Flexible die hot pressing furniture edge sealing device and furniture heteromorphous component edge sealing technique

A technology of special-shaped components and edge banding devices, which is applied to furniture parts, furniture accessories, household appliances, etc., can solve the problems of low processing accuracy, poor product quality uniformity, long production cycle, etc., and achieve good edge banding quality and stability. Good, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

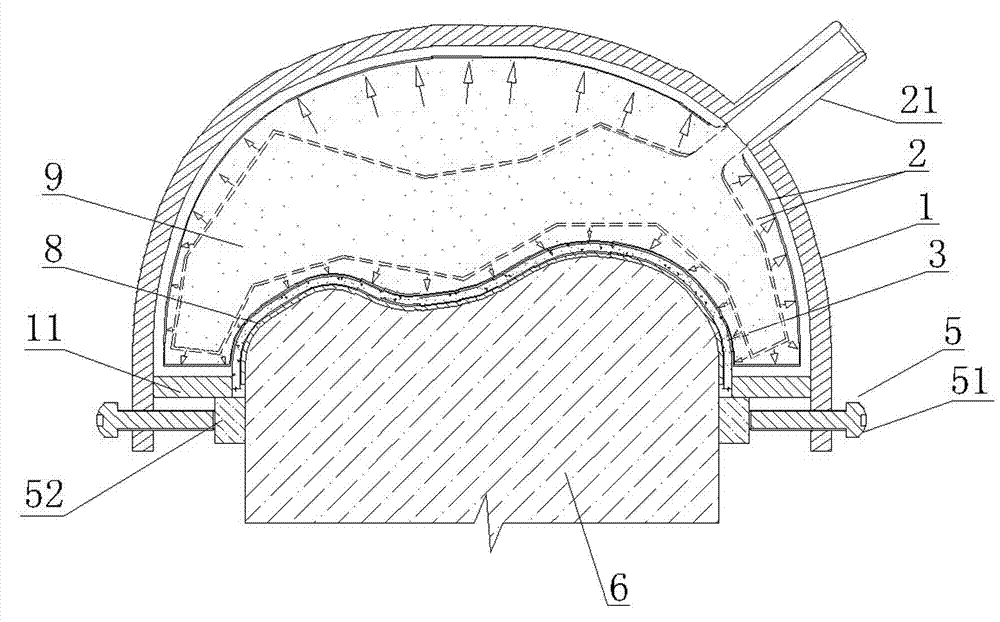

[0015] Such as figure 1 As shown, the soft-molded hot-pressing furniture edge sealing device of the present invention includes an outer shell 1 with a lower installation port, an inflatable, expandable and pressurized air bag 2 installed in the outer shell 1, and an air bag 2 located in the air-filled The flexible heat pipe 3 under the bag 2 can be hot-pressed on the edge strip 8 of the edge of the furniture special-shaped member 6, and the inflatable bag 2 is provided with an inflation port 21 protruding from the outer shell 1, so The capacity of the gas 9 in the inflatable bag 2 is greater than the capacity of the outer shell 1, and the inflatable bag 2 can pressurize the heat pipe 3 when it is inflated and expanded, so that the edge banding strip located under the heat pipe 3 in the installation port 8 After the glued surface is heated and pressed, it is rapidly molded and solidified, so that the edge banding strip 8 can be reliably attached to the edge of the special-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com