Drilling machine with metal filling cleaning device

A technology for cleaning devices and metal shavings, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., and can solve problems such as large product errors, drilling errors, and worn metal sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

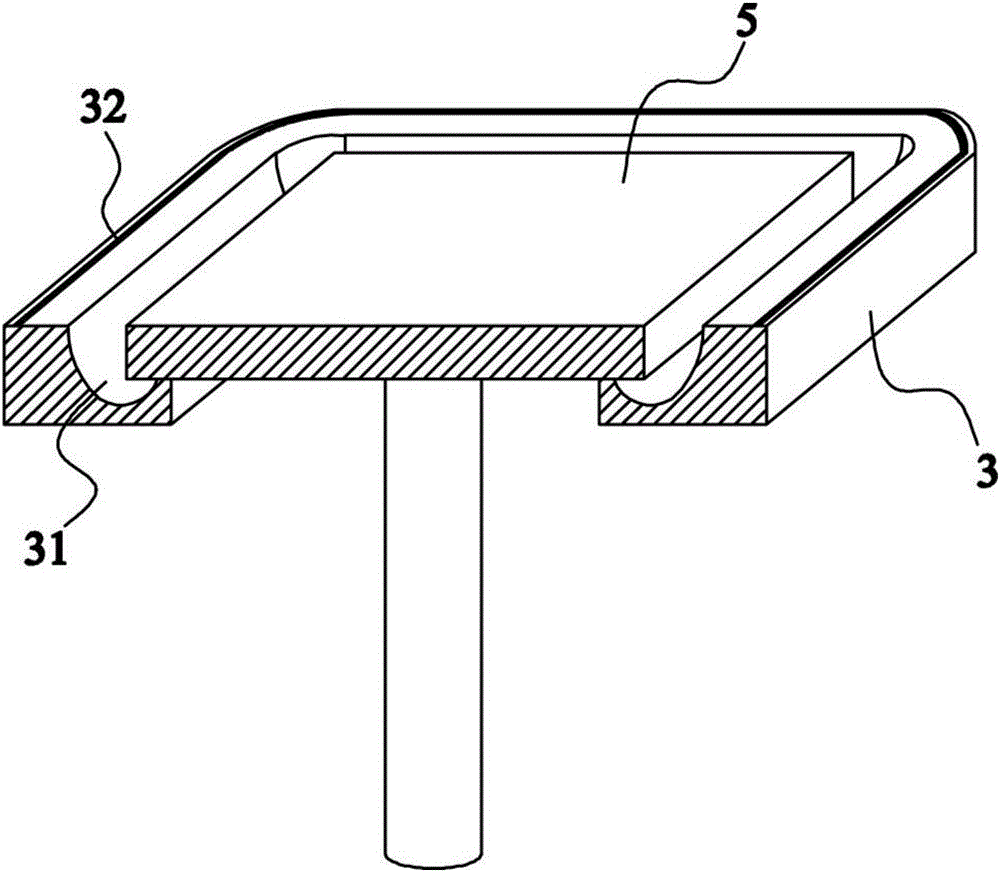

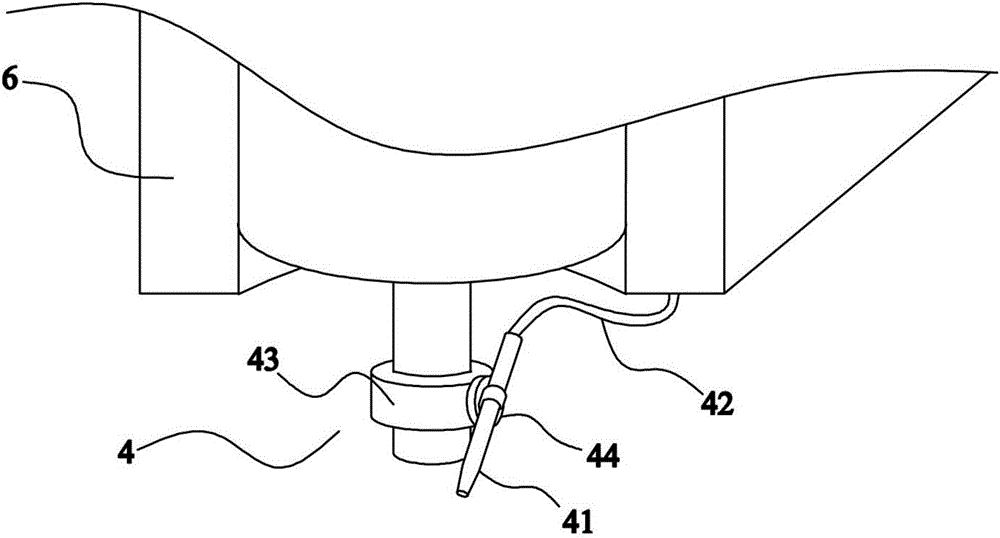

[0018] A drilling machine with a metal chip cleaning device of the present invention is provided with a metal chip cleaning device that absorbs metal chips on the drilling machine, so that the operator can avoid the The metal shavings extruded from the drilling are scattered on the ground, which is not easy to clean, and the timely collection ability of the metal shavings cleaning device can also prevent the metal shavings from causing abrasion damage to the upper and lower surfaces of the metal sheet during the drilling process.

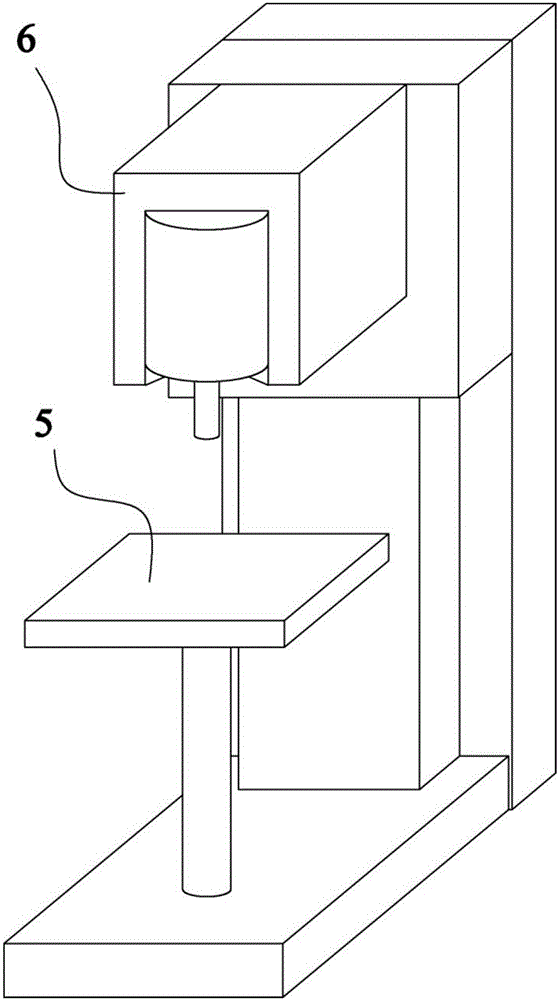

[0019] A kind of drilling machine with metal shavings cleaning device of the present invention, in its preferred embodiment, please refer to figure 1 and figure 2 As shown, the drilling machine with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com