Patents

Literature

35results about How to "Adjust the moving distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

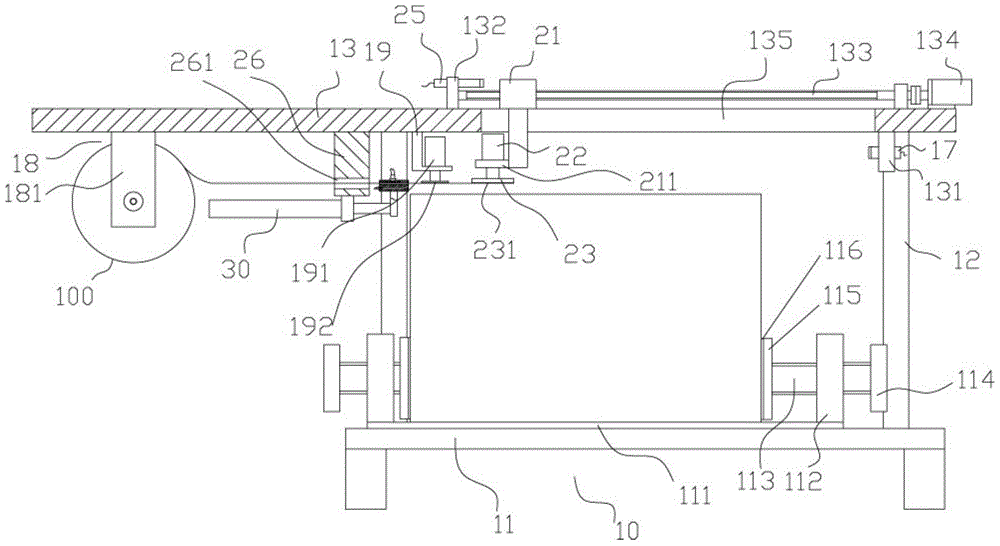

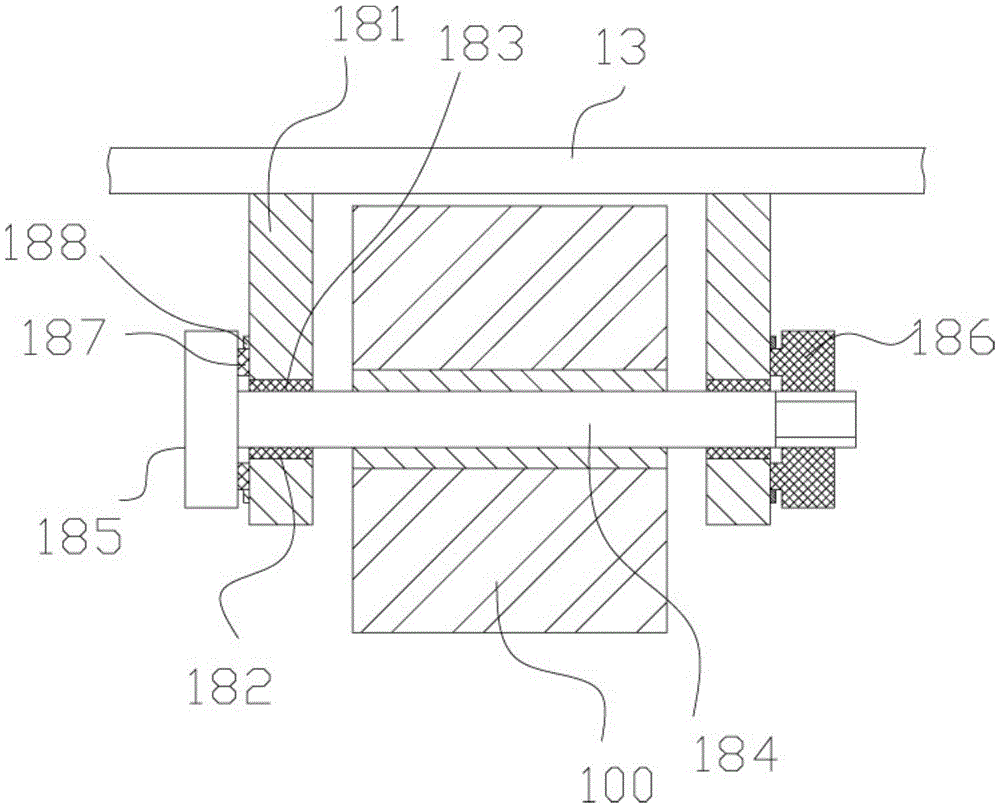

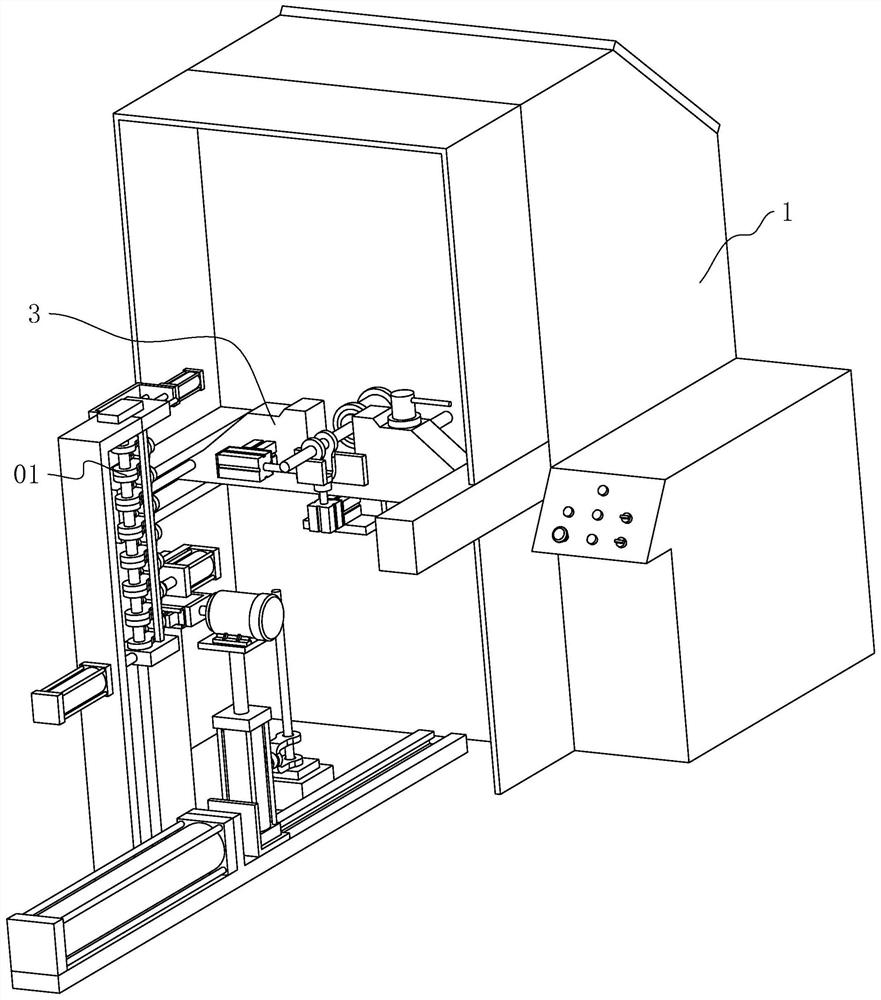

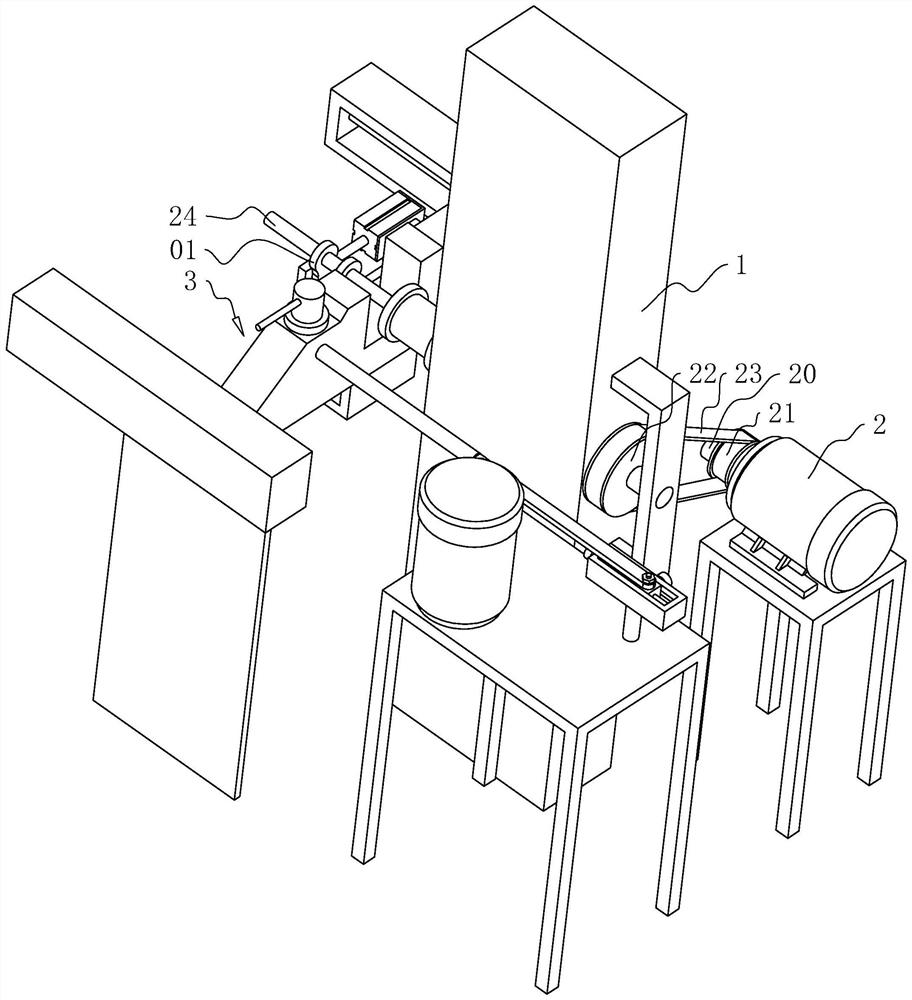

Position adjustable packing case adhesive tape sealing device

ActiveCN105000223AMeet the needs of pastingAdjust the moving distanceWrapper twisting/gatheringCouplingDrive motor

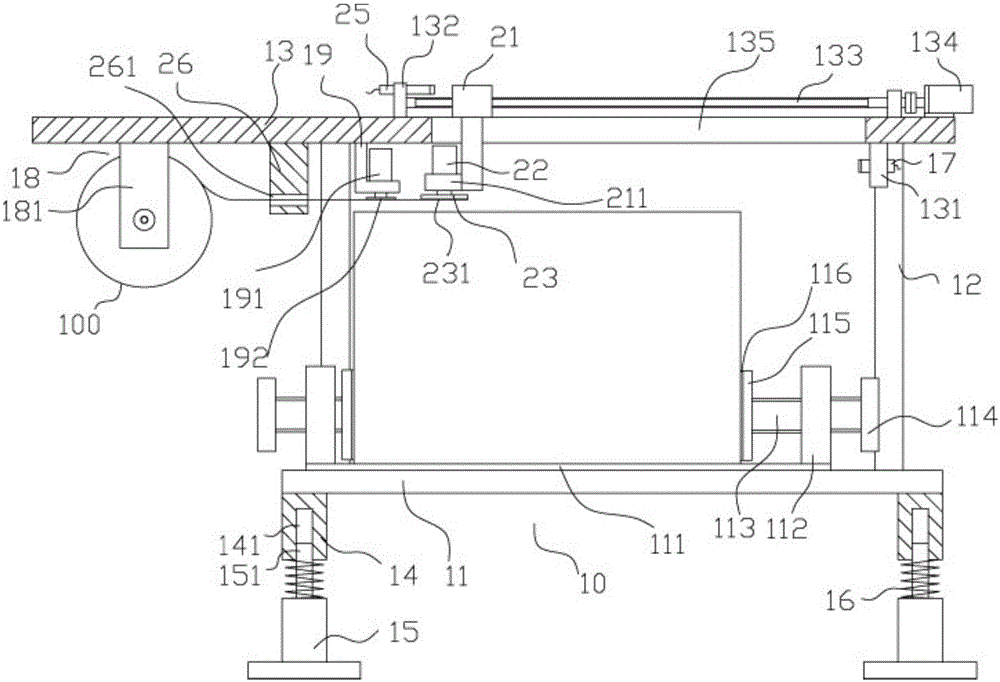

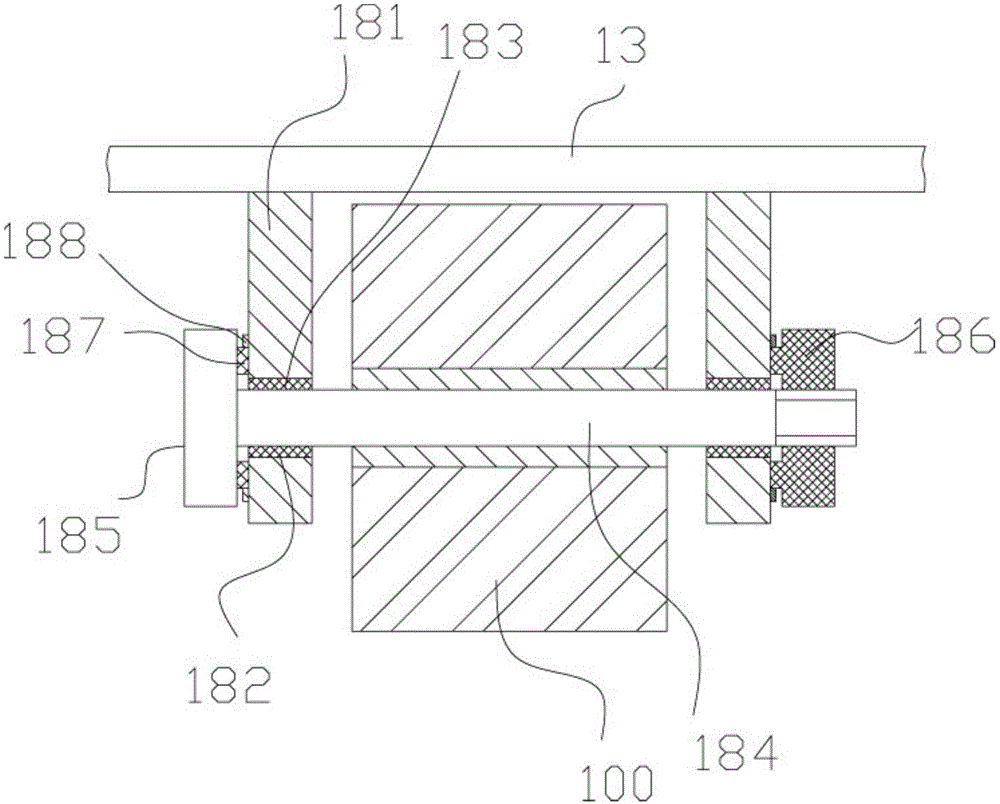

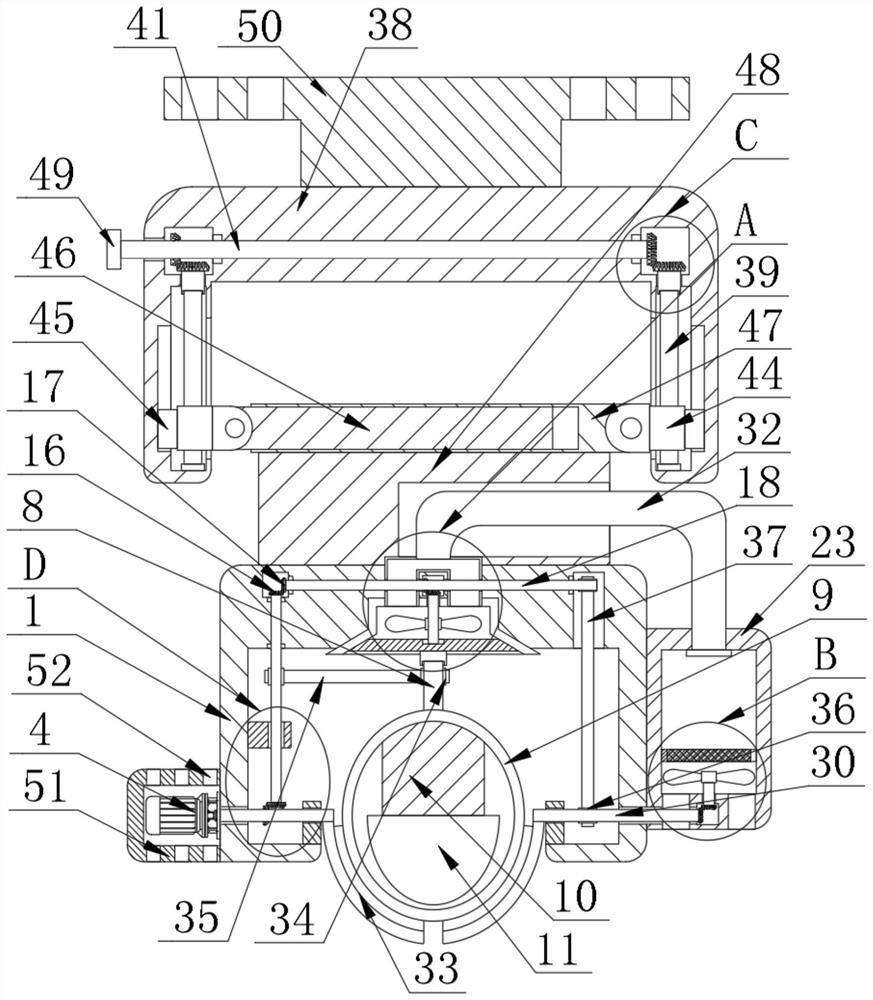

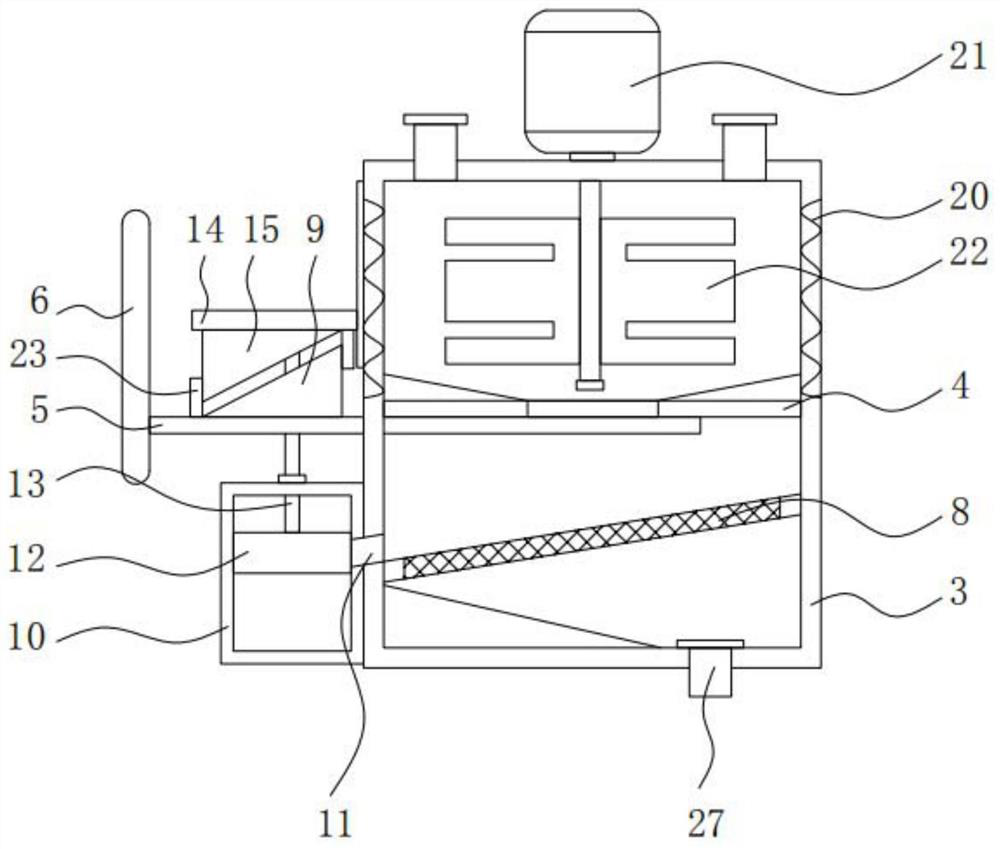

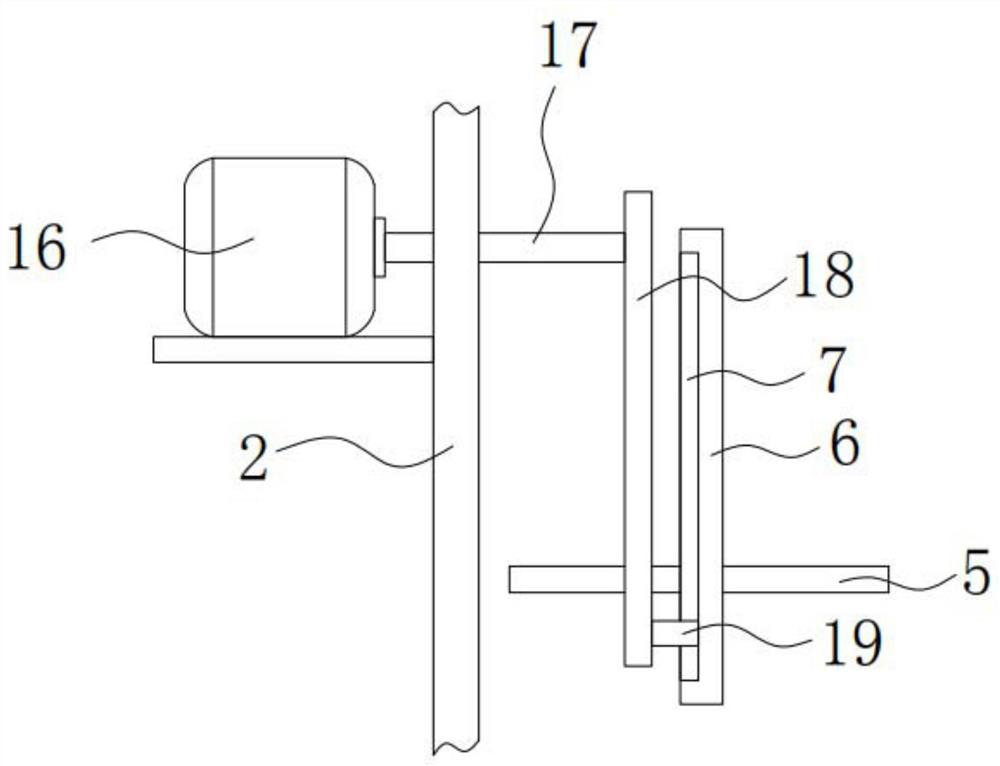

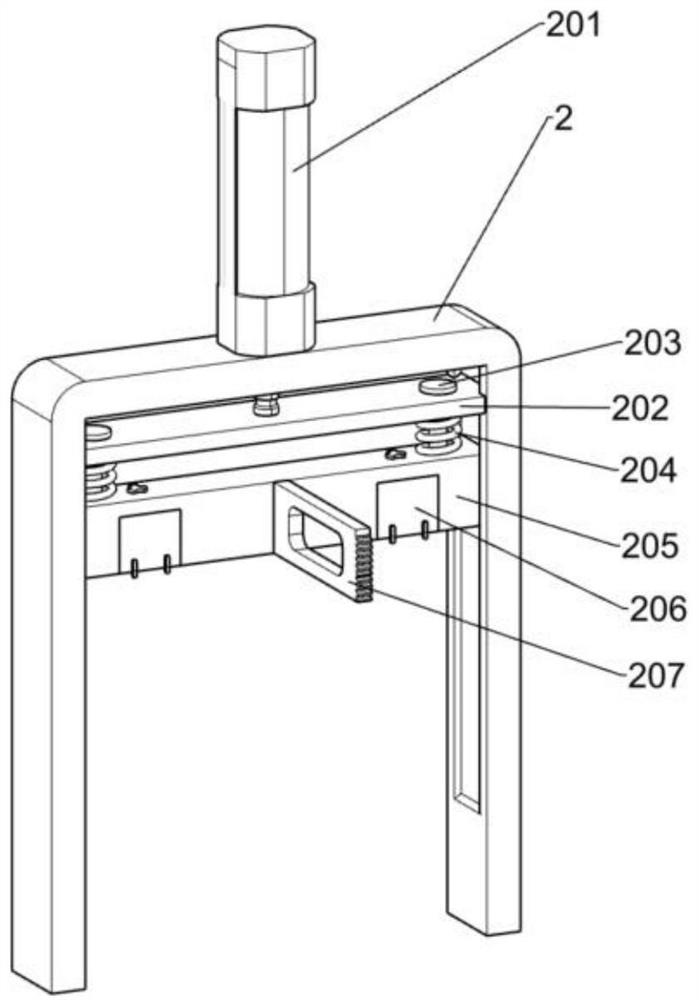

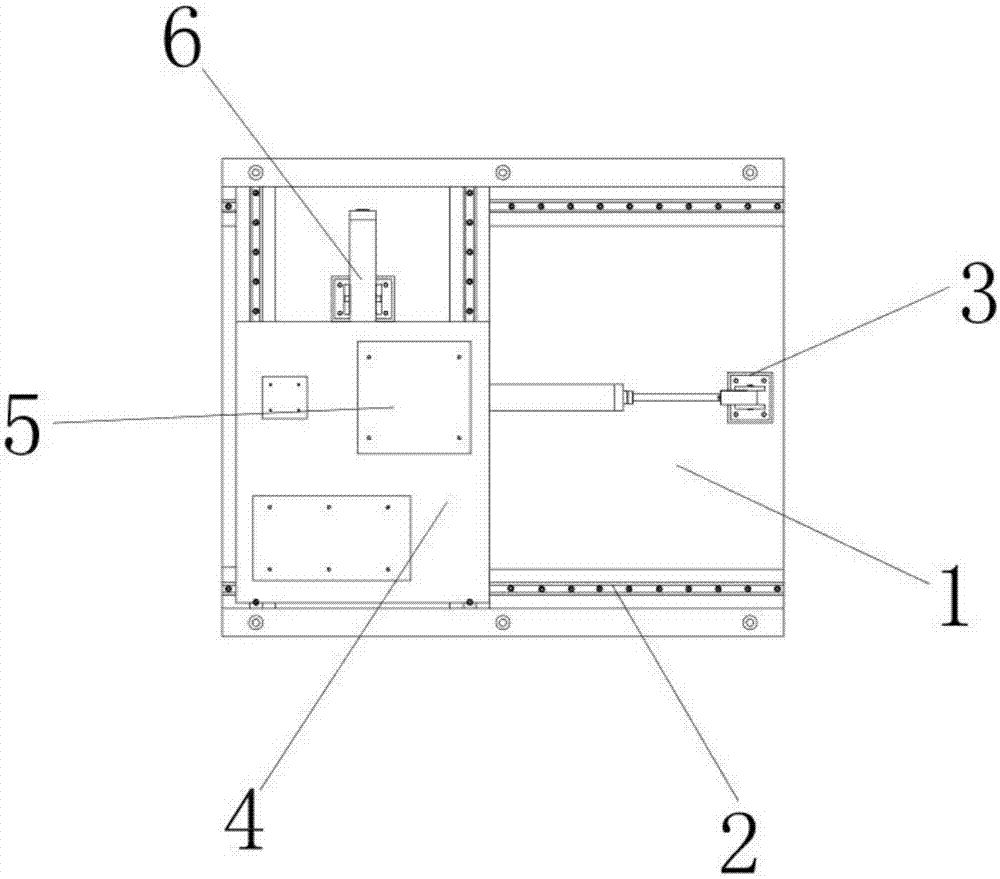

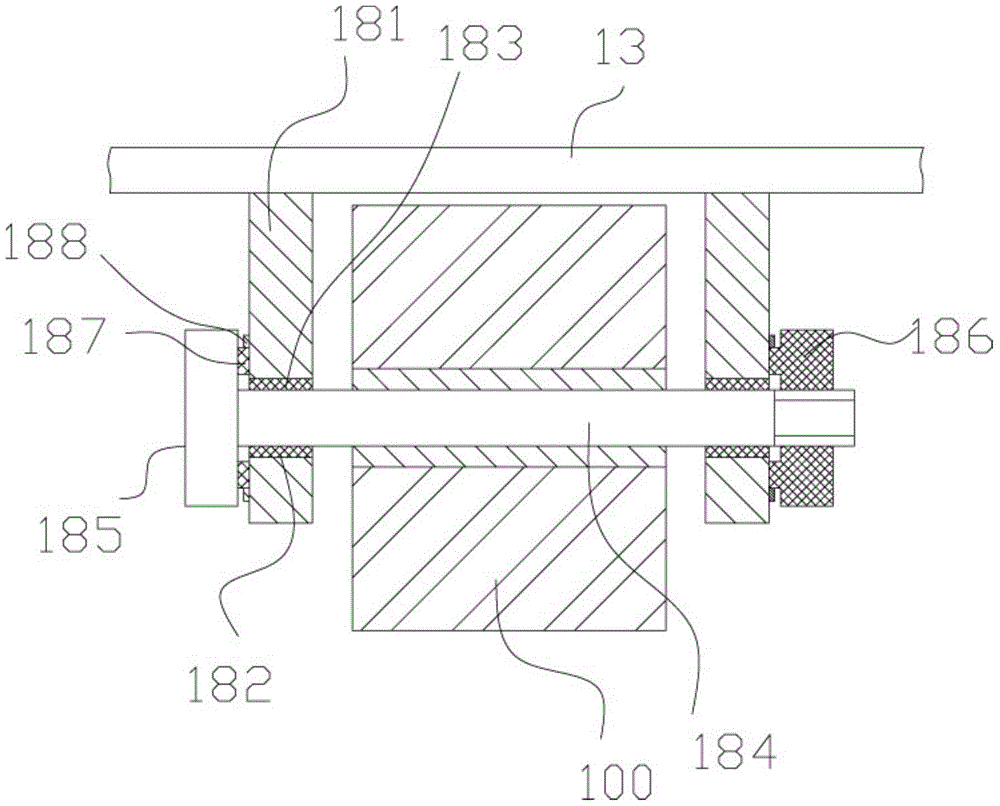

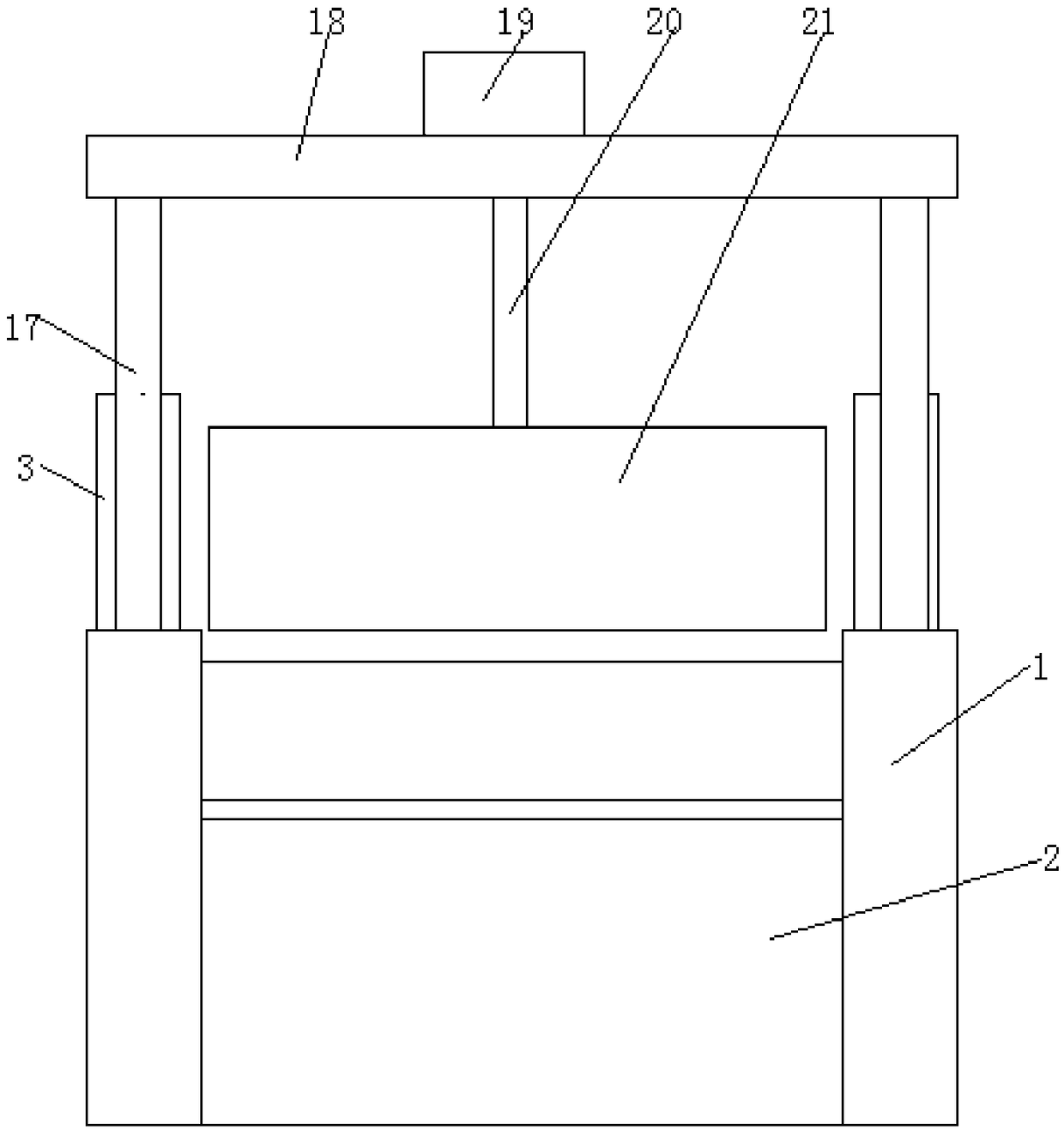

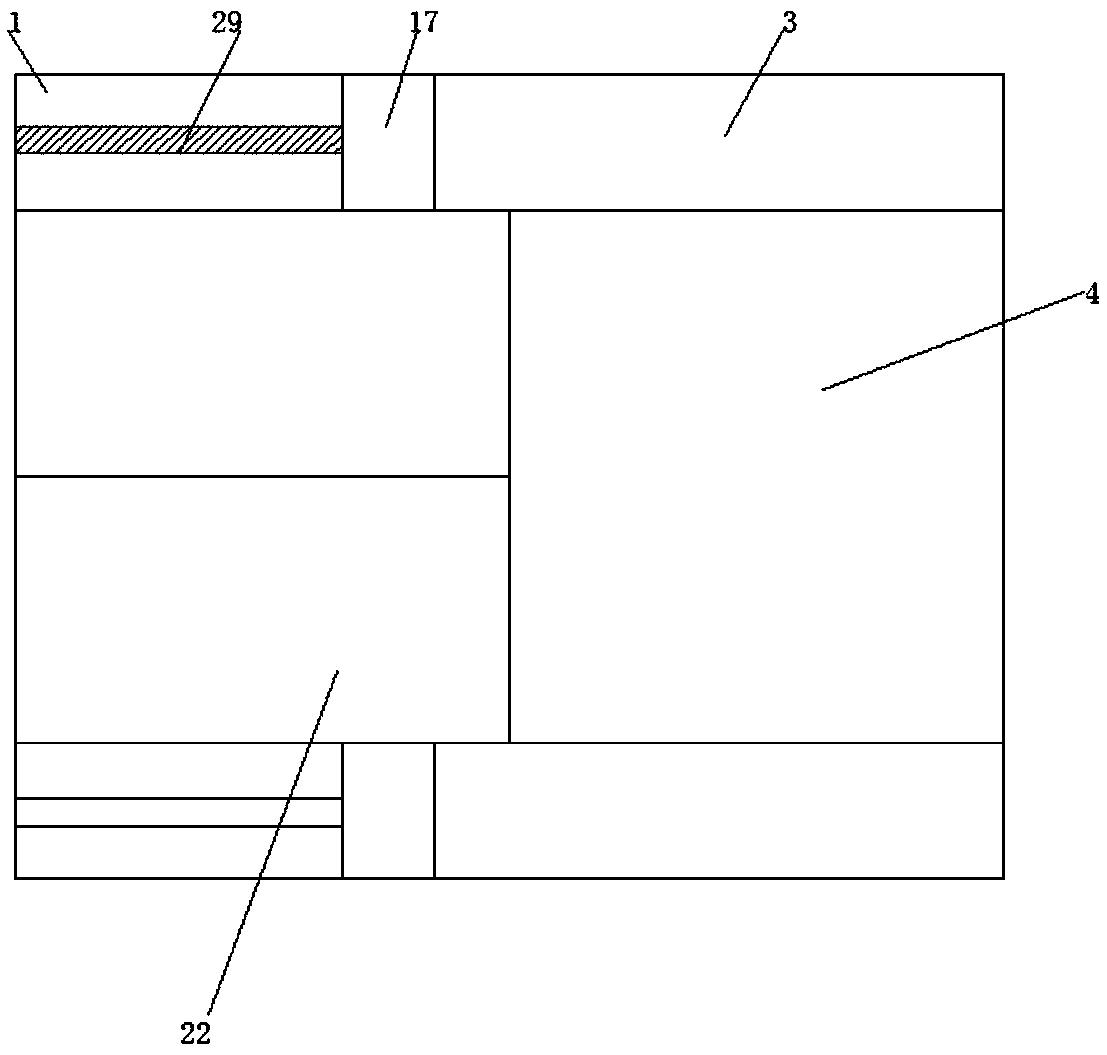

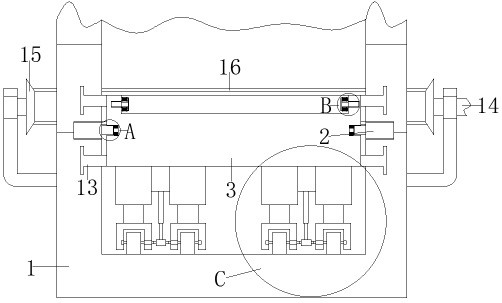

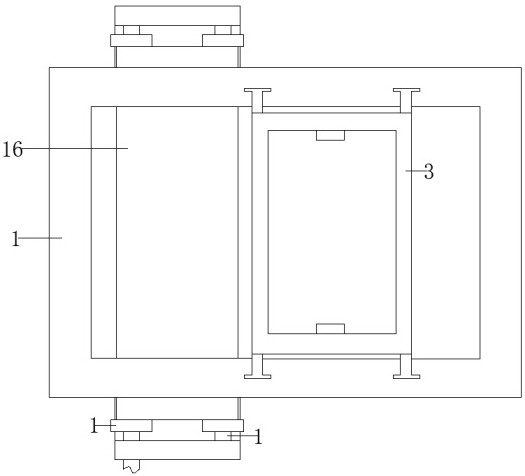

The invention discloses a position adjustable packing case adhesive tape sealing device. The device comprises a machine frame, wherein a plurality of supporting pillars are fixed to a top plate of the machine frame, two vertical blocks are fixed to the plane of an upper supporting plate, and the two ends of an adjusting screw are hinged to the two vertical blocks; a driving motor is fixed to the right side of the upper supporting plate, an output shaft of the driving motor is connected with the right end, stretching out of the corresponding vertical block, of the adjusting screw through a coupler, and a sliding block is connected to the adjusting screw in a screwed mode and inserted in a through groove in the upper supporting plate below the adjusting screw; the front side wall and rear side wall of the sliding block are abutted against the front side wall and rear side wall of the through groove, and a thrusting cylinder is fixed to the sliding block; a push rod of the thrusting cylinder is vertically downward, a pressing block is fixed to the push rod, and a bonding layer is fixed to the bottom surface of the pressing block. By the adoption of the device, adhesive tape can be automatically and quickly stuck to a packaging case, efficiency is high, manual sticking is not needed, working intensity is relieved, and the packing case can be clamped by rotating the screw so that manual clamping can be avoided.

Owner:佛山市东合众包装制品有限公司

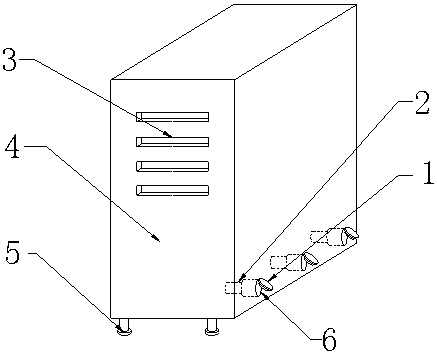

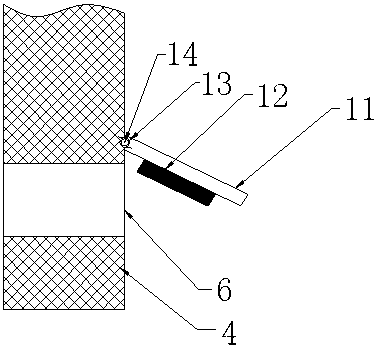

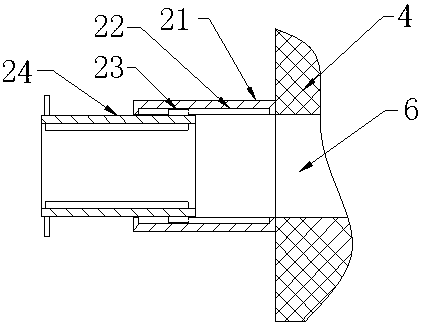

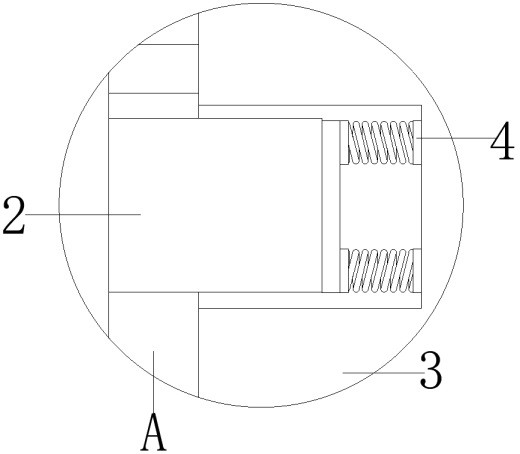

Outgoing-line device for switchgear

InactiveCN107863695ARealize automatic sealing functionImprove sealingBus-bar/wiring layoutsSubstation/switching arrangement cooling/ventilationBody positionsEngineering

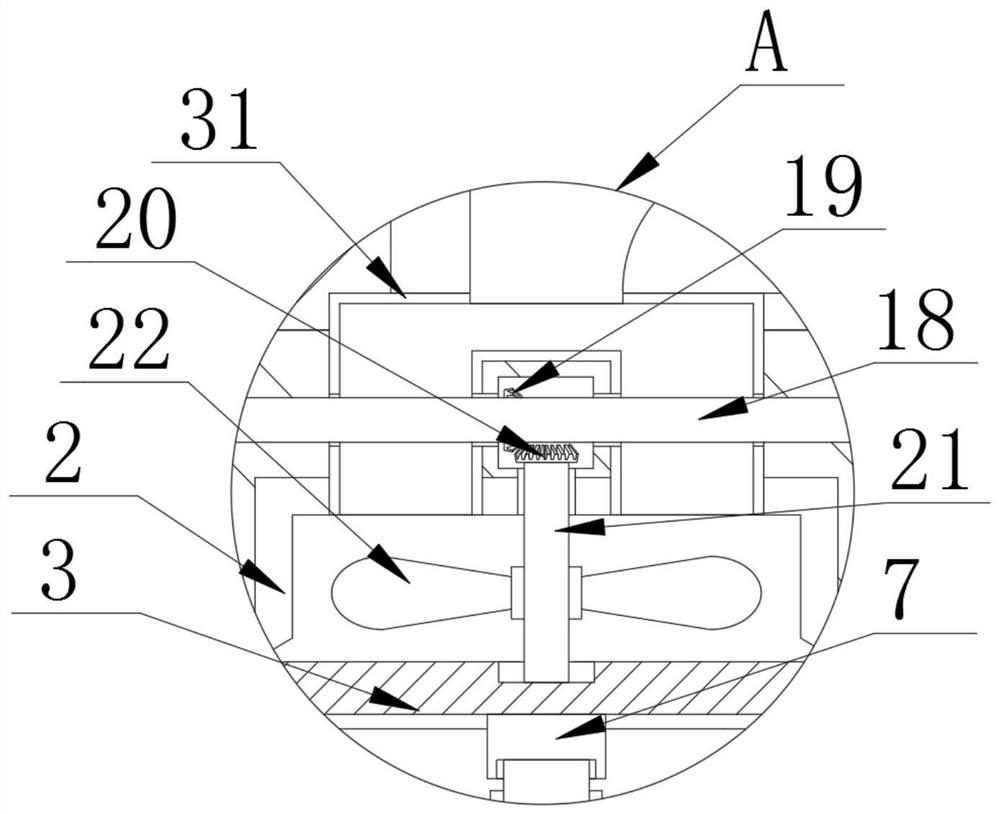

The invention provides a switch cabinet outlet device, which includes a sealing cover, a dustproof plug, a torsion spring, a rotating shaft, a sleeve, a chute, a slider and a wire protection sleeve. The sealing cover is installed on the annular side of the rotating shaft, and the dustproof plug is installed on the The middle position of the lower end face of the sealing cover, the rotating shaft is installed at the lower part of the rear end face of the switch cabinet body, and the rotating shaft is connected with the switch cabinet body through a torsion spring. This design realizes the automatic sealing function, good sealing effect, good dustproof effect, and the sleeve is fixed At the lower part of the rear end surface of the switchgear body, the chute is set on the inner annular side of the sleeve, the slider is fixed on the annular side of the grommet, and the slider is assembled in the chute, and the grommet is installed in the sleeve. The design realizes the protection function of the circuit, is convenient for operators to adjust, and has a wide protection range. The invention has reasonable structure, good sealing performance, good protection performance, long service life and high reliability.

Owner:ZHONGSHAN HOUYUAN ELECTRONICS TECH CO LTD

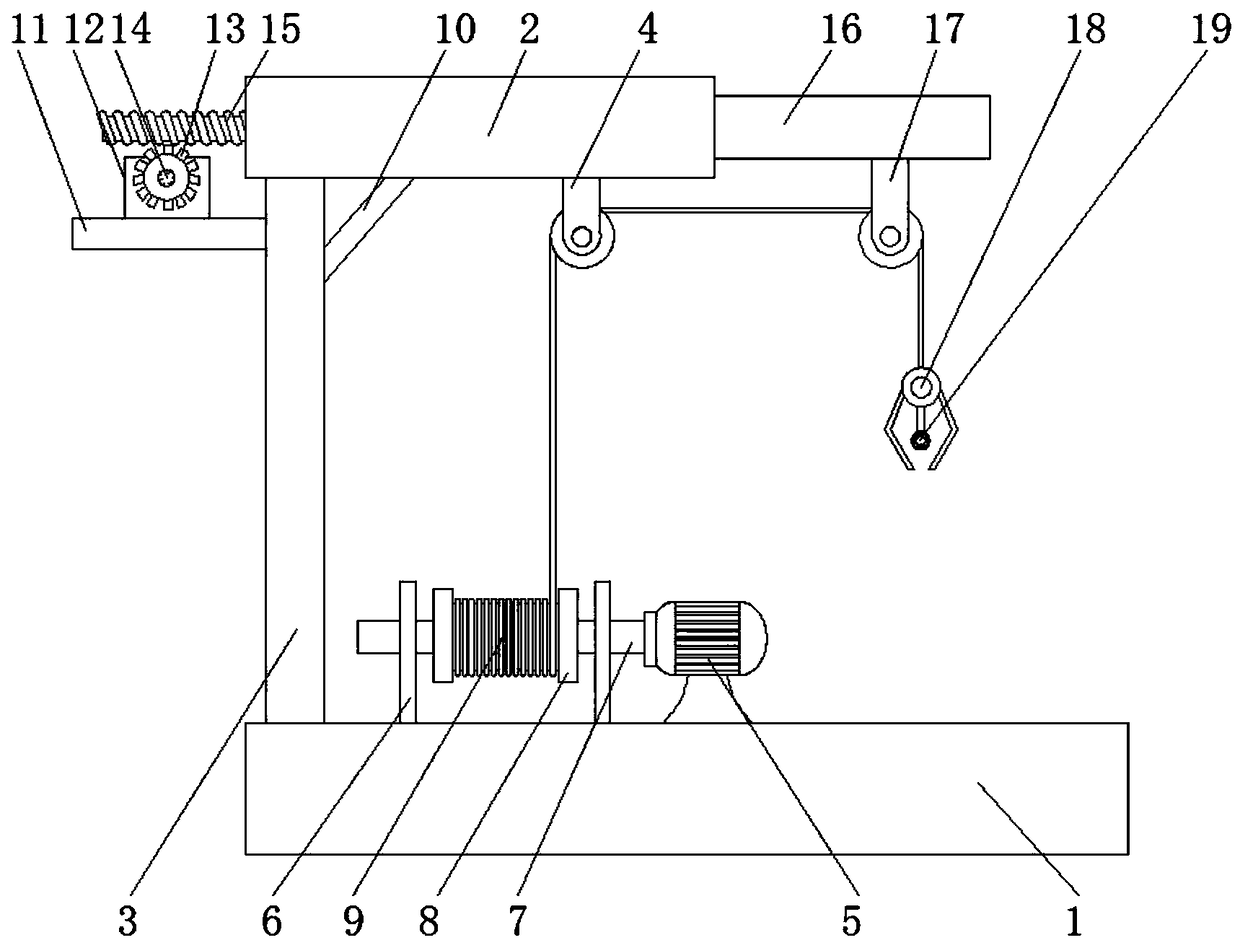

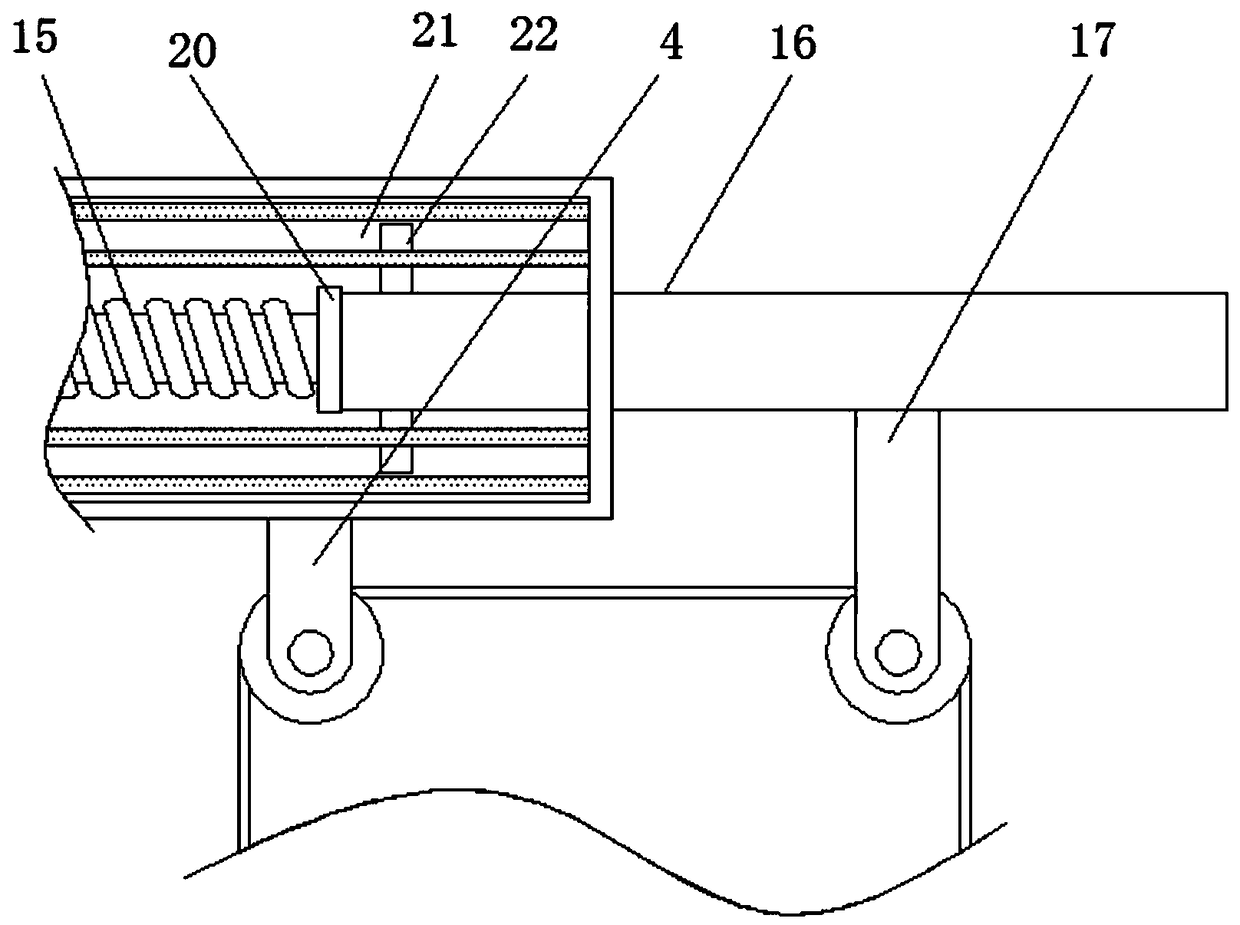

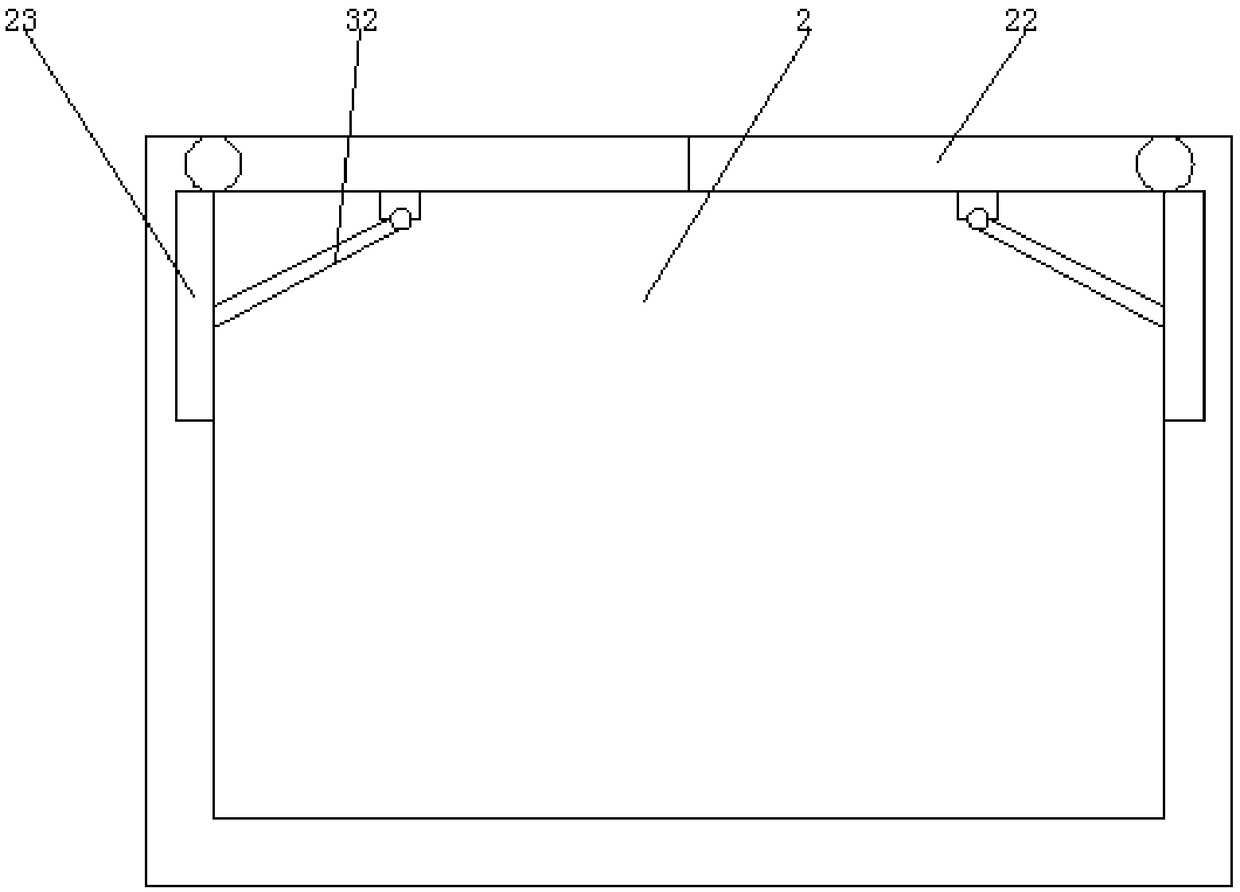

Ship hoisting device

InactiveCN108975175AEasy to take backLifting distance adjustmentPortable liftingCranesMarine engineeringElectric machinery

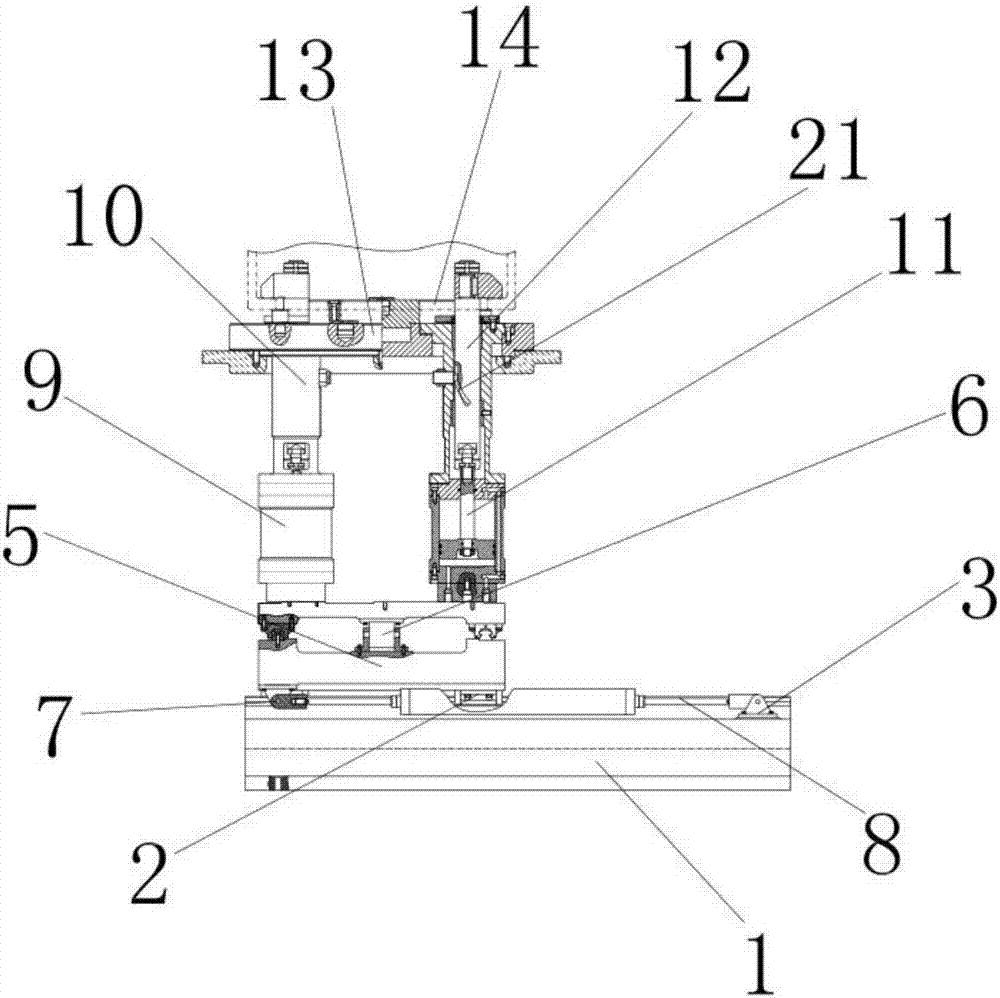

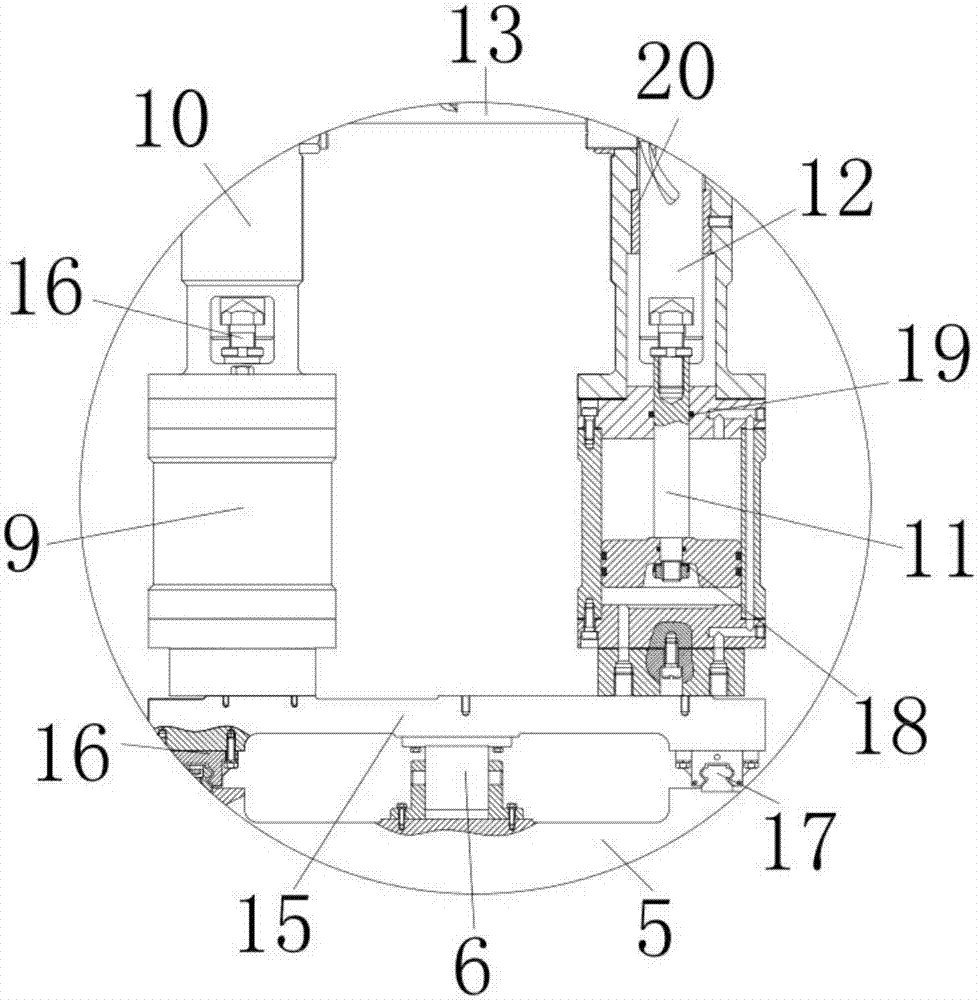

The invention discloses a ship hoisting device. The ship hoisting device comprises a device base and a cross beam, wherein a steel column is fixedly arranged on the upper surface close to the cross beam of the device base; a bottom plate is arranged on the top of the outer wall of one side of the steel column; angle steel is fixedly arranged at a position far away from the bottom plate between thesteel column and the cross beam; the lower surface close to the angle steel of the cross beam is provided with a first fixed pulley; the upper surface of the device base is provided with a copper core motor and a limiting frame; a rotation rod is movably arranged at one end passing through the limiting frame of the copper core motor; the outer surface of the rotation rod is sleeved with a coilingsleeve; the upper surface of the bottom plate is provided with a positive-negative rotation motor; a threaded rod is arranged at a position at which the cross beam passes through one side wall. The hoisting device is more convenient for pulling out and withdrawing a traction line, and the moving range of the coiling sleeve is fixed. Meanwhile, ship hoisting operation under different distances canbe realized. The ship hoisting device is novel in structure, and has very high practicability.

Owner:芜湖籁余新能源科技有限公司

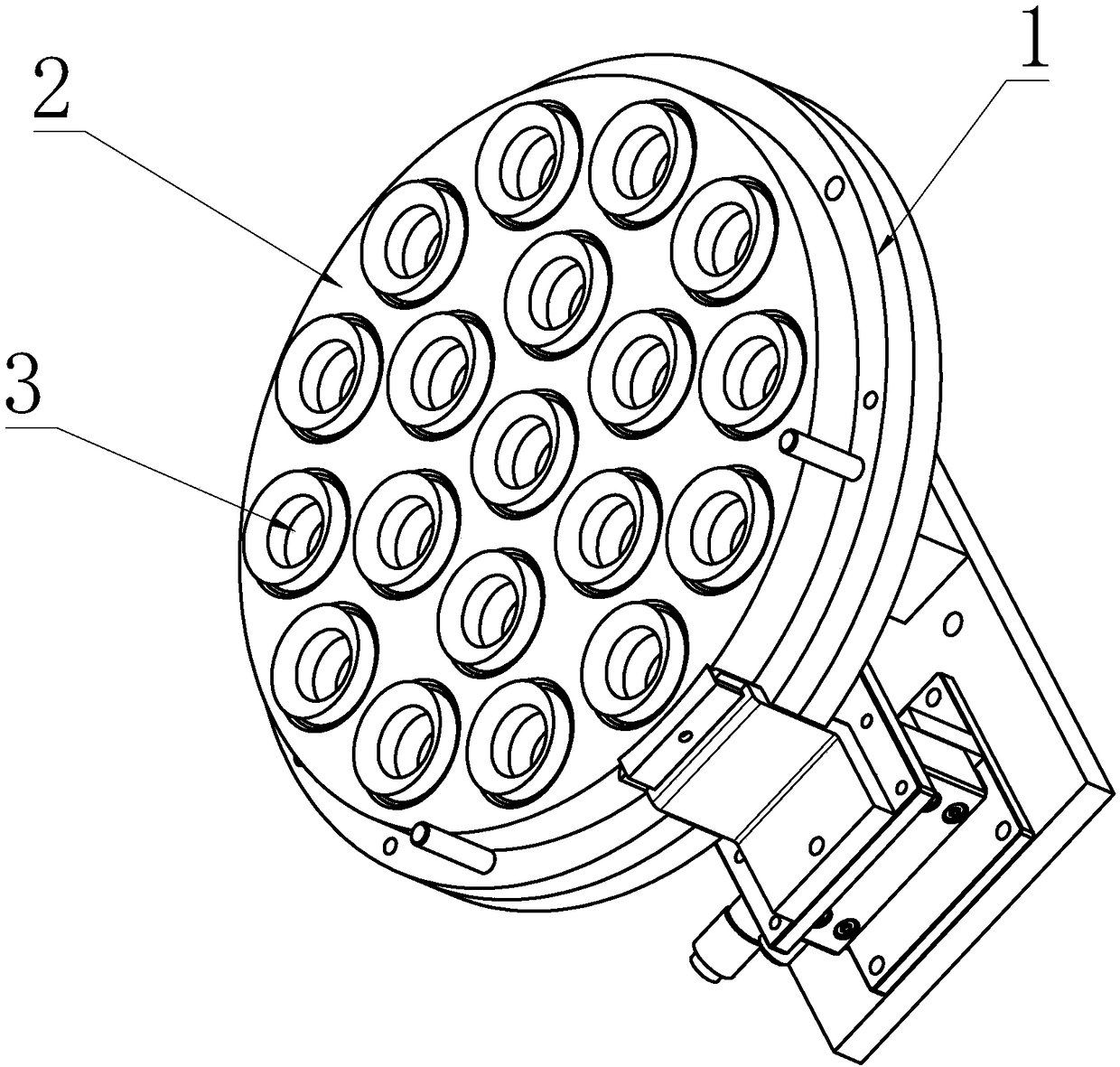

Intelligent visual monitoring device based on Internet of Things

PendingCN112780911AAdjust the moving distanceAdjustable angleTelevision system detailsColor television detailsVisual monitoringThe Internet

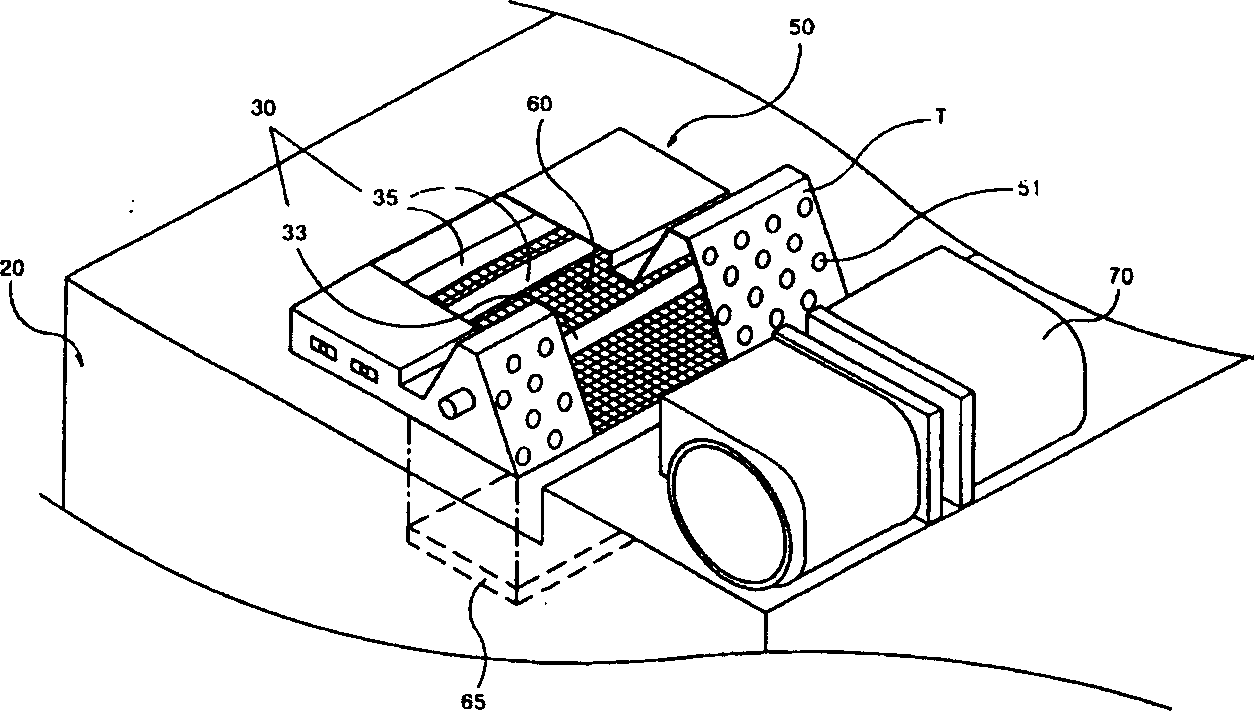

The invention discloses an intelligent visual monitoring device based on the Internet of Things, which comprises a shell; a cavity I, a cavity II and a cavity III are arranged at the top of the shell; the cavity II is located on the inner sides of the cavity I and the cavity III; an air duct is embedded in the inner wall of the top of the shell and located at the bottom of the cavity II; a fixed rod is fixedly embedded in the air duct; a cleaning mechanism is arranged in the shell; an adjusting mechanism is arranged on the outer side of the top of the shell; and a fixing mechanism comprises a motor, and the motor is fixedly installed on one side of the shell. The intelligent visual monitoring device based on the Internet of Things provided by the invention has the beneficial effects that dust on the surface of a protective cover is cleaned, the rotation of the motor can also make a connecting rod rotate, the dust on the surface of the protective cover can be efficiently cleaned by rotating the protective cover and matching the protective cover with a cleaning brush, so that the dust cannot be accumulated on the surface of the protective cover to influence the shooting picture of a camera, the dust on the surface does not need to be manually and regularly cleaned, and the labor intensity of people can be reduced.

Owner:广东聚晨晋力通信设备科技有限公司

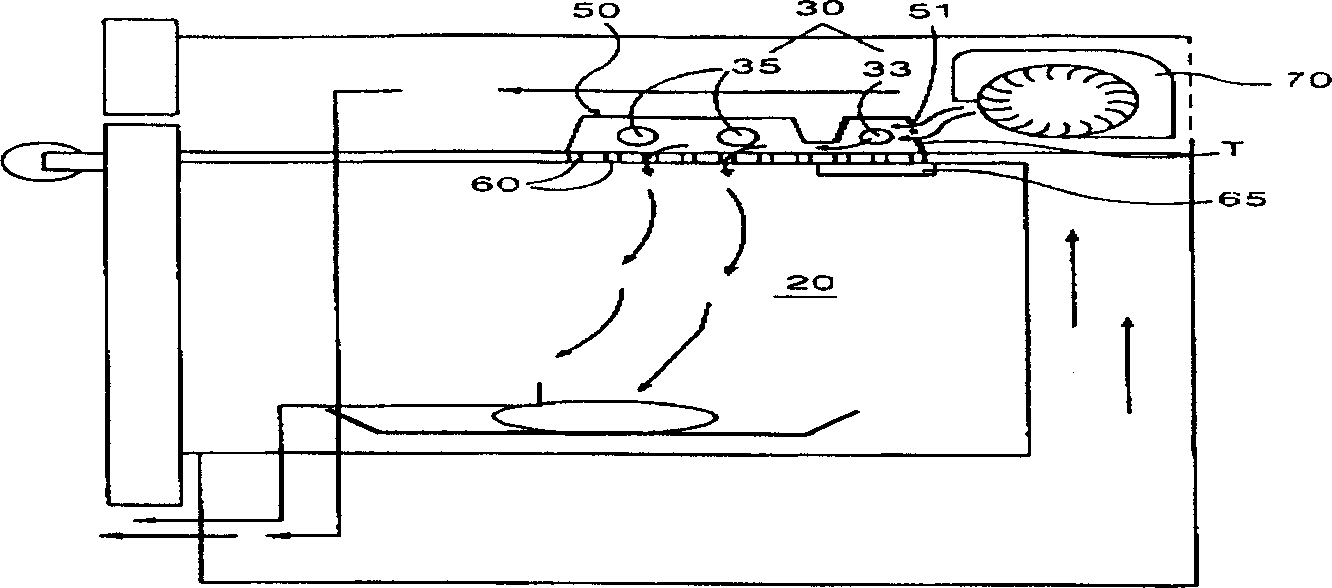

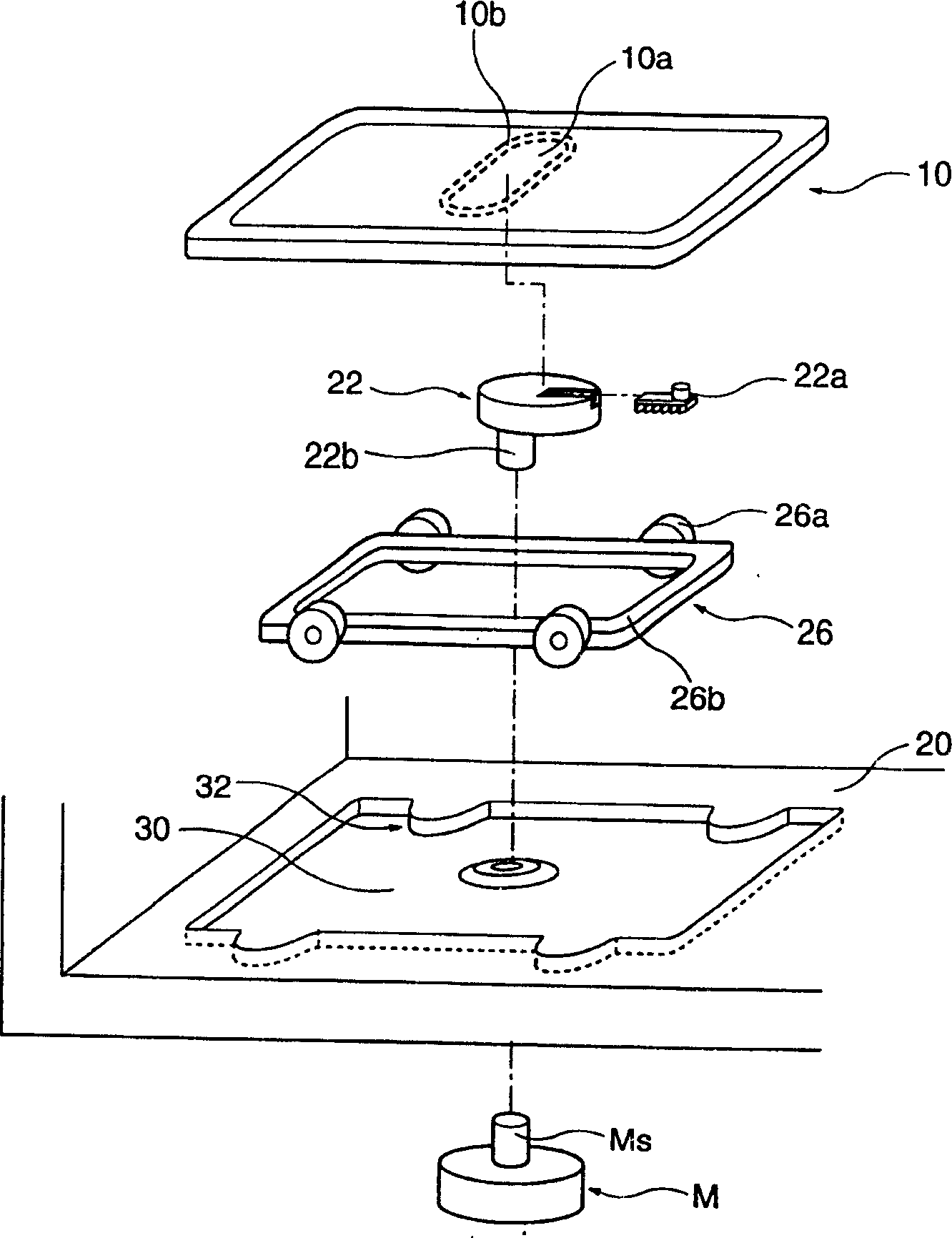

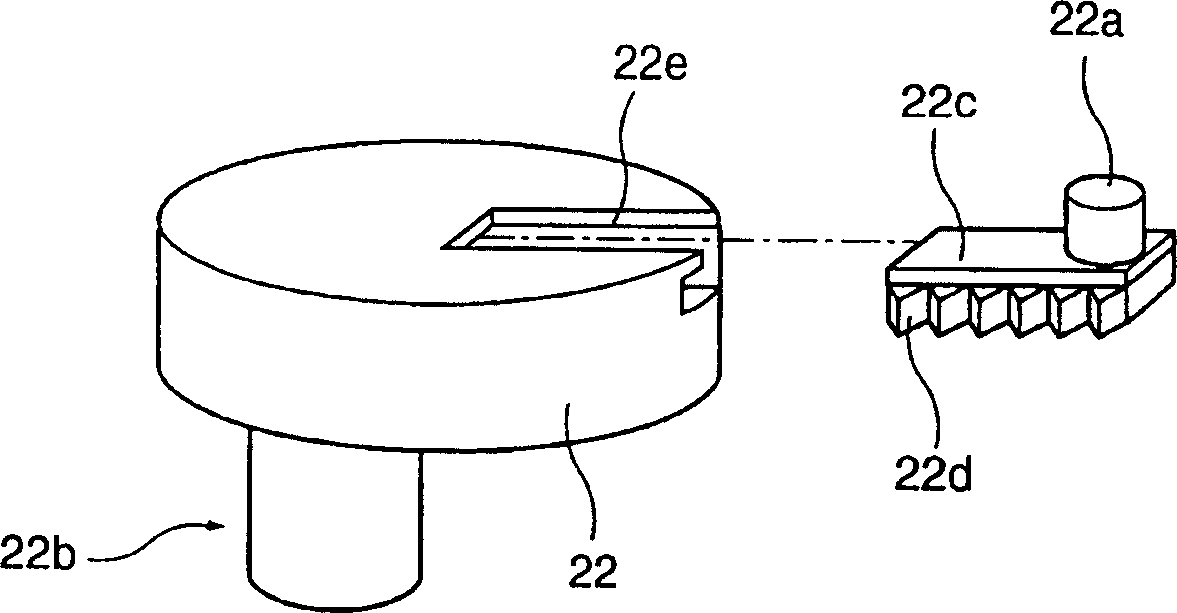

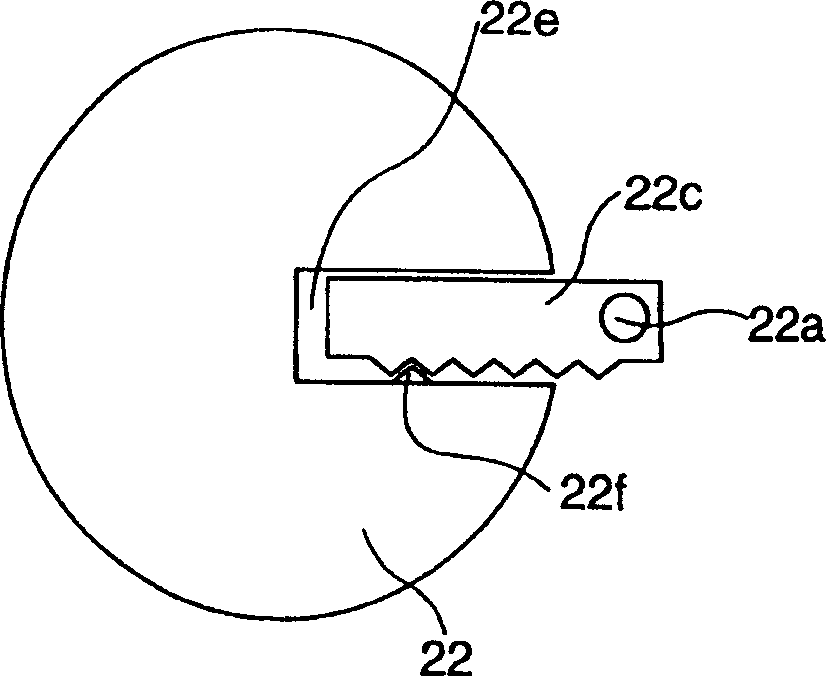

Tray linear movement distance regulator for microwave oven

InactiveCN1458455AAdjust the moving distanceDomestic stoves or rangesStoves/ranges shelves or racksMicrowave ovenEngineering

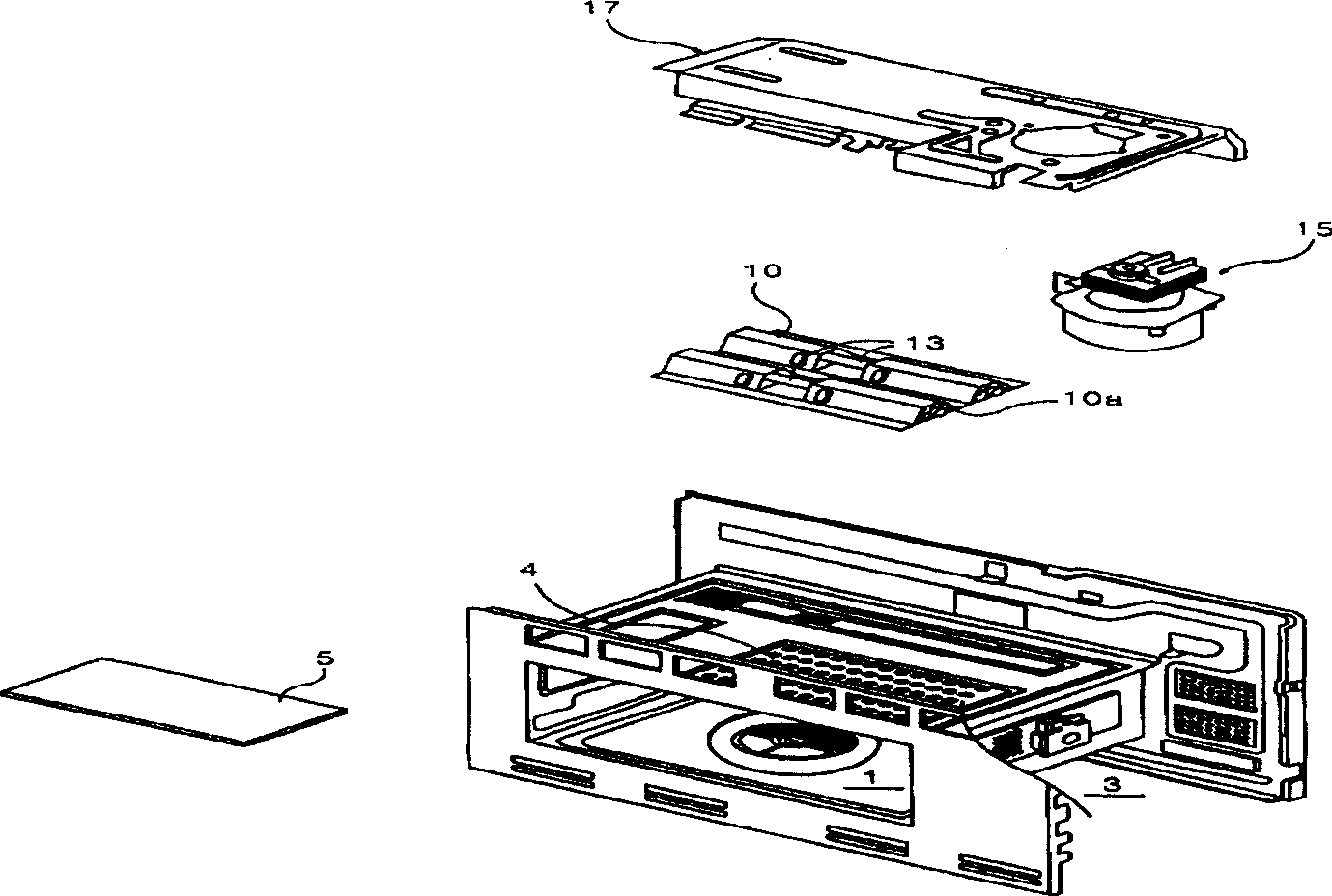

The present invention relates to one regulator to make the tray reciprocate linearly right and left inside the heating chamber of microwave oven. The tray motion distance regulator consists of a tray with slot in the bottom, driving motor to produce rotating force, rotating part with radial slot, eccentric shaft with eccentric lug for inserting into the radial slot, and fixing structure to fix the eccentric shaft inserted into the slot. Under the action of the rotating eccentric lug, the tray reciprocates linearly right and left within the range corresponding to the eccentric amount. The present invention can increase the useable space inside the heating chamber via the motion of the tray and can regulate the moving distance of the tray.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

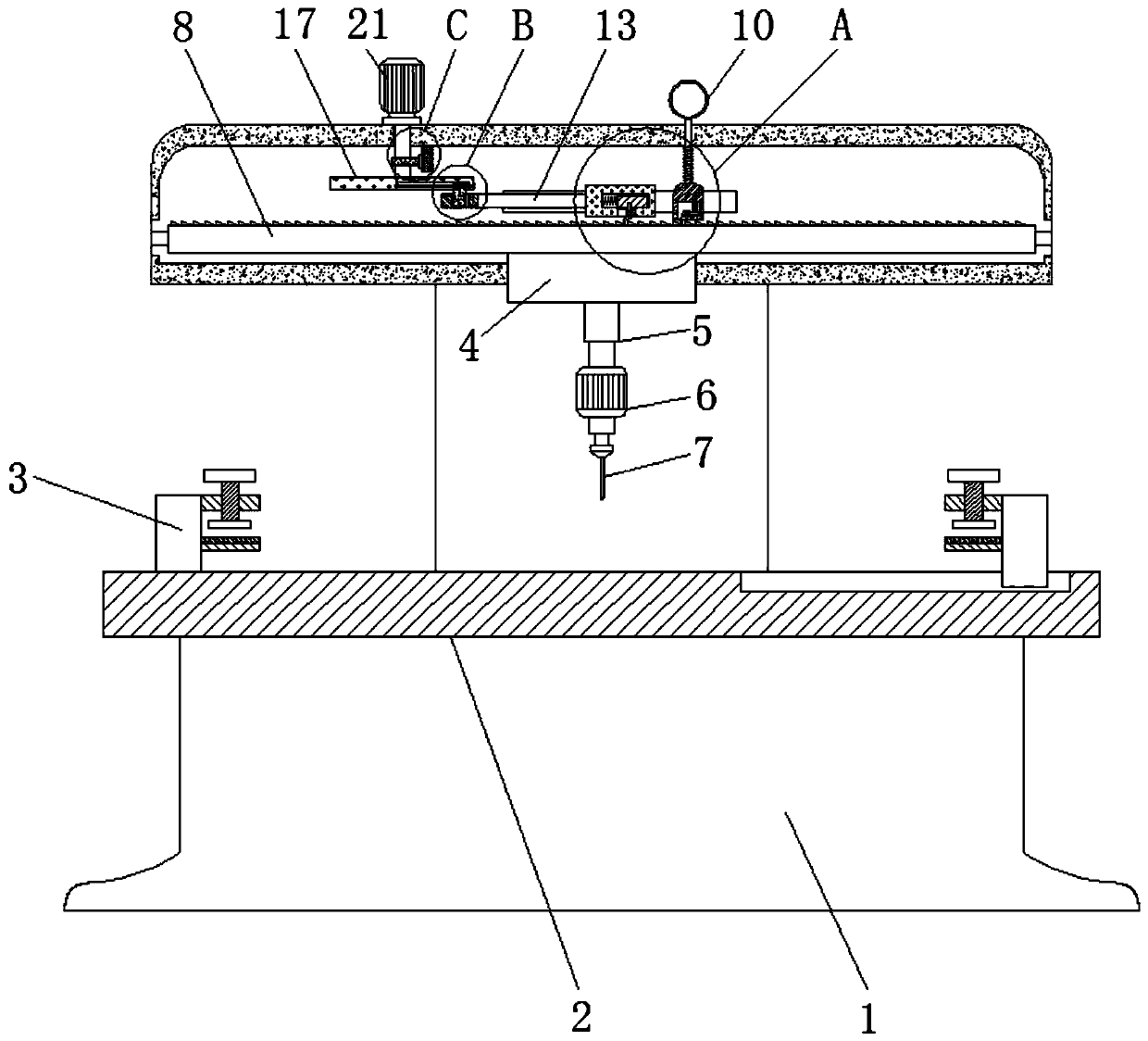

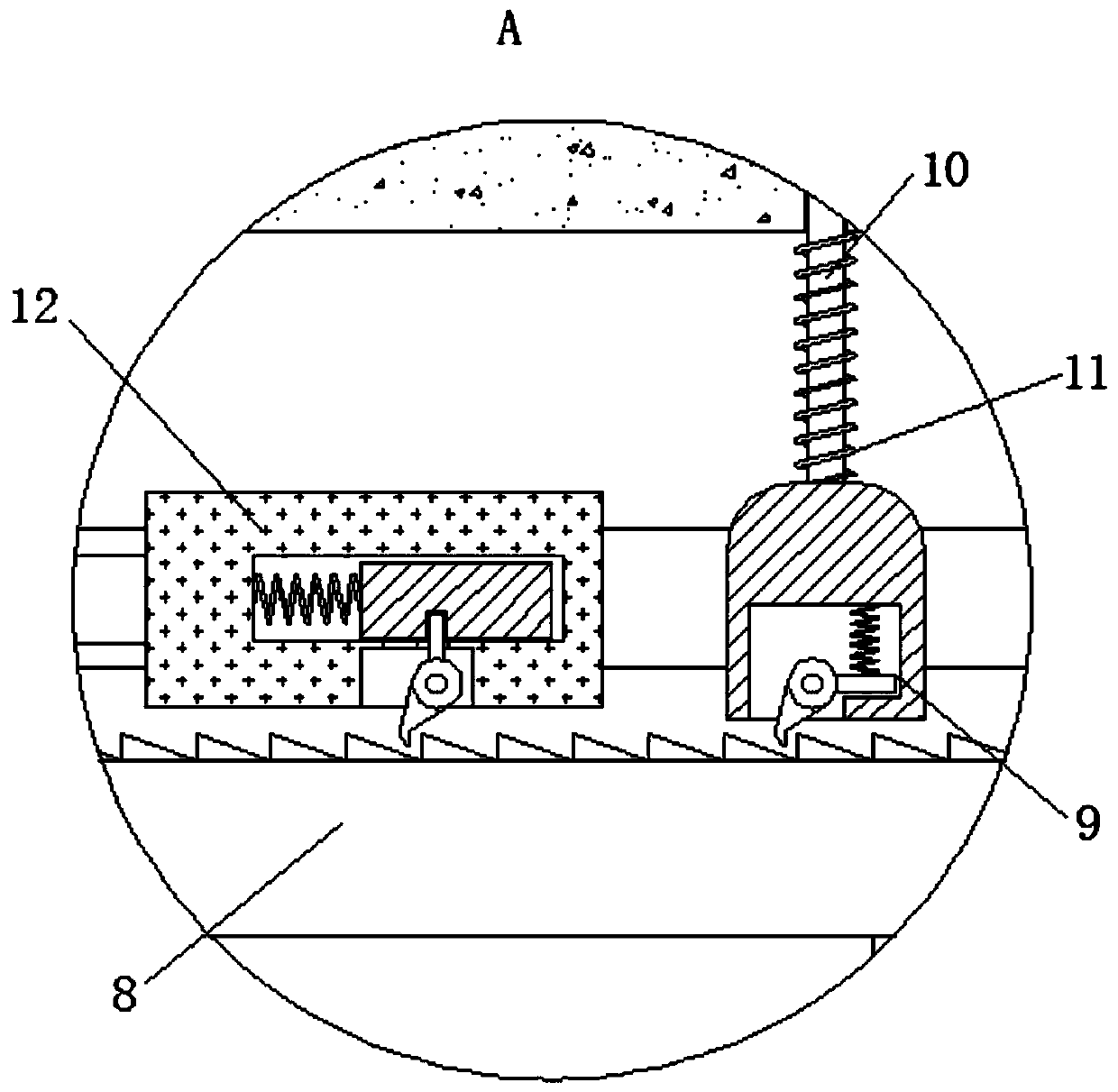

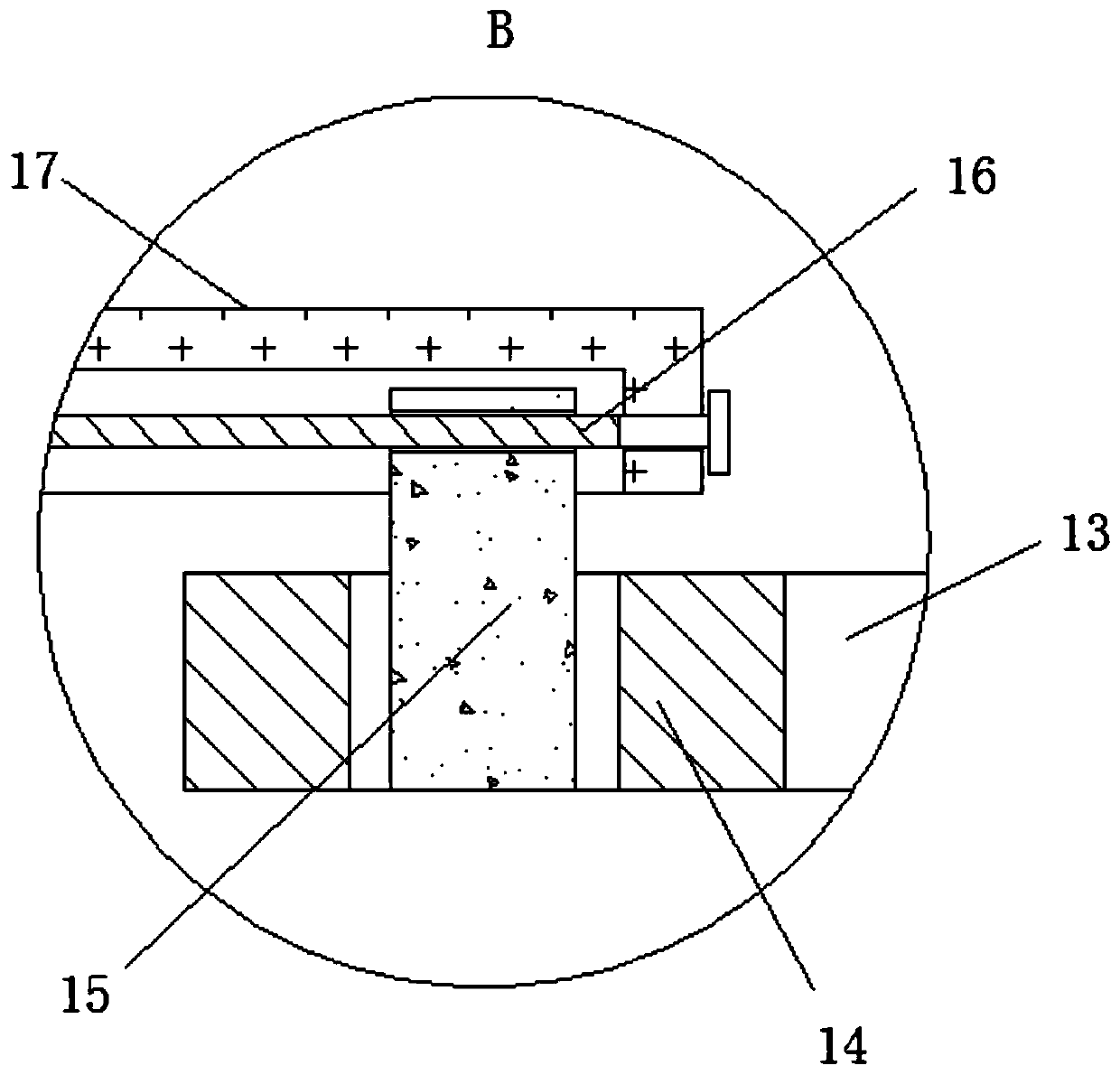

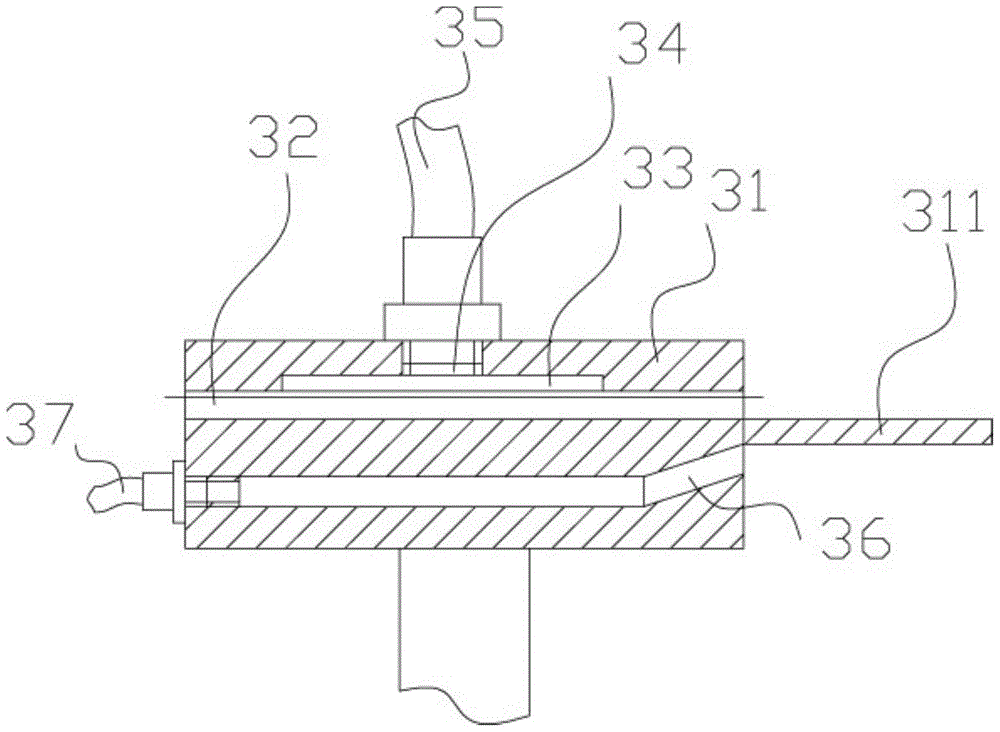

Sheet metal equidistant perforating device based on ratchet motion principle

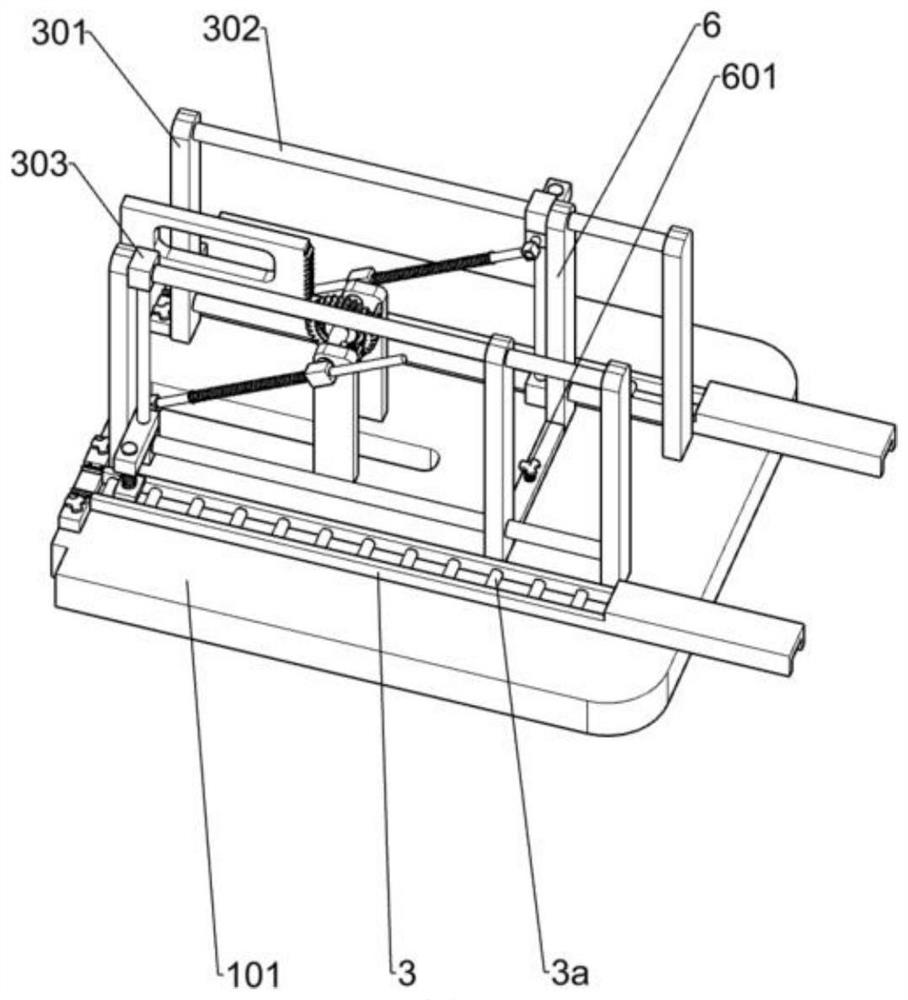

ActiveCN111375797AInstallation fixedAchieve the effect of fixing sheet metal partsBoring/drilling componentsBoring/drilling machinesRatchetElectric machinery

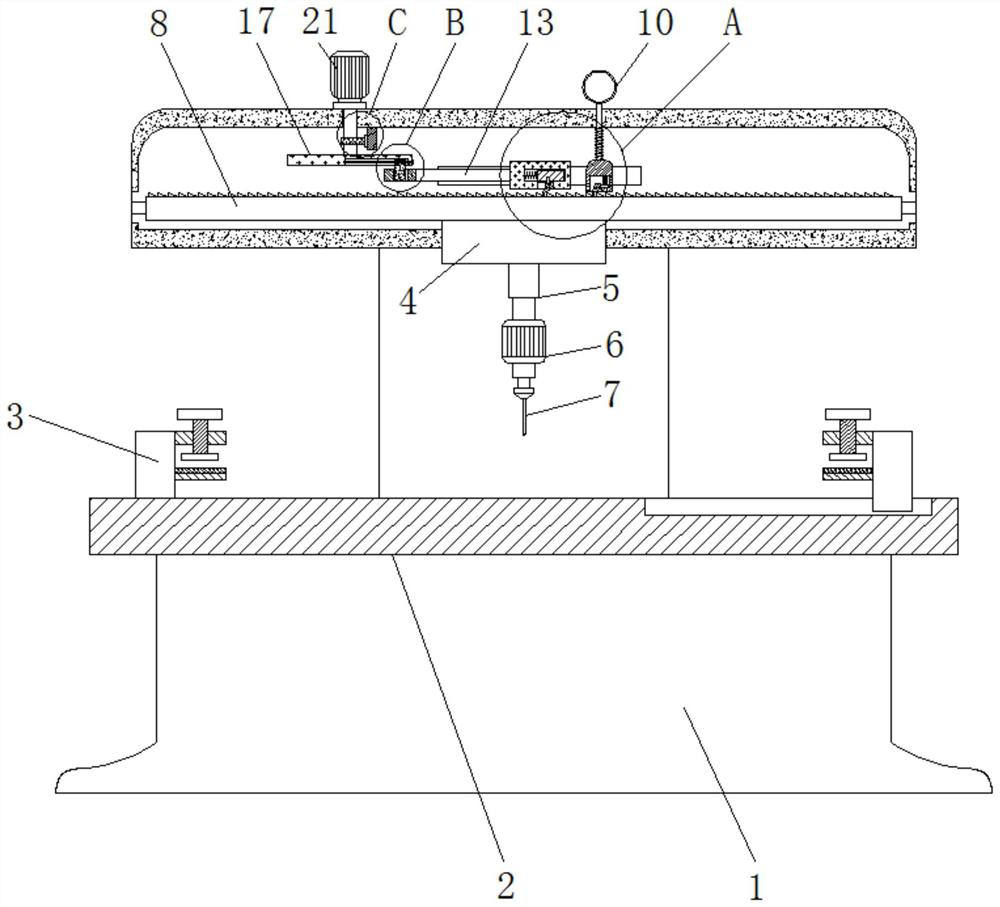

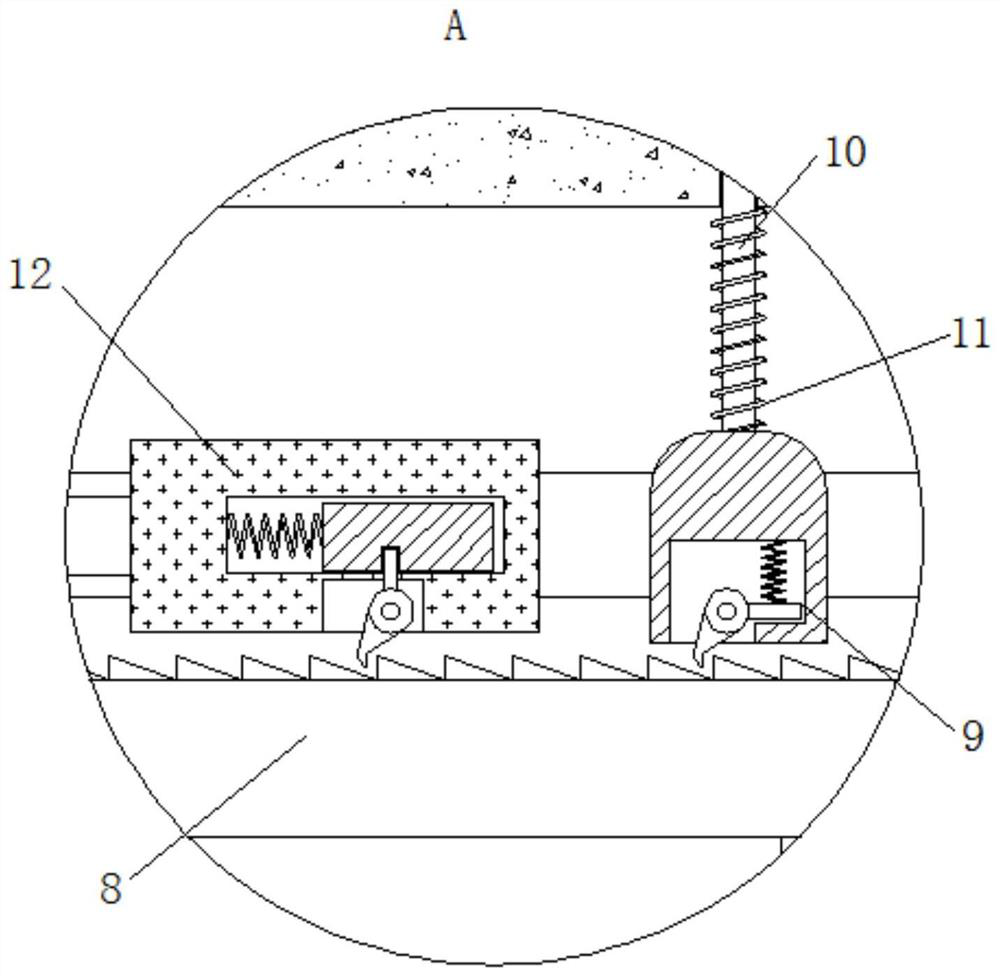

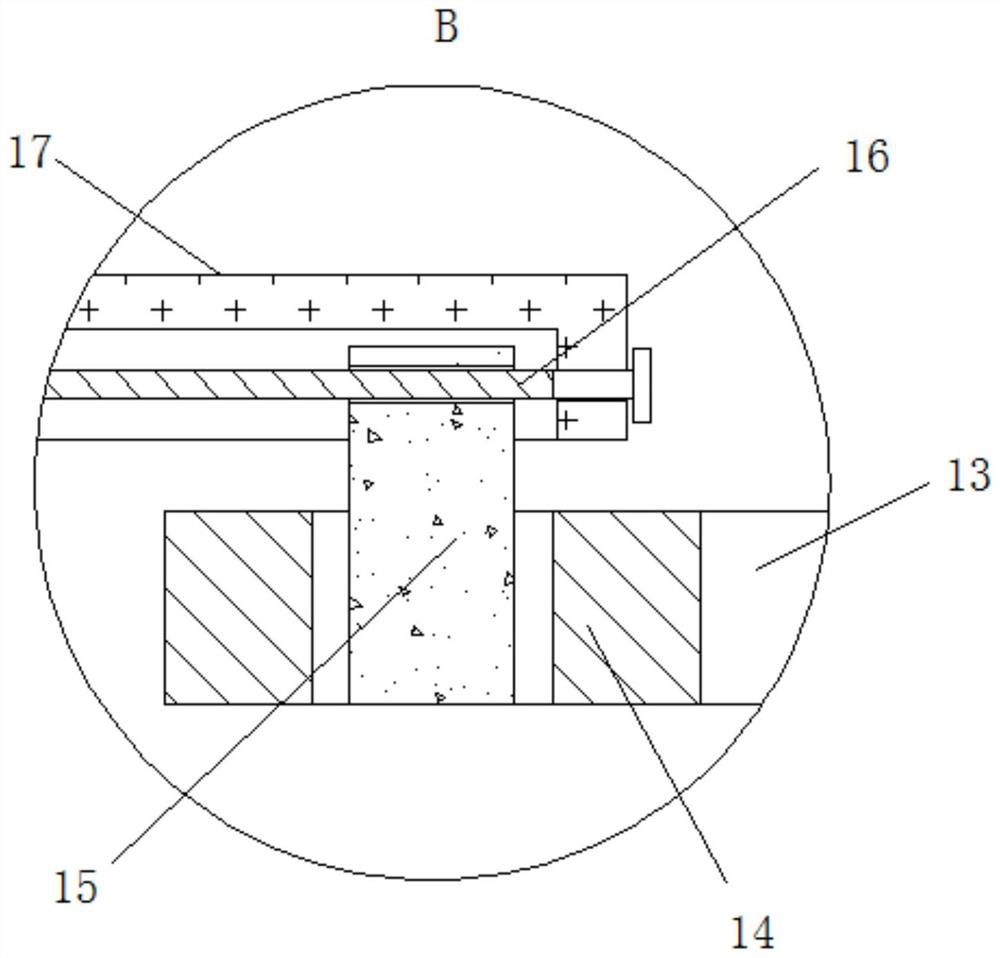

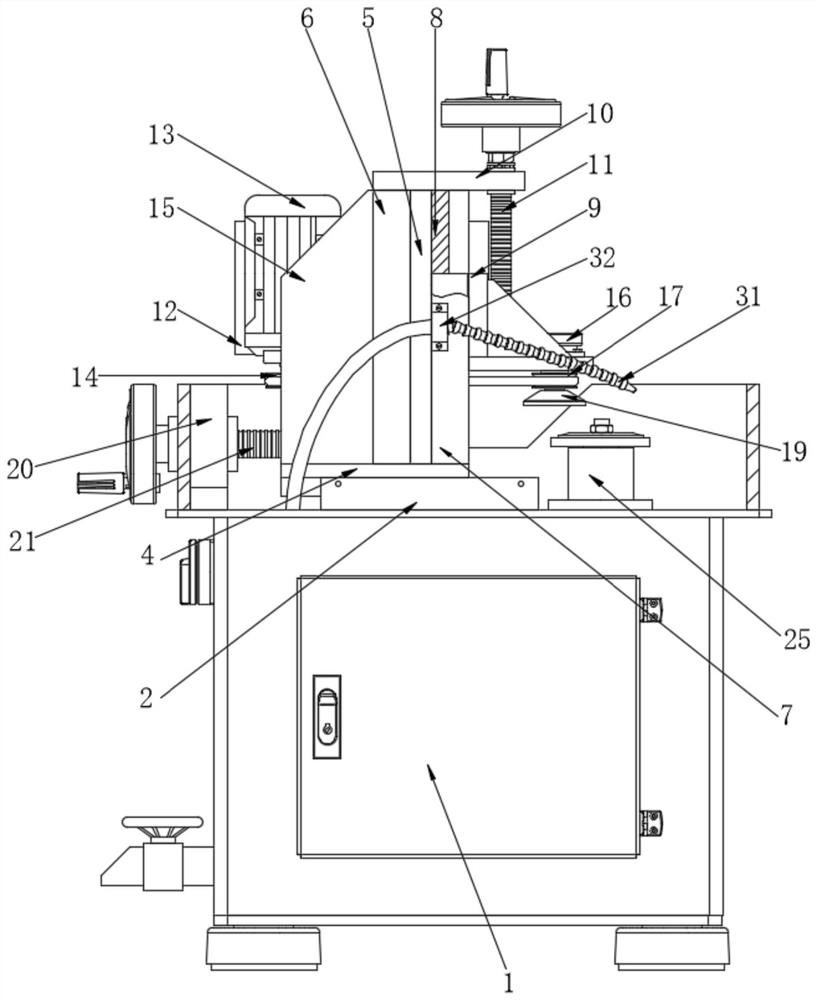

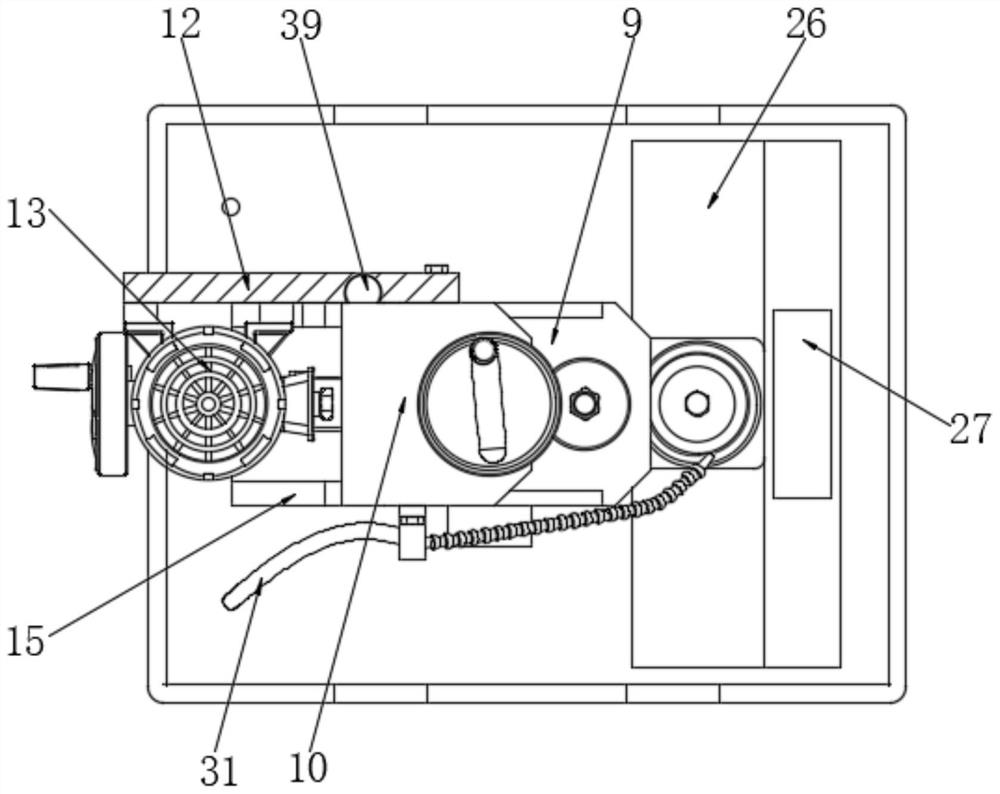

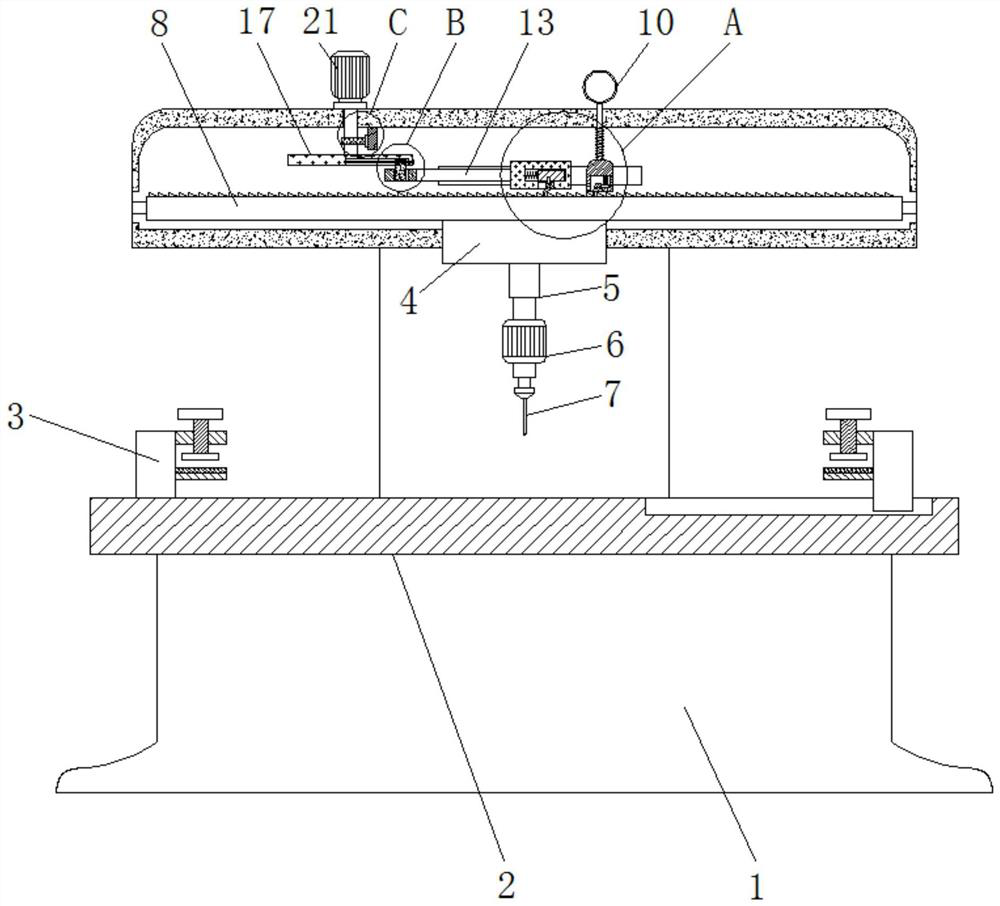

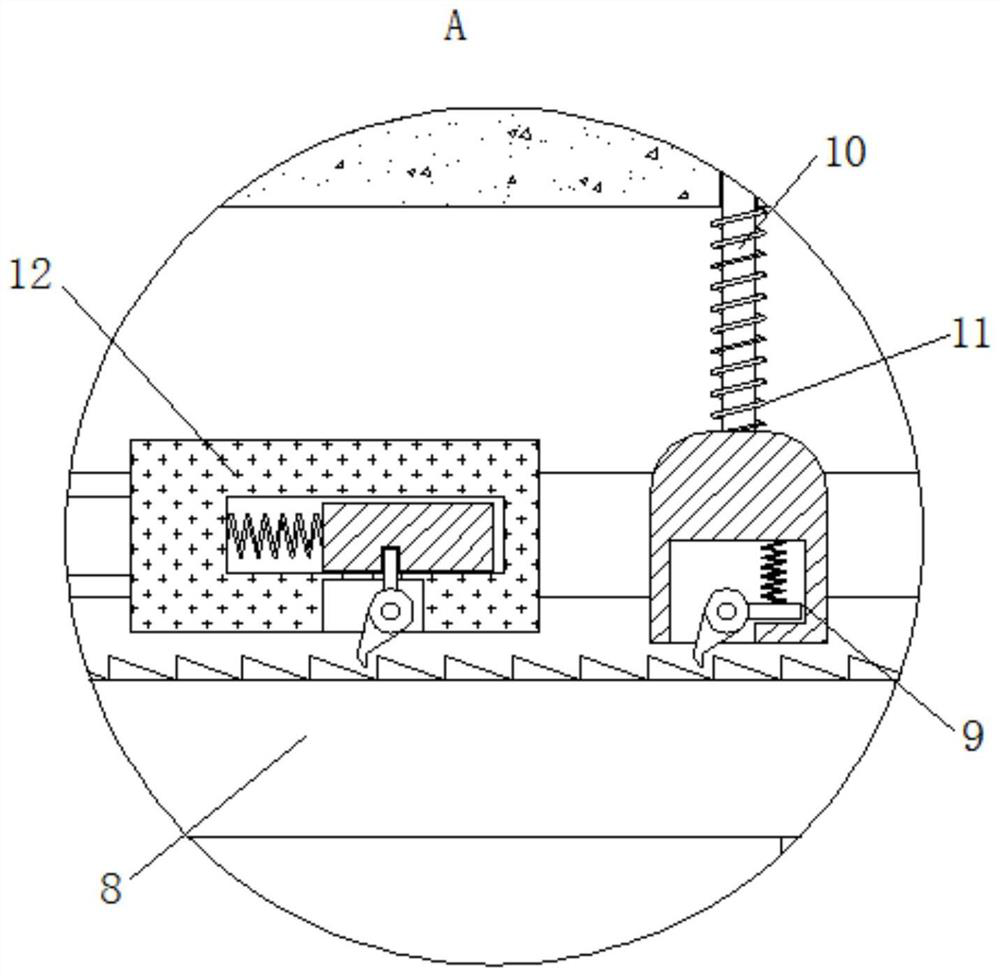

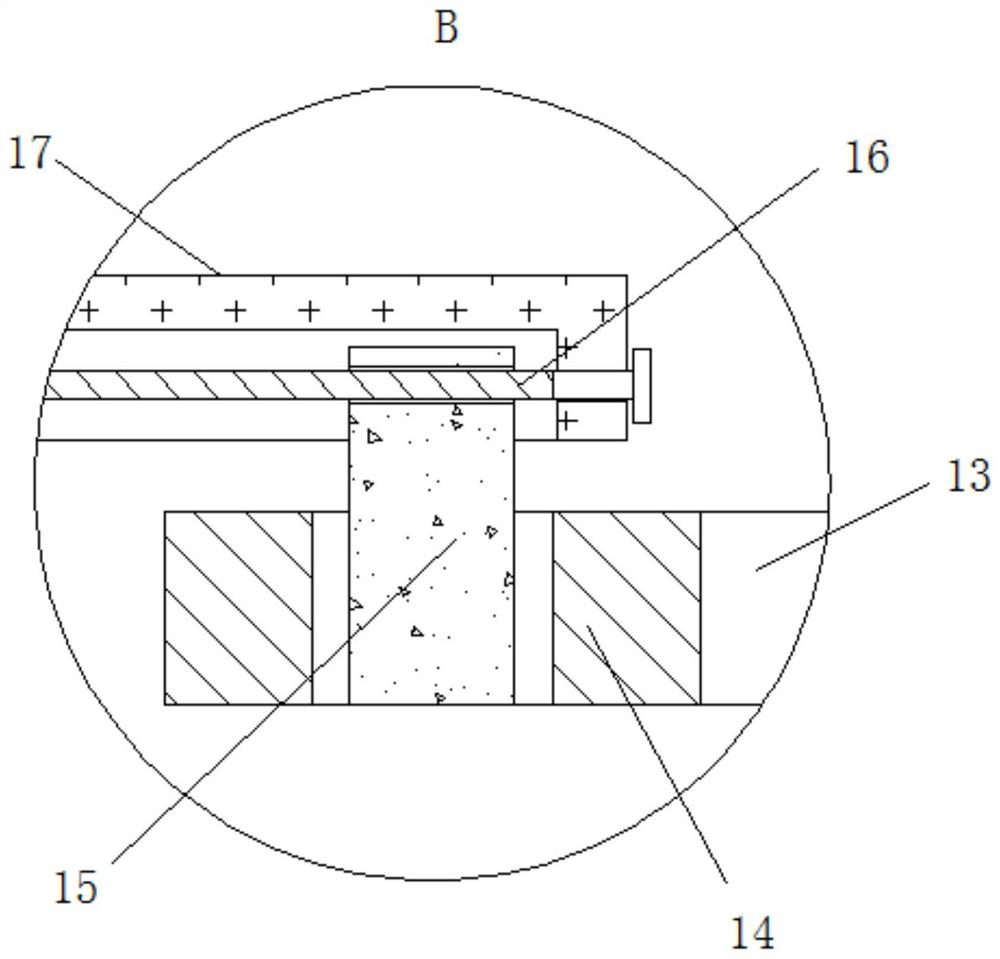

The invention relates to the technical field of mechanical equipment, and discloses a sheet metal equidistant perforating device based on a ratchet motion principle. The sheet metal equidistant perforating device based on the ratchet motion principle comprises a rack, a workbench is fixedly connected to the inside of the rack, a fixing block is fixedly connected to the top of the workbench, and asliding block is slidably connected to the inside of the rack; a lifting rod is fixedly connected to the bottom of the sliding block, a perforating motor is fixedly connected to the bottom of the lifting rod, a drill bit is movably connected to the bottom of the perforating motor, a ratchet bar is fixedly connected to the top of the sliding block, and a limiting pawl block is movably connected tothe top of the ratchet bar; through cooperation of the ratchet bar, the limiting pawl block, an adjusting pawl block, a connecting rod, a limiting ring and a movable pin, an effect of driving the ratchet bar to slide rightwards equidistantly is achieved, it is guaranteed that the rightward moving distances of the drill bit are equal and hole distances among drilled holes are equal, the product quality is improved, therefore, the trouble that measurement and marking need to be carried out in advance is avoided, and the production efficiency of sheet metal perforating is effectively improved.

Owner:张家港市金帆箱柜有限公司

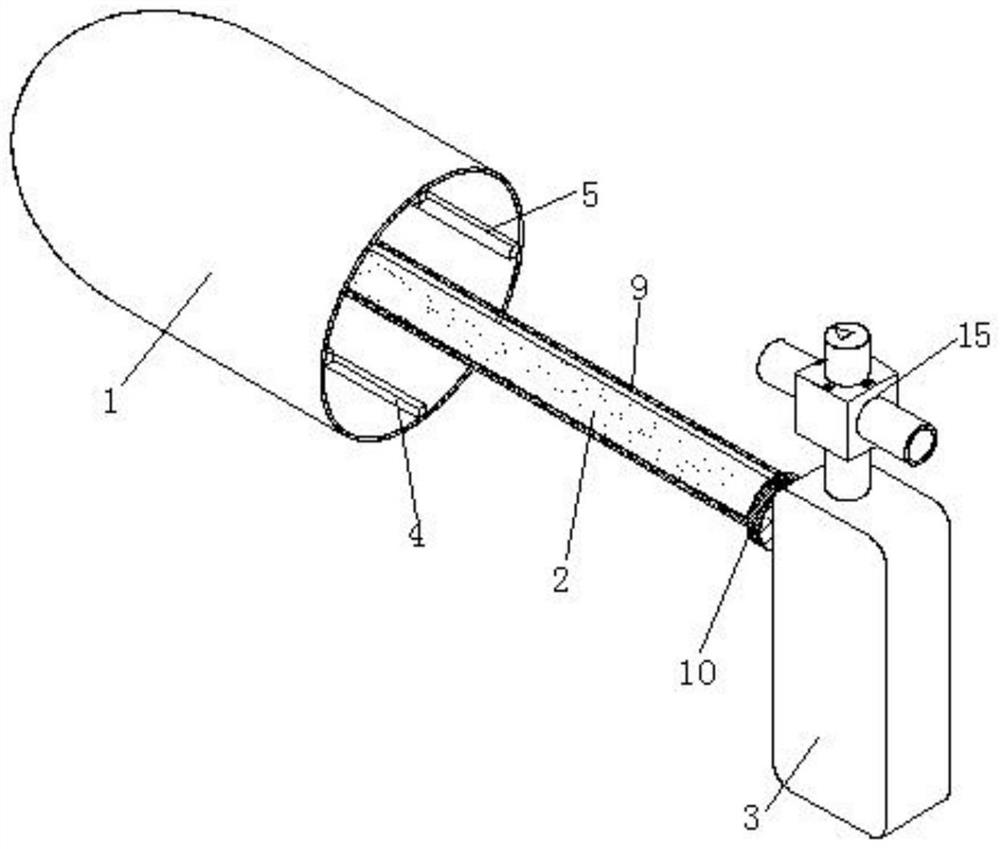

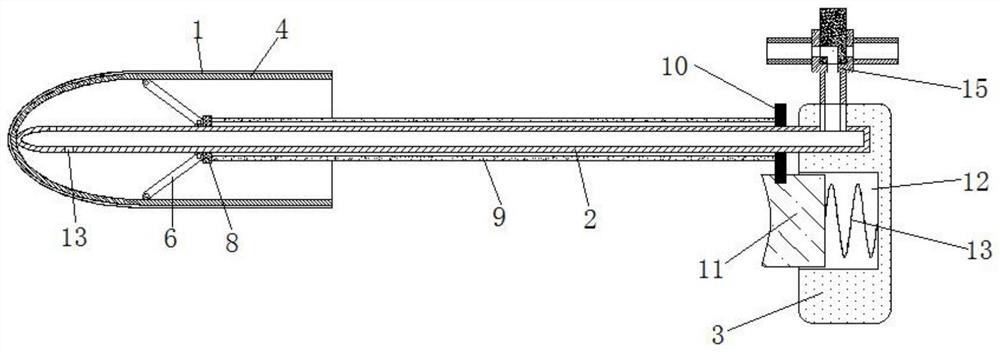

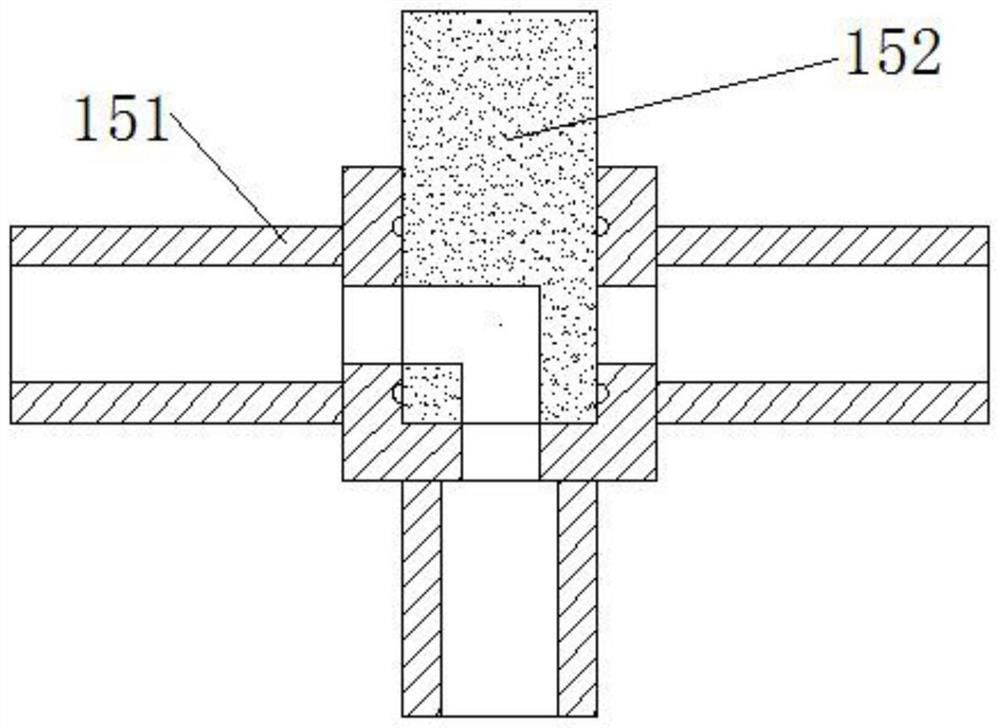

Cleaning device in robot ultrasonic knife operation

InactiveCN114129281AAdjust the expansionEasy to take outDiagnosticsSurgeryRobotic systemsStructural engineering

The invention belongs to the technical field of medical auxiliary devices, and discloses a robot ultrasonic scalpel cleaning device which comprises a cleaning bag and a hollow long rod, one end of the hollow long rod is sleeved with the cleaning bag, the other end of the hollow long rod is connected with a handle, and a U-shaped elastic supporting rod is fixedly connected to the inner wall of the cleaning bag; two sets of inclined supporting rods hinged to first sliding rings are symmetrically hinged to the inner side wall of the U-shaped elastic supporting rod, the first sliding rings are slidably connected to the surface of the hollow long rod in a sleeving mode, and the ends, back on to the inclined supporting rods, of the first sliding rings are fixedly connected with one or more sets of connecting rods; by arranging the cleaning bag capable of being folded and unfolded, the cleaning bag can be conveniently placed in the body of a patient, and the robot ultrasonic knife can be placed in water in the cleaning bag to work for mechanical oscillation to flush out tissues and blood clots attached to a knife head area without being taken down from an operation arm of a robot system; normal output power and use of the ultrasonic knife are ensured, and the failure rate is reduced, so that the expenditure of patients or hospitals is reduced.

Owner:郭东华

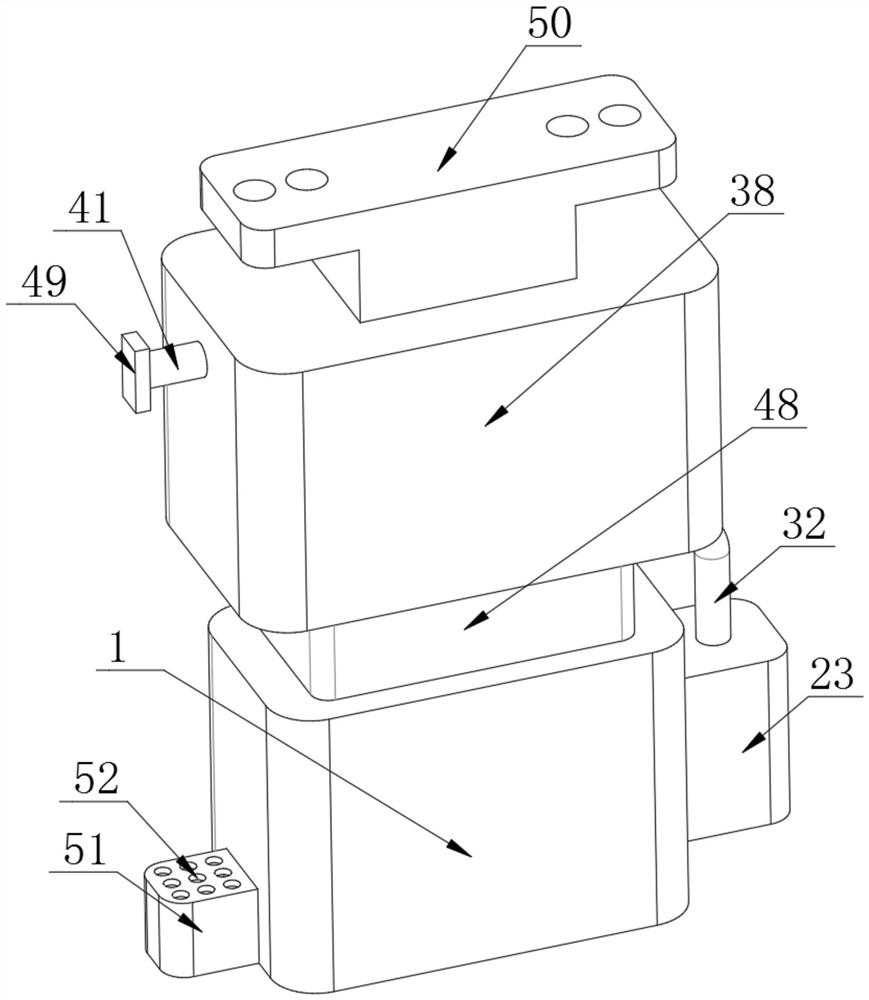

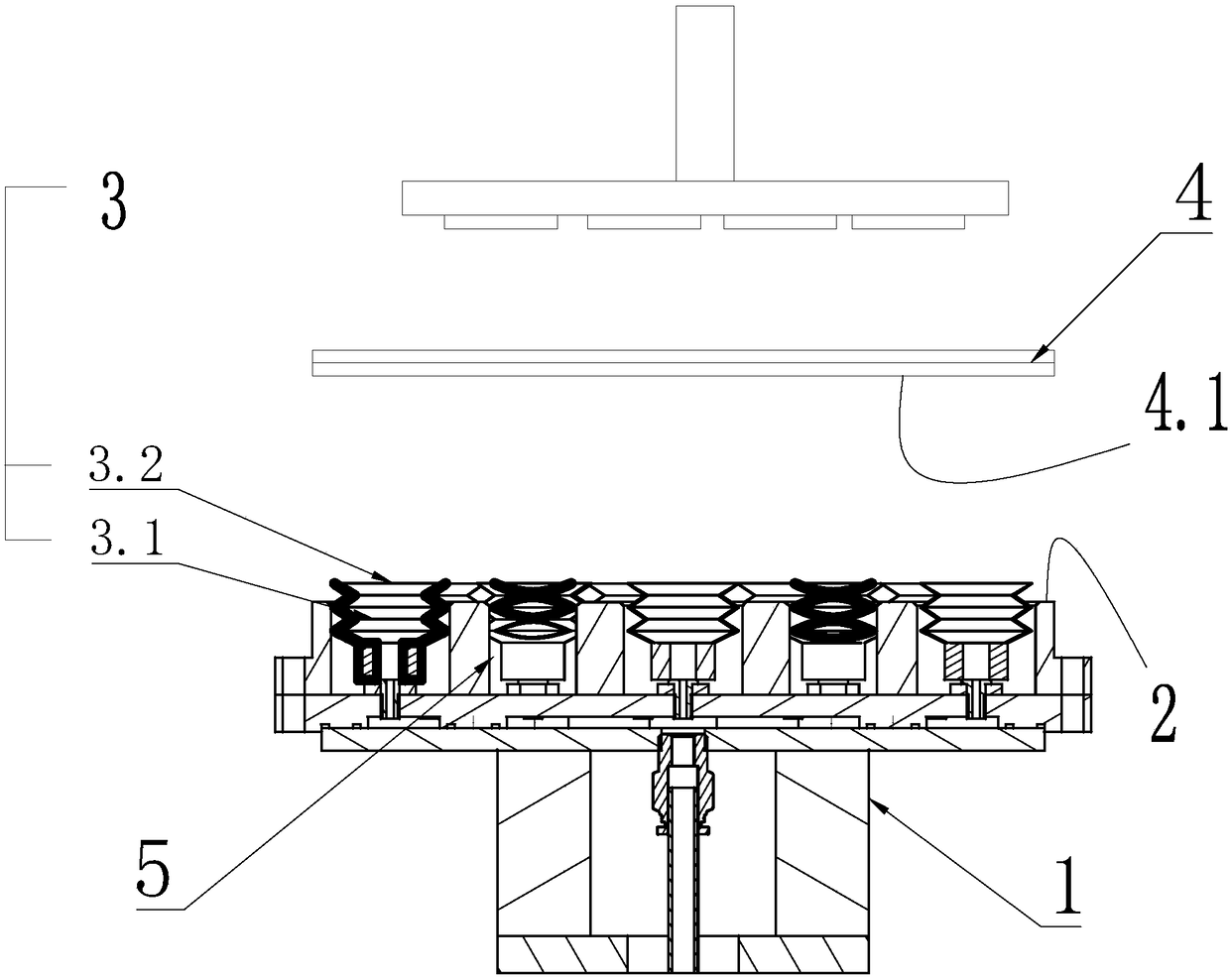

Workbench for de-bonding bonded sheet product and clamping method

PendingCN108807233AImprove fitAdjust the intensitySemiconductor/solid-state device manufacturingBiochemical engineeringDe bonding

The invention discloses a workbench for de-bonding a bonded sheet product. The workbench comprises a carrying platform and is characterized in that the carrying platform is provided with a datum planeand at least one sucker group; when the product is placed on the carrying platform, the sucker groups contact with the products before the datum plane contacts with the product and suck the back of the product, and the sucker groups drive the product on the sucker groups to move towards the datum plane until the back of the product is abutted against the datum plane. The workbench has the advantages that the surface of the product can be well attached to the workbench through the suckers, good sucking can be achieved even if the surface of the product is warped or the surface precision of theproduct is poor, and the product can be well fixed and positioned on the carrying platform through the datum plane; the workbench can clamp the product poor in flatness and thus is high in universality during de-bonding.

Owner:ZHEJIANG MICROTECH MATERIAL CO LTD

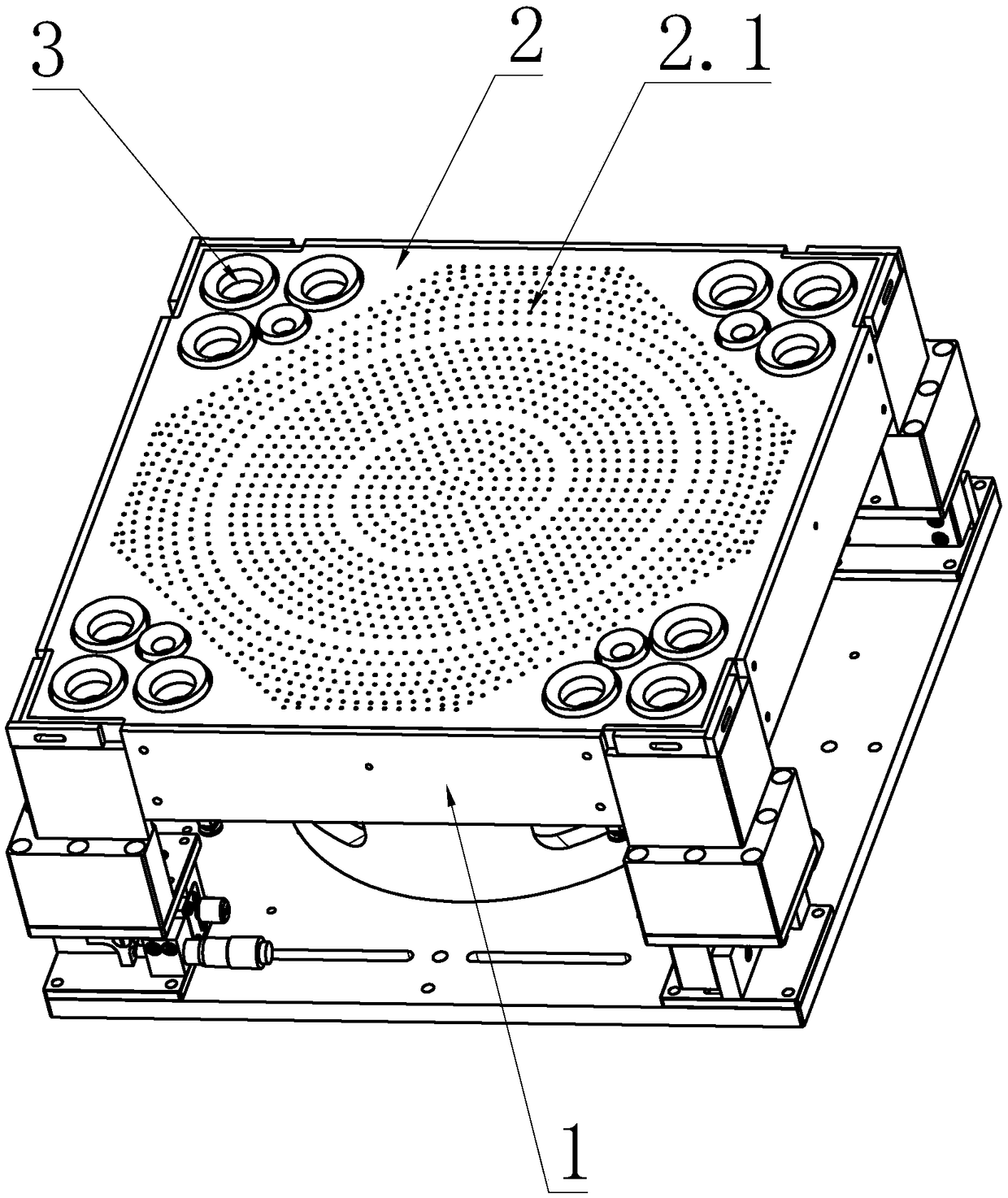

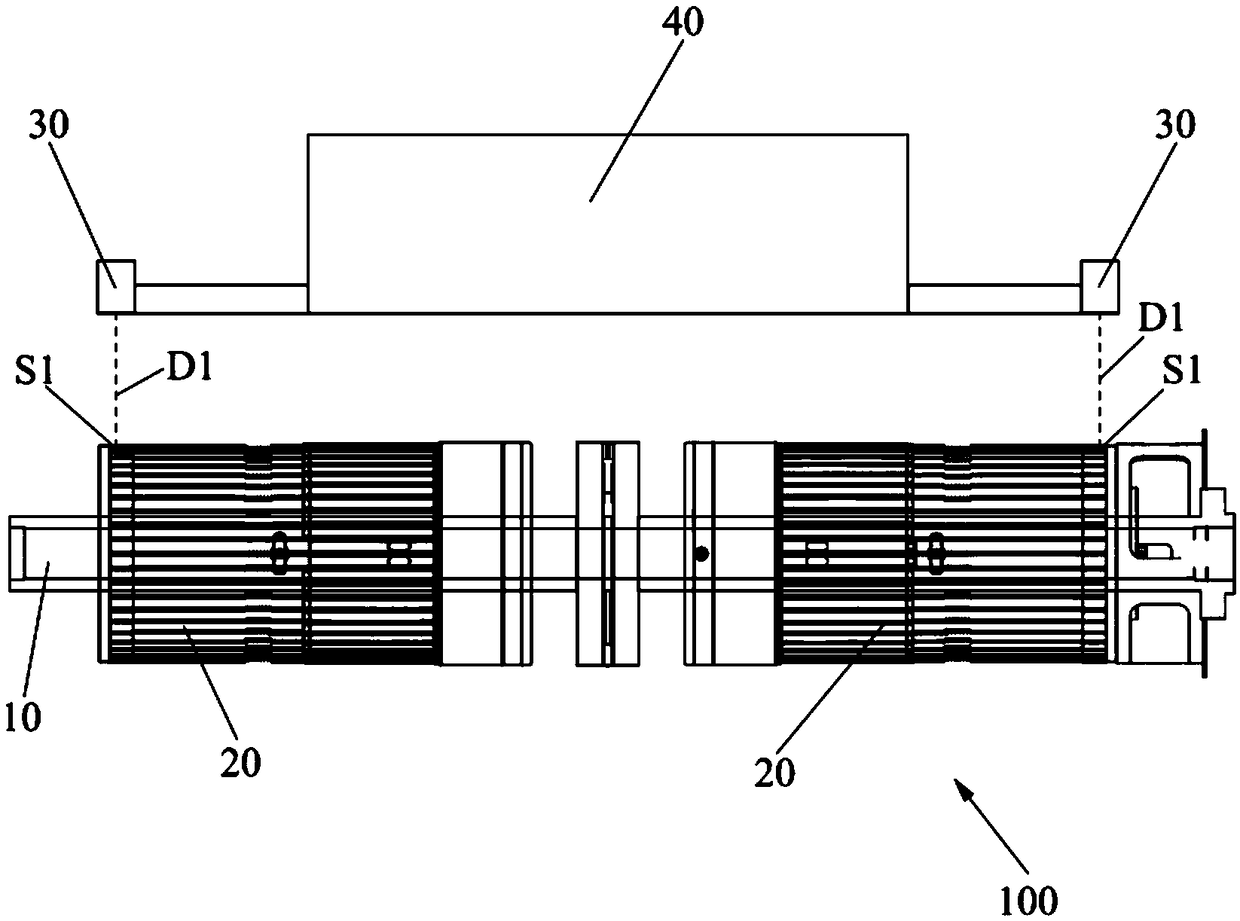

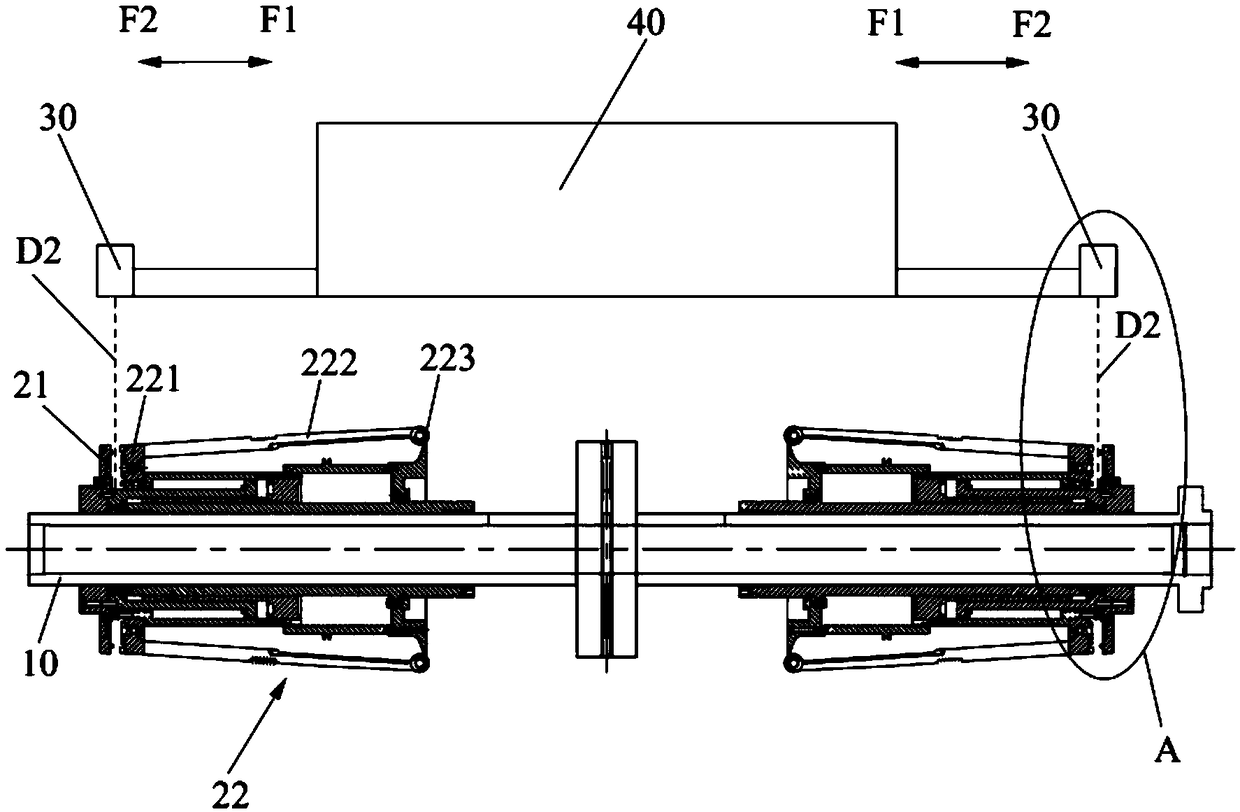

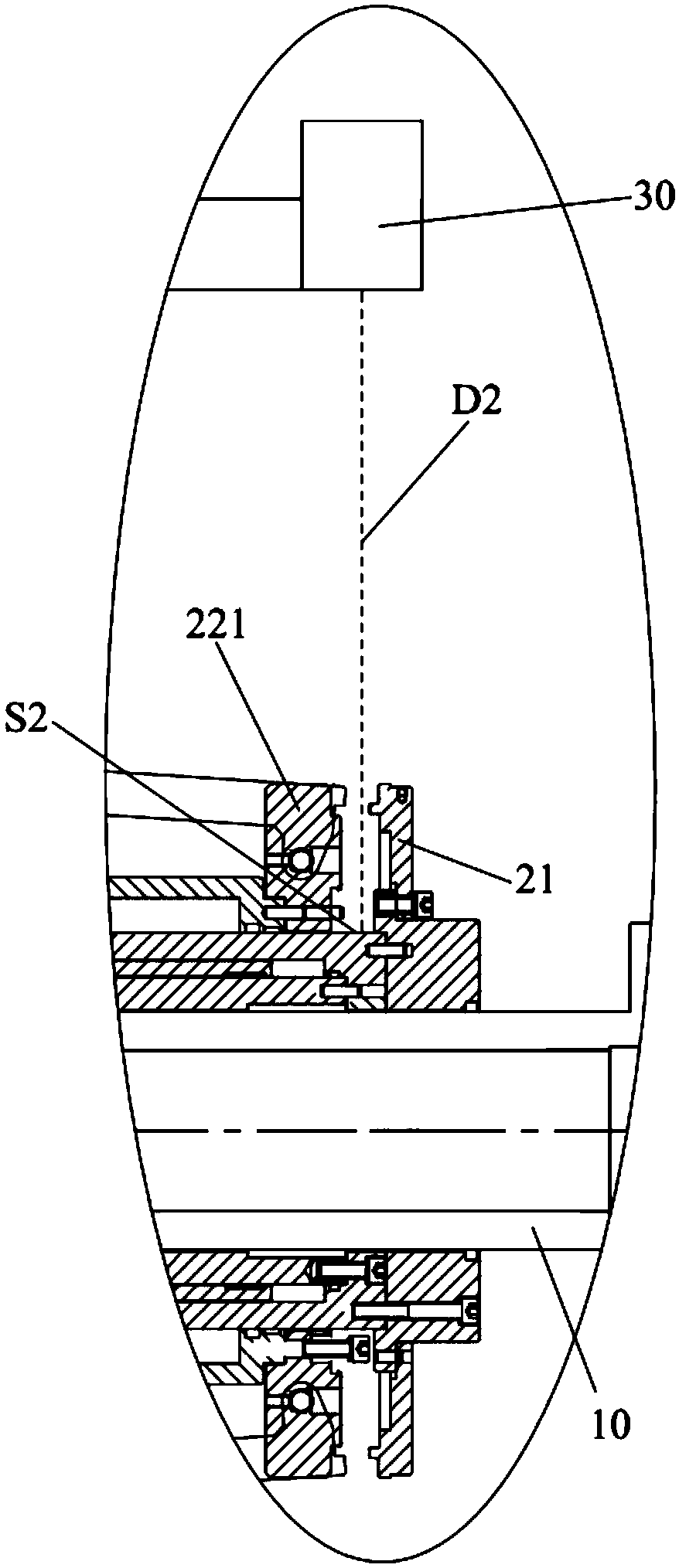

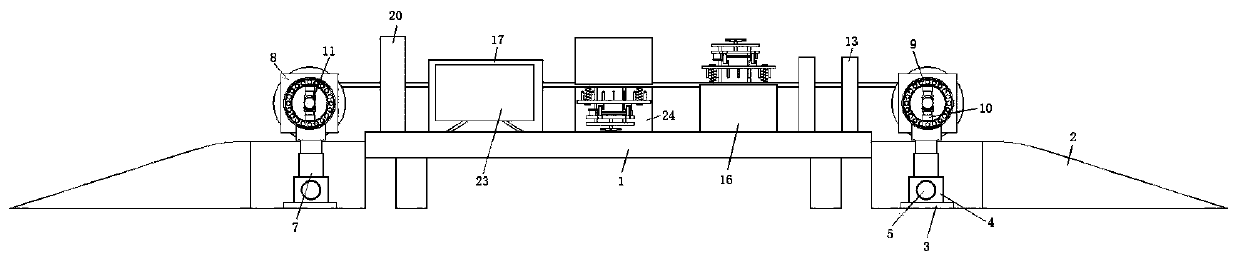

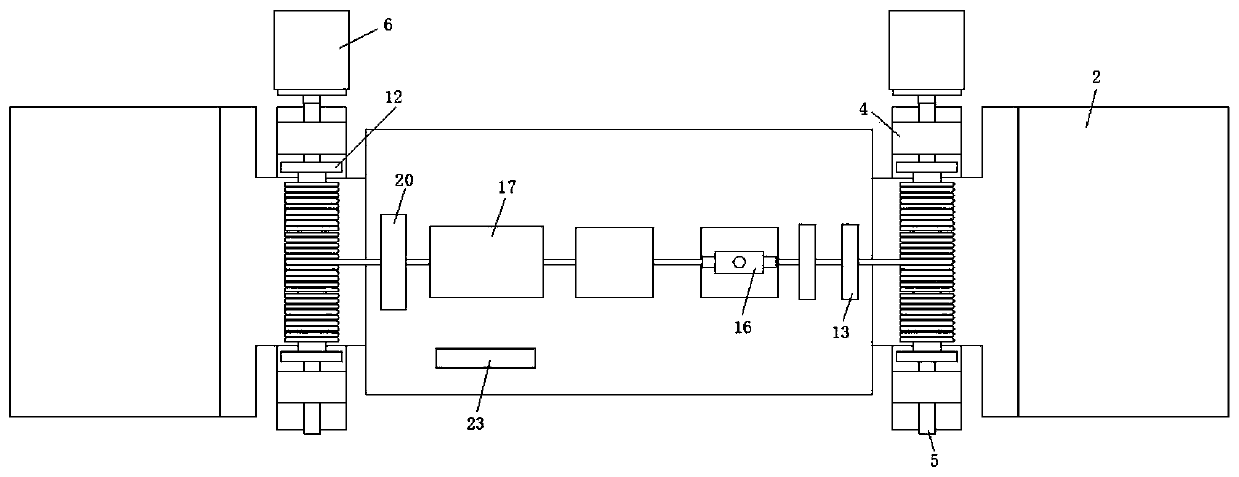

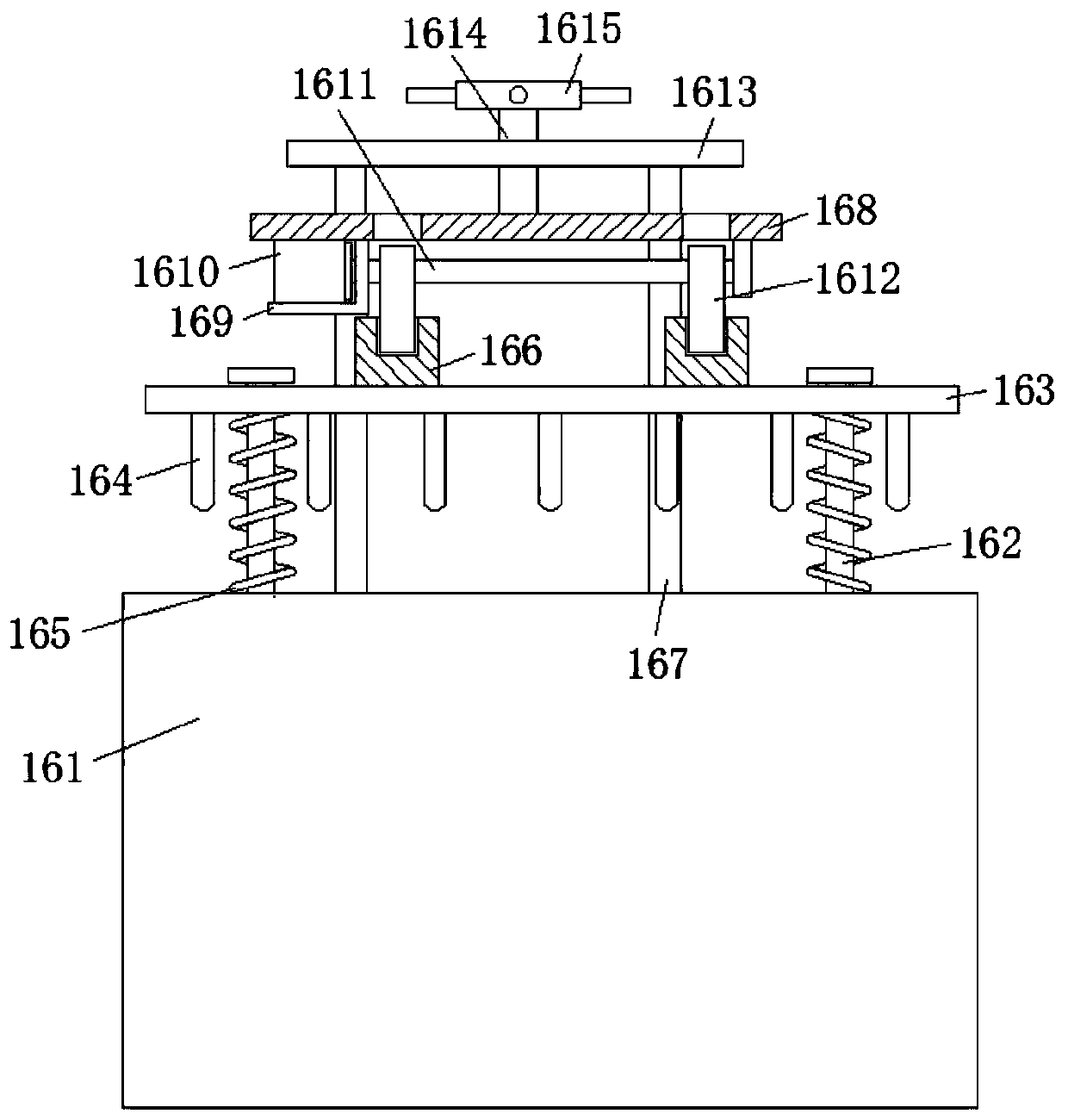

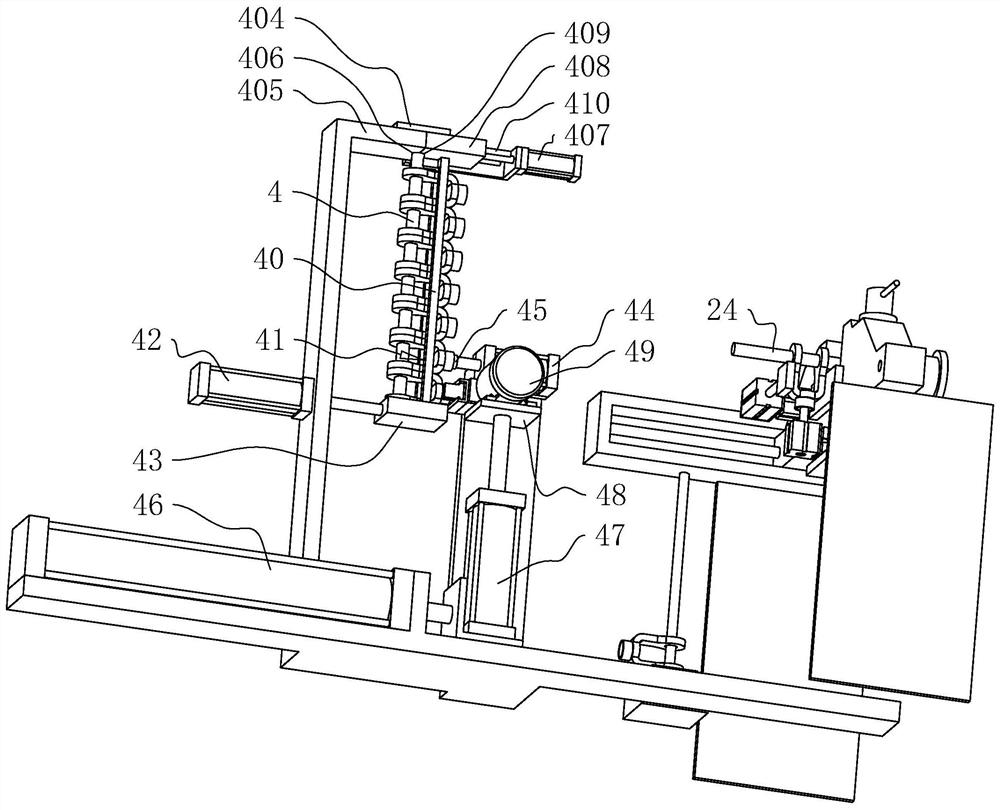

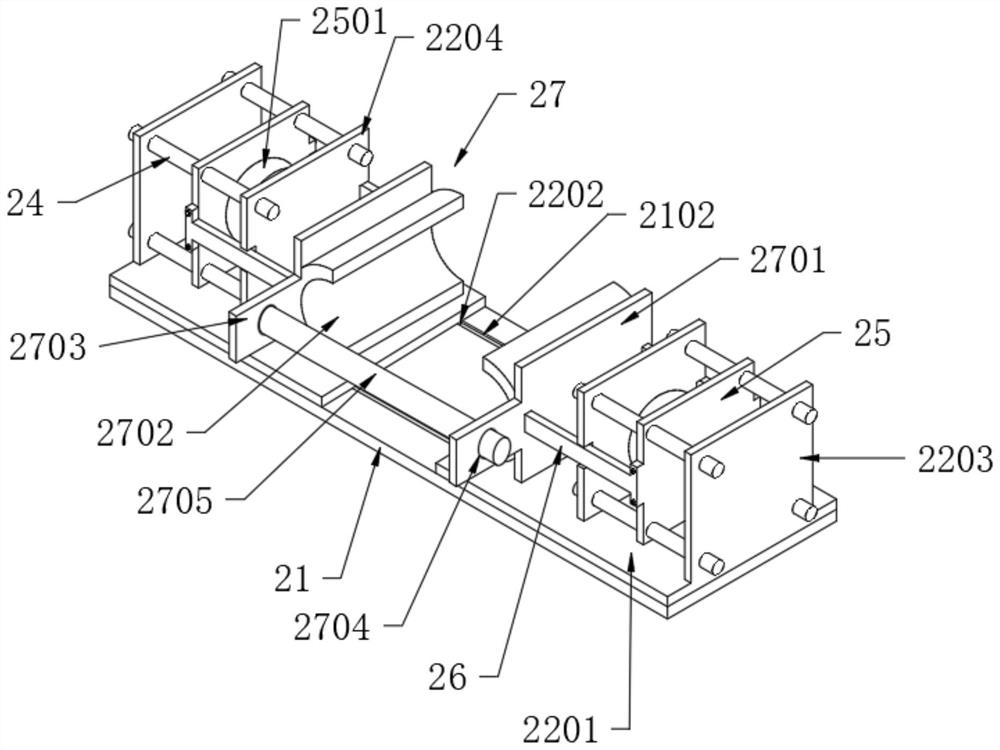

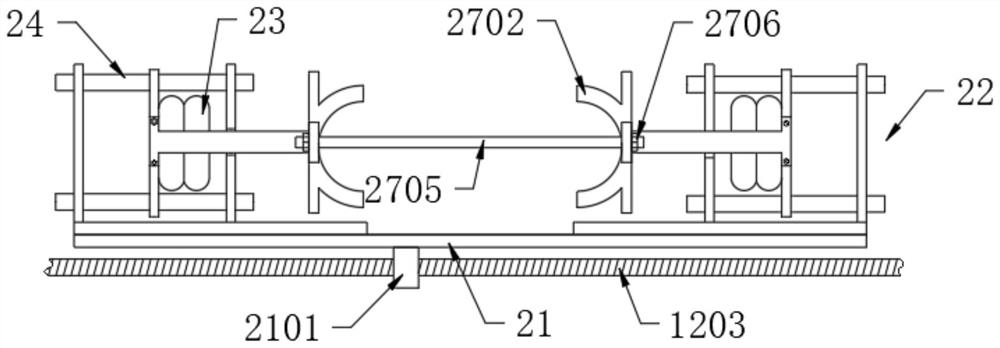

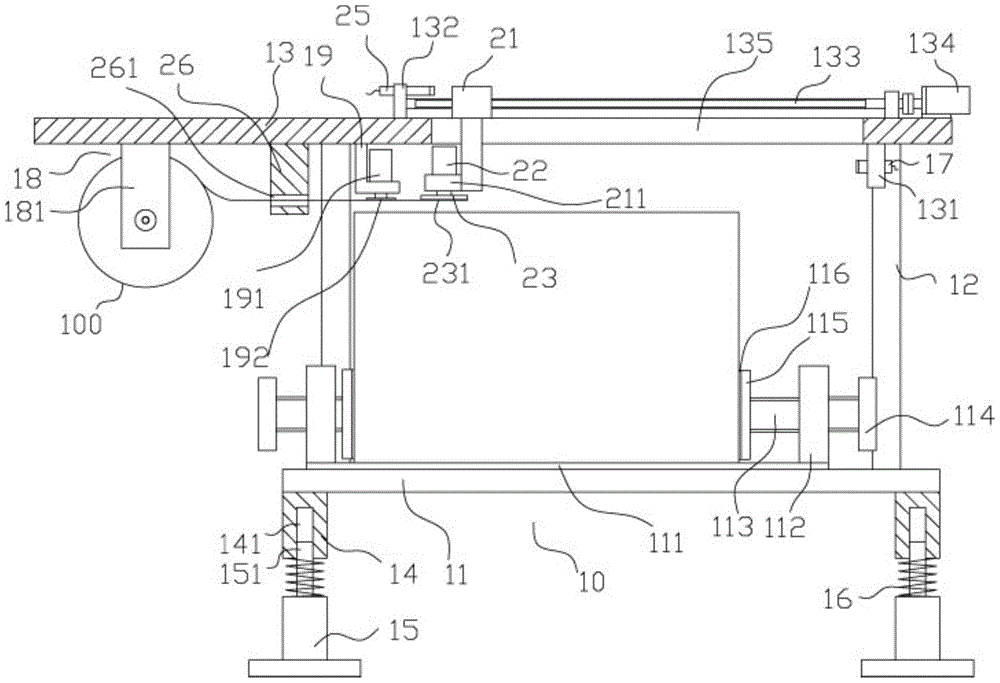

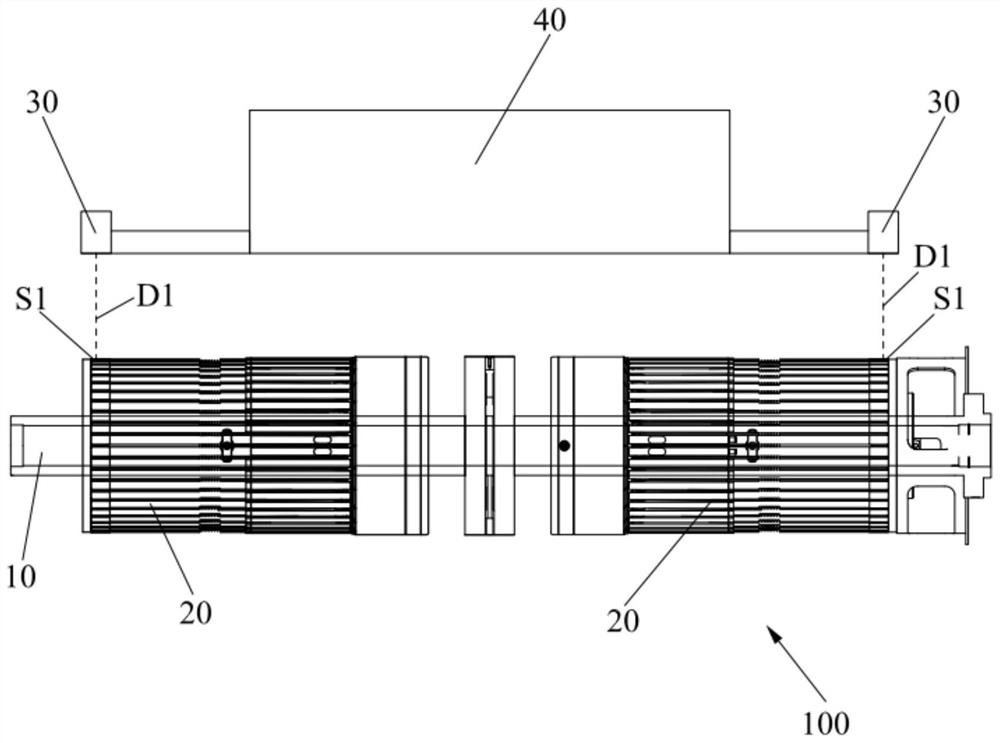

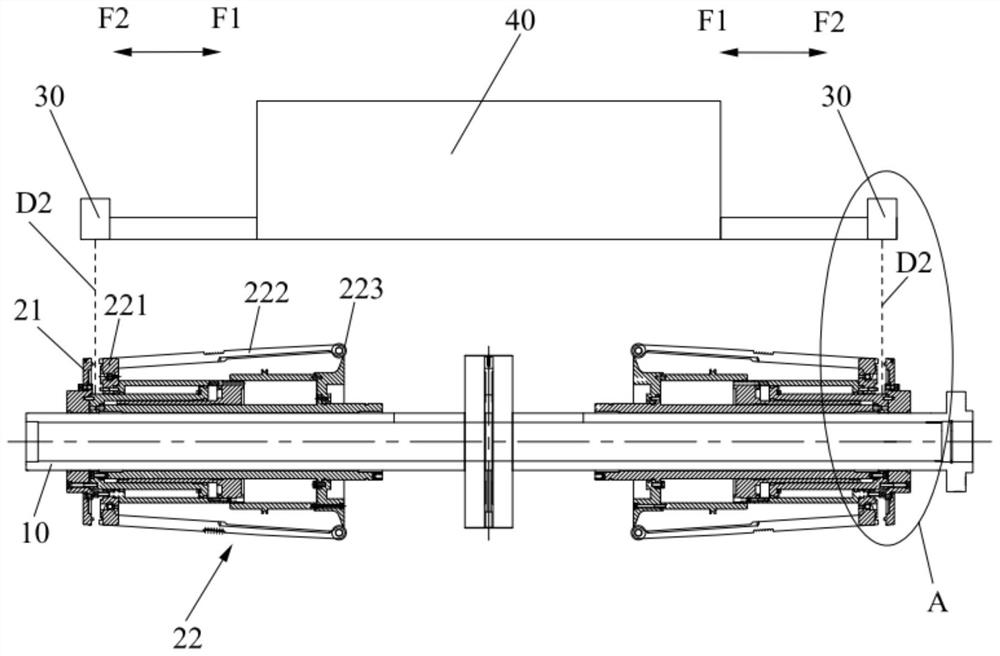

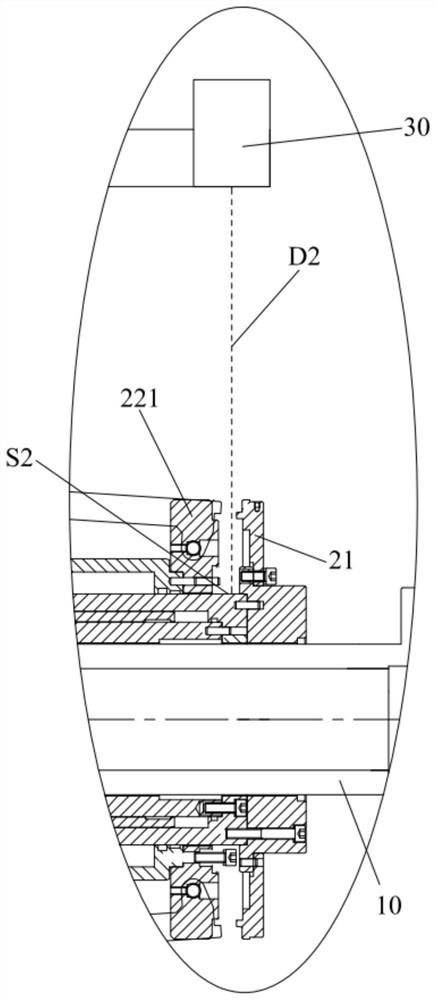

Position detection system and position detection method for tire building drum

The invention discloses a position detection system and a position detection method for a tire building drum, and belongs to the technical field of tire building. The position detection system comprises two ranging components, a drive unit and a control unit, wherein the two ranging components are arranged at the radial outer side of the tire building drum, and radially aligned with support discson two anti-package rod assemblies separately; the drive unit is used for driving the synchronous opposite or reverse axial movement of the two ranging components; and the control unit is in signal connection with the drive unit and the tire building drum, and used for controlling the movement of the anti-package rod assemblies and controlling the working state of the drive unit. The position detection method is based on the position detection system, and used for carrying out position confirmation on the anti-package rod assemblies on the tire building drum. The drive unit is capable of driving the ranging components to detect at different positions, so that a more accurate detection result is achieved; and moreover, the movement distances of the two ranging components can be adjusted, then different tires are matched, and convenient adjustment is achieved.

Owner:SAFE RUN & HISCENT MACHINERY SUZHOU

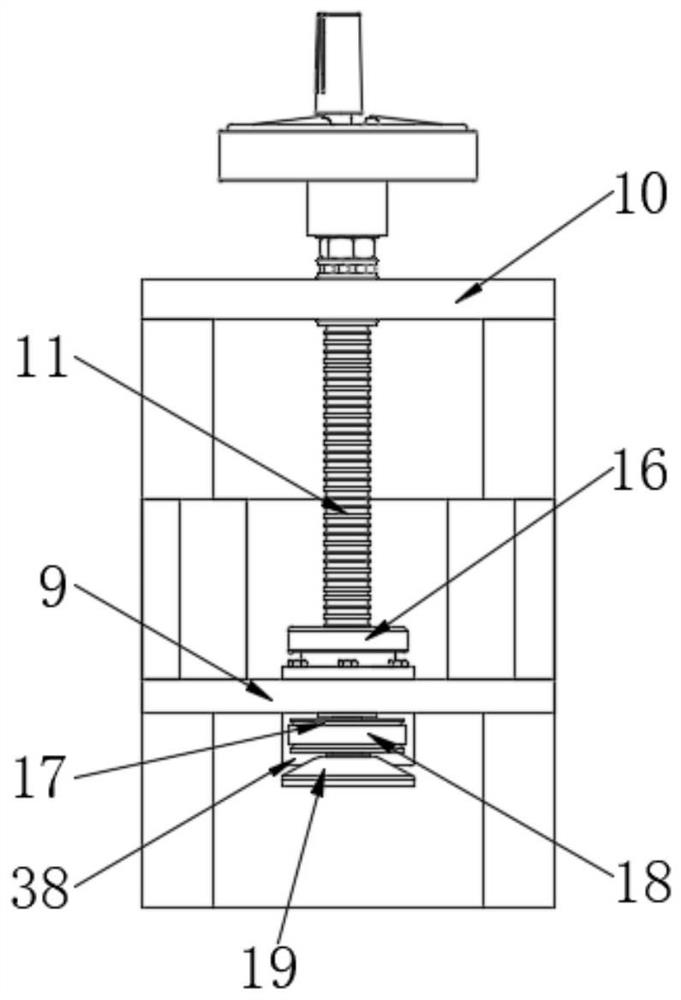

Insulating layer detection device for crosslinked polyethylene cable processing

ActiveCN111487121AAchieving compressive strengthEasy to detectMaterial strength using tensile/compressive forcesInvestigating material hardnessCompressive resistanceRolling-element bearing

The invention discloses an insulating layer detection device for crosslinked polyethylene cable processing. The device comprises a detection table; transfer tables are arranged on the two sides of thedetection table; and rectangular notches are formed in the front side and the rear side of the end, close to the detection table, of each transfer table. Supporting plates are fixedly connected to the bottom ends of the rectangular notches; mounting blocks are slidably connected to the top surfaces of the supporting plates; a reciprocating lead screw is connected between the two supporting plateson the same side through threads; first servo motors are arranged on the rear sides of the mounting blocks at the rear ends; the output ends of the first servo motors are fixedly connected with the reciprocating lead screw; air cylinders are fixedly connected to the top faces of the mounting blocks through screws; rectangular blocks are fixedly connected to the output ends of the air cylinders through screws; circular holes are formed in the middles of the rectangular blocks; and rolling bearings are fixedly connected to the inner walls of the circular holes. The device is reasonable in design and high in detection precision, can achieve the detection of the compressive strength, temperature resistance and appearance of the cross-linked polyethylene cable, and well guarantees the deliveryquality of the cross-linked polyethylene cable.

Owner:涌纬集团股份有限公司

Metal plate equidistant punching device based on ratchet motion principle and punching method of metal plate equidistant punching device

InactiveCN113245590AInstallation fixedAchieve the effect of fixing sheet metal partsBoring/drilling componentsBoring/drilling machinesRatchetPunching

The invention relates to the technical field of mechanical equipment, and discloses a metal plate equidistant punching device based on the ratchet motion principle and a punching method of the metal plate equidistant punching device. The metal plate equidistant punching device comprises a machine frame, a workbench is fixedly connected to the interior of the machine frame, a fixing block is fixedly connected to the top of the workbench, and a sliding block is slidably connected to the interior of the machine frame; and the bottom of the sliding block is fixedly connected with a lifting rod, the bottom of the lifting rod is fixedly connected with a punching motor, the bottom of the punching motor is movably connected with a drill bit, the top of the sliding block is fixedly connected with a ratchet bar, and the top of the ratchet bar is movably connected with a limiting pawl block. Through cooperative use of the ratchet bar, the limiting pawl block, an adjusting pawl block, a connecting rod, a limiting ring and a movable pin, the effect that the ratchet bar is driven to slide rightwards at equal intervals is achieved, it is guaranteed that the rightward moving distance of the drill bit is equal, the hole distance of drilled holes is equal, the product quality is improved, the trouble of pre-measurement and marking is avoided, and the production efficiency of metal plate punching is effectively improved.

Owner:WENZHOU GAIYI MASCH CO LTD

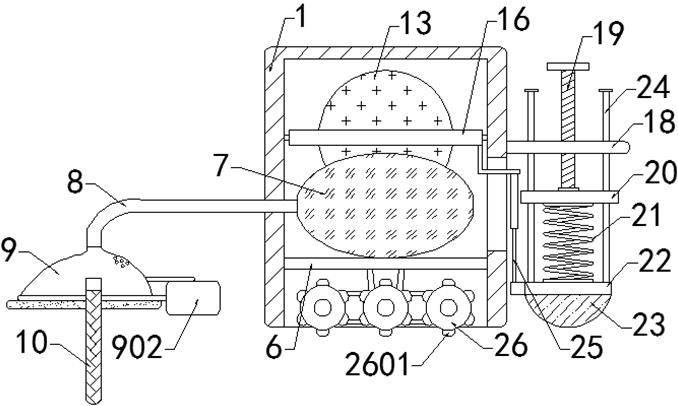

Tidal enteral nutrition pump

ActiveCN112932978AFilter impactAfter the filter plate is filteredDomestic articlesFeeding-tubesAnimal scienceMedicine

The invention discloses a tidal enteral nutrition pump which comprises a base, a supporting plate is fixedly connected to the top of the base, a box is fixedly connected to the front face of the supporting plate, a partition plate is fixedly connected between the two sides of the inner wall of the box, and a first baffle is slidably connected to the bottom of the partition plate. According to the tidal enteral nutrition pump provided by the invention, a nutrient solution is filtered, so that the situation that cakes enter the nutrition pump pipe to cause blockage is prevented, the cakes can be prevented from being fed into the body of a patient to be inconveniently digested, meanwhile, the cakes are convenient to clean, the influence of accumulation of the cakes on filtration of the filter plate is reduced, and by adopting tidal input, according to the gastrointestinal motility function of the human body, the gastrointestinal motility rhythm is simulated, the nutrient solution is dripped for a period of time, paused for a period of time, dripped again for a period of time, paused again for a period of time, and intermittently dripped, so that the nutrient solution can be intermittently conveyed, and the situation that a patient feels uncomfortable can be reduced.

Owner:溧阳市人民医院

Fine grinding equipment for surface of artificial diamond product

PendingCN114147553AImprove processing qualityAdjust the moving distanceGrinding drivesOther manufacturing equipments/toolsElectric machineryEngineering

The invention discloses artificial diamond product surface fine grinding equipment which comprises a working box, a supporting plate is fixedly connected to the top of the working box, the supporting plate is arranged above the working box, and a sliding plate capable of sliding in the supporting plate is used for grinding the surface of an artificial diamond product. A second threaded rod on a supporting block is matched with an inner threaded hole of a connecting piece to further push a moving assembly on the upper portion to move towards the side close to the diamond, a sliding frame and a moving plate can move up and down through rotation of a first threaded rod, driving force on a driving motor is transmitted to a short shaft through a belt, and the short shaft is driven to rotate; by means of the structure, the moving distance and the moving position of the grinding head and the diamond can be finely adjusted, the structure is simple, control is convenient, and the diamond machining quality can be effectively improved.

Owner:ANHUI YAZHU DIAMOND

A carton tape seal mechanism that can automatically take out the tape

InactiveCN104986391BMeet the needs of pastingAdjust the moving distanceWrapper twisting/gatheringCartonDrive motor

Owner:XIAN INT UNIV

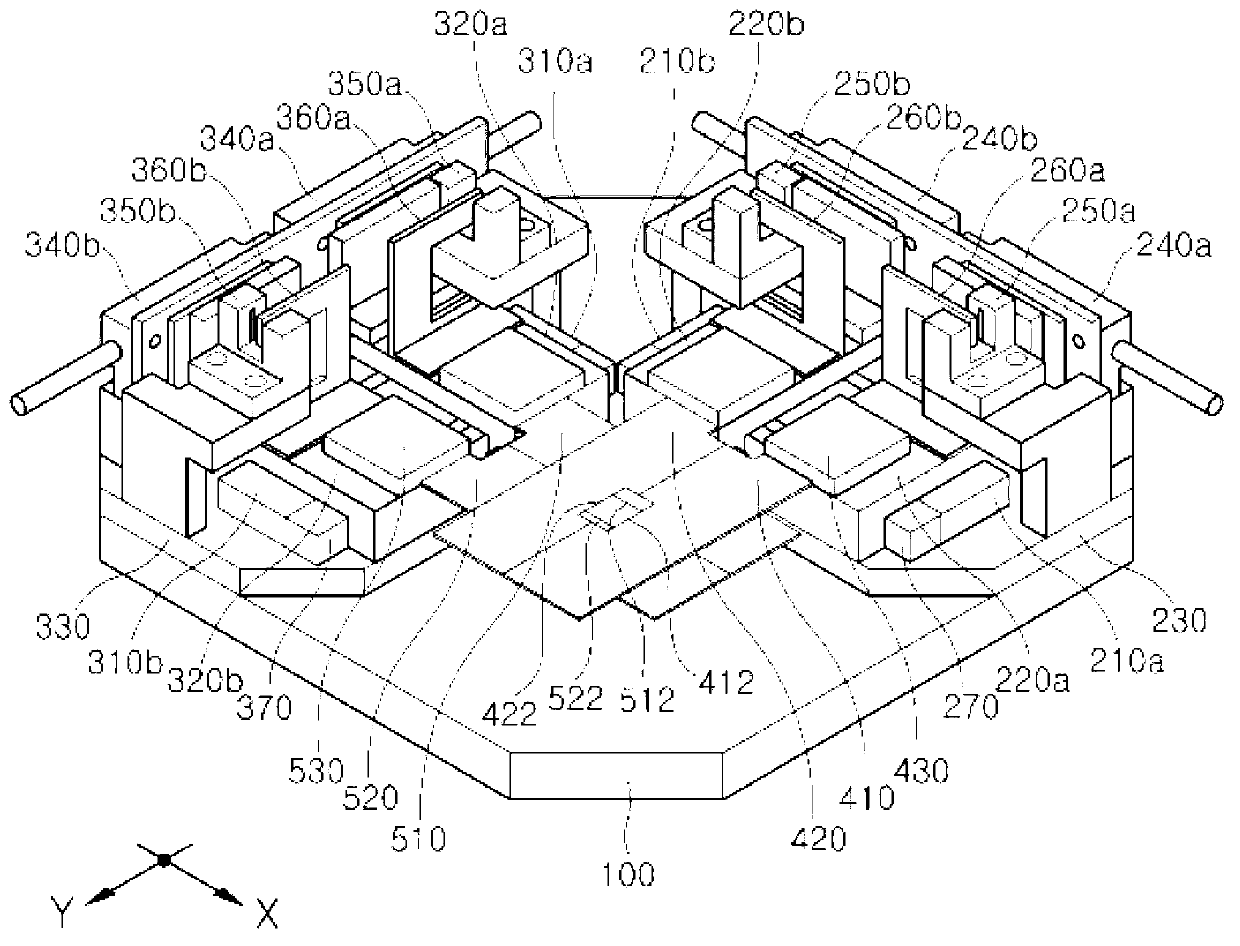

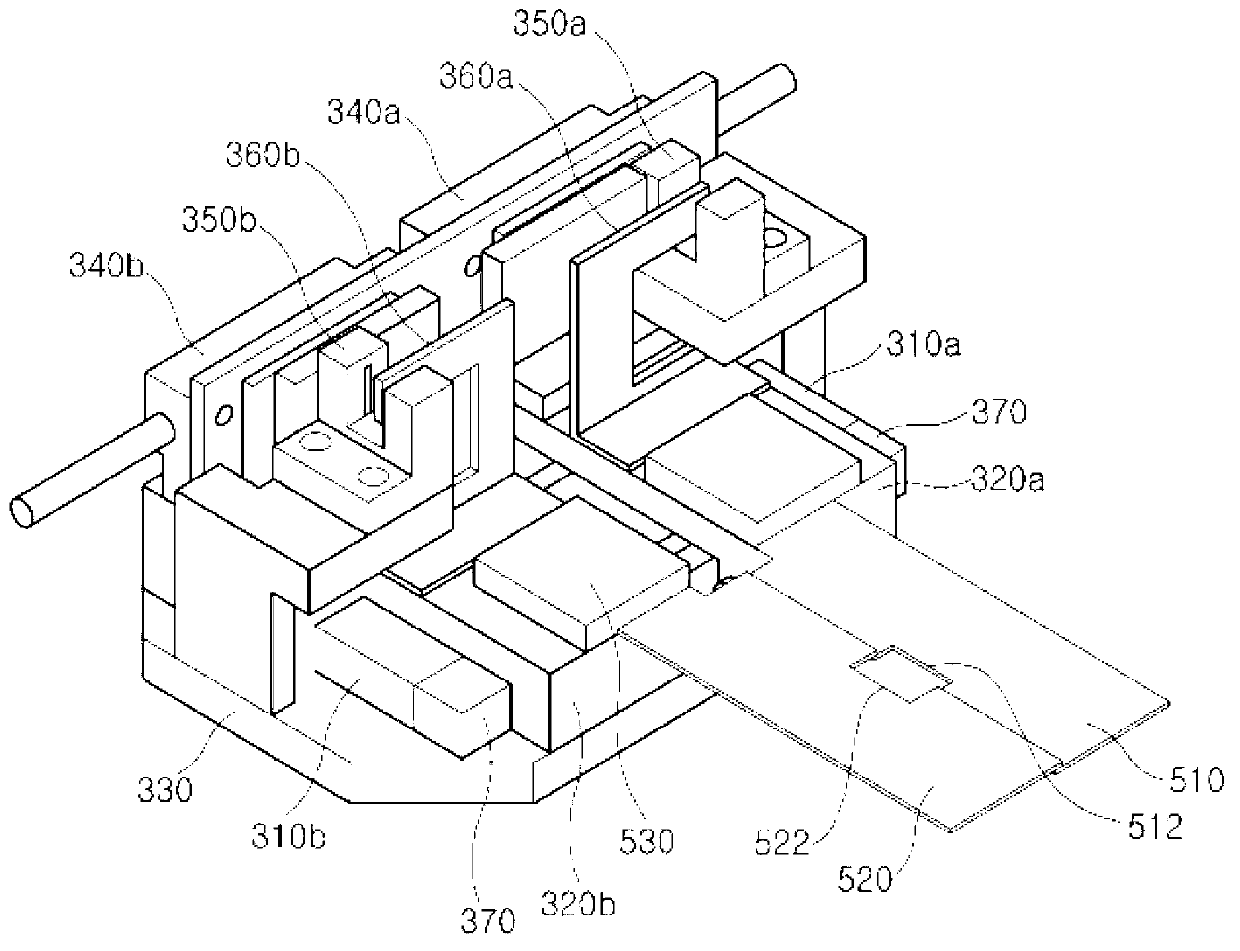

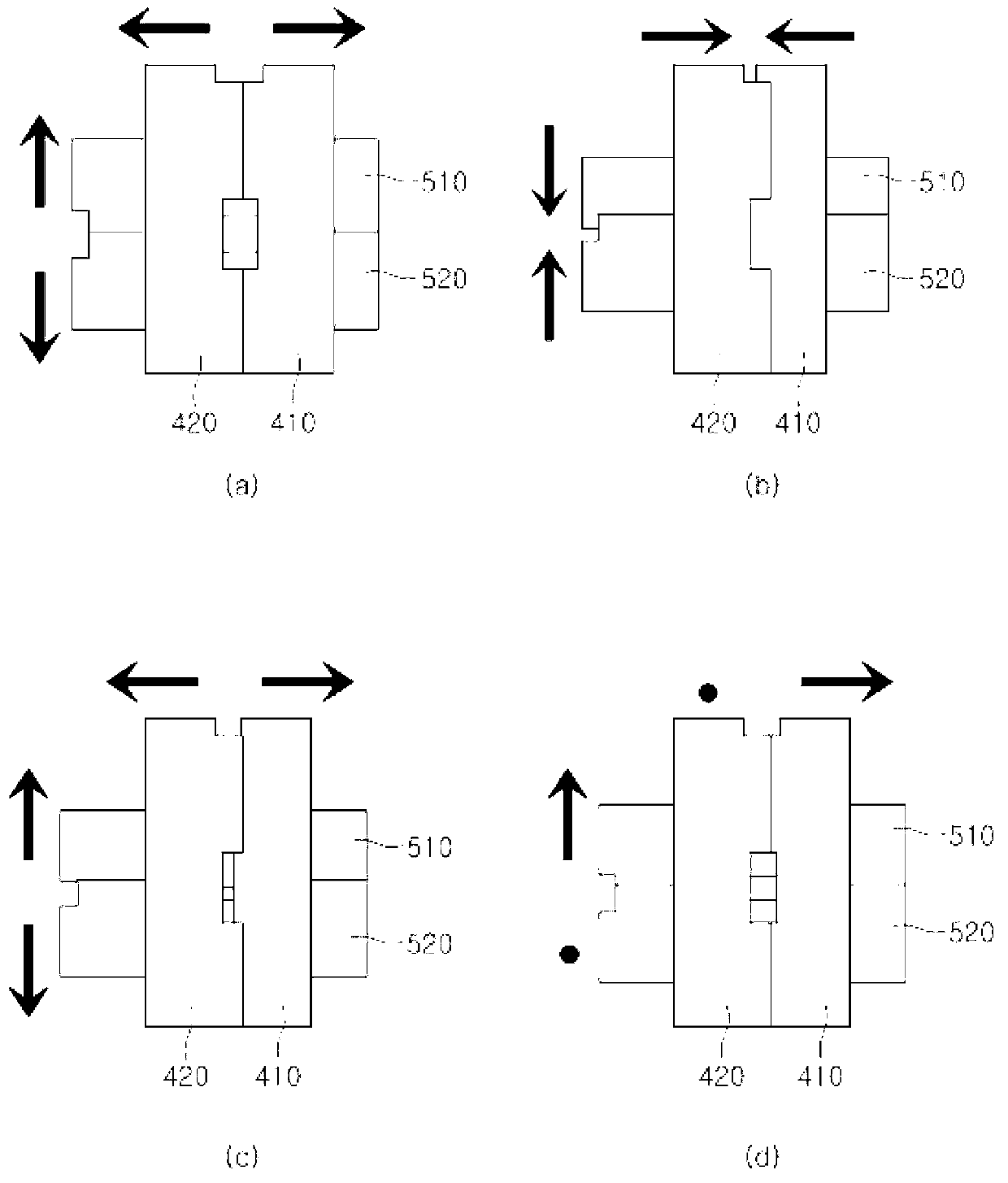

Crack width adjusting device

ActiveCN102998759AImprove the efficiency of conditioning processesAdjust the moving distanceLaser detailsStatic indicating devicesEngineeringElectrical and Electronics engineering

The invention discloses a crack width adjusting device comprising first, second, third and fourth movable terminals, and first and second stators, wherein the first and second movable terminals are connected to mutually parallel first and second crack blades respectively, and the third and fourth movable terminals are connected to third and fourth crack blades respectively. The third and fourth crack blades are orthogonal to the first and second crack blades and are mutually parallel to each other. The first stator is arranged at the lower parts of the first and second mutually parallels and is used for driving the first and second movable terminals to move linearly respectively. The second stator is arranged at the lower parts of the third and fourth mutually parallels and is used for driving the third and fourth movable terminals to move linearly respectively.

Owner:CHARM ENG CO LTD

Auxiliary breathing device for pulmonary patient

InactiveCN113952567ARealize the pressing effectMeet the needs of useElectrotherapyRespiratory masksMedicineElectric machinery

The invention discloses an auxiliary breathing device for a pulmonary patient. The auxiliary breathing device comprises a fixing box, wherein side plates are symmetrically fixed to side edges of the fixing box, the side plates are connected with adjusting screw rods through threads, and the adjusting screw rods are connected to clamping plates through bearings. The auxiliary breathing device further comprises a partition plate, wherein the partition plate is fixed in the fixing box, a compressed air bag is arranged on the partition plate, the side edge of the compressed air bag is connected with a connecting pipe, the connecting pipe penetrates through the fixing box, the tail end of the connecting pipe is connected with a mask, an elastic rope is fixed to the mask for wearing, and a soft rubber pad is fixed to the lower end face of the mask for protection; and a motor, wherein the motor is fixed to the fixing box, and a disc is fixed to the tail end of an output shaft of the motor. According to the auxiliary breathing device for the pulmonary patient, an adjustable automatic extrusion mechanism is adopted for replacing manual extrusion to achieve the pressing effect on the compressed air bag, a uniform pressing effect can be guaranteed, gas flow can be adjusted according to actual requirements, and therefore, use requirements of different patients are met.

Owner:史广超

Universal joint fork ear hole grinding device

ActiveCN111922804BReduce the chance of skewExtend your lifeRevolution surface grinding machinesGrinding drivesUniversal jointElectric machinery

Owner:杭州胜华汽车电子科技有限公司

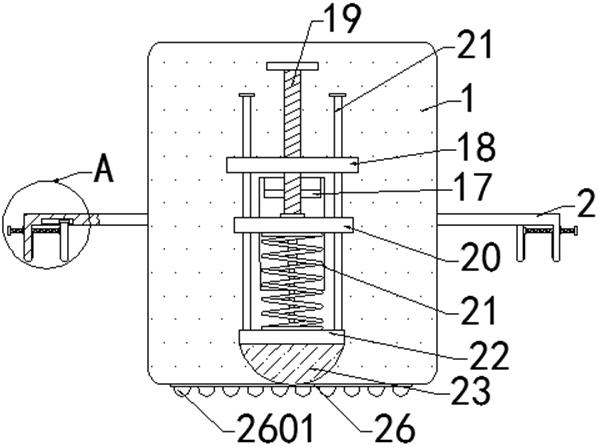

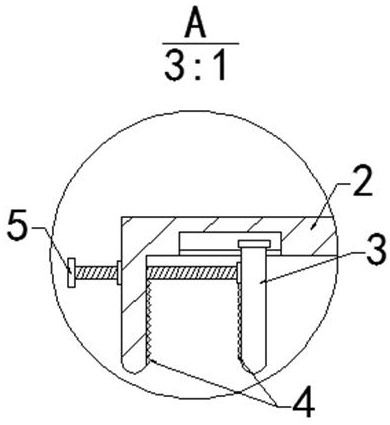

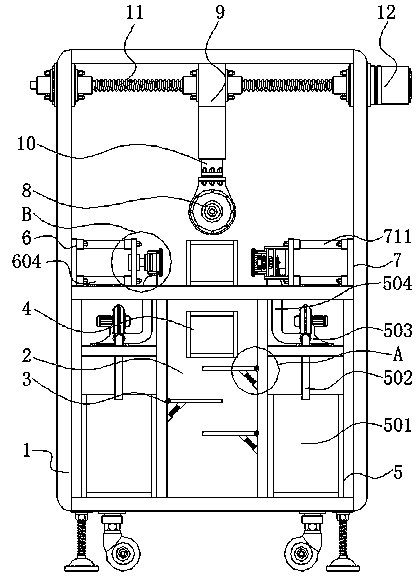

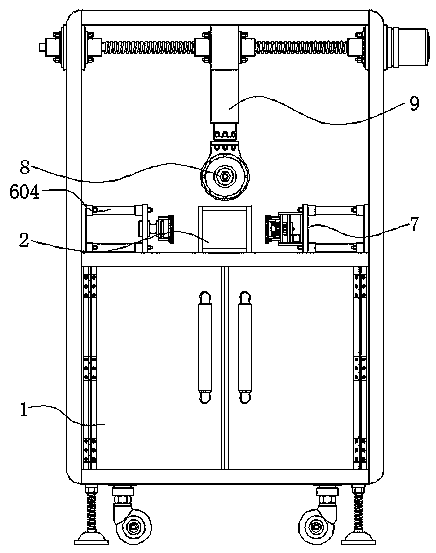

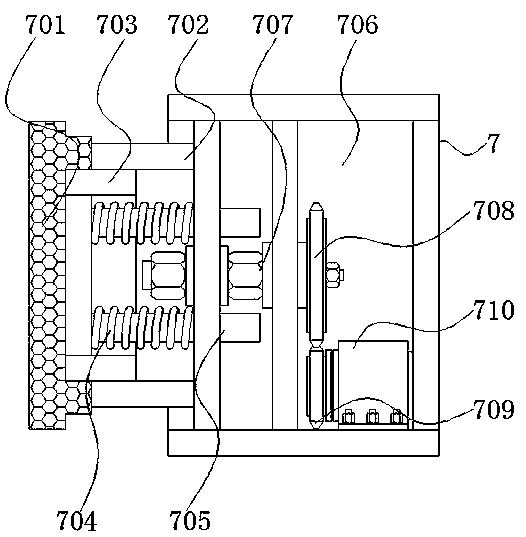

Grinding machine with clamping structure and convenient to adjust for bearing machining

InactiveCN110977757AReduce descent speedTransport stableGrinding carriagesGrinding drivesEngineeringStructural engineering

The invention discloses a grinding machine with a clamping structure and convenient to adjust for bearing machining, and the grinding machine relates to the technical field of grinding machines. Specifically, the grinding machine with the clamping structure and convenient to adjust for bearing machining comprises a bottom cabinet main frame and a scrap removing mechanism, wherein a main chamber frame is arranged in the bottom cabinet main frame; a buffer mechanism is arranged in the main chamber frame; a pipeline is mounted at the rear end of the main chamber frame; the scrap removing mechanisms are arranged on the left side and the right side of the main chamber frame; an auxiliary limiting mechanism is mounted above the bottom cabinet main frame; and a main limiting mechanism is mountedon one side of the auxiliary limiting mechanism. The grinding machine with the clamping structure and convenient to adjust for bearing machining is provided with the scrap removing mechanism, can effectively guide scraps into a scrap storage tank along the interiors of a discharge pipe and a suction pipe, collects the scraps by using the scrap storage tank in a centralized mode, and avoids the action effect of the grinding machine on parts from being affected due to the fact that the scraps accumulate in the bottom cabinet main frame.

Owner:东莞市史雷帝三维数控科技有限公司

A sheet metal isometric punching device based on the principle of ratchet movement

ActiveCN111375797BInstallation fixedAchieve the effect of fixing sheet metal partsBoring/drilling componentsBoring/drilling machinesRatchetPunching

The invention relates to the technical field of mechanical equipment, and discloses a sheet metal isometric punching device based on the principle of ratchet movement, including a frame, the inside of the frame is fixedly connected with a workbench, and the top of the workbench is fixed A fixed block is connected, the inside of the frame is slidably connected with a slider, the bottom of the slider is fixedly connected with a lifting rod, the bottom of the lifting rod is fixedly connected with a punching motor, and the bottom of the punching motor is movable A drill bit is connected, and a ratchet bar is fixedly connected to the top of the slider, and the top of the ratchet bar is movably connected with a limit pawl block, and the ratchet bar, the limit pawl block, the adjustment pawl block, and the connecting rod , the limit ring and the movable pin are used together to achieve the effect of driving the ratchet bar to slide to the right at an equal distance, so as to ensure that the drill bit moves to the right at the same distance and the hole spacing of the drilling holes is equal, thereby improving product quality. Avoid the trouble of pre-measurement punctuation, effectively improve the production efficiency of sheet metal punching.

Owner:张家港市金帆箱柜有限公司

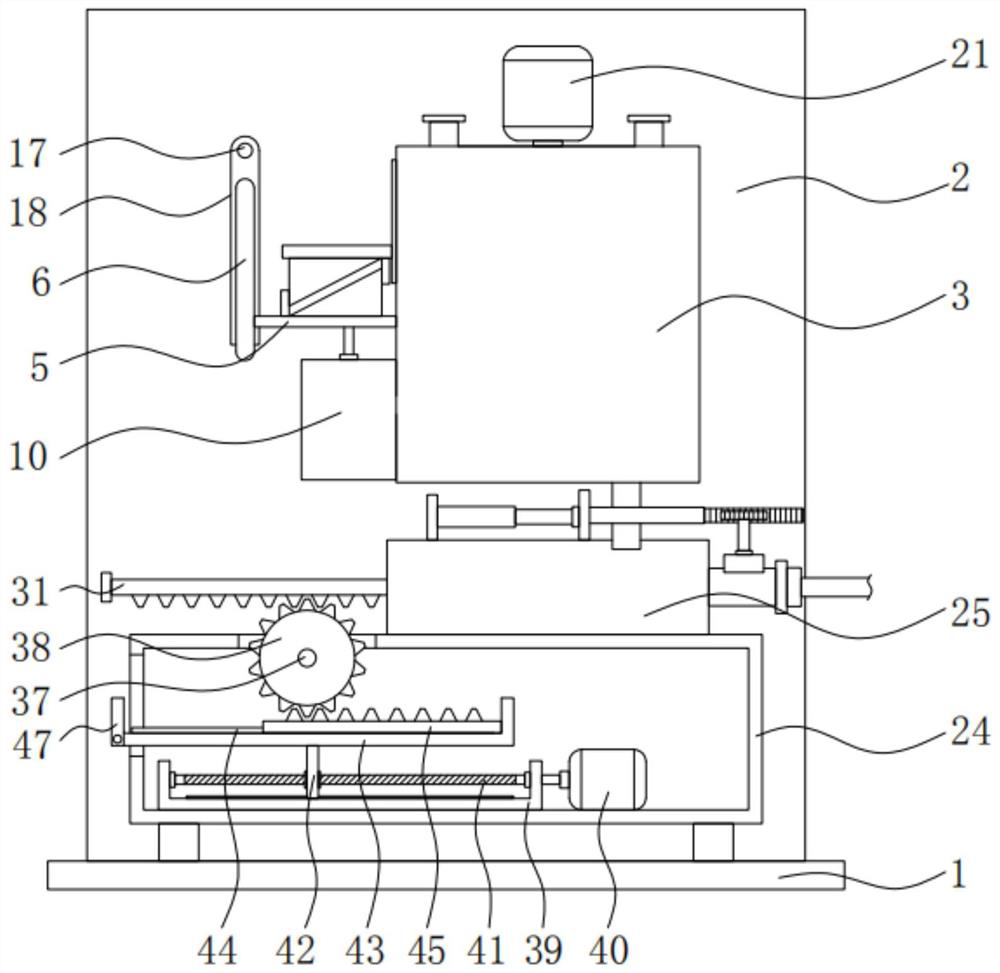

A mechanical automatic cut-off device

ActiveCN112404571BSave time on truncationIncrease productivityShearing machinesShearing machine accessoriesWorkbenchIndustrial engineering

The invention relates to a cutting device, in particular to a mechanical automatic cutting device. The technical problem to be solved is to provide an automatic cutting device for strip-shaped steel plates which realizes automatic feeding and whose cutting length of steel plates can be adjusted. The technical scheme of the present invention is a mechanical automatic cutting device, including brackets, etc.; a cutting mechanism, a feeding mechanism and a material box, one side of the workbench is fixedly installed on the bracket, the cutting is fixed and installed in the middle of the nail, and the cutting mechanism is located on the workbench. One side, the feeding mechanism is fixedly installed on the workbench, and the material box is fixedly installed on the side of the bracket close to the workbench. The present invention adds a feeding mechanism, which realizes alternate feeding processes, saves the cutting time of the steel plate, and improves the overall production efficiency of the device.

Owner:福建省嘉泰智能装备有限公司

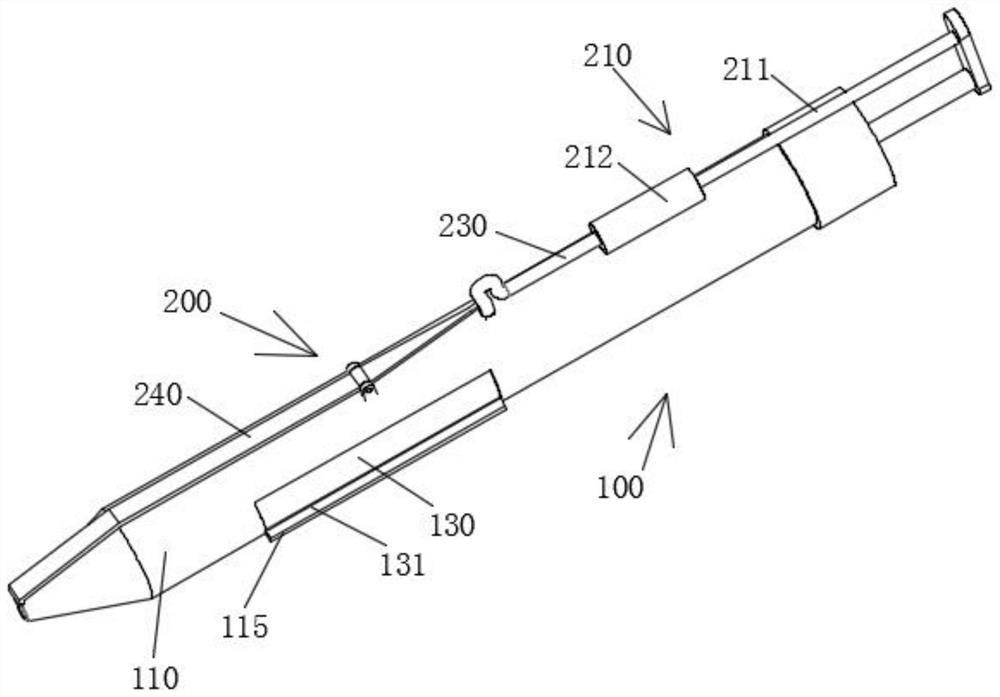

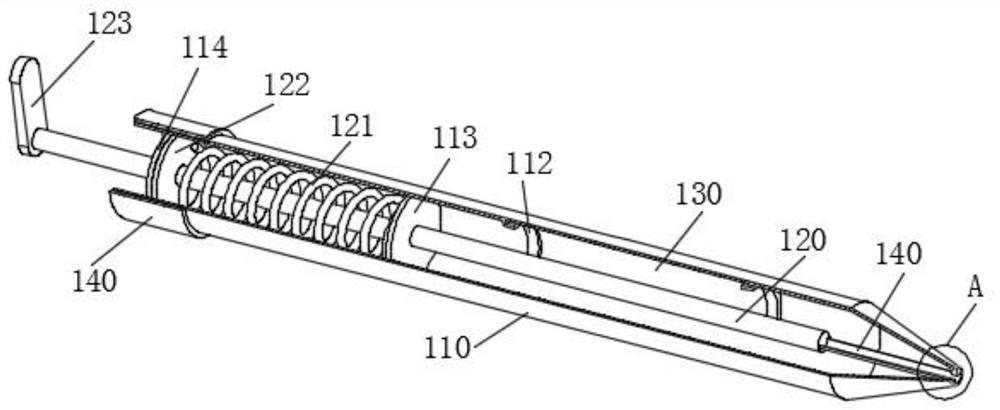

Quantity-controllable dendrobium officinale pollination pen

InactiveCN112243857AAvoid interferenceEasy to control pollinationPlant genotype modificationPollinationFlower pollen

The invention relates to the technical field of pollination pens, in particular to a quantity-controllable dendrobium officinale pollination pen which comprises a pollen outlet module. The pollen outlet module comprises a pen tube and a first round rod, a first annular baffle is fixedly connected to the middle of an annular inner wall of the pen tube, and a second annular baffle is fixedly connected to the annular inner wall of the end, deviating from the tip, of the pen tube; and the first round rod is slidably connected with the first annular baffle and the second annular baffle in a sleevedmanner. According to the quantity-controllable dendrobium officinale pollination pen, through the arrangement of a clearing module, when a pollen feeding pipe moves inwards, a blocking piece makes contact with the inner wall of the pollen feeding pipe, pollen on the inner wall of the pollen feeding pipe is scraped off, the accuracy of the pollination quantity of pollen each time is improved, andtherefore the pollination rate is increased; through the arrangement of a threaded sleeve, the maximum moving distance of the first round rod is adjusted, so that the moving distance of the pollen feeding pipe is adjusted, and the pollination quantity of the pollen each time can be adjusted according to needs; and meanwhile, due to the arrangement of a pressing plate, the quantity-controllable dendrobium officinale pollination pen is convenient and quick to operate, and the pollination work efficiency is improved.

Owner:黄国虎

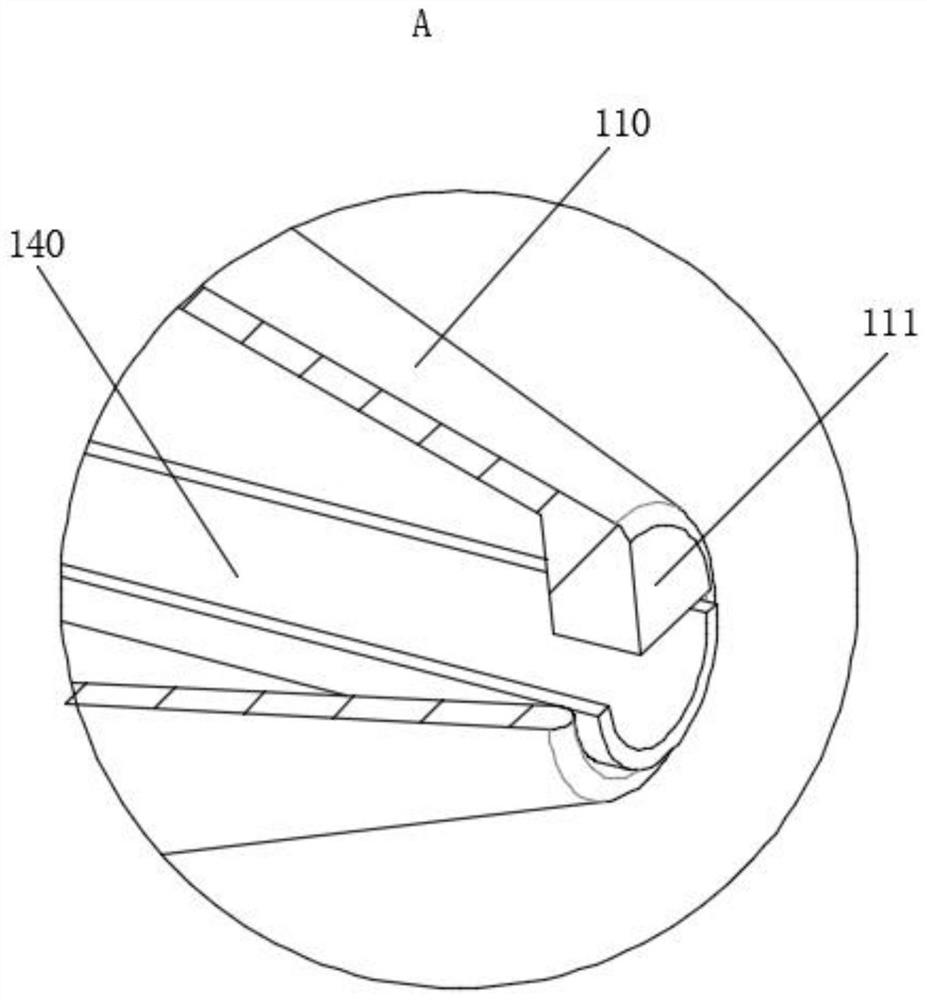

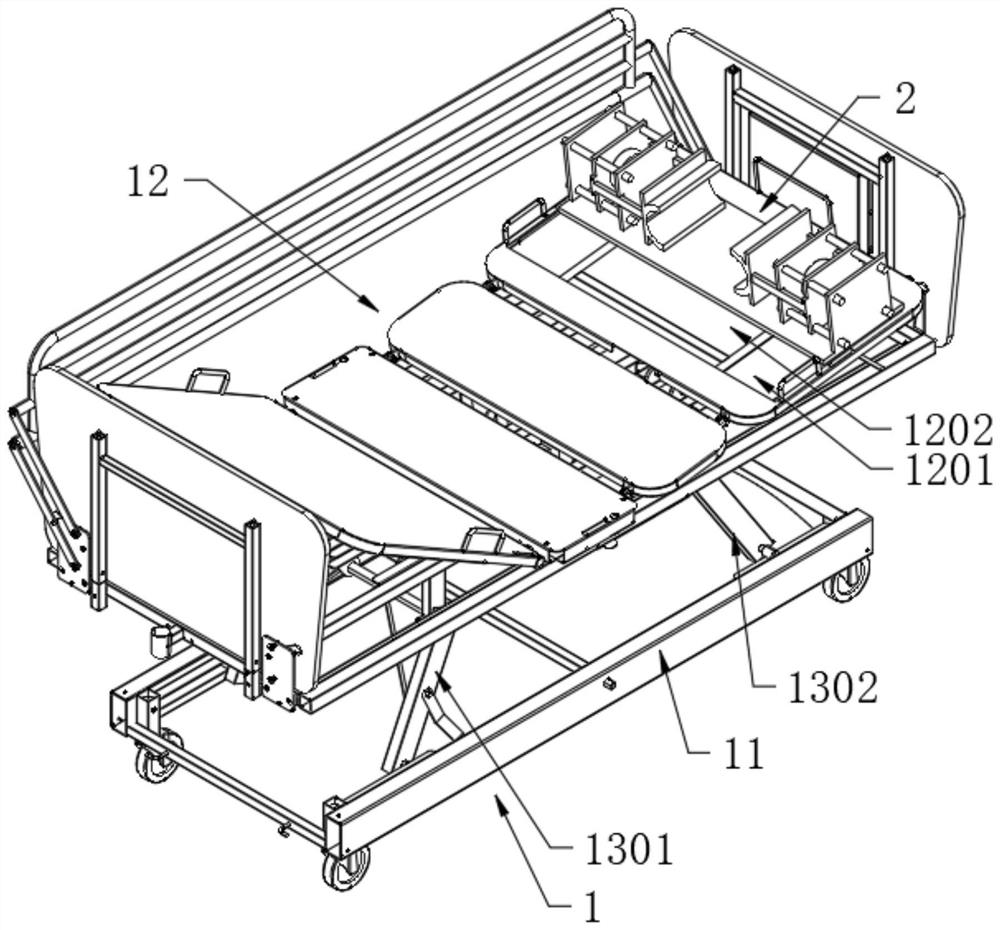

Orthopedic medical bed and method of use thereof

ActiveCN112155887BNo bufferPrevent old injuries from recurringDiagnosticsNursing bedsSurgeryBiomedical engineering

The invention discloses an orthopedic medical bed and a using method thereof, belonging to the field of material transportation, comprising: a supporting mechanism, including a base and a supporting bed board arranged above the base, and the base and the supporting bed board are supported and fixed by a supporting frame; The splint device includes a support slide plate slidably arranged above the support bed board, a fixed plate arranged on both sides above the support slide plate, and an air bag fixed inside the fixed plate; the fixed plate is provided with two groups, and the two groups The fixed plates are respectively arranged at both ends of the supporting slide plate, and guide rods are respectively fixedly connected between the two sets of fixed plates, and the guide rods are slidably connected with a moving slide plate, and the air bag is fixed on the inner side of the moving slide plate. The two sides of the mobile slide are fixedly connected with connecting plates, and the inner ends of the connecting plates are fixedly connected with the splint body, which is convenient for adjusting the clamping strength, so that the patient can have a certain degree of comfort while having good treatment on the legs.

Owner:重庆大学附属三峡医院

3D printing laser cutting device used for machining inlaying blade line gap of die cutting board

InactiveCN107984098AEasy to separateFirmly connectedWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingHorizontal and vertical

The invention discloses a 3D printing laser cutting device used for machining an inlaying blade line gap of a die cutting board. A base is included; a fixed corner brace is installed on the upper surface of the base; the lower surface of the fixed corner brace is connected with the upper surface of the base; a sliding rod is installed on the inner wall of the fixed corner brace; the outer wall ofthe sliding rod is connected with the inner wall of the fixed corner brace; a slider is installed on the outer wall of the sliding rod; and the inner wall of the slider is connected with the outer wall of the sliding rod. According to the laser cutting device used for machining the inlaying blade line gap of the die cutting board, due to the cooperation among the base, the fixed corner brace, thesliding rod and a connection rod, and under the effects of a top base, the top base can be driven by the slider to move in the X axis direction on the sliding rod; the defects that a clamp can waggle,a workbench cannot be adjusted in the horizontal direction or the vertical direction, the machining efficiency is low, the machining quality is poor and waste is caused are overcome; and the machining production efficiency is improved, and the 3D printing laser cutting device used for machining the inlaying blade line gap of the die cutting board is applicable to application and popularization.

Owner:HKUST TIANGONG INTELLIGENT EQUIP TECH (TIANJIN) CO LTD

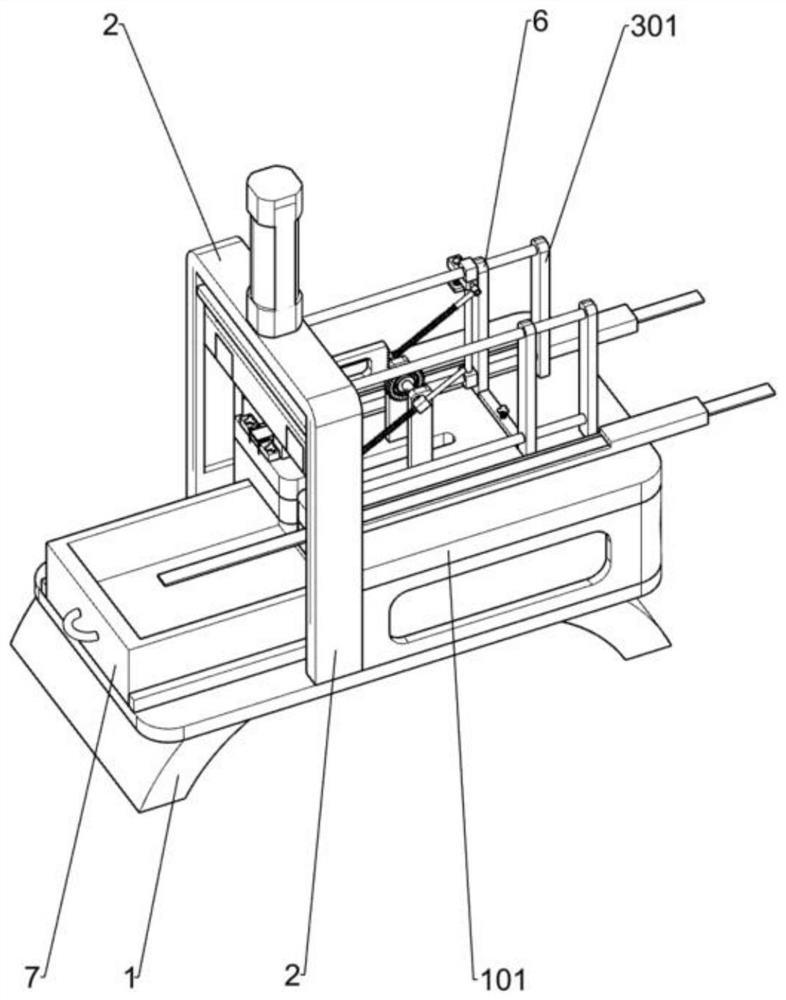

A position-adjustable packing box tape seal device

ActiveCN105000223BMeet the needs of pastingAdjust the moving distanceWrapper twisting/gatheringCouplingDrive motor

The invention discloses a position adjustable packing case adhesive tape sealing device. The device comprises a machine frame, wherein a plurality of supporting pillars are fixed to a top plate of the machine frame, two vertical blocks are fixed to the plane of an upper supporting plate, and the two ends of an adjusting screw are hinged to the two vertical blocks; a driving motor is fixed to the right side of the upper supporting plate, an output shaft of the driving motor is connected with the right end, stretching out of the corresponding vertical block, of the adjusting screw through a coupler, and a sliding block is connected to the adjusting screw in a screwed mode and inserted in a through groove in the upper supporting plate below the adjusting screw; the front side wall and rear side wall of the sliding block are abutted against the front side wall and rear side wall of the through groove, and a thrusting cylinder is fixed to the sliding block; a push rod of the thrusting cylinder is vertically downward, a pressing block is fixed to the push rod, and a bonding layer is fixed to the bottom surface of the pressing block. By the adoption of the device, adhesive tape can be automatically and quickly stuck to a packaging case, efficiency is high, manual sticking is not needed, working intensity is relieved, and the packing case can be clamped by rotating the screw so that manual clamping can be avoided.

Owner:佛山市东合众包装制品有限公司

Movable hoisting device for ships

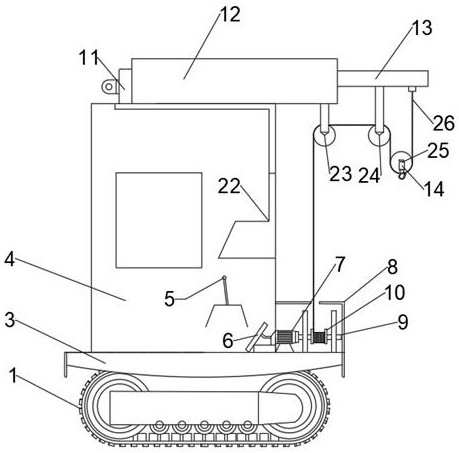

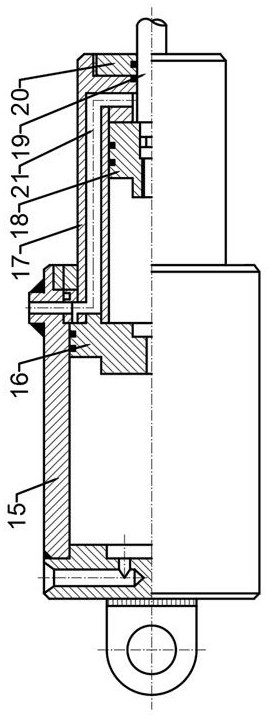

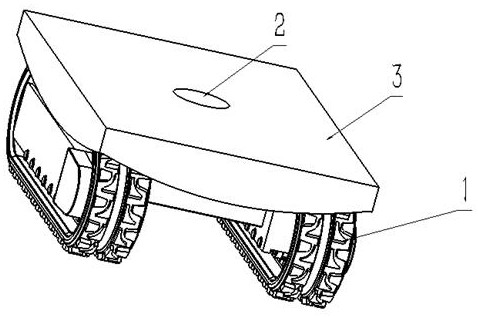

InactiveCN113602979ARealize hoistingLower center of gravityCranesTrolleysHydraulic cylinderMarine engineering

The invention discloses a movable hoisting device for ships. The device structurally comprises a crawler belt, a forward and reverse motor, a double-acting telescopic hydraulic cylinder and the like, wherein the crawler belt is fixedly connected with a connecting shaft; the connecting shaft is fixedly connected with a bottom frame; the bottom frame is movably connected with a cab; the forward and reverse motor is fixedly connected with the bottom frame; the forward and reverse motor is installed in a protective cover; the forward and reverse motor is controlled by a pedal to be switched on and switched off; the bottom frame is movably connected with a joystick; the cab is fixedly connected with a fixed beam; and the double-acting telescopic hydraulic cylinder penetrates through the fixed beam and is fixedly connected with a shifting beam. According to the device, the crawler belt capable of moving flexibly is arranged, so that hoisting in different hoisting environments is realized; the double-acting telescopic hydraulic cylinder is arranged, so that hoisting under different hoisting distances is realized; and the pedal, the forward and reverse motor, a hauling rope and the like are arranged, so that small and medium-sized materials of a ship are simply and conveniently hoisted.

Owner:JIANGSU UNIV OF SCI & TECH

Cutting equipment for paper printed matter

InactiveCN108972643AAdjust the moving distancePrecise cut sizeMetal working apparatusDrive motorEngineering

The invention provides cutting equipment for paper printed matter. The equipment comprises equipment bodies, a collection box is fixedly installed at the inner sides of the equipment bodies, a movabledevice is fixedly installed at the top of each equipment body, and a limiting plate is fixedly installed on the surfaces of the equipment bodies; each movable device is internally provided with an adjusting box, each adjusting box is internally provided with a screw rod box, and each screw rod box is internally provided with a threaded rod. According to the cutting equipment for the paper printedmatter, through the arrangement of worms and the cooperation of worm wheels meshed with the worms, the screw rod boxes can move left and right to adjust the position of movable columns; through the arrangement of sliding rods and the cooperation of sliding blocks, the screw rod boxes are stable during movement; the threaded rods are driven to rotate by rotating crank handles, the small-scale adjustment of the movement distance of the movable columns is facilitated, and the cutting size is more accurate; gear rods are driven to rotate through the arrangement of driving motors, when the crank handles cannot be screwed, force can be applied by relying on the driving motors, the movement distance of the movable columns is conveniently adjusted, and therefore the size of the paper printed matter to be cut is controlled.

Owner:SUZHOU ANTEK INDAL

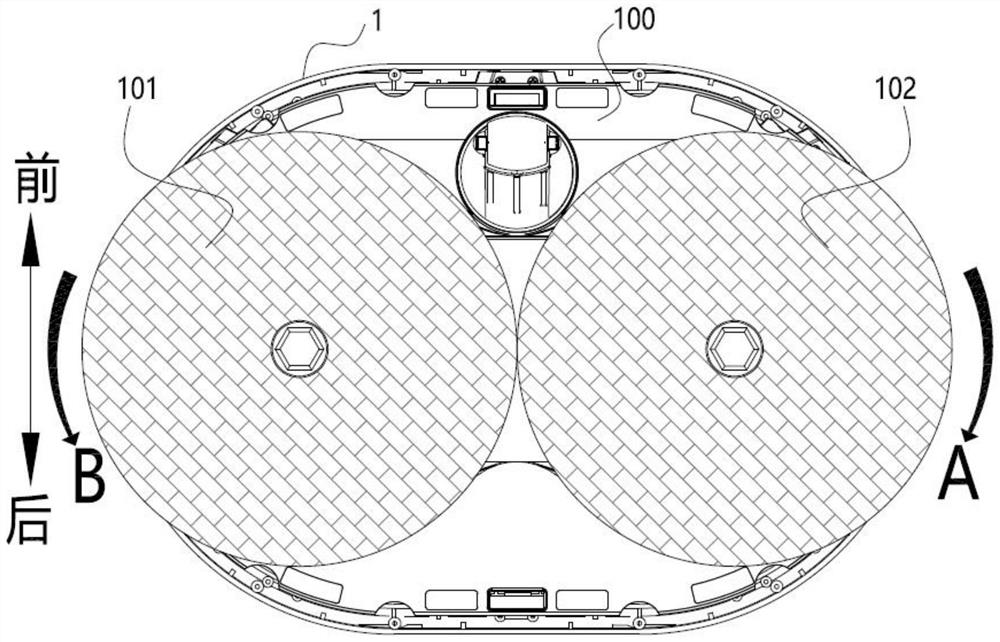

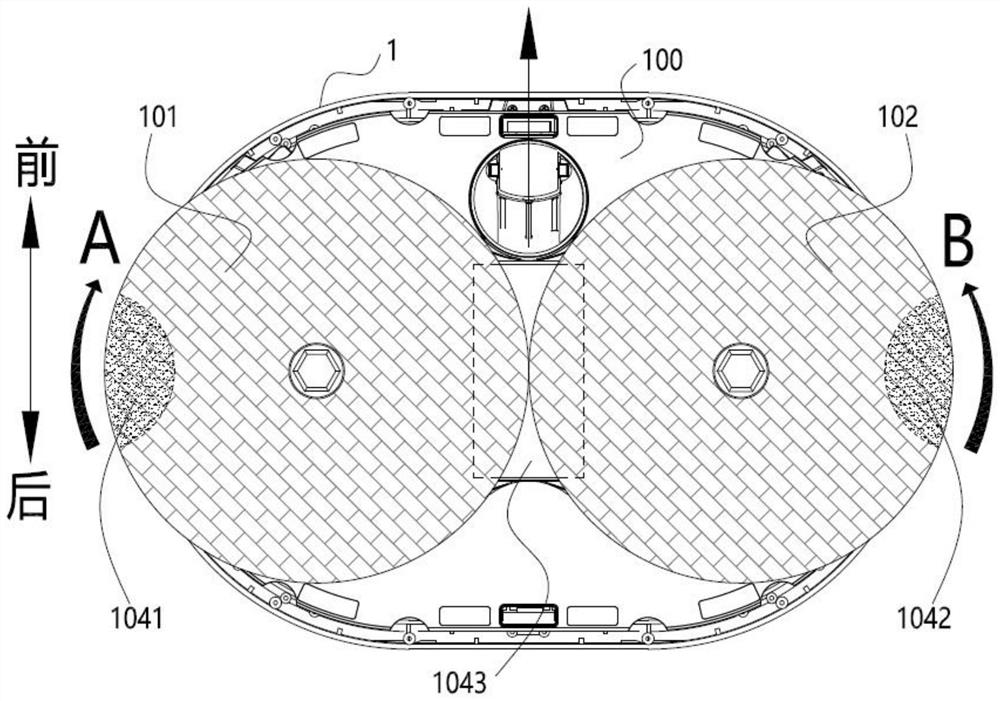

Control method of cleaning machine

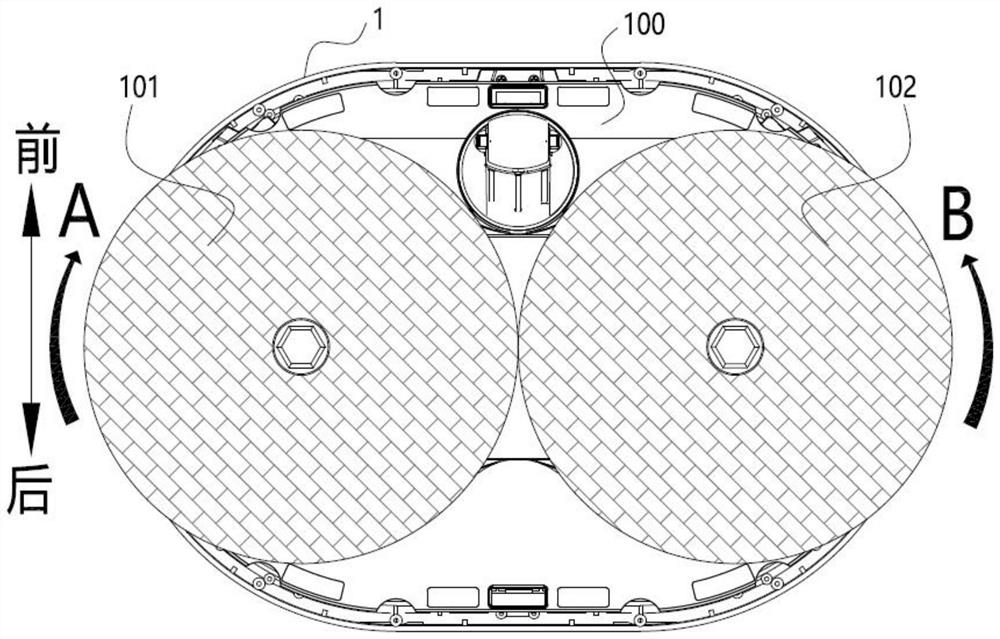

ActiveCN114098564AEasy to cleanSimple structureCarpet cleanersFloor cleanersControl engineeringElectric machinery

According to the control method of the cleaning machine, the cleaning machine comprises a machine body, the machine body comprises a first rotary mopping piece and a second rotary mopping piece, and the first rotary mopping piece and the second rotary mopping piece are each arranged to be of a structure capable of being attached to the ground to horizontally rotate and move; the first rotary dragging piece and the second rotary dragging piece rotate horizontally and control the cleaning machine to move in the first direction; when an obstacle exists in the first moving direction of the cleaning machine, the method at least comprises the step of controlling the first rotary dragging piece and / or the second rotary dragging piece to change the pressure so as to correspondingly enable the first rotary dragging piece and / or the second rotary dragging piece to control the cleaning machine to move in the second direction; when the first rotary mopping piece and the second rotary mopping piece make contact with the ground and rotate horizontally, unbalanced friction force is formed to serve as a power source for movement of the cleaning machine. According to the scheme, the problems that according to an existing cleaning machine with two mops as moving power sources, the moving path is prone to deviation, slipping is prone to occurring in steering movement, obstacles cannot be well avoided, and a motor is prone to being damaged are solved.

Owner:QUFU SINODOD INTELLIGENT TECH CO LTD

Automatic positioning machining operation table for aluminum edge framing profile

InactiveCN113231843AAdjust the moving distanceEasy to fixLarge fixed membersMetal working apparatusAluminium preparationsElectric machinery

The invention discloses an automatic positioning machining operation table for an aluminum edge framing profile, and relates to the technical field of aluminum edge framing profiles. The following scheme is proposed for the problems that in the production process of aluminum products, according to different machining procedures, the operation table needs to automatically position the aluminum products and further needs to flexibly move. The automatic positioning machining operation table comprises an operation table body, fixing mechanisms are arranged in the operation table body in a sleeved mode, an operation plate is arranged on the sides, close to each other, of the fixing mechanisms, a positioning mechanism is connected to the interior of the top of the operation plate, a plurality of movable lifting mechanisms are connected to the bottom of the operation plate, and a conveying mechanism is arranged behind the operation plate; and the fixing mechanisms comprise a plurality of first pushing rod motors arranged in the operation table body in a sleeved mode, and movable cavities are formed in the two sides of the operation plate. According to the automatic positioning machining operation table for the aluminum edge framing profile, the products can be automatically positioned, the moving distance of the device on parallel horizontal lines at the same height can be adjusted, operation is easy, and the working efficiency is high.

Owner:安徽帮德电气有限公司

A position detection system and position detection method for a tire building drum

ActiveCN109291481BAdjust the moving distanceThe test result is accurateTyresControl cellStructural engineering

The invention discloses a position detection system and a position detection method for a tire building drum, and belongs to the technical field of tire building. The position detection system comprises two ranging components, a drive unit and a control unit, wherein the two ranging components are arranged at the radial outer side of the tire building drum, and radially aligned with support discson two anti-package rod assemblies separately; the drive unit is used for driving the synchronous opposite or reverse axial movement of the two ranging components; and the control unit is in signal connection with the drive unit and the tire building drum, and used for controlling the movement of the anti-package rod assemblies and controlling the working state of the drive unit. The position detection method is based on the position detection system, and used for carrying out position confirmation on the anti-package rod assemblies on the tire building drum. The drive unit is capable of driving the ranging components to detect at different positions, so that a more accurate detection result is achieved; and moreover, the movement distances of the two ranging components can be adjusted, then different tires are matched, and convenient adjustment is achieved.

Owner:SAFE RUN & HISCENT MACHINERY SUZHOU

Tray linear movement distance regulator for microwave oven

InactiveCN1289861CAdjust the moving distanceDomestic stoves or rangesStoves/ranges shelves or racksMicrowave ovenEngineering

The present invention relates to one regulator to make the tray reciprocate linearly right and left inside the heating chamber of microwave oven. The tray motion distance regulator consists of a tray with slot in the bottom, driving motor to produce rotating force, rotating part with radial slot, eccentric shaft with eccentric lug for inserting into the radial slot, and fixing structure to fix the eccentric shaft inserted into the slot. Under the action of the rotating eccentric lug, the tray reciprocates linearly right and left within the range corresponding to the eccentric amount. The present invention can increase the useable space inside the heating chamber via the motion of the tray and can regulate the moving distance of the tray.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com