Hand-pressing type applicator

An applicator and hand-pressed technology, applied in the field of applicators, can solve the problems of small cotton swab application area, dust pollution of liquid medicine, uneven application of liquid medicine, etc., and achieve the effect of safe application, clean air and uniform application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

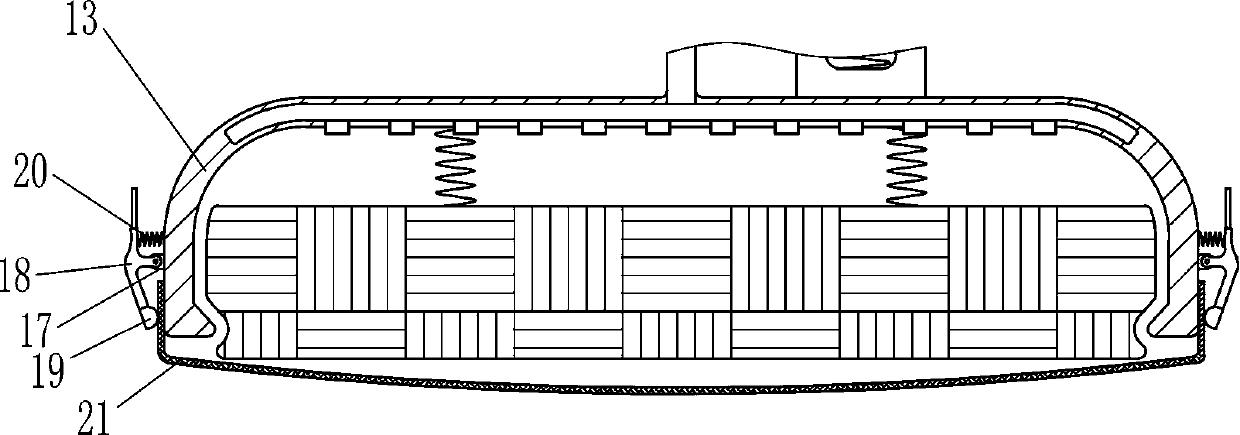

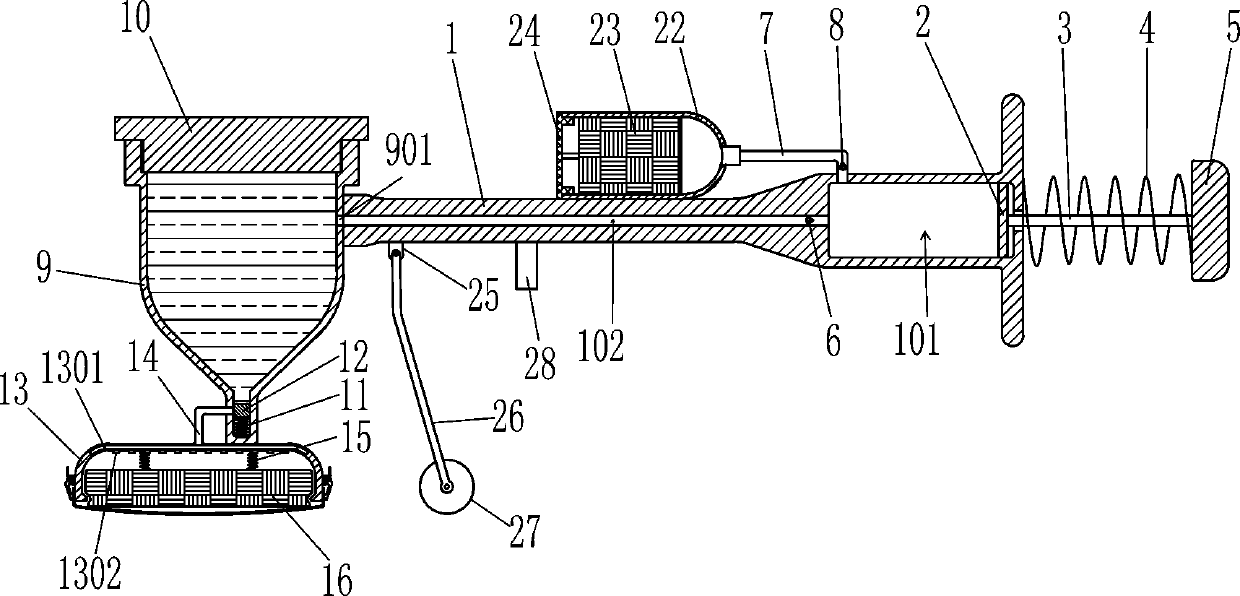

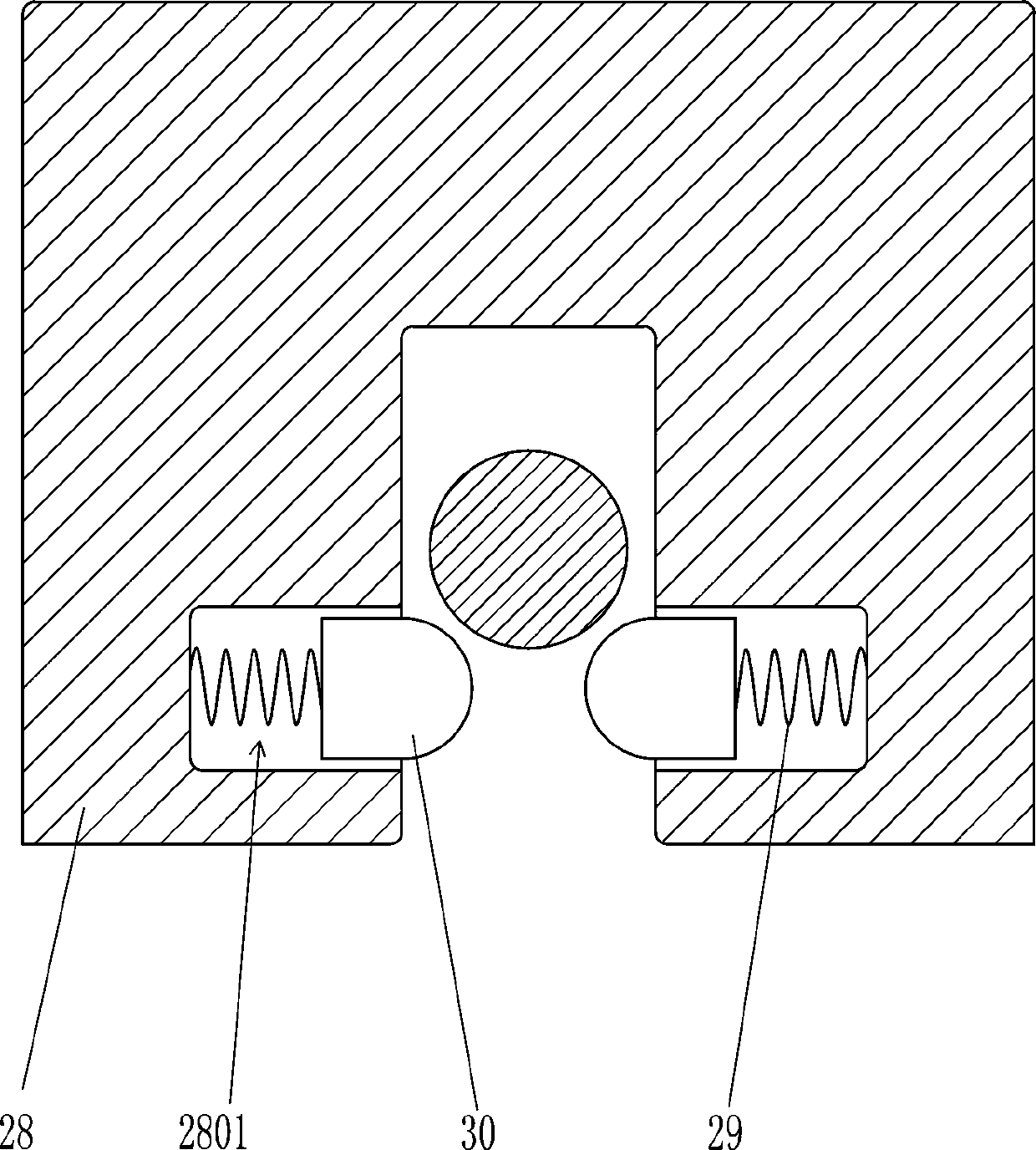

[0021] A hand-pressed applicator, such as Figure 1-3 As shown, it includes handle rod 1, piston 2, push rod 3, first spring 4, pressure plate 5, first valve 6, suction pipe 7, second valve 8, medicine bottle 9, bottle cap 10, second spring 11. Blocking block 12, applicator housing 13, spray head 1302, water spray pipe 14, third spring 15 and medical sponge 16, the handle bar 1 has a first cavity 101 and a through hole 102, the first cavity 101 Located on the right side of the through hole 102, the first cavity 101 communicates with the through hole 102, the first cavity 101 is provided with a sliding piston 2, the middle part of the right side of the piston 2 is provided with a push rod 3, and the right end of the push rod 3 is provided with a pressure plate 5 , the left side of the pressing plate 5 is connected with the first spring 4, the left end of the first spring 4 is connected with the right side of the handle bar 1, the right end of the push rod 3 passes through the h...

Embodiment 2

[0023] A hand-pressed applicator, such as Figure 1-3As shown, it includes handle rod 1, piston 2, push rod 3, first spring 4, pressure plate 5, first valve 6, suction pipe 7, second valve 8, medicine bottle 9, bottle cap 10, second spring 11. Blocking block 12, applicator housing 13, spray head 1302, water spray pipe 14, third spring 15 and medical sponge 16, the handle bar 1 has a first cavity 101 and a through hole 102, the first cavity 101 Located on the right side of the through hole 102, the first cavity 101 communicates with the through hole 102, the first cavity 101 is provided with a sliding piston 2, the middle part of the right side of the piston 2 is provided with a push rod 3, and the right end of the push rod 3 is provided with a pressure plate 5 , the left side of the pressing plate 5 is connected with the first spring 4, the left end of the first spring 4 is connected with the right side of the handle bar 1, the right end of the push rod 3 passes through the ha...

Embodiment 3

[0026] A hand-pressed applicator, such as Figure 1-3 As shown, it includes handle rod 1, piston 2, push rod 3, first spring 4, pressure plate 5, first valve 6, suction pipe 7, second valve 8, medicine bottle 9, bottle cap 10, second spring 11. Blocking block 12, applicator housing 13, spray head 1302, water spray pipe 14, third spring 15 and medical sponge 16, the handle bar 1 has a first cavity 101 and a through hole 102, the first cavity 101 Located on the right side of the through hole 102, the first cavity 101 communicates with the through hole 102, the first cavity 101 is provided with a sliding piston 2, the middle part of the right side of the piston 2 is provided with a push rod 3, and the right end of the push rod 3 is provided with a pressure plate 5 , the left side of the pressing plate 5 is connected with the first spring 4, the left end of the first spring 4 is connected with the right side of the handle bar 1, the right end of the push rod 3 passes through the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com