End seal main machine

An end-sealing and host technology, which is applied in the field of equipment for sealing the ends of steel-plastic composite pipes, can solve the problems of reducing production efficiency, increasing operator burden, and laboriousness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

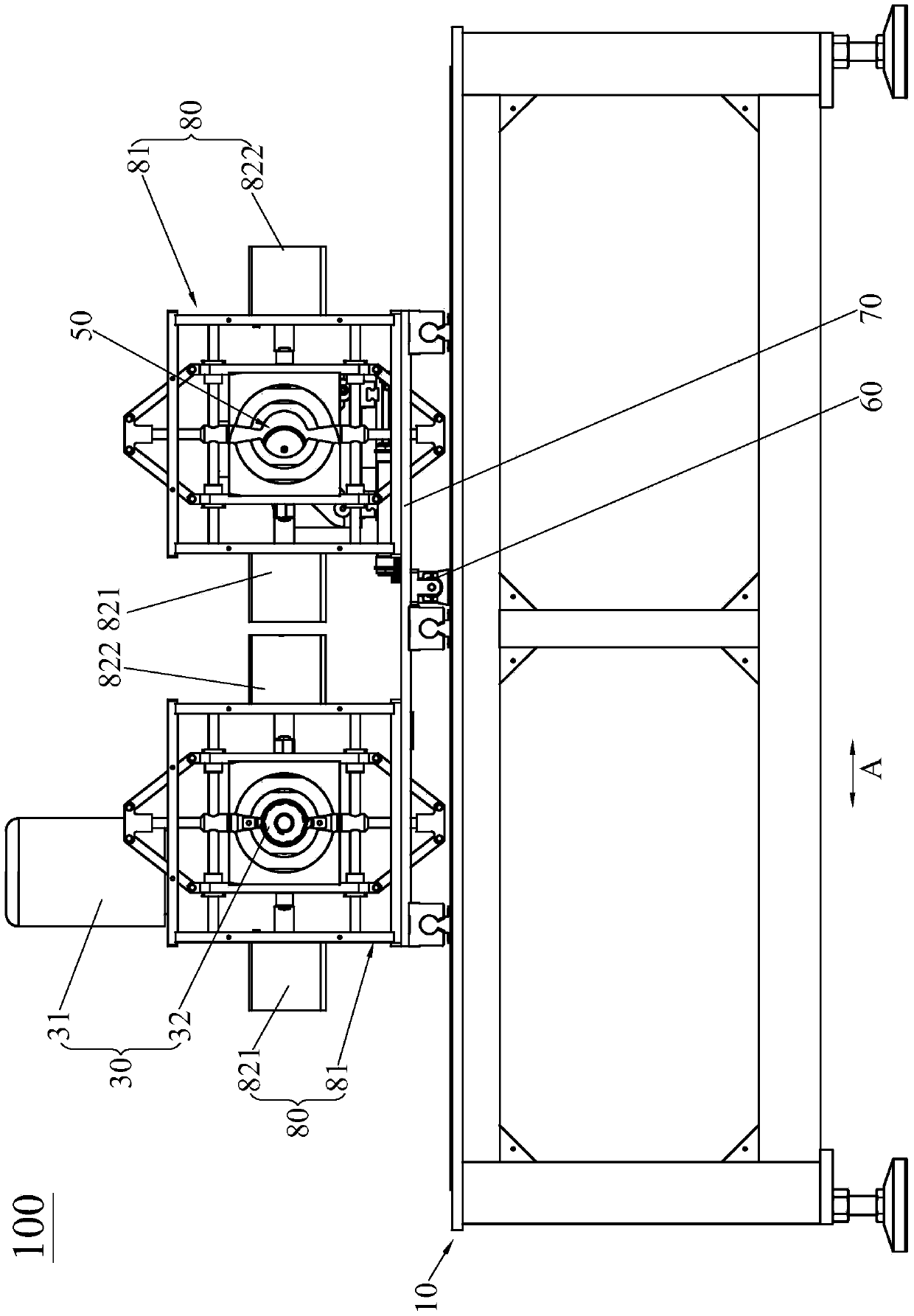

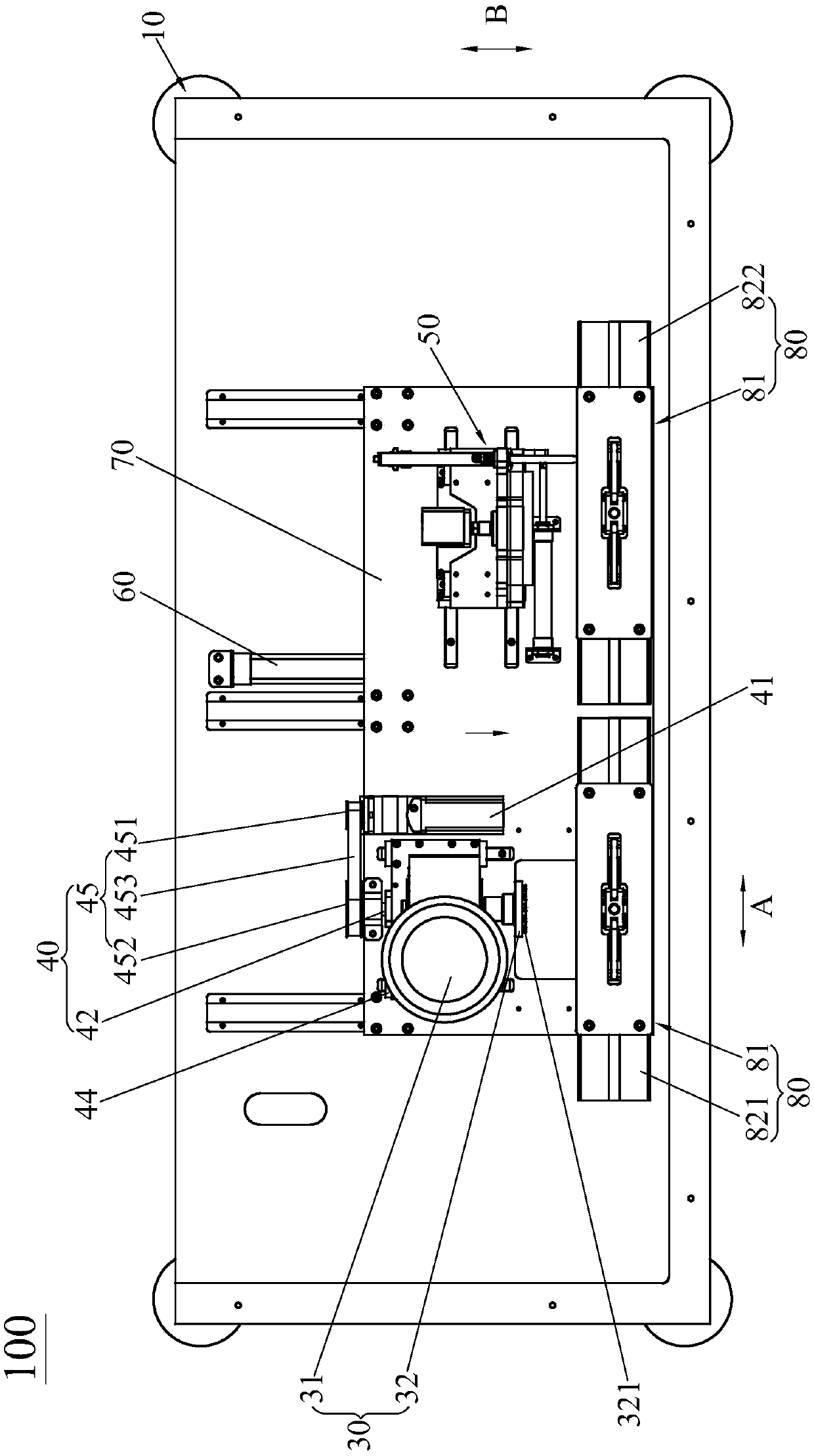

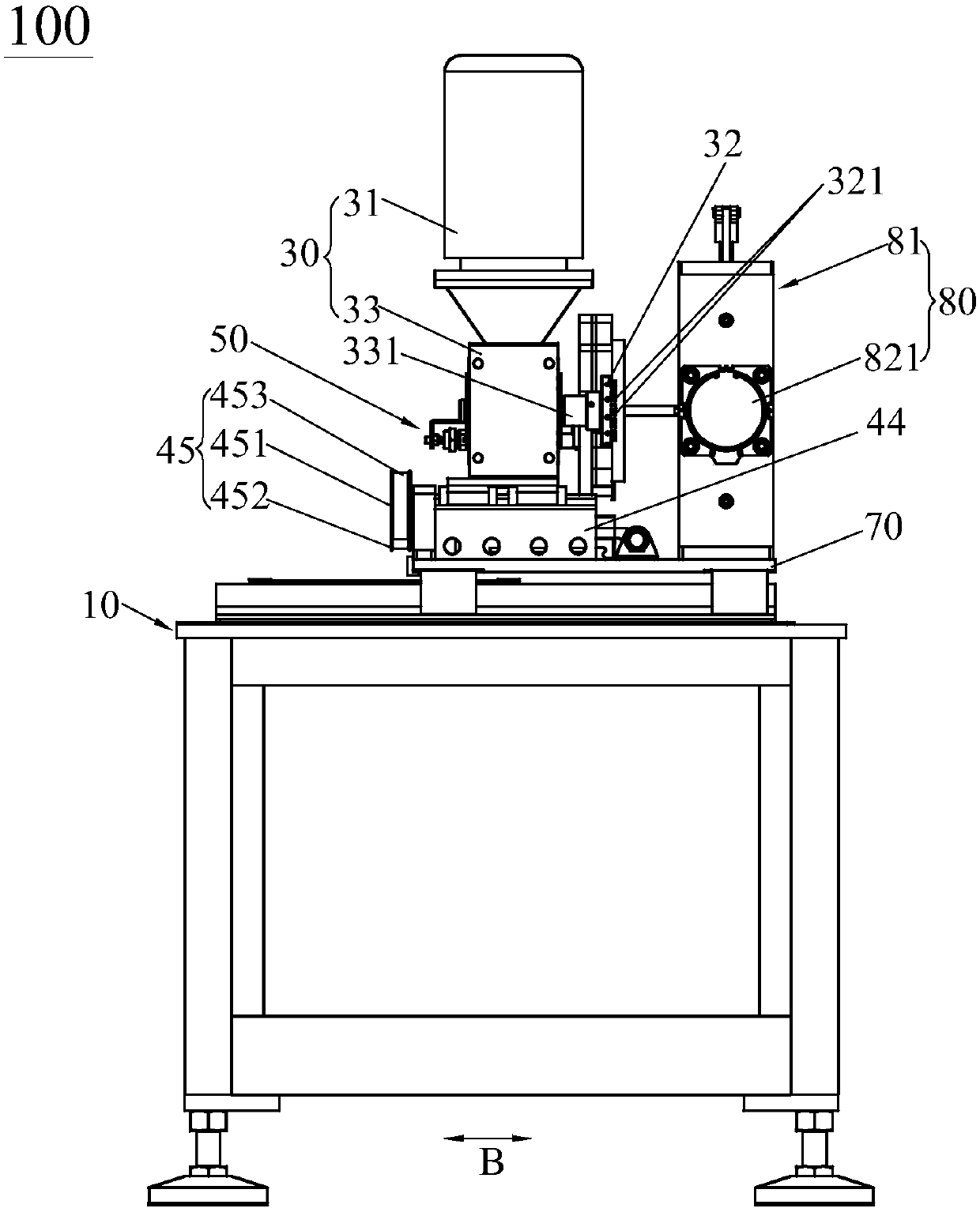

[0028] see Figure 1 to Figure 3 , the end sealing main machine 100 of the present invention is suitable for sealing the end of the steel-plastic composite pipe 200, so as to cut off the middle steel belt layer 220 in the end of the steel-plastic composite pipe 200 to a predetermined depth (the depth is flexible according to actual conditions) set), so that the end of the steel-plastic composite pipe 200 forms an annular recessed space 230 (see Figure 8a shown) and heat-melt the inner and outer plastic layers 210 to fill the recessed structure 230 (see Figure 8bshown), so as to realize the sealing of the end of the steel-plastic composite pipe 200. Wherein, the end sealing machine 100 of the present invention includes a frame 10 , a flat end device 30 , a fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com