Label pasting device for logistics packaging

A technology for label sticking and packaging, applied in the field of label sticking equipment for logistics packaging, can solve the problems of weak sticking, low label sticking efficiency, and inability to automatically unload materials, and achieve the effect of speeding up the sticking speed, improving the speed and good sticking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

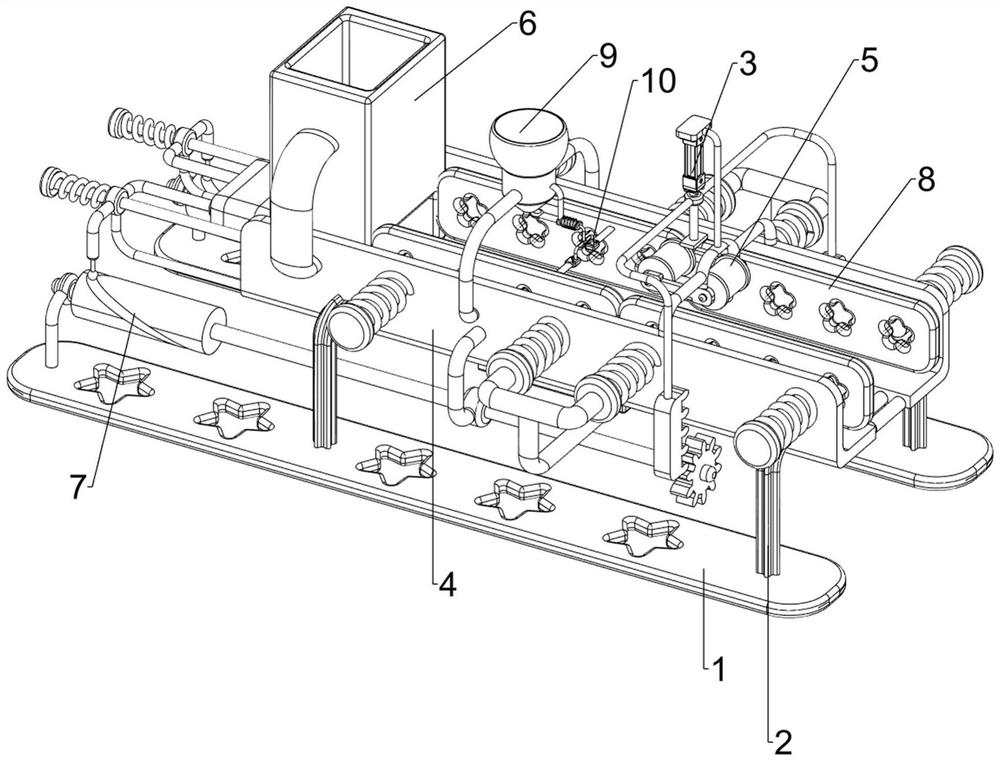

[0070] A label sticking equipment for logistics packaging, such as figure 1As shown, it includes a base plate 1, a first support frame 2, a cylinder 3, a transmission mechanism 4 and a pressing mechanism 5. The two base plates 1 are provided with four first support frames 2, and the inner sides of the upper parts of the four first support frames 2 A transmission mechanism 4 is provided, and the right side of the top of the transmission mechanism 4 is provided with a pressing mechanism 5, and a cylinder 3 is installed on the top of the pressing mechanism 5.

[0071] When people put labels on express boxes, the speed is relatively slow. The present invention helps people increase the speed of labeling. Place the express box on the conveying mechanism 4 and push it to the right. When the express box is located below the pressing mechanism 5, start the cylinder 3, and 3 Drive the pressing mechanism 5 to run, and the pressing mechanism 5 sticks the label on the express box. After t...

Embodiment 2

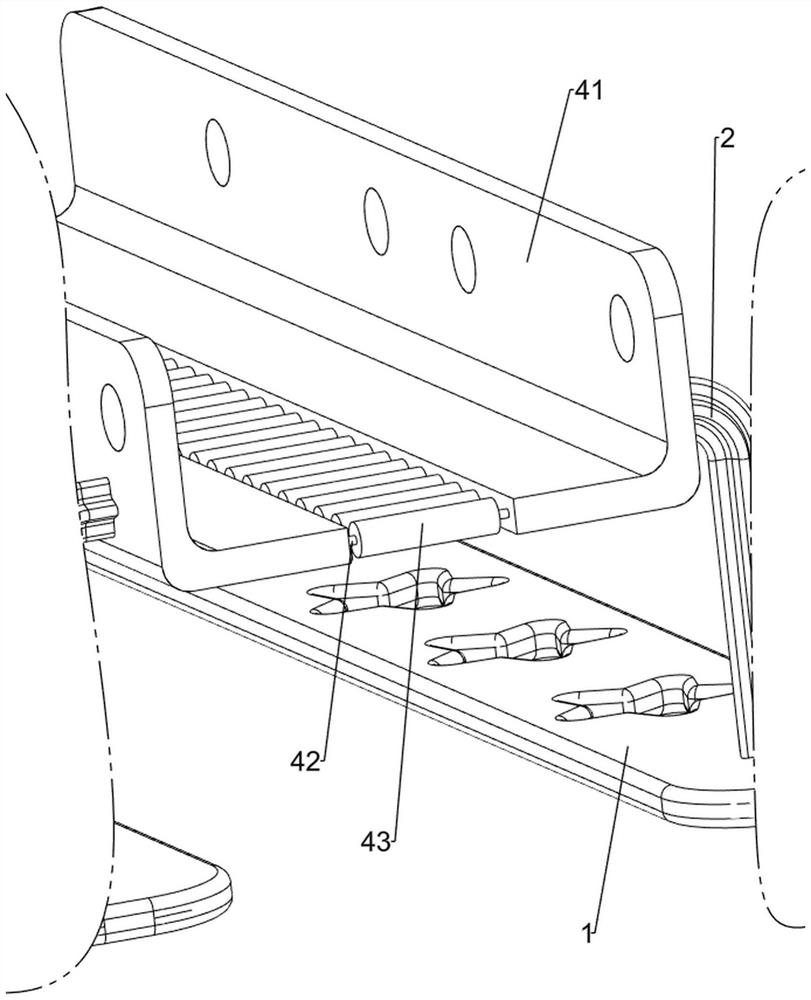

[0073] On the basis of Example 1, such as figure 2 and image 3 As shown, the transmission mechanism 4 includes a second support frame 41, a first rotating shaft 42 and a roller 43. The inner side of the upper part of the first support frame 2 on the front and rear sides is connected with the second support frame 41, and the second support frame 41 on the front and rear sides A first rotating shaft 42 is arranged on the inner side of the lower part to uniformly rotate, and a drum 43 is arranged in the middle of the first rotating shaft 42 .

[0074] When the express box needs to be transported, the express box is placed in the second support frame 41 and pushed to the right. During the pushing process, due to the friction force, the express box drives the roller 43 to rotate, so that the first rotating shaft 42 rotates, and when the express box is stopped , just stop pushing the express box, and repeat the above steps when using the device again.

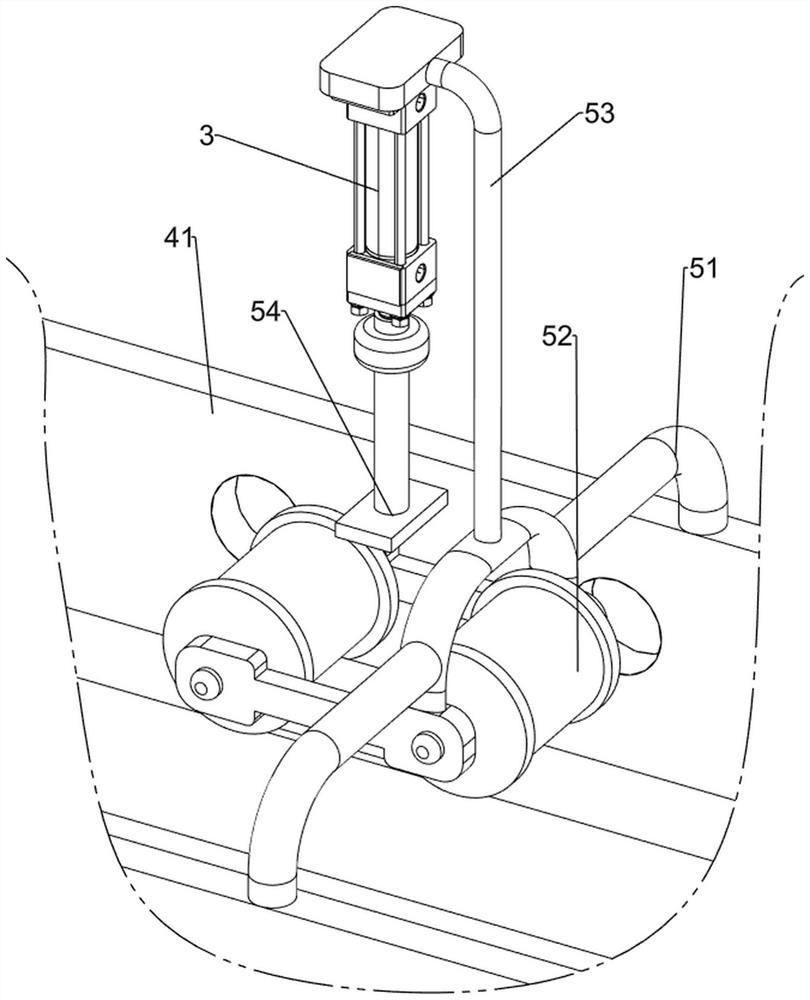

[0075] Press down mechani...

Embodiment 3

[0078] On the basis of Example 2, such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, it also includes a blanking mechanism 6. The left side of the transmission mechanism 4 is provided with a blanking mechanism 6. The blanking mechanism 6 includes a blanking frame 61, a slide bar 62, a push block 63 and a first spring 64. The left part of the second support frame 41 is provided with a blanking frame 61, and the lower part of the left side of the blanking frame 61 is provided with two slide bars 62, and the slide bar 62 middle part of the front and rear sides is slidingly provided with a push block 63, and the push block 63 is connected to the The blanking frame 61 cooperates, and the left side of the slide bar 62 is wound with a first spring 64 , and the first spring 64 is connected with the slide bar 62 and the push block 63 .

[0079] People can place all the express delivery in the blanking frame 61. Due to gravity, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com