Insulating layer detection device for crosslinked polyethylene cable processing

A cross-linked polyethylene, detection device technology, applied in the measurement device, the use of a stable tension/pressure test material strength, test material hardness and other directions, can solve the problems of low efficiency, labor consumption, etc., to ensure the detection quality, guarantee Factory quality, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

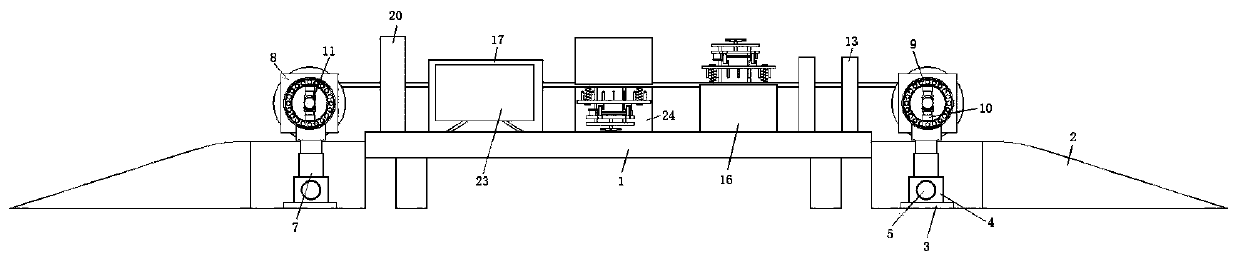

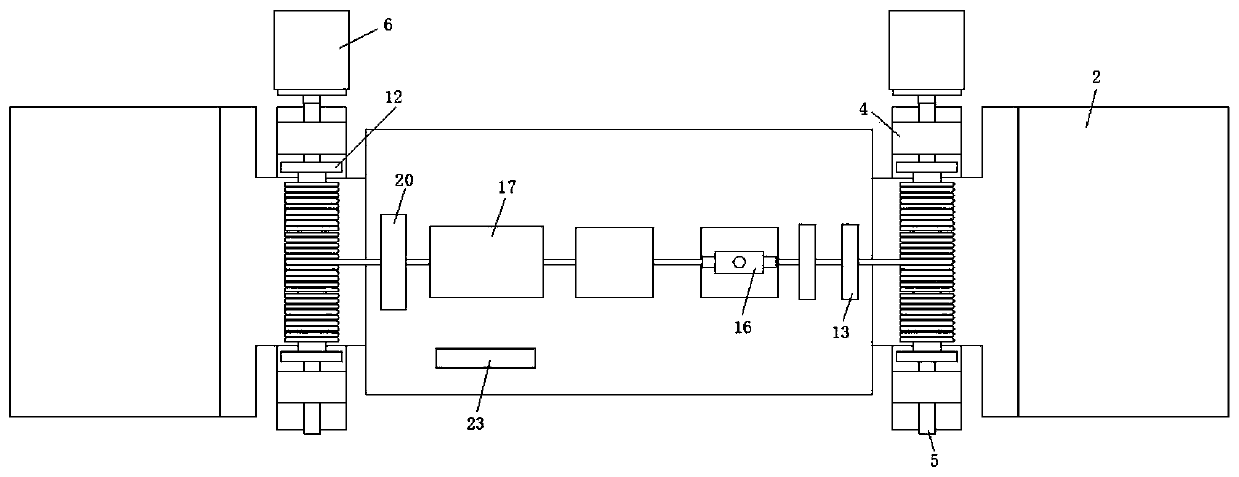

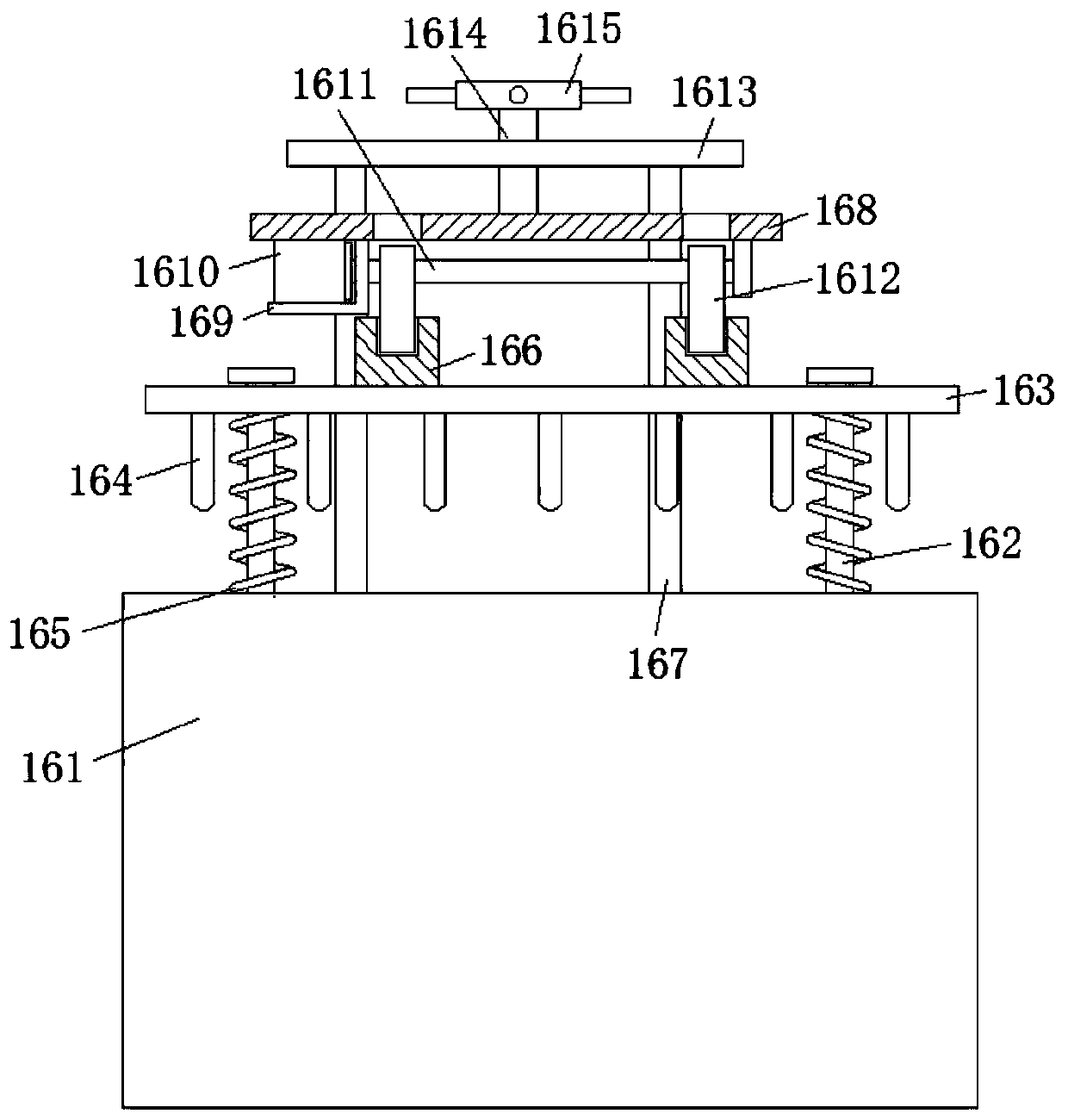

[0032] refer to Figure 1-6, a cross-linked polyethylene cable processing insulating layer detection device, including a detection platform 1, both sides of the detection platform 1 are provided with a transfer platform 2, the transfer platform 2 close to the detection platform 1 front and rear sides are provided with a rectangular gap, rectangular The bottom ends of the shaped notches are fixedly connected with support plates 3, and the top surfaces of the support plates 3 are slidably connected with mounting blocks 4, and the two support plates 3 on the same side are connected with reciprocating screw rods 5 through threads, and the rear end mounting blocks 4 The rear side of each is equipped with a servo motor 6, the output end of the servo motor 6 is fixedly connected with the reciprocating screw rod 5, the top surface of the mounting block 4 is fixedly connected with the cylinder 7 by screws, and the output ends of the cylinder 7 are fixedly connected by screws There is a...

Embodiment 2

[0035] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, there are two hardness detection mechanisms 16, and the detection seats 161 on the two hardness detection mechanisms 16 are respectively located at the upper and lower ends of the cable.

[0036] In this embodiment, the hardness detection mechanism 16 is provided on the upper and lower sides of the cable, so that the upper and lower ends of the cable can complete the compressive strength detection operation at the same time, which greatly enhances the reliability of the detection.

Embodiment 3

[0038] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the top surface of the transfer platform 2 is inclined downward from the center of the detection platform 1 to both sides, and the reciprocating screw rod 5 is slidingly connected to the transfer platform 2, and the reciprocating The threads on the front and rear sides of the outer wall of the screw mandrel 5 are opposite.

[0039] In this embodiment, the winding rollers 12 are loaded and unloaded more conveniently by setting them all at a slant on the transfer table 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com