Pasting method of microwave oven glass door

A technology for glass doors and microwave ovens, applied in the direction of furnace/stove doors, etc., can solve the problems of reduced productivity, the door cover cannot be quickly entered, and the time required for single-component silica gel to cure is long, so as to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment.

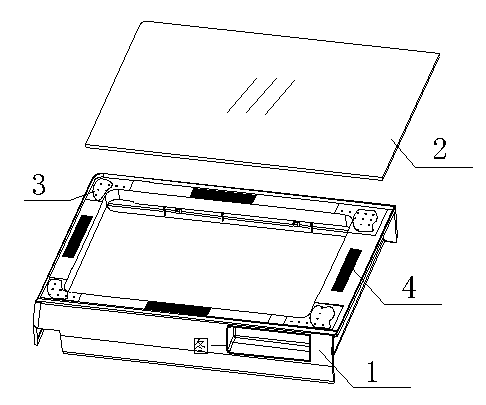

[0010] Such as figure 1 The structure schematic diagram when the present invention pastes as shown, comprises door cover 1, is coated with single-component silica gel 3 on the four corners of the panel of door cover 1, sticks pressure-sensitive adhesive tape 4 in the middle of the four sides of panel , and then paste the glass door 1 on the panel, and the glass door 2 can be quickly pasted on the door cover 1 through the pressure-sensitive adhesive tape 4. Using the strong initial adhesion of the pressure-sensitive adhesive tape, the glass is glued before the single-component silica gel 3 is cured. The door is pasted on the door cover and reaches a certain sticking strength, so that the pasted door cover 1 can directly enter the production line. After 24 hours, the one-component silica gel is completely cured. At this time, the main adhesive force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com