Universal joint fork ear hole grinding device

A universal joint fork and ear hole technology, which is applied in the field of universal joint fork ear hole grinding devices, can solve the problems such as the deviation of the concentricity of the fork lug through hole, and achieve the effect of prolonging the life and reducing the possibility of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

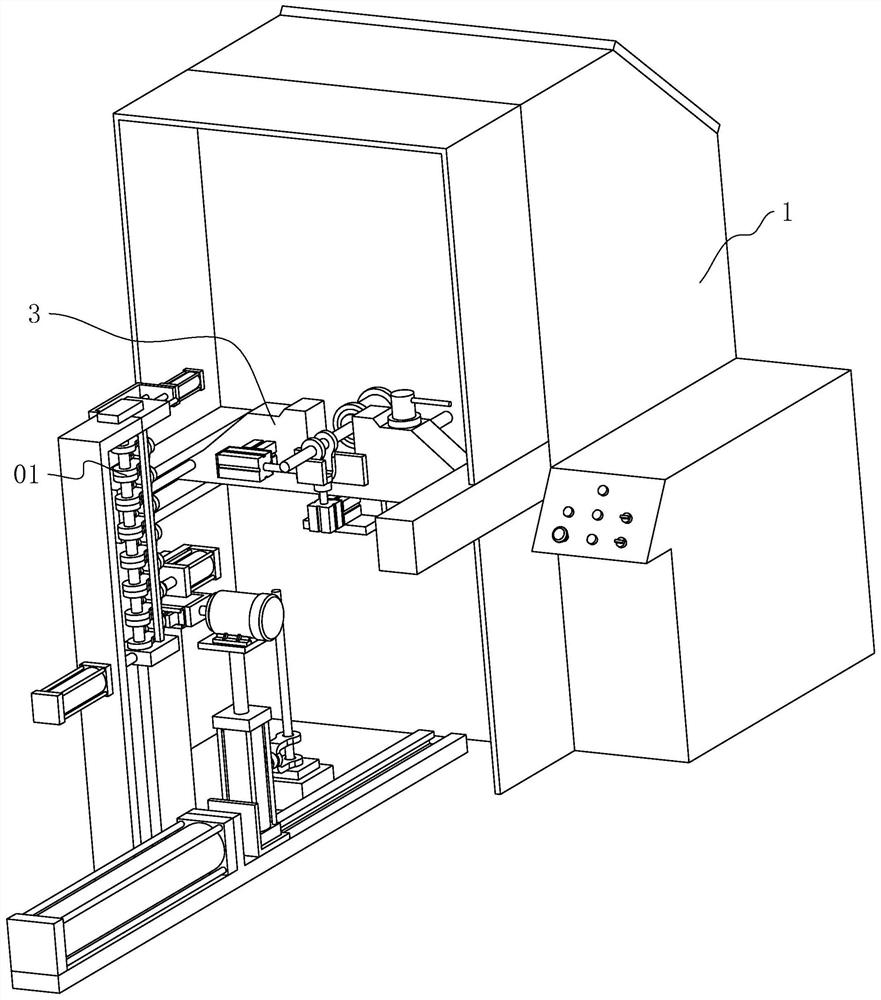

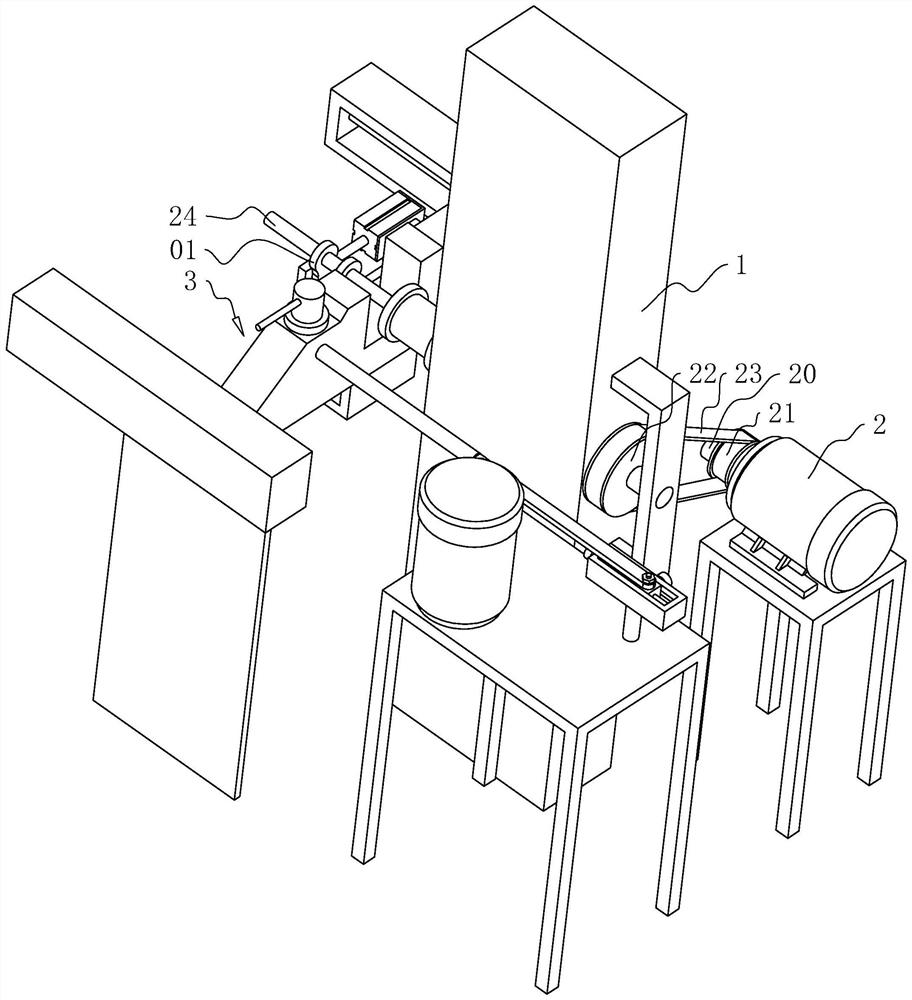

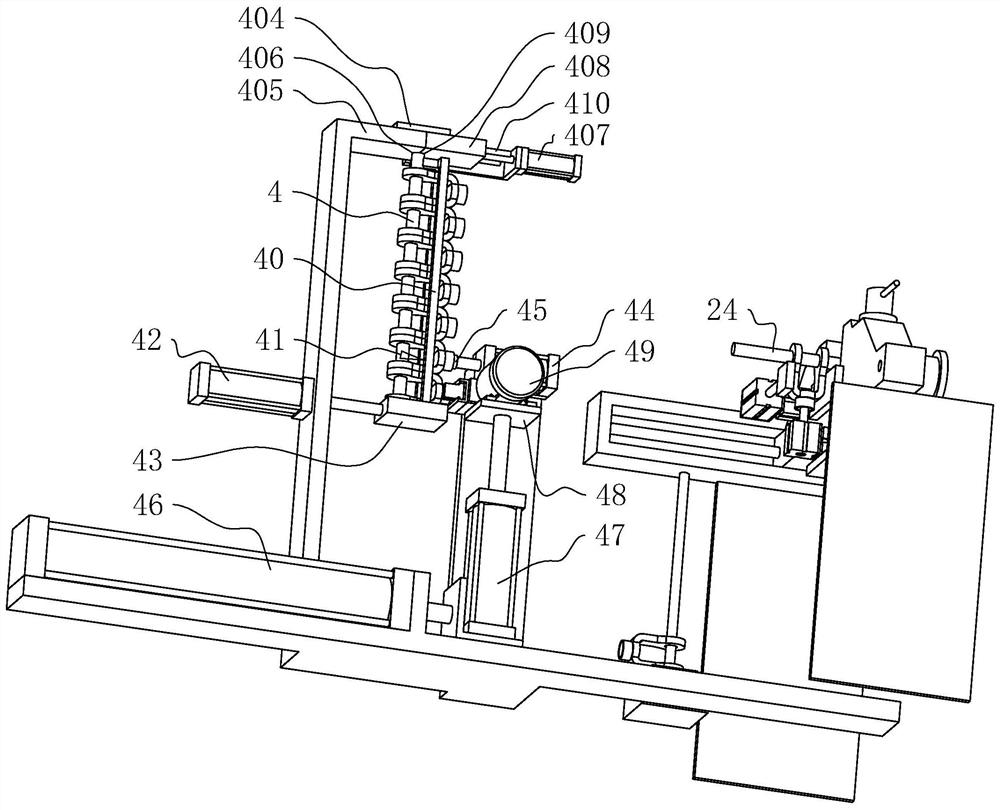

[0042] The embodiment of the present application discloses a universal joint fork ear hole grinding device.

[0043] refer to figure 1 and figure 2 , a universal joint fork earhole grinding device, comprising a frame 1, the frame 1 is provided with a positioning assembly 3 for fixing the universal joint fork 01, the frame 1 is provided with a grinding motor 2, and the motor shaft of the grinding motor 2 Coaxially is provided with rotating rod 20, and rotating rod 20 is coaxially provided with driving pulley 21, rotates on frame 1 and is provided with driven pulley 22, and driving pulley 21 and driven pulley 22 are connected by conveyor belt 23, from The driving pulley 22 is provided with a reamer 24 for polishing the earholes of the two universal joint forks 01, and the reamer 24 is set horizontally; The two ear holes of 01 are set on the reamer 24, the positioning assembly 3 fixes the universal joint fork 01, and the grinding motor 2 is used to drive the driving pulley 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com