Cover layer seal film for strain gauge, and production method and using method thereof

A strain gauge and sealing film technology, which is applied in the field of cover sealing film for strain gauges, can solve problems such as unstable quality, poor product consistency, and low manual production efficiency, and achieve improved dimensional consistency, high production efficiency, and pasting accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a preparation method of the cover sealing film for the above-mentioned strain gauge, comprising the following steps:

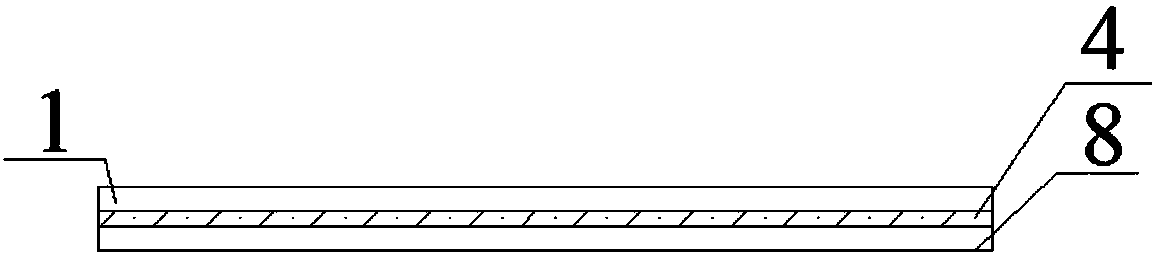

[0042] Step S1, coating the adhesive layer 4 on the surface of the sealing layer of the strain gauge cover layer 1, curing it at 60-120°C for 0.5-4h, pasting the cover layer release paper 8 on the adhesive layer to obtain the following: figure 2 The complete overlay seal film shown, then a number of marking points are made on the strain gage overlay 1.

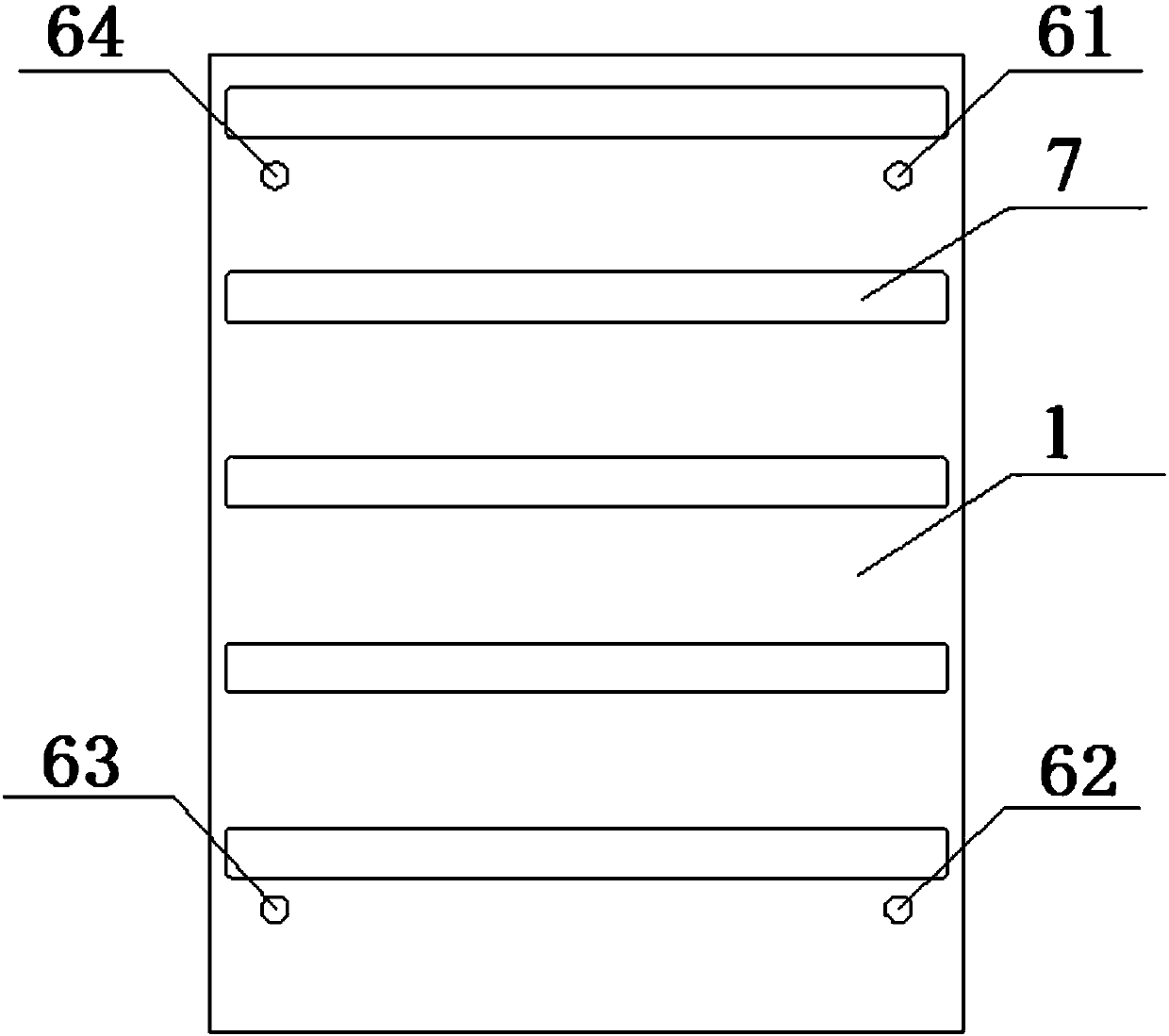

[0043] Step S2, cutting off the position of the strain gauge cover layer 1 and the corresponding strain gauge pad 2 by mechanical or laser means, so that the position is hollowed out, and the following is obtained: image 3 and 7 The cap layer sealing film after hollowing out is shown as the cap layer sealing film; the precision of cutting is ±0.03mm.

[0044] For the convenience of storage and use, the cover seal film is made into a roll.

[0045] Preferably, the curing tempe...

Embodiment 1

[0054] Such as figure 2 As shown, firstly, a complete cover sealing film not larger than 110×250mm is prepared, and then the corresponding position on the cover sealing film is cut mechanically or by laser according to the shape and size of the corresponding strain gauge pad 2, and at the same time, the The four corner positions of the sealing film are cut to obtain marking points, forming such as image 3 As shown in the hollowed out structure, then use the cover layer fake sticking machine to identify the marking points on the cover layer sealing film and the strain gauge substrate 3 respectively, and then make them correspond one by one, such as image 3 and 4 As shown, the specific strain gauge base marking point A51 corresponds to the strain gauge cover layer marking point A61, the strain gauge base marking point B52 corresponds to the strain gauge cover layer marking point B62, and the strain gauge base marking point C53 corresponds to the strain gauge cover layer mark...

Embodiment 2

[0056] First, a complete cover sealing film not larger than 110×250mm is prepared, and then the corresponding position on the cover sealing film is cut mechanically or by laser according to the shape and size of the corresponding strain gauge pad 2, and at the same time, the cover sealing film The four corner positions of are cut to obtain marked points, forming such as Figure 7 As shown in the hollowed out structure, then use the cover layer fake sticking machine to identify the marking points on the cover layer sealing film and the strain gauge substrate 3 respectively, and then make them correspond one by one, such as Figure 7 and 8 As shown, the specific strain gauge base marking point A51 corresponds to the strain gauge cover layer marking point A61, the strain gauge base marking point B52 corresponds to the strain gauge cover layer marking point B62, and the strain gauge base marking point C53 corresponds to the strain gauge cover layer marking point Corresponding to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com