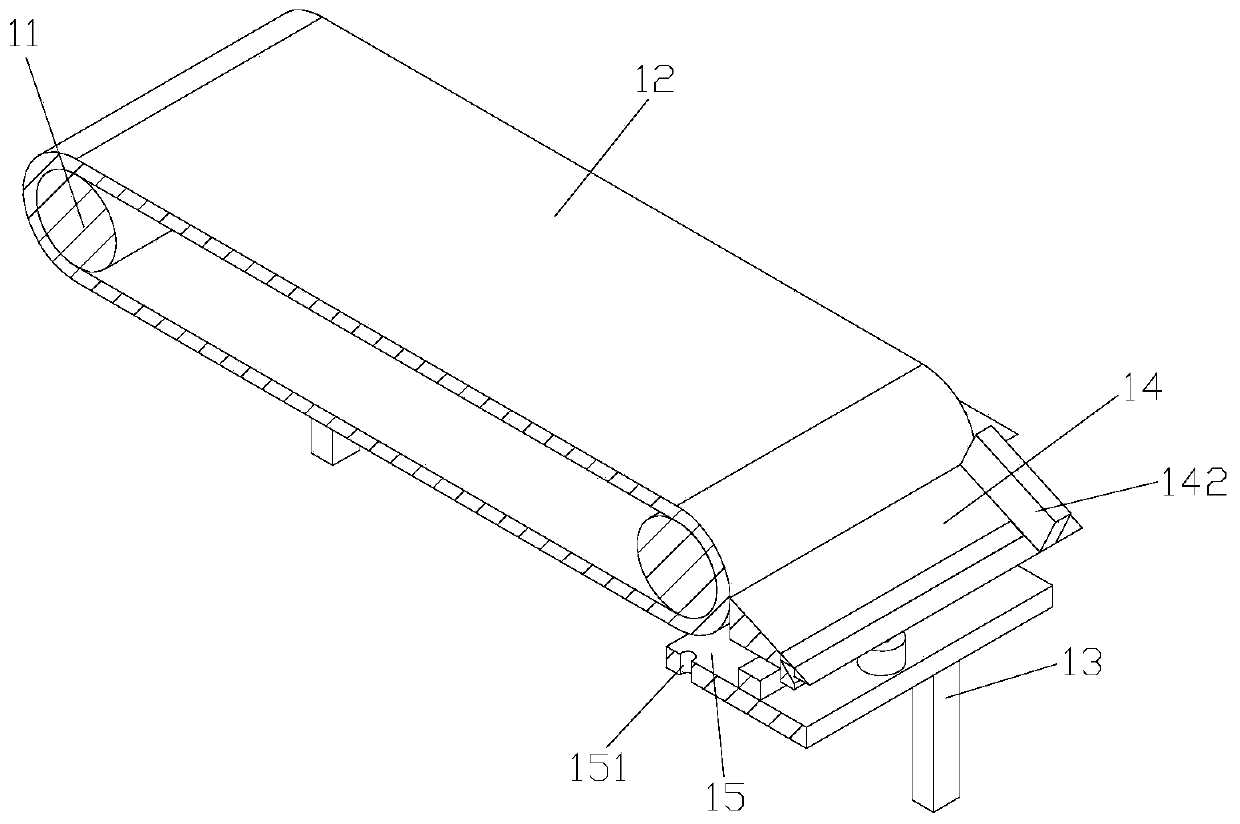

[0031] Such as Figure 1-18 As shown, a continuously working chip compaction system includes a conveying device 1, a receiving device, a conveying device 2 and a compacting device 4. The conveying device 1 includes a first transmission roller 11, which is sleeved on The first conveyor belt 12 on the first transmission roller 11 and the first support feet 13 located on both sides of the first transmission roller 11, the first transmission roller is two, the first conveyor belt is fixed, the first The driving roller is connected with a first driving motor, and the first driving motor provides rotational power for the first driving roller; the conveying device 2 is arranged below the first conveyor belt 12, and the material receiving device is arranged on the conveying device 2 Above, the material receiving device includes a material receiving plate 3, a first baffle plate 31 and a second baffle plate 32 arranged on the material receiving plate 3, the first baffle plate and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com