Monitor lens capable of automatically cleaning in real time

A technology for automatic cleaning and lens, applied in cleaning methods and utensils, cleaning methods using tools, TV, etc., can solve the problems of inconvenient cleaning of monitoring lens and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

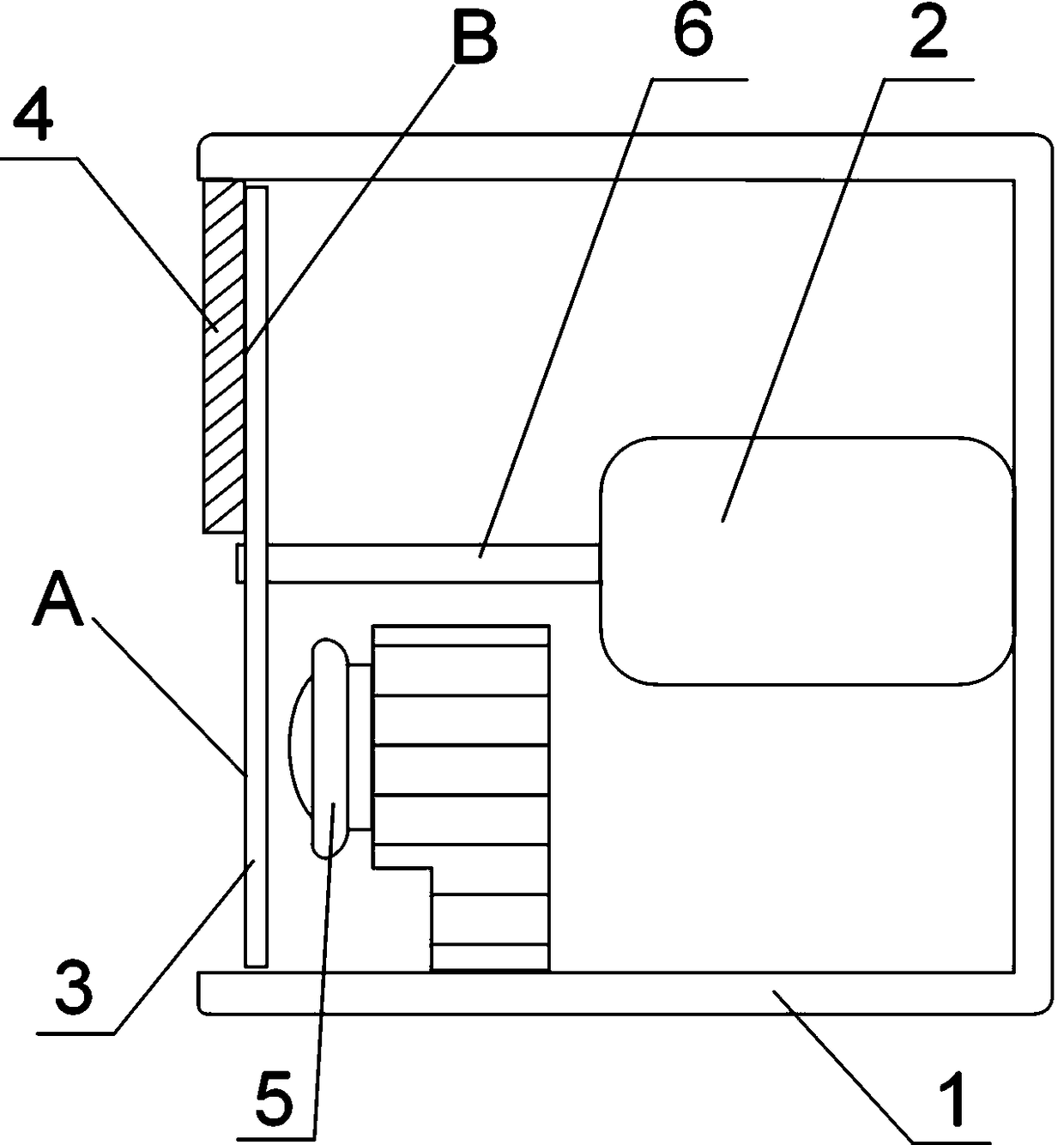

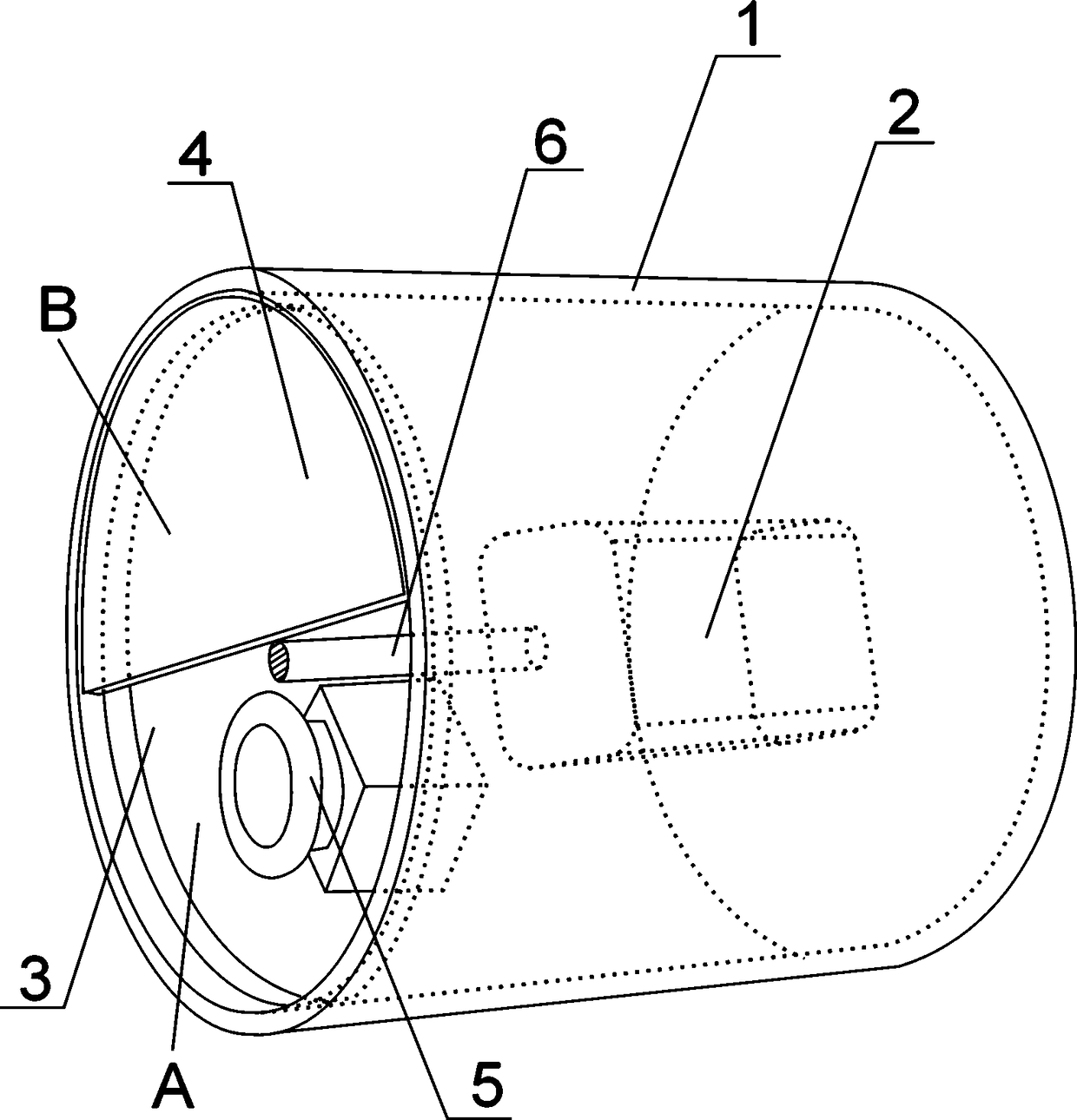

[0012] Using the above scheme, if figure 1 , figure 2 As shown, the camera (5) is located inside the casing of the monitoring lens, and the camera is monitored through the dust-proof glass (3). Due to the barrier effect of the dust-proof glass (3), the external environmental pollution can only affect the dust-proof glass ( 3) The surface, so when the camera monitoring area (A) of the dust-proof glass is blinded by dirt and needs to be cleaned, the electric motor (2) is started, and the motor shaft (6) drives the dust-proof glass (3) to rotate. When the dust-proof glass camera monitors the penetration area (A) and rotates past the cleaning sheet (4), due to the wiping action of the dust-proof glass and the cleaning sheet contact area (B) on the glass surface, this area will be cleaned and then rotated to The dust-proof glass camera monitors through the area (A), and the camera (5) will continue to monitor the camera through the cleaned clear glass. If the dirt in the externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com