Digitalized making method of dental orthodontic appliance and fixed appliance

A technology of appliances and teeth, applied in dentistry, orthodontics, orthodontics, etc., can solve the problems of increased treatment risk, tooth movement, heavy workload, etc., so as to reduce treatment time and hospital return visits, and maintain orthodontics. Distortion correction force, effect of reducing difficulty and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

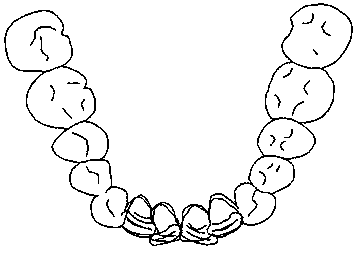

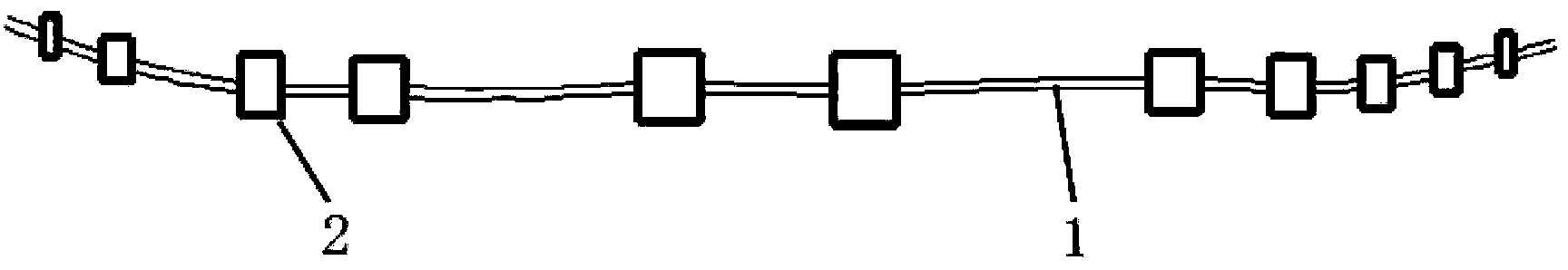

[0026] Refer to attached Figure 1-4 :

[0027] The manufacturing method of the orthodontic appliance of the present invention comprises the following manufacturing steps:

[0028] 1) CT data acquisition: take CT images of the patient's oral cavity. CT scans can be performed with spiral CT at a scanning interval of no more than 1 mm, or dental cone-beam CT (CBCT) with a middle field of view and above, to ensure Capable of scanning the patient's infraorbital rim to the complete mandible. Save the scanned results with standard medical image format DICOM files.

[0029] 2) Reconstruction of 3D model of oral tissue: Input the medical image of CT scan into medical image processing and 3D reconstruction software such as MIMICS to reconstruct the patient's oral cavity model, including teeth and alveolar bone. In order to obtain each individual tooth, the root of the tooth is separated from the entire image during image processing to obtain a complete tooth including the crown and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com