Linear glue spreading machine and linear composite glue flake spreading machine

A gluing machine and gluing sheet technology, which is applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of low efficiency, weak bonding of gluing sheets, high labor costs, etc., to reduce costs, not easy to crack, and combine film firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

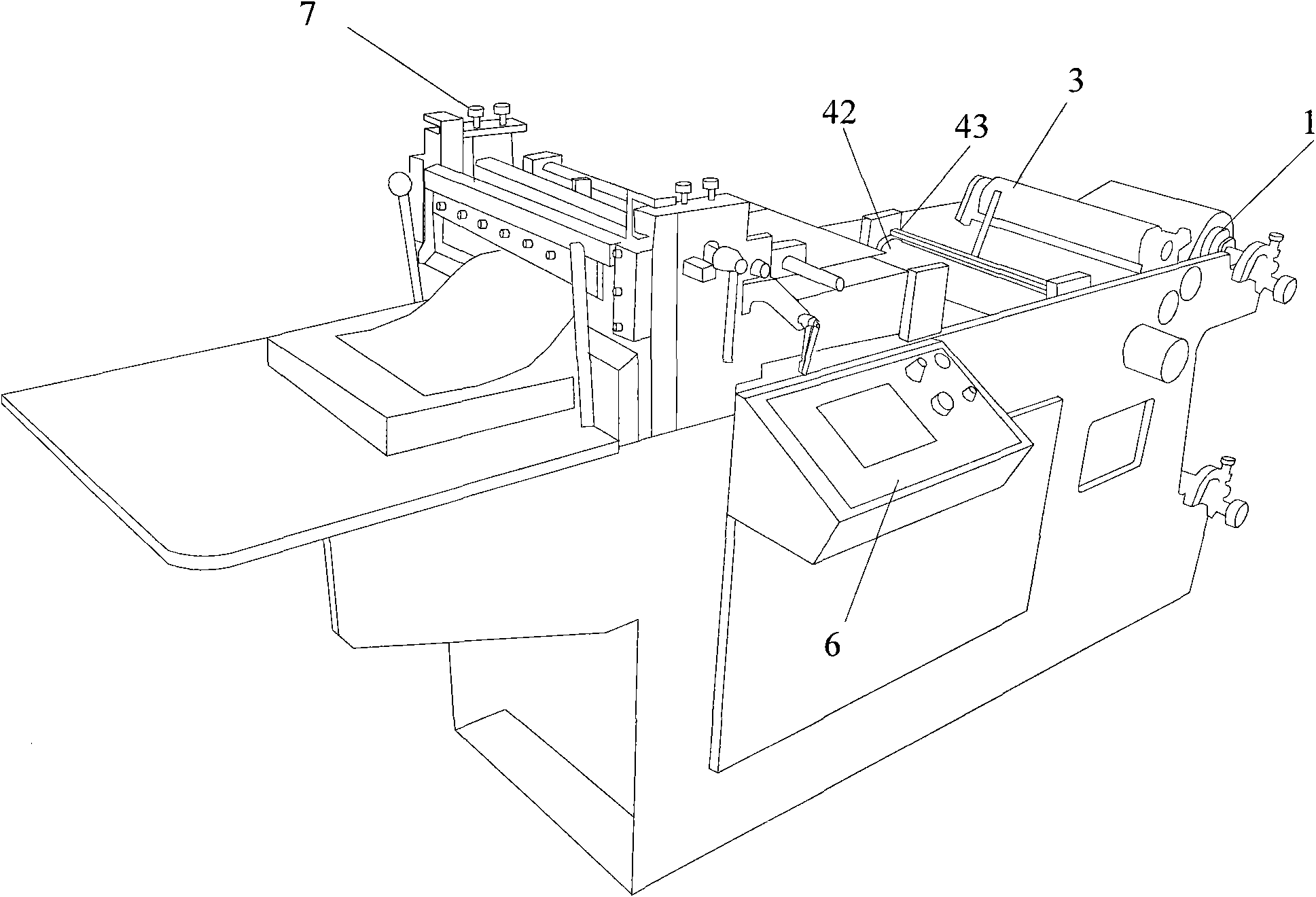

[0026] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

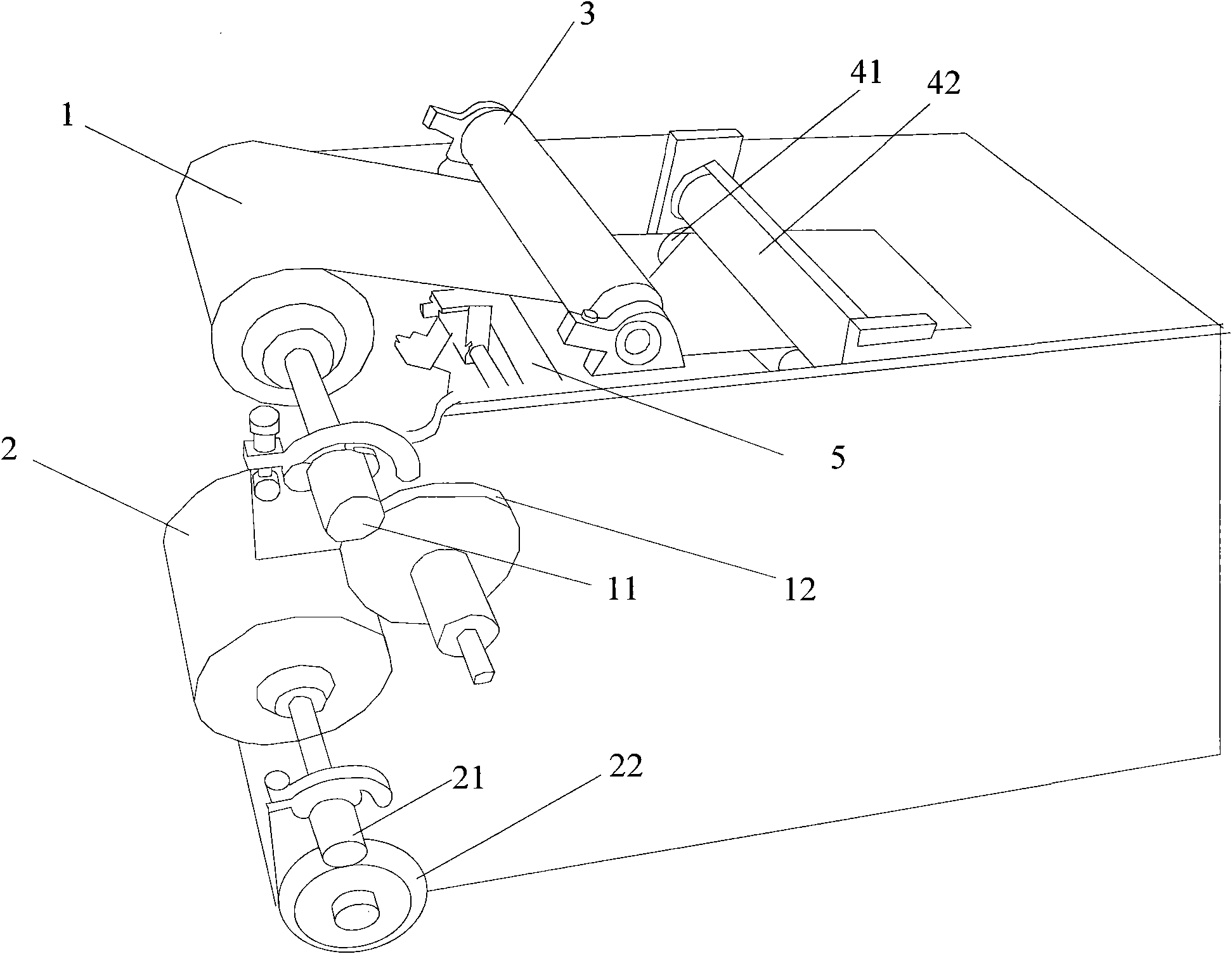

[0027] see figure 1 , figure 1 It is the structural diagram of the embodiment of the linear gluing machine. The motor in the frame drives the rotating shaft 1 coiled around the first polyester film through the transmission gear 11 and the transmission gear 12, and drives the coiled second polyester film through the transmission gear 21 and the transmission gear 22. The axis 2 of the membrane rotates. After the first polyester film is glued by the gluing device 5, it is compacted and pasted with the second polyester film by the roller 41 and the pressing roller 42.

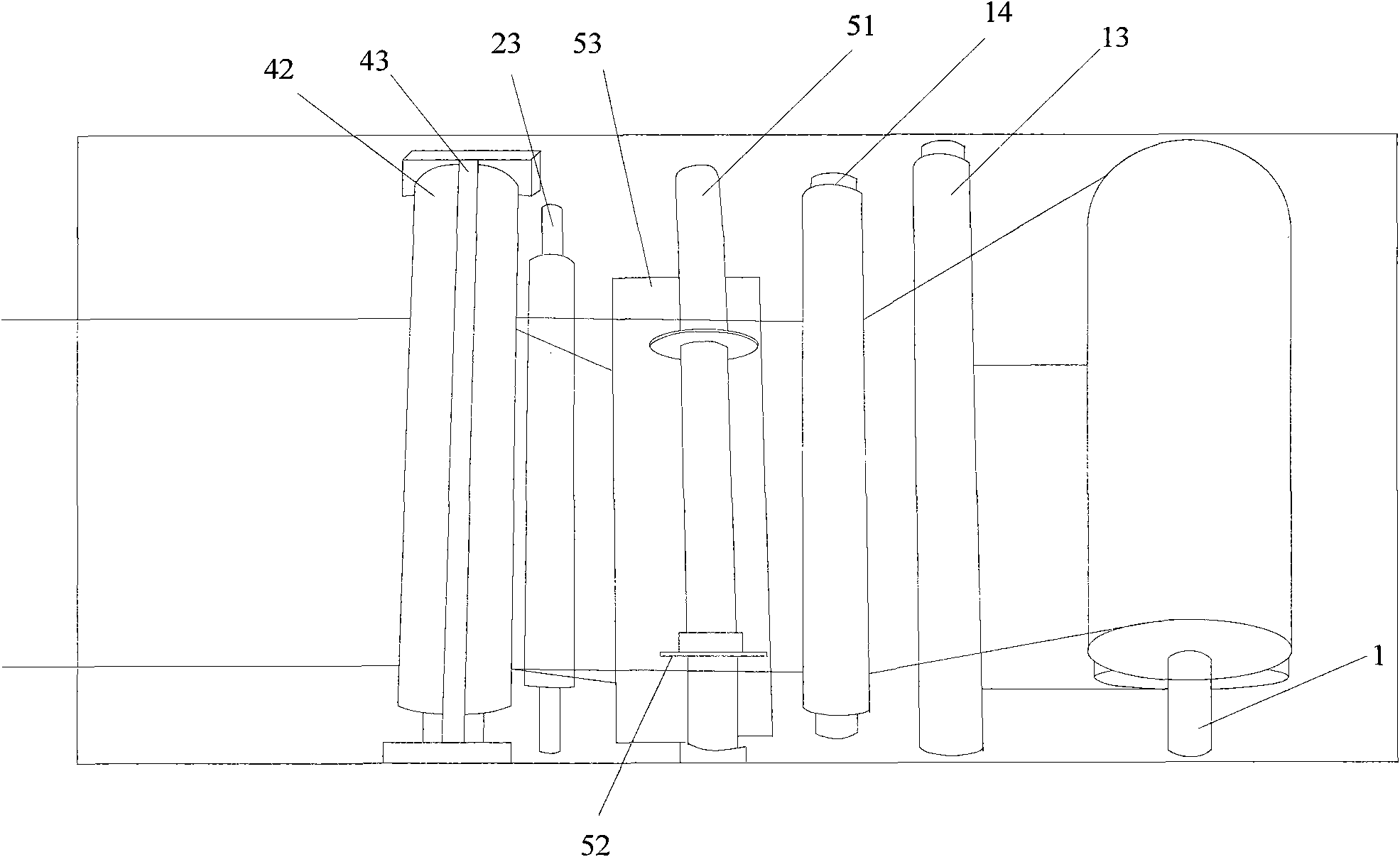

[0028] see figure 2 , the first polyester film passes through the rotation of the positioning rotating shaft 13 and the positioning rotating shaft 14, and passes through the top of the gluing device 5. The gluing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com