Ultrasonic cleaning machine used for edible vegetable oil production

An edible vegetable oil and ultrasonic technology, which is applied in the production of fat oil/fat, the cleaning method of using liquid, and the generation of fat, etc., can solve the problems of inability to absorb and remove metal impurities, no ultraviolet disinfection lamp, and inability to be sterilized by cleaning materials, etc. , to avoid the reduction of material purity, reduce cumbersomeness, and facilitate cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

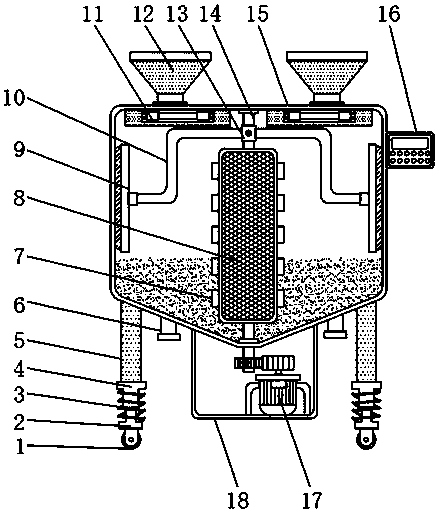

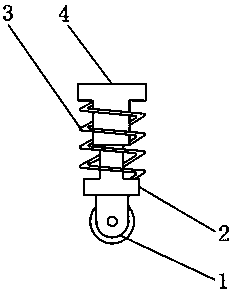

[0021] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, an ultrasonic cleaning machine for edible vegetable oil production, comprising an ultrasonic cleaning machine body 15 and a support 10, a side of the ultrasonic cleaning machine body 15 is provided with a PLC controller 16, and the ultrasonic cleaning machine The top of the body 15 is provided with a feed inlet 12, the bottom of the ultrasonic cleaning machine body 15 is provided with a discharge port 6, and the inside of the ultrasonic cleaning machine body 15 is provided with a rotating shaft 14, and the bottom of the ultrasonic cleaning machine body 15 is close to the discharge port. A protective cover 18 is provided at one side of the mouth 6, and a support rod 5 is provided at the bottom end of the ultrasonic cleaning machine body 15 close to the other side of the discharge port 6, and the inner top of the ultrasonic cleaning machine body 15 is close to the side of the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com