Control method of cleaning machine

A control method and cleaning machine technology, applied to cleaning machinery, cleaning equipment, carpet cleaning, etc., can solve the problems of motors being easily damaged, slipping, and moving paths, etc., and achieve simple overall structure, good linear movement, and clean good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

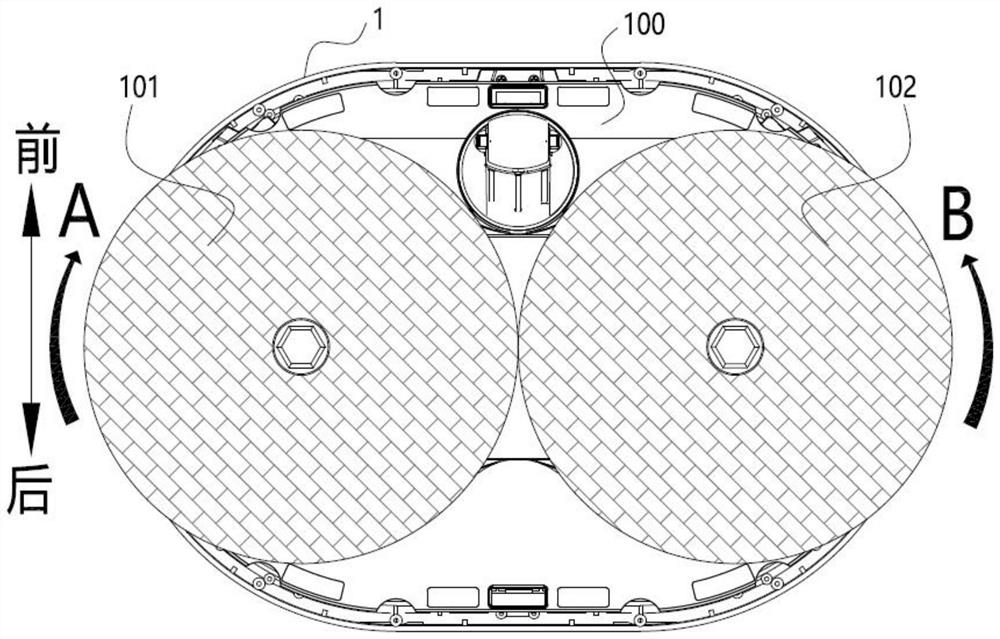

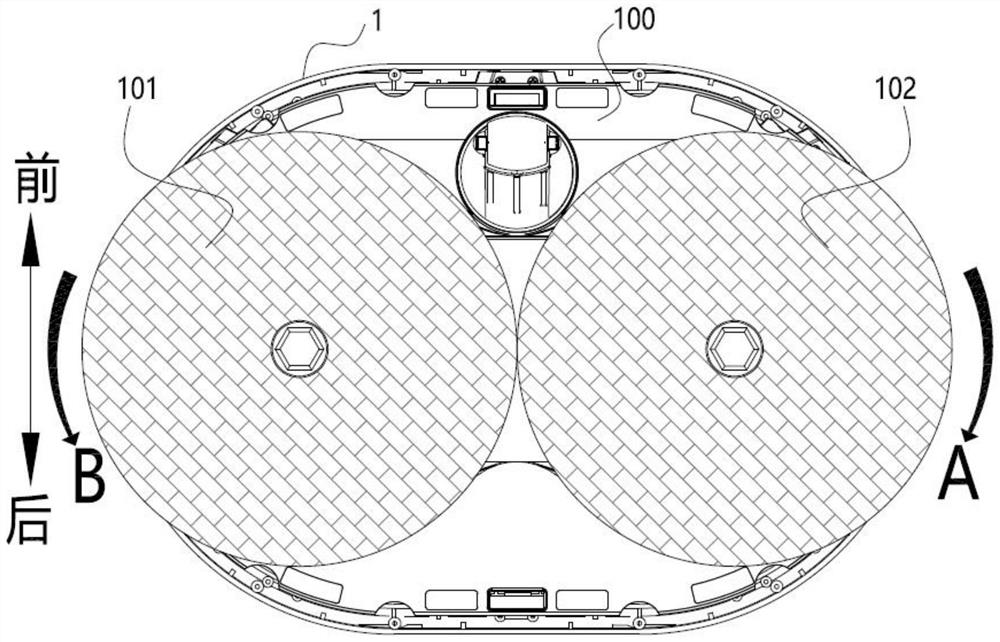

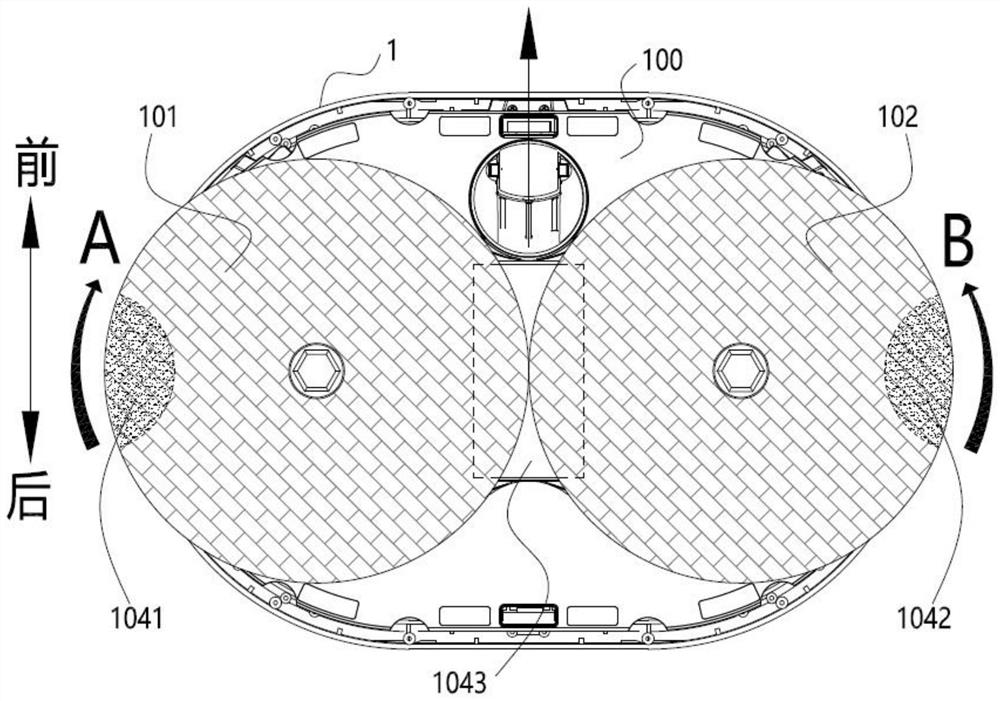

[0047] Embodiment: the control method of cleaning machine of the present invention, as Figure 1 to Figure 8 As shown in the configuration, the cleaning machine 1 is mainly used to move and walk on the ground for mopping and cleaning. Specifically, the cleaning machine 1 is provided with a first rotating drag member 101 and a second rotating dragging member 102 to mop and clean the ground. The first rotary dragging part 101 and the second rotary dragging part 102 are arranged as a structure that can rotate horizontally. At the same time, the cleaning machine 1 of this program does not need to be provided with driving wheels to drive and move, and the first rotary dragging part 101 and the second rotary dragging part The rotational power of 102 is used as the power source for the movement of the cleaning machine 1, and the overall structure of the cleaning machine 1 is simple and low in cost.

[0048] The cleaning machine 1 includes a machine main body 100. The machine main bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com