Precoating glue table tennis bat series glue and manufacturing method thereof

A table tennis racket and the technology of its manufacturing method are applied in the direction of rackets, sports accessories, etc., which can solve the problems of slow drying speed of water-based glue, hazards to health and the environment, and inconvenient pasting on site, and achieve the effects of convenient portability, convenient use, and convenient pasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

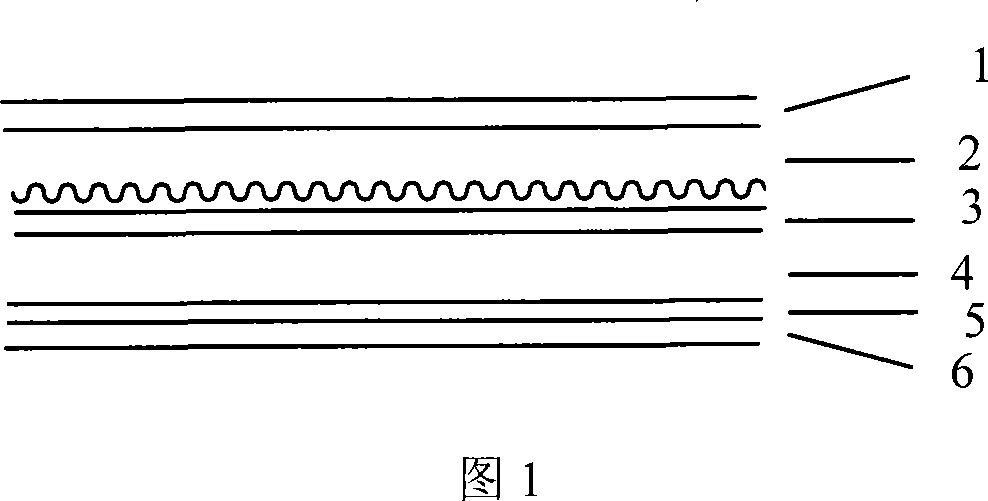

[0023] Apply a layer of N-1 solvent natural rubber pressure-sensitive adhesive on the rubber sponge of the traditional table tennis racket, control the thickness of the dry film to about 10 μm, and pass through a drying tunnel at about 80°C for about 60 seconds to remove the organic solvent, and then apply it on the pressure-sensitive adhesive. A piece of 60g glassine release paper is pasted on the surface of the table tennis racket to obtain the pre-coated table tennis racket cover glue of the present invention.

Embodiment 2

[0025] Apply a layer of S-792 solvent styrene-butadiene rubber pressure-sensitive glue on the sponge of the traditional table tennis racket rubber, control the thickness of the dry film to about 18 μm, and pass through the drying tunnel at about 80°C for about 60 seconds to remove the organic solvent, and then apply the pressure-sensitive adhesive Paste one piece of 52g kaolin coated release paper on the surface of the glue, then obtain the pre-coated table tennis racket cover glue of the present invention.

Embodiment 3

[0027] Apply a layer of S-6201 solvent-butadiene rubber pressure-sensitive glue on the rubber sponge of the traditional table tennis racket, control the thickness of the dry film to about 25 μm, and pass through a drying tunnel at about 80°C for about 80 seconds to remove the organic solvent, and then apply the pressure-sensitive adhesive Paste one piece of 80g glassine release paper on the surface of the glue, then obtain the pre-coated table tennis racket cover glue of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com