Composition for building material and product thereof

A technology for building materials and compositions, applied in the field of building additives, can solve the problems of poor compressive performance, unsatisfactory, high temperature resistance, poor low temperature performance, etc., achieves good thermal insulation performance, does not reduce compressive strength, and improves high temperature resistance. and the effect of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] In one embodiment, the preparation method of described phosphoric acid ester compound modified guar gum, comprises the steps:

[0075] (1) Add epichlorohydrin to a buffer solution with a pH value of 4.5-5.5, heat up to 80-85°C for 4 hours, add absolute ethanol, extract, and separate to obtain an intermediate;

[0076] (2) Wet the guar collagen powder with isopropanol, basify the reaction with NaOH aqueous solution for 30 minutes, then add the intermediate described in step (1) dropwise, heat up to 100°C, react for 0.5h, add cationic etherification agent, Continue the etherification reaction with NaOH for 3 hours, lower the temperature, adjust the pH to 7, filter with suction, wash, and dry to obtain the phosphate compound-modified guar gum;

[0077] The buffer is a mixture of sodium dihydrogen phosphate and disodium hydrogen phosphate;

[0078] The solid content of the intermediate is 67%, and the viscosity is 100mPa·s; the addition amount of the epichlorohydrin is joi...

Embodiment 1

[0097] Embodiment 1 provides a kind of composition for building materials, and described composition for building materials comprises component A, component B, component C, component D;

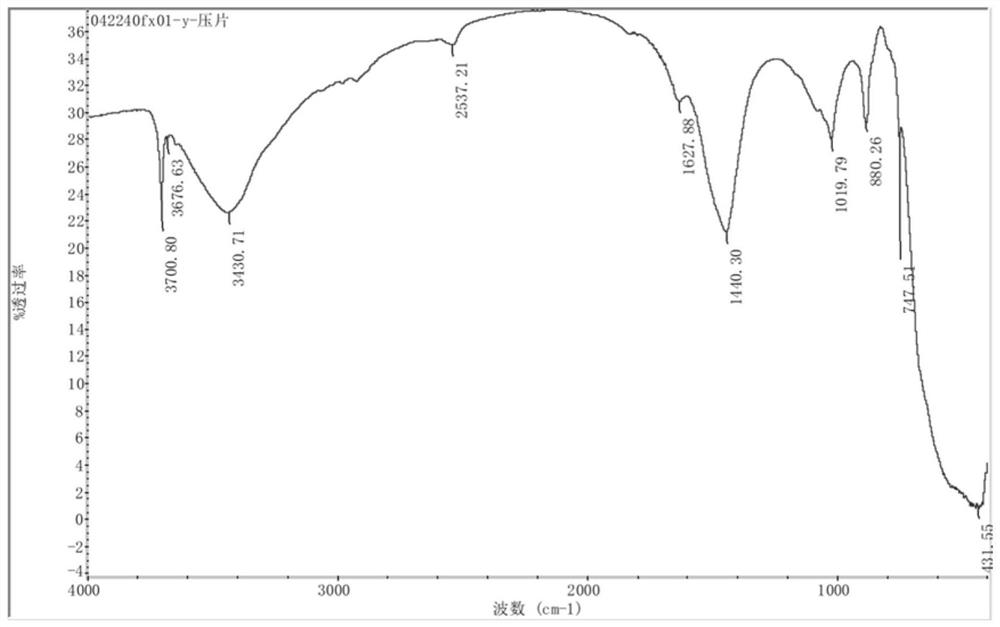

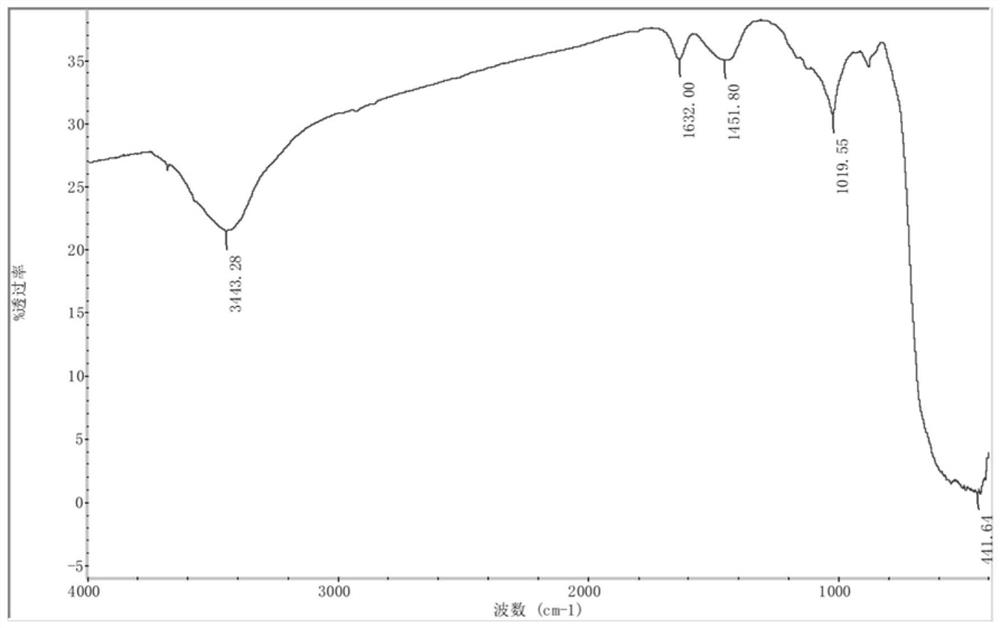

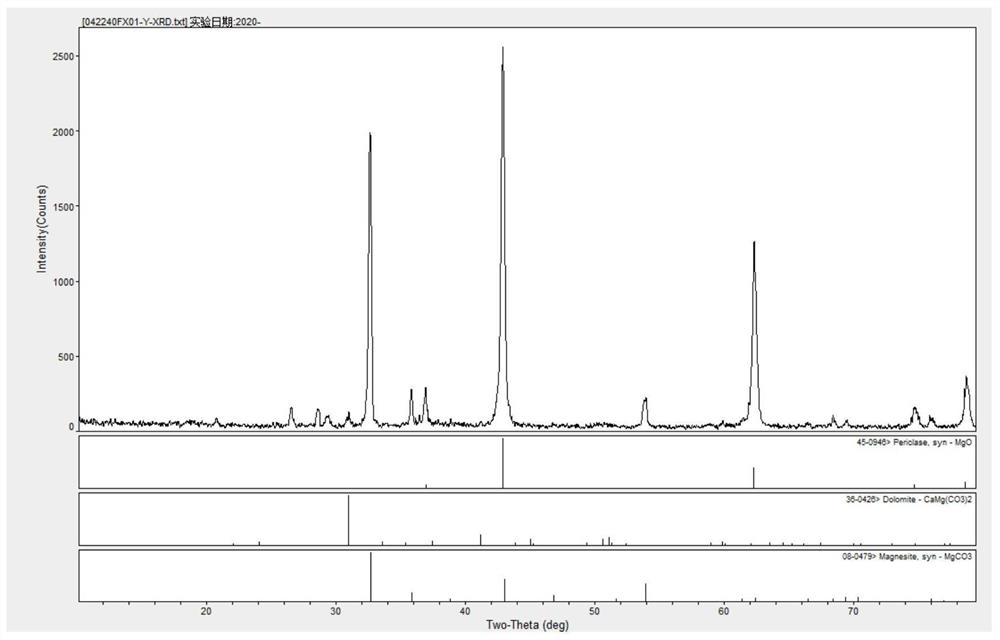

[0098] The component A includes lightly burned magnesium powder; in parts by weight, the lightly burned magnesium powder includes 67.5 parts of magnesium oxide, 27.5 parts of the second magnesium salt, and 5.5 parts of silicon-containing compounds; the component A is in the muffle Furnace ashing at 650°C for 4 hours, the obtained ash content is 87.5wt%; said component A is mixed with its raw materials, and then crushed, and the particle size D5 of the crushed particles is in the range of 27-35um, and D90 is in the range of 80-90um;

[0099] The second magnesium salt includes acidic magnesium salt and basic magnesium salt; the mass ratio of the acidic magnesium salt and the basic magnesium salt is 2.7:1; the acidic magnesium salt is a mixture of magnesium carbonate and calcium magnesium carbonate...

Embodiment 2

[0112] Embodiment 2 provides a kind of building material composition, with embodiment 1, difference is:

[0113] In parts by weight, the light-burned magnesium powder includes 62 parts of magnesium oxide, 25 parts of the second magnesium salt, and 4 parts of silicon-containing compounds;

[0114] The weight ratio of component C to component B is 1:0.2; the ratio of the total mass of component C and component B to the mass of component A is 50:105.

[0115] The building material and its preparation method are the same as in Example 1, except that it contains the building material composition described in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com