Corrugated pipe machining method

A processing method and technology for corrugated pipes, which are applied in the field of corrugated pipe manufacturing, can solve the problems of scattered debris and increase the burden of cleaning workers, and achieve the effect of preventing the inconvenience of cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

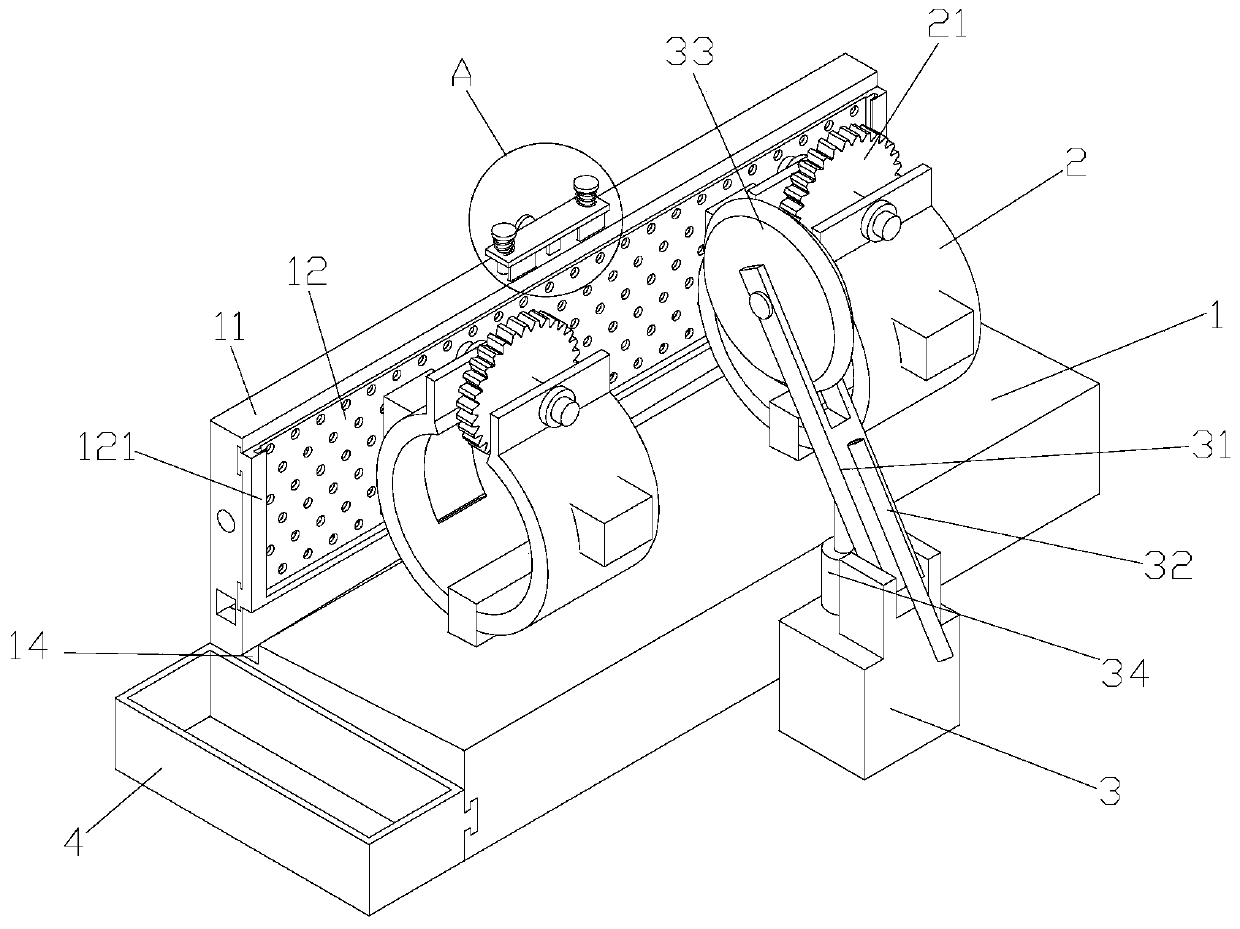

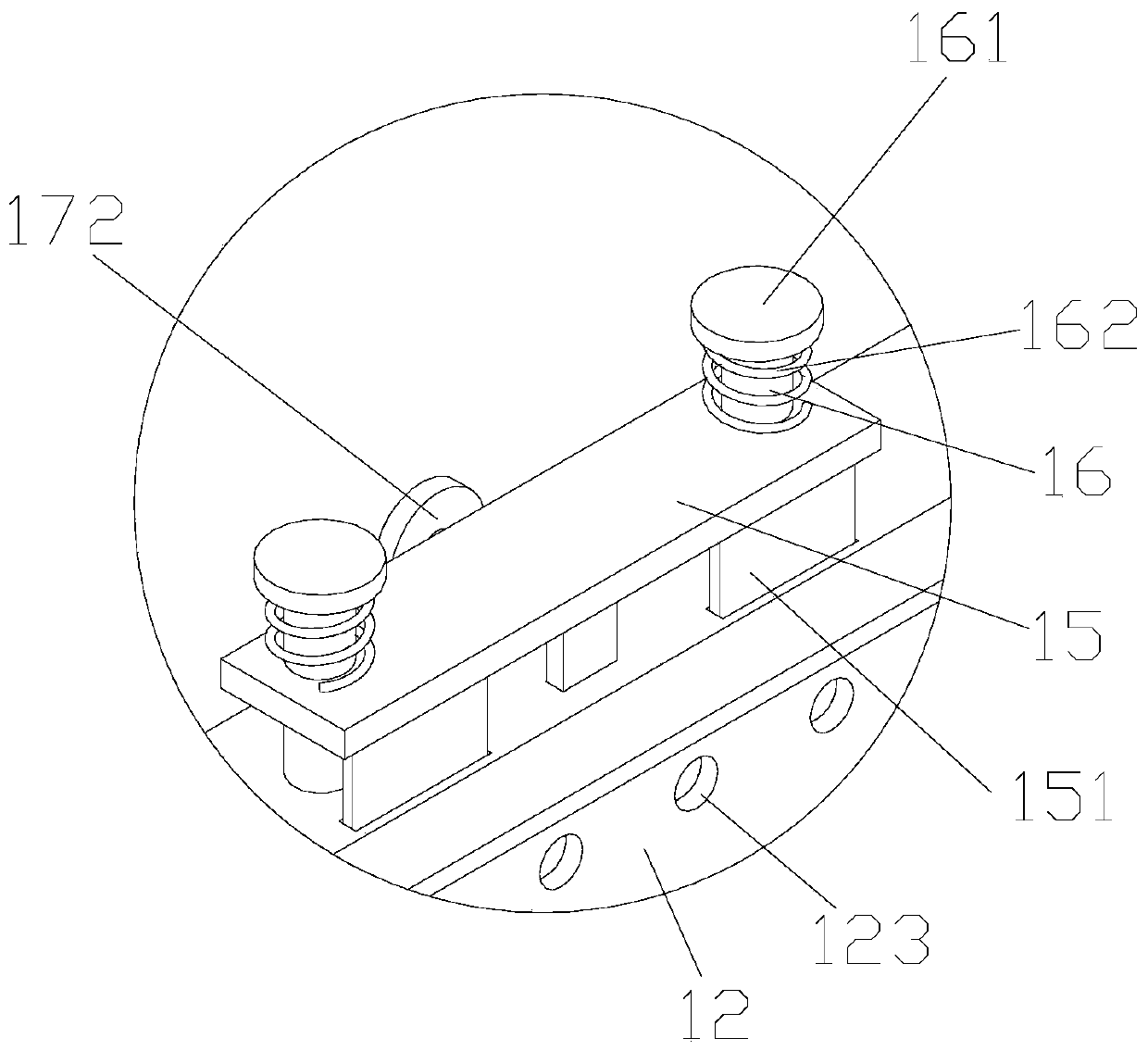

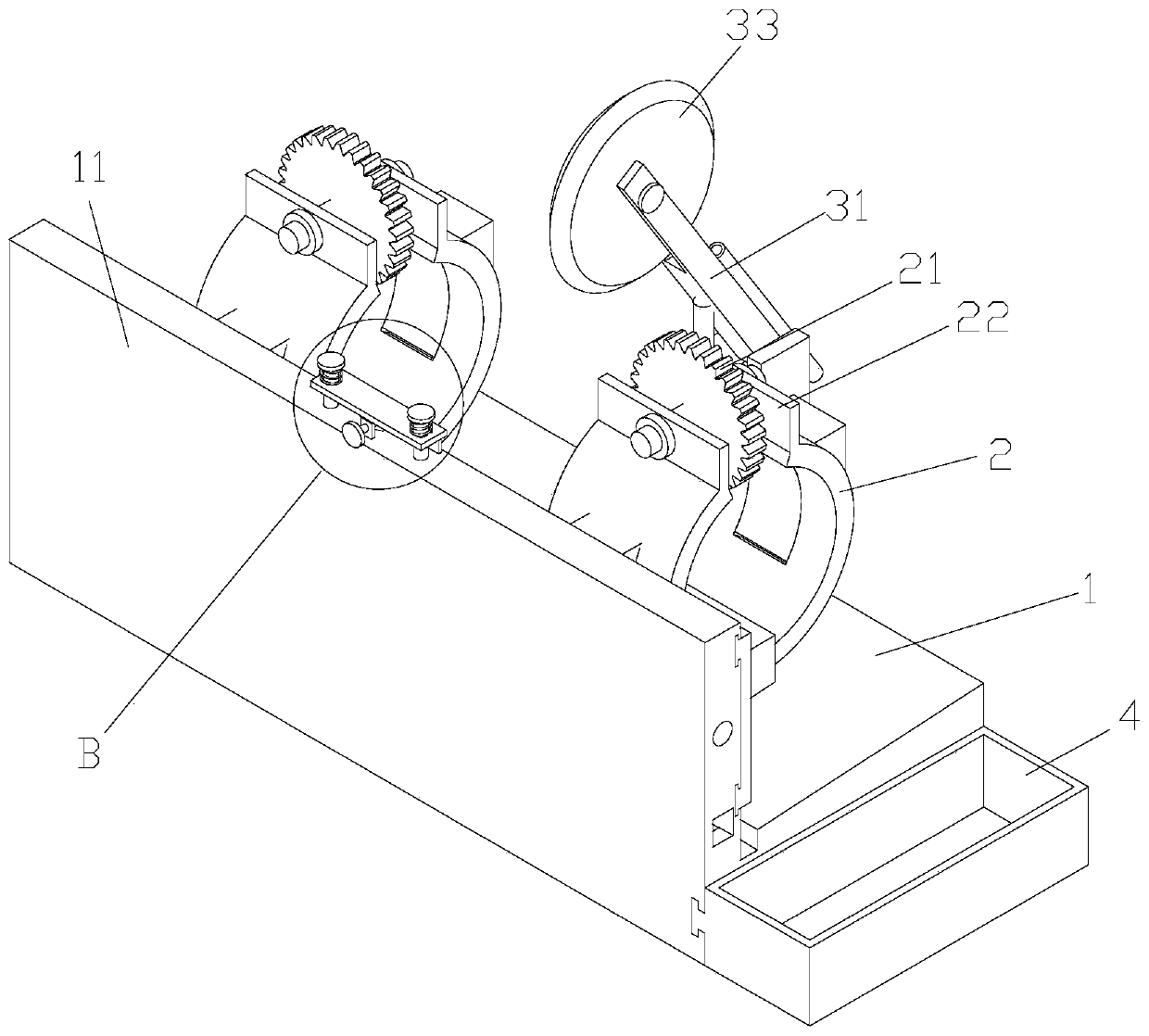

Embodiment 1

[0036] A corrugated pipe processing method, comprising: a. feeding: put raw materials into a vacuum feeder, so that the raw materials are fully mixed in the feeder; b. drying: put the mixed raw materials into a desiccant, Dry the raw materials by means of hot air drying; c. Plasticization: Put the mixed material into the plasticizer to heat and plasticize, so that the raw materials are in a liquid state, and through the mutual cooperation of the extruder and the extrusion die, the liquid The raw material is extruded according to the required shape; d. Forming: Put the extruded raw material into the corrugated pipe forming machine to obtain the corrugated pipe prototype; e. Cooling: Put the corrugated pipe into the spray water tank, The surface is sprayed to keep the surface of the corrugated pipe at room temperature; f. Drying: blow the surface of the corrugated pipe through a fan to dry the moisture on the corrugated pipe; g. Cutting: put the corrugated pipe into the cutting m...

Embodiment 2

[0048] A corrugated pipe processing method, comprising: a. feeding: put raw materials into a vacuum feeder, so that the raw materials are fully mixed in the feeder; b. drying: put the mixed raw materials into a desiccant, Dry the raw materials by means of hot air drying; c. Plasticization: Put the mixed material into the plasticizer to heat and plasticize, so that the raw materials are in a liquid state, and through the mutual cooperation of the extruder and the extrusion die, the liquid The raw material is extruded according to the required shape; d. Forming: Put the extruded raw material into the corrugated pipe forming machine to obtain the corrugated pipe prototype; e. Cooling: Put the corrugated pipe into the spray water tank, The surface is sprayed to keep the surface of the corrugated pipe at room temperature; f. Drying: blow the surface of the corrugated pipe through a fan to dry the moisture on the corrugated pipe; g. Cutting: put the corrugated pipe into the cutting m...

Embodiment 3

[0050] A corrugated pipe processing method, comprising: a. feeding: put raw materials into a vacuum feeder, so that the raw materials are fully mixed in the feeder; b. drying: put the mixed raw materials into a desiccant, Dry the raw materials by means of hot air drying; c. Plasticization: Put the mixed material into the plasticizer to heat and plasticize, so that the raw materials are in a liquid state, and through the mutual cooperation of the extruder and the extrusion die, the liquid The raw material is extruded according to the required shape; d. Forming: Put the extruded raw material into the corrugated pipe forming machine to obtain the corrugated pipe prototype; e. Cooling: Put the corrugated pipe into the spray water tank, The surface is sprayed to keep the surface of the corrugated pipe at room temperature; f. Drying: blow the surface of the corrugated pipe through a fan to dry the moisture on the corrugated pipe; g. Cutting: put the corrugated pipe into the cutting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com