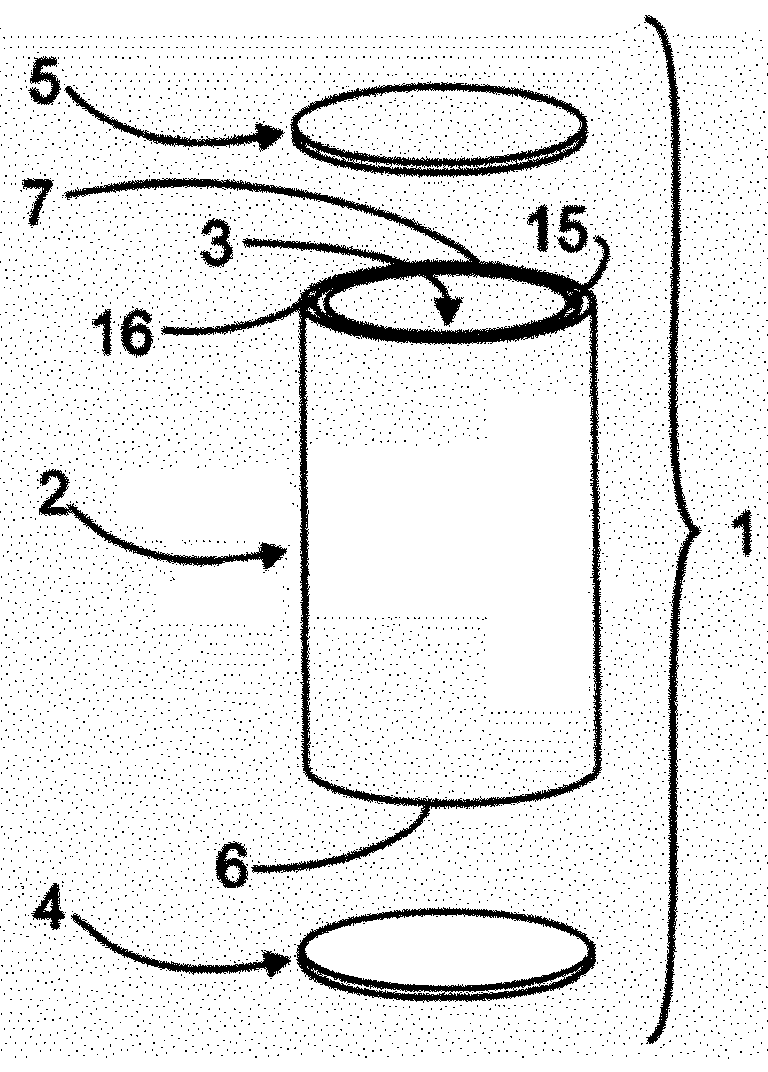

Pressure-resistant container

A tank shell and internal pressure technology, applied in the field of pressure-resistant tanks, can solve problems such as damage, tank shell tearing, bursting, etc., and achieve the effect of firm and good restraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

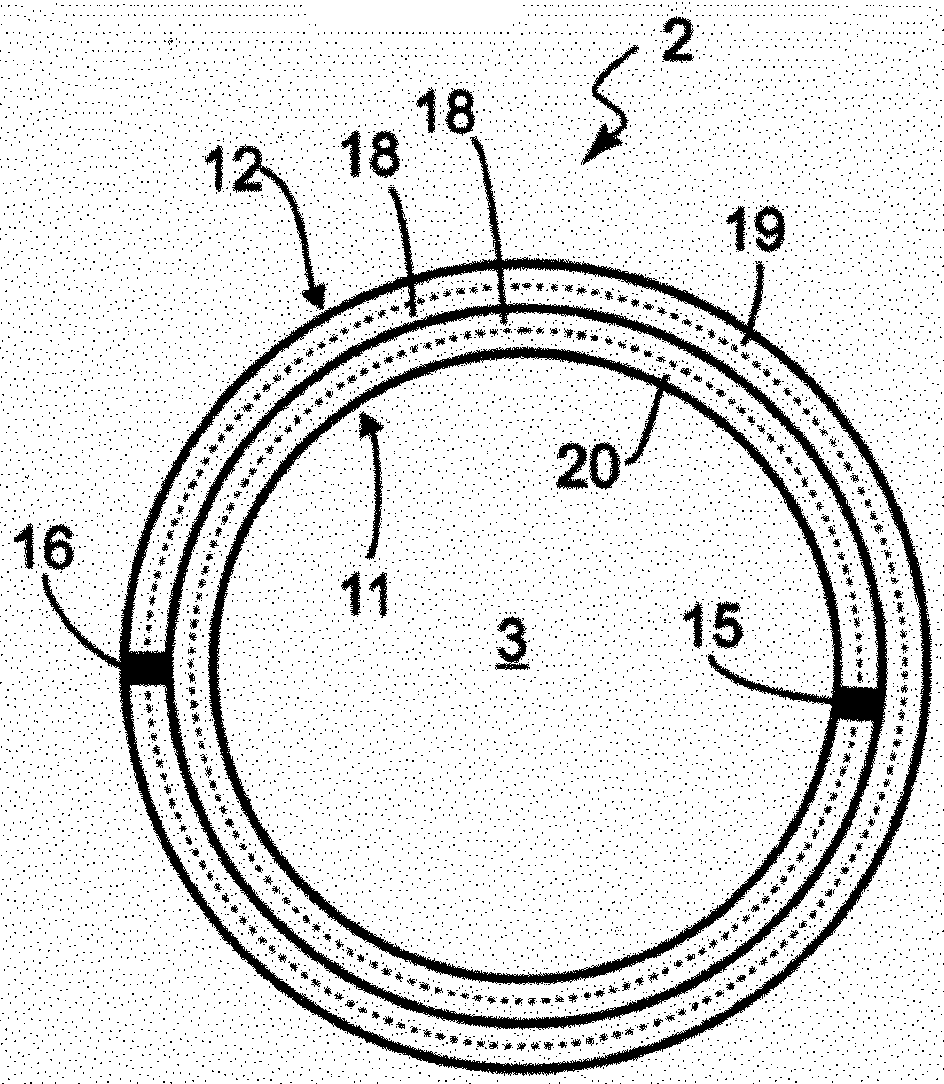

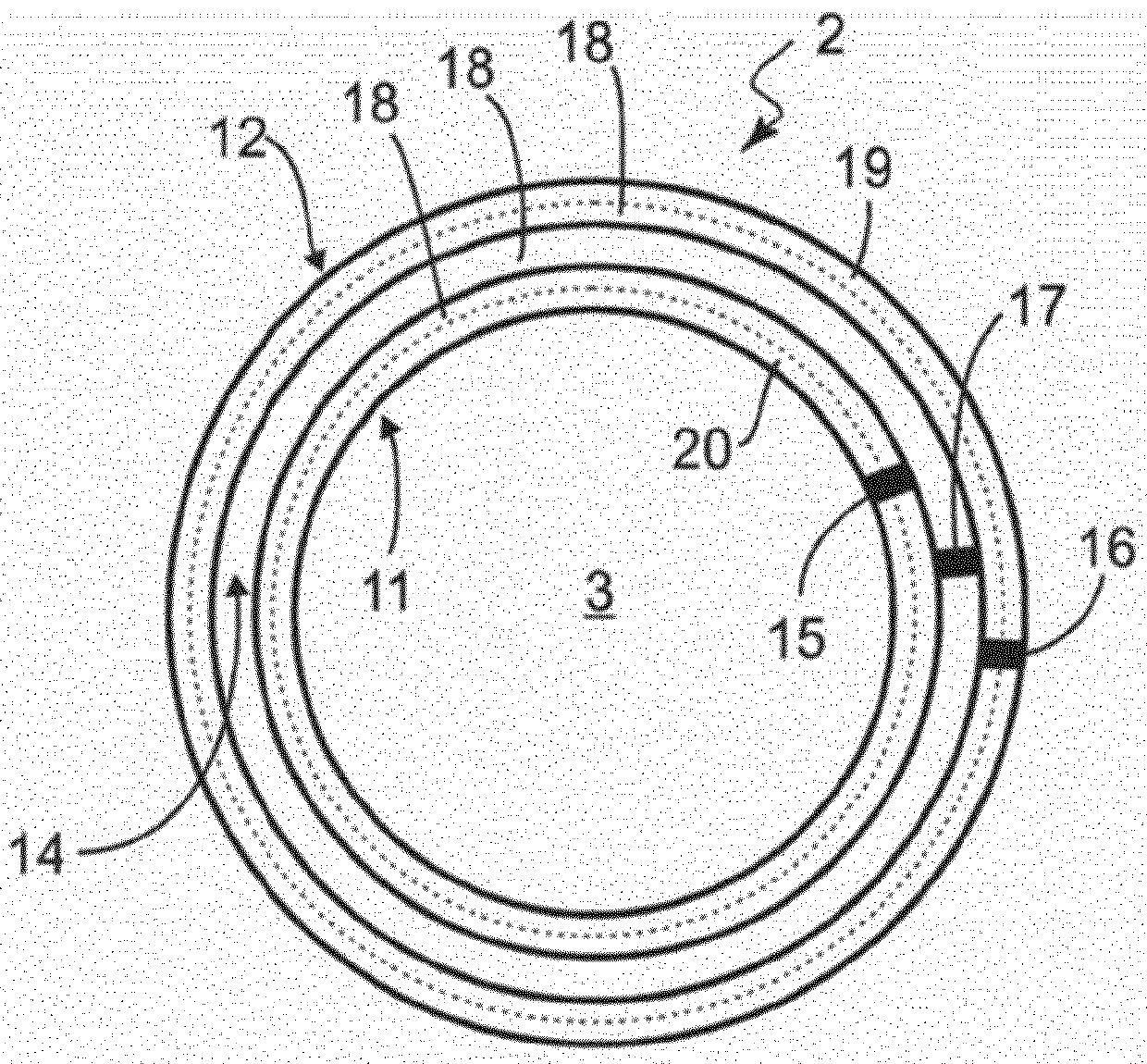

example 1

[0219] use Figure 27 A particularly preferred layer structure for a beverage can with a height of 134 mm and an outer diameter of 52.4 mm and a filling volume of 250 ml of carbonated beverages was produced. As paper or kraft layer 105, use a less tear-resistant, wood-free paper, especially Lumiflex TM 110 gsm Stora Enso AG provided with a PE coating on the outside of the rear of the tank. The top and bottom of beverage cans are sealed with standard bottoms, and the lids of aluminum cans are sealed with standard closures.

[0220] The layers used and the resulting layer structure are specified in the table below.

[0221]

[0222]

[0223] Tensile strength MD (machine direction) indicates the tensile strength of kraft paper in the longitudinal direction of the tank body 101 , and tensile strength CD (cross direction) indicates the tensile strength of kraft paper in the circumferential direction of the tank body 101 . It can be seen that the conventional paper used for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com