Patents

Literature

62results about How to "Equal spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for one-size nano-particle fluorescence microsphere

InactiveCN101342472AAvoid adsorptionImprove uniformityMicroballoon preparationLuminescent compositionsSolubilityOil phase

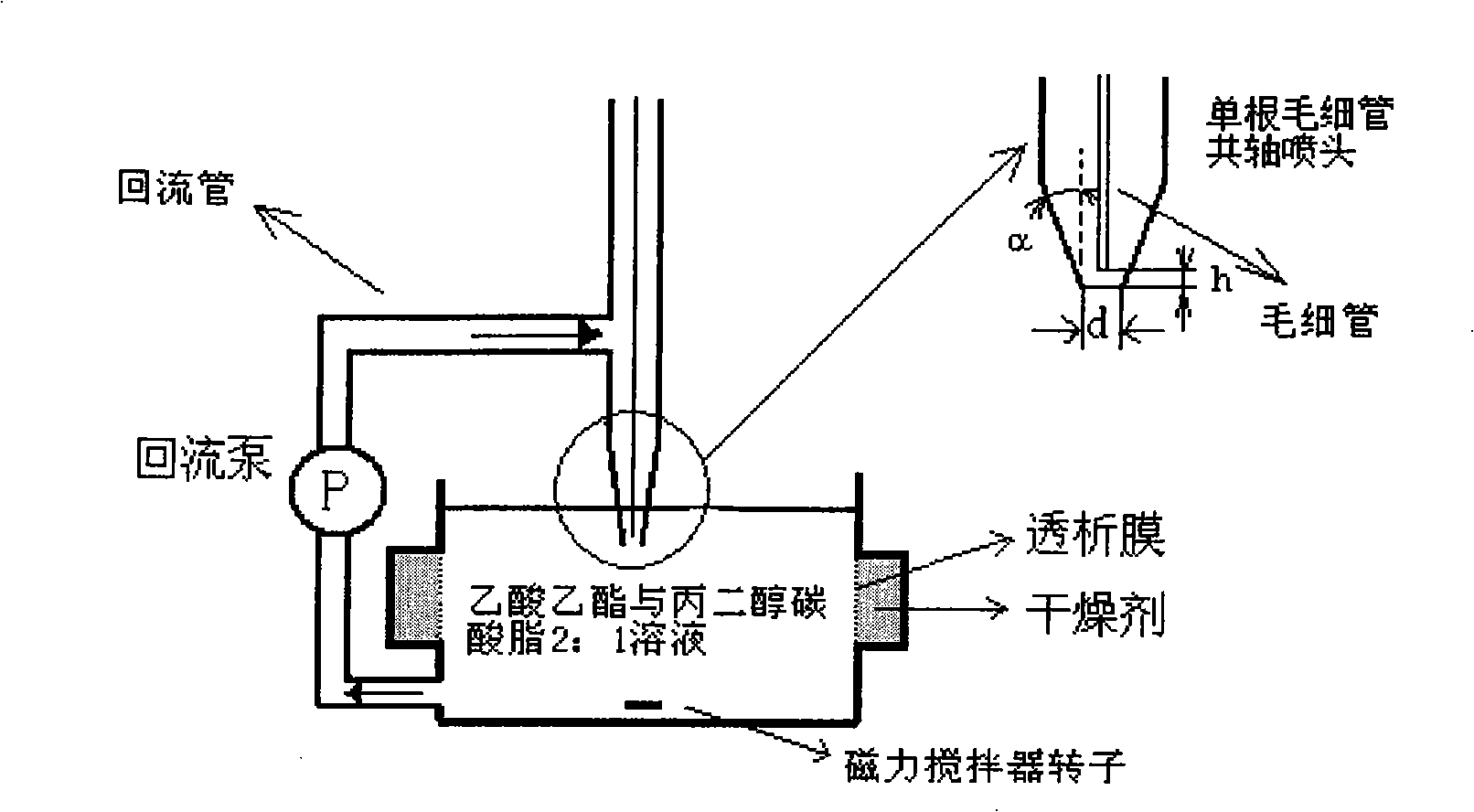

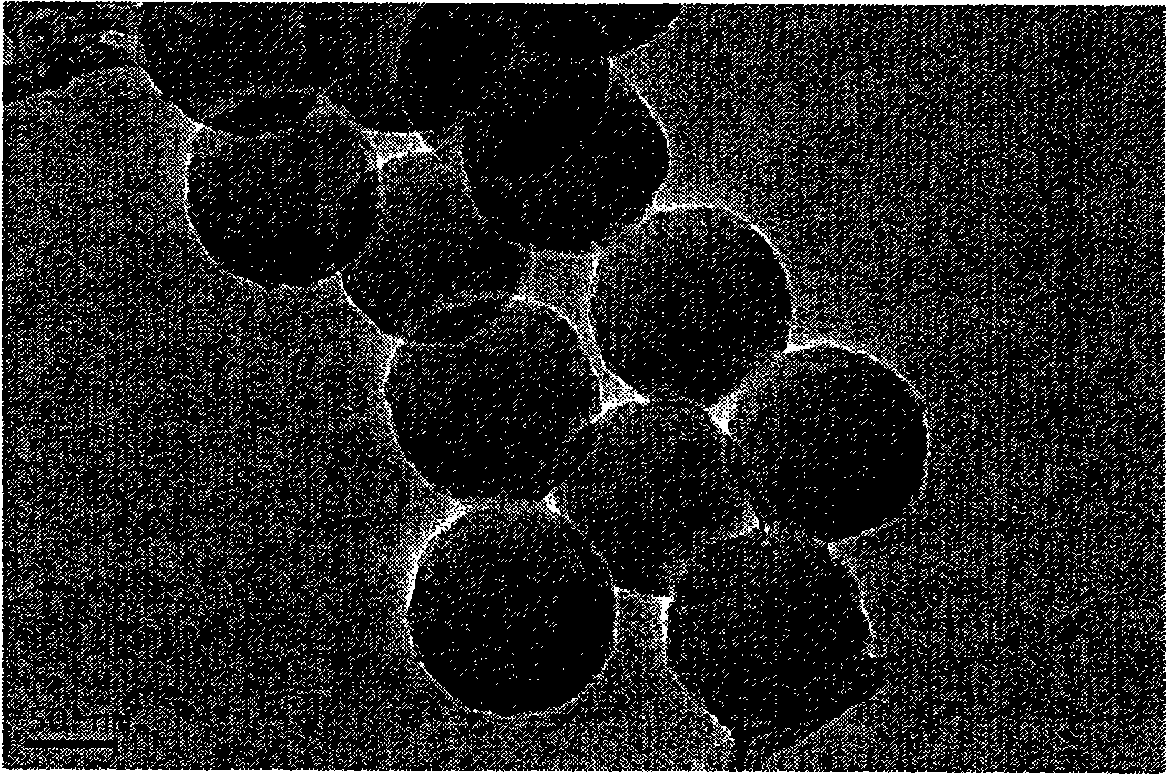

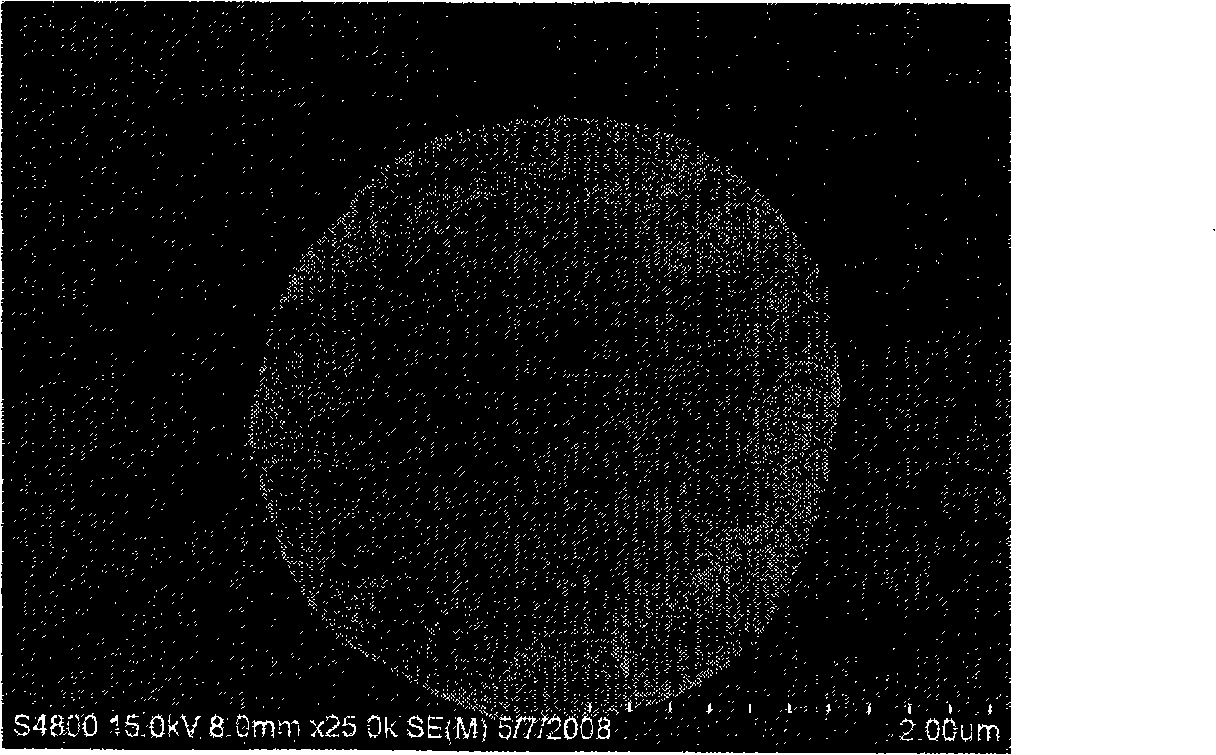

The present invention provides a preparation method of an uniform-size nanoparticle fluorescent microsphere. The density of fluorescent nanoparticle colloidal aqueous solution of the microsphere is adjusted to the micro-mol level so as to obtain the colloidal solution evenly scattered in the aqueous solution; the evenly scattered colloidal solution in the aqueous solution is injected into oil-phase solvent through capillary at the speed of 0.5 to 1.25 percent Vs / min so as to form droplets and Vs is the volume of the oil-phase solvent; the oil-phase solvent adopts bi- or multi-mixture with the solubility between 2 to 10 percent and the density equal to the density of water; containers and reflux pipes adopt the hydrophobic material; the water in droplets is absorbed by the oil phase and the nanoparticles form a dense sphere; an absorbent continuously absorbs the water dissolved in the oil phase, so that the water content in the oil phase is far lower than the saturation; the nanoparticle polymer with the size from dozens of nano to hundreds of nano, the spherical height higher than 5 percent and the size error less than 10 percent is obtained through regulating the density of the quantum pot colloidal solution and the velocity of the reflux pipe.

Owner:SOUTHEAST UNIV

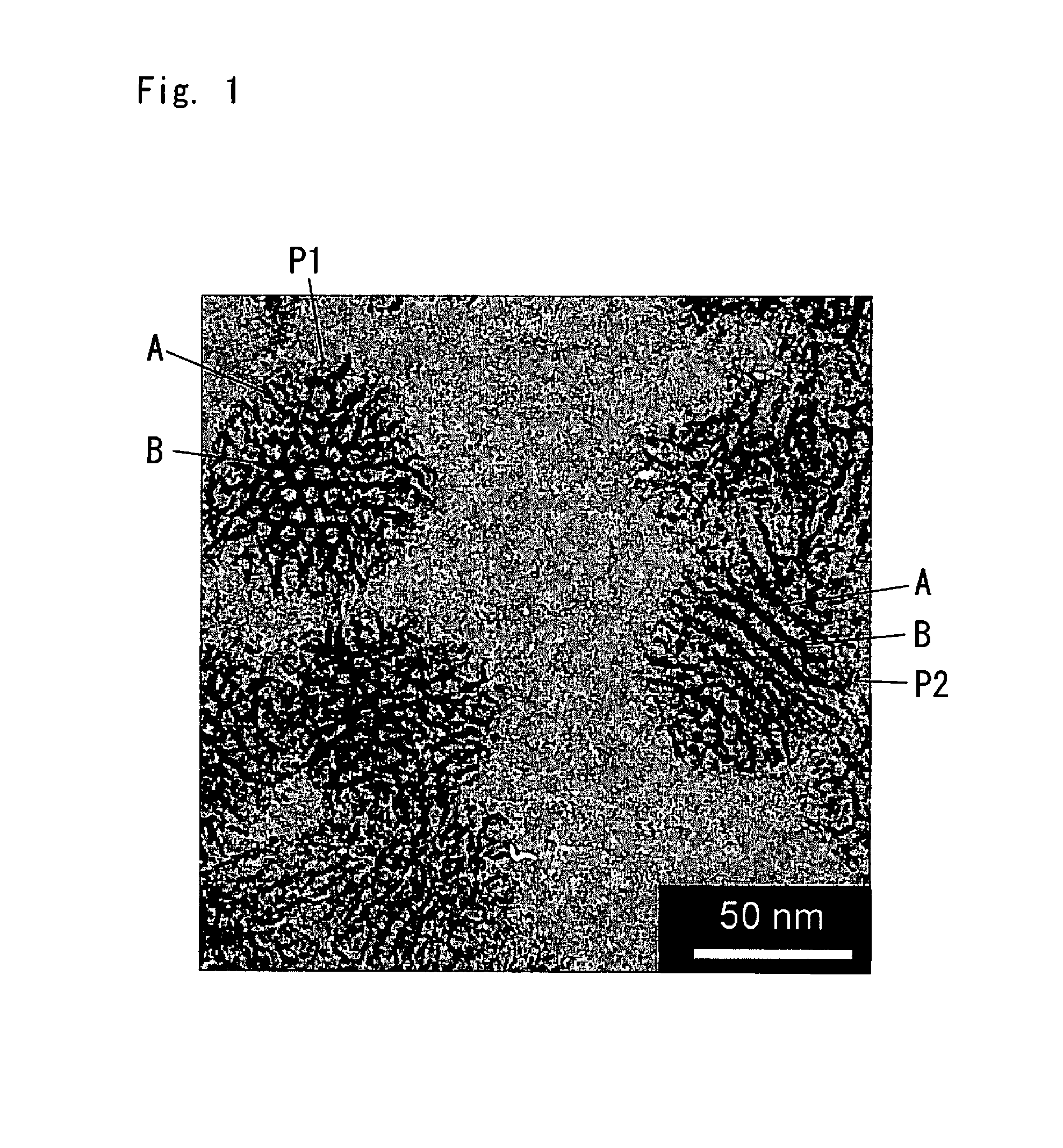

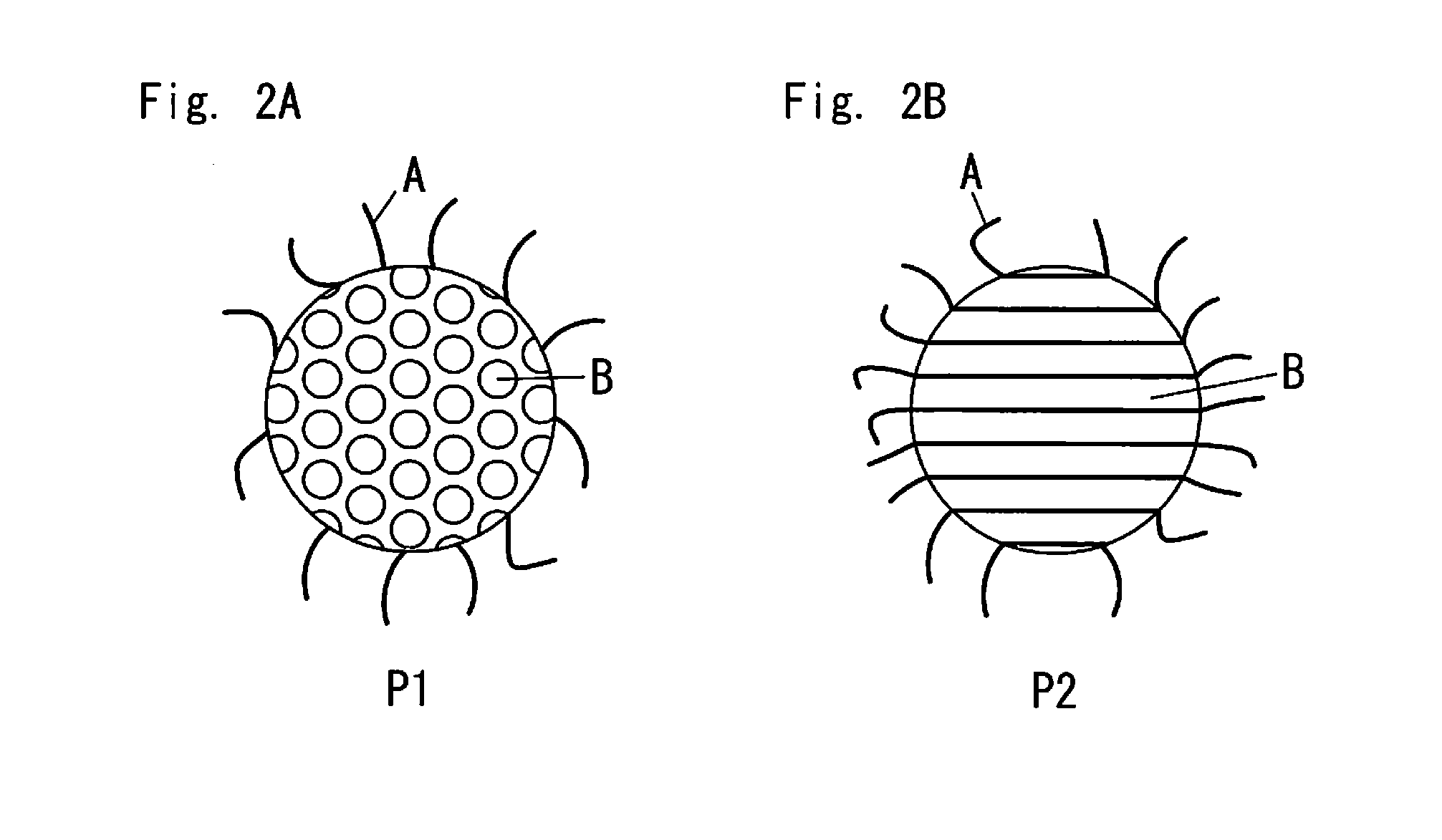

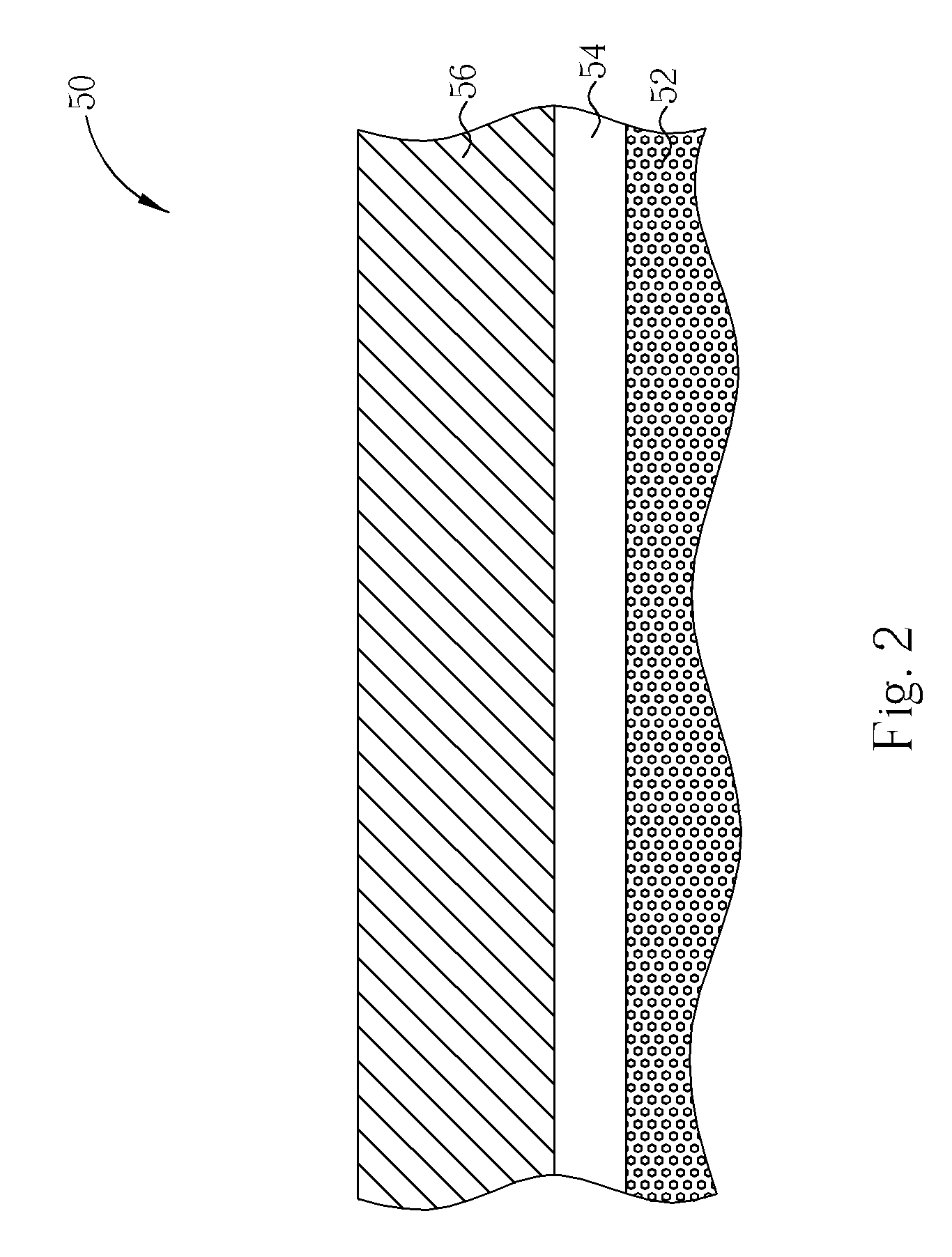

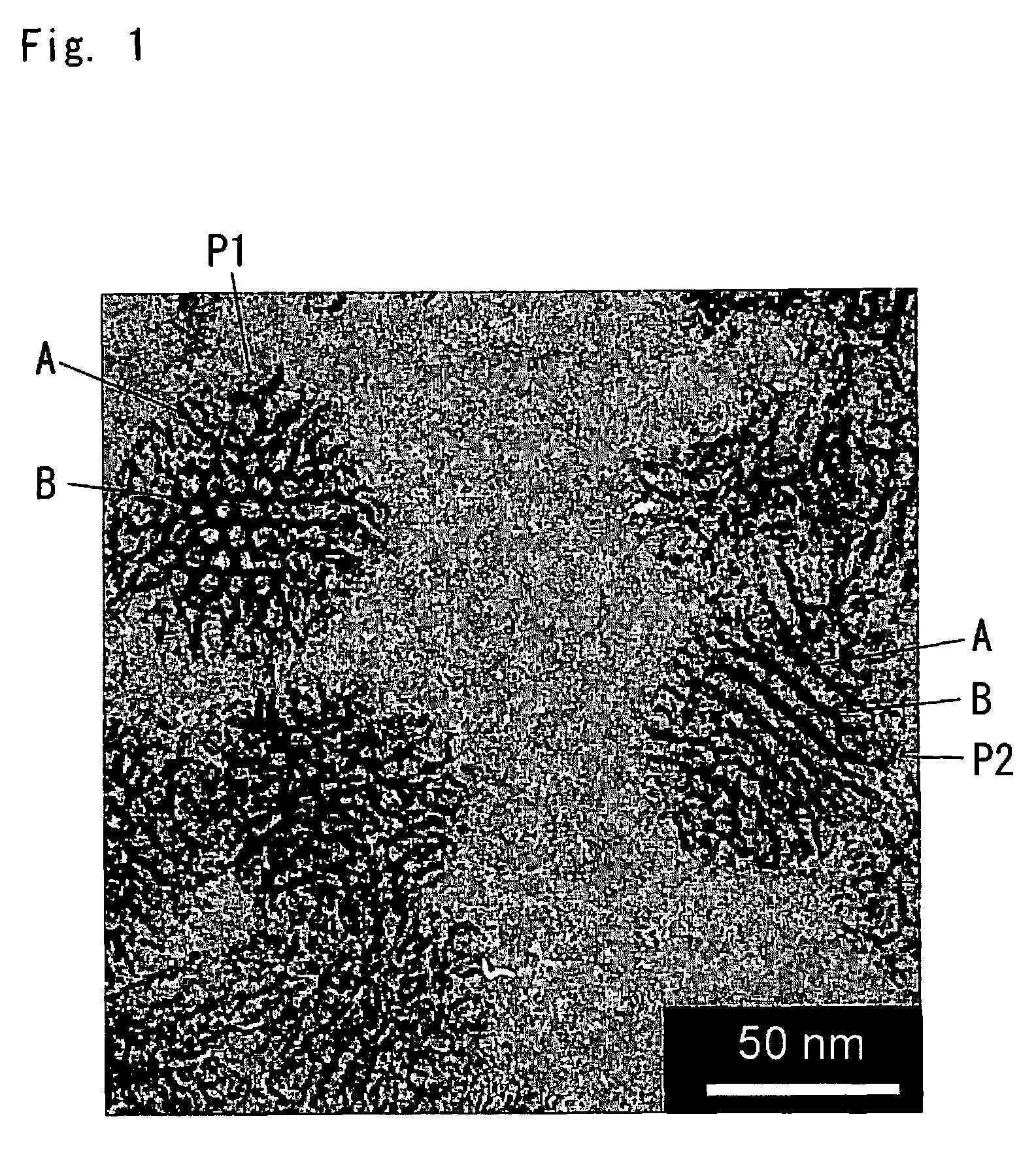

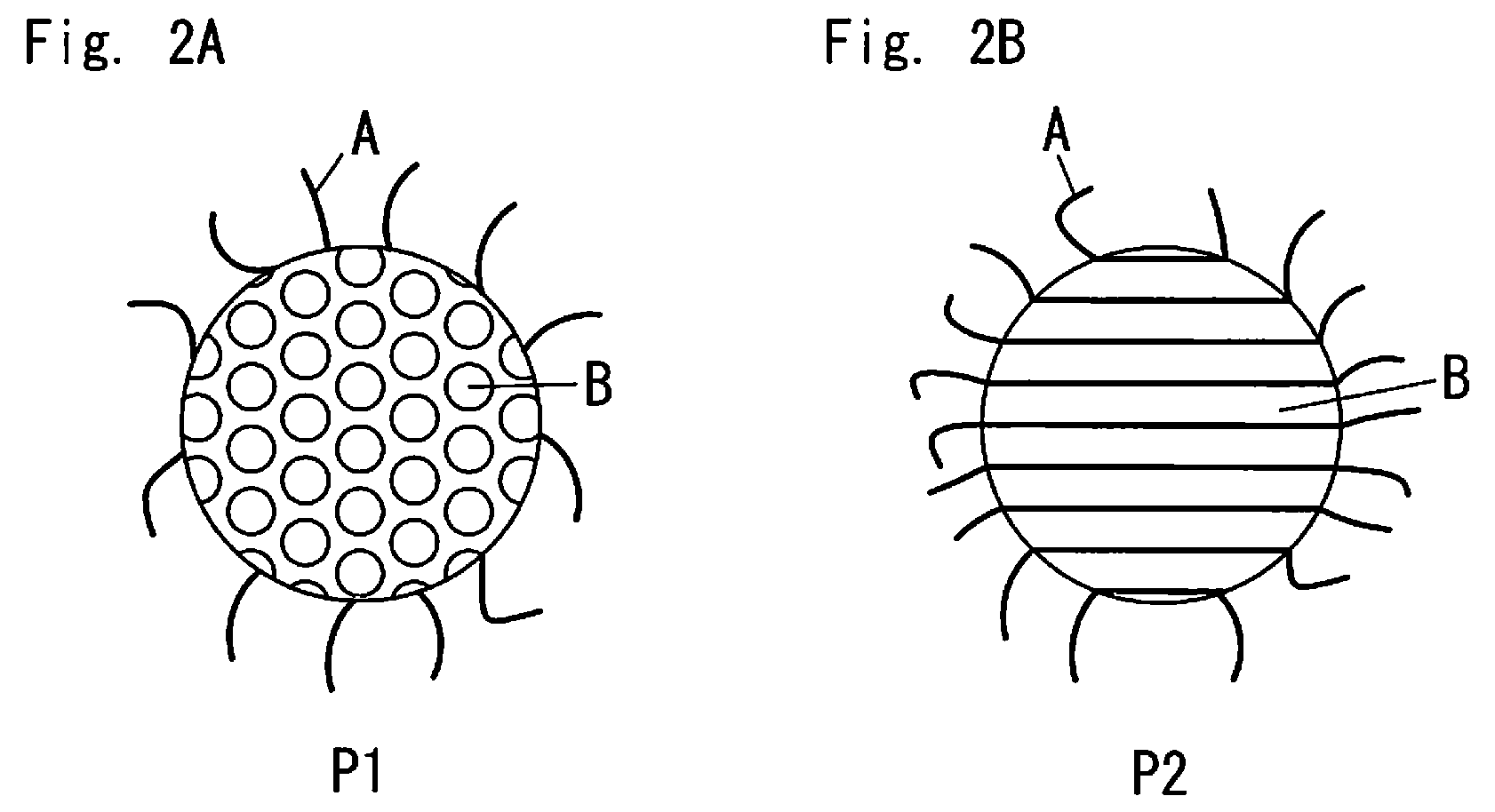

Method for producing fine mesoporous silica particles, fine mesoporous silica particles, liquid dispersion of fine mesoporous silica particles, composition containing fine mesoporous silica particles and molded article containing fine mesoporous silica particles

ActiveUS20120192762A1High strengthFunction increaseMaterial nanotechnologyPigmenting treatmentSilica particleMicroparticle

Fine mesoporous silica particles are provided by which not only the functions of low reflectance (Low-n), low dielectric constant (Low-k) and low thermal conductivity but also improved strength of a molded article are achieved. The fine mesoporous silica particles are manufactured by a process including a surfactant composite fine silica particle preparation step and a mesoporous particle formation step. In the silica fine particle preparation step, a surfactant, water, an alkali and a hydrophobic part-containing additive including a hydrophobic part for increasing the volume of micelles are mixed with a silica source to thereby prepare surfactant composite fine silica particles. In the mesoporous particle formation step, the mixture is mixed with an acid and an organosilicon compound to thereby remove the surfactant and hydrophobic part-containing additive from the surfactant composite fine silica particles and provide the surface of each silica fine particle with an organic functional group. The fine mesoporous silica particles have mesopores inside each particle, and are modified on the surface with organic functional groups.

Owner:PANASONIC CORP +1

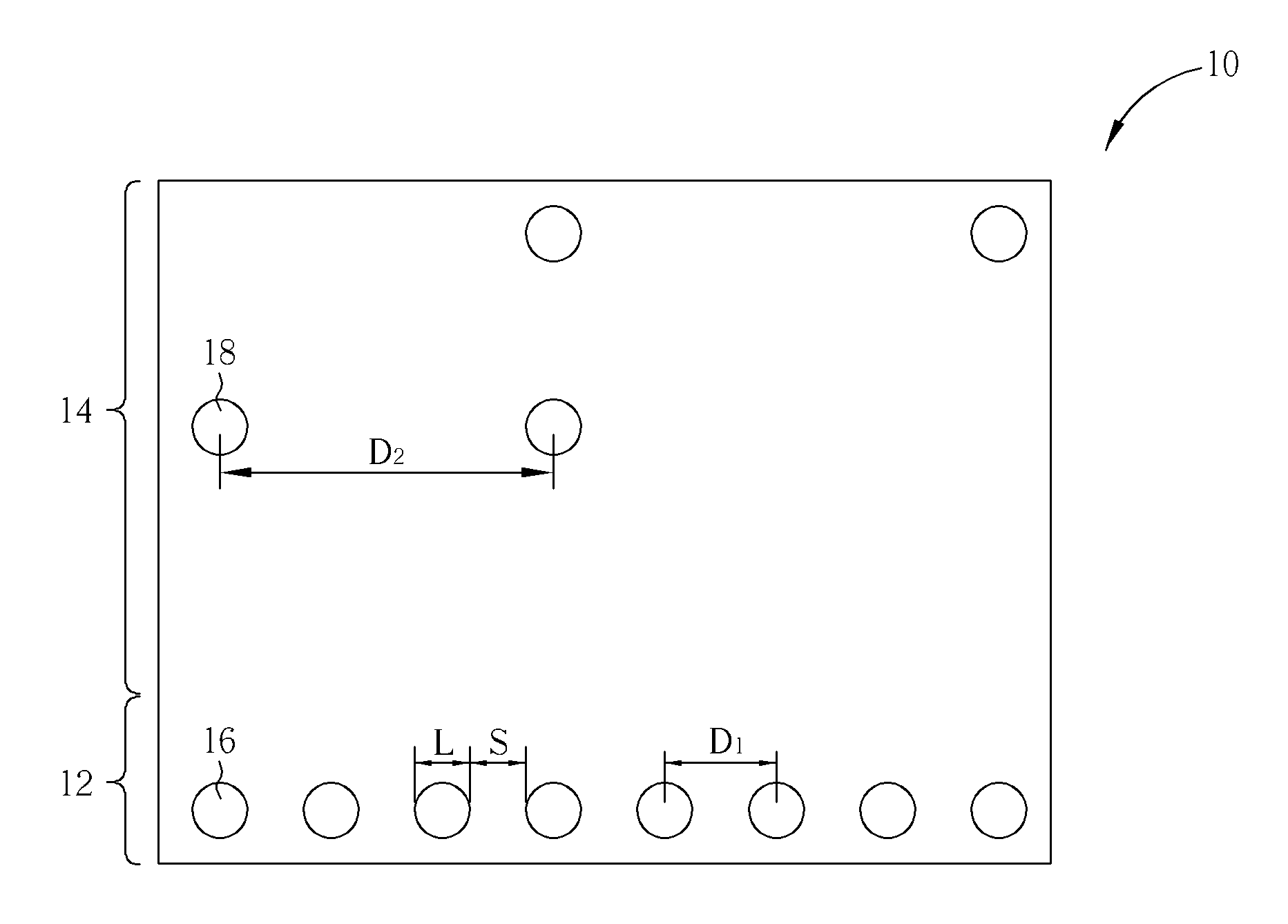

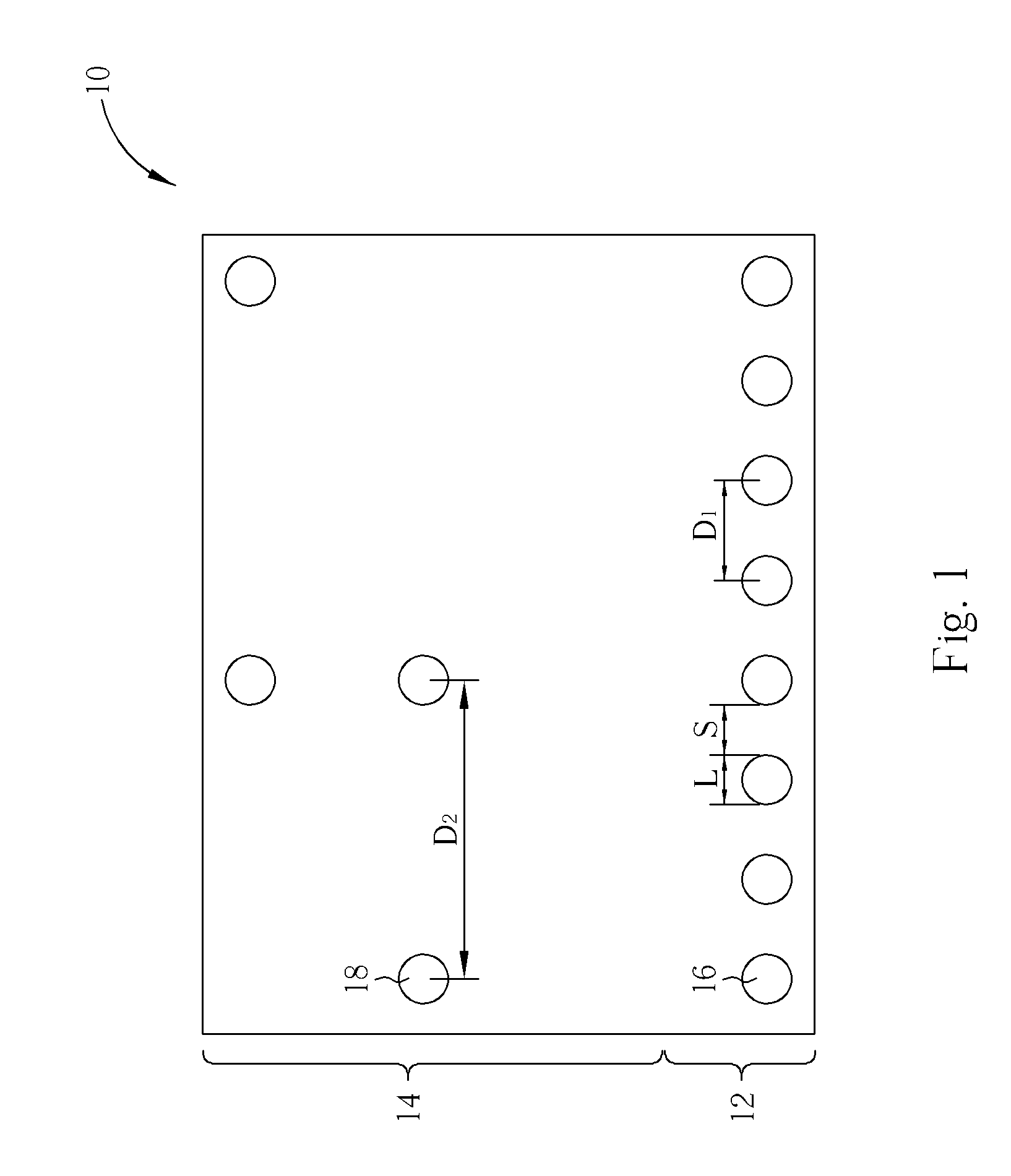

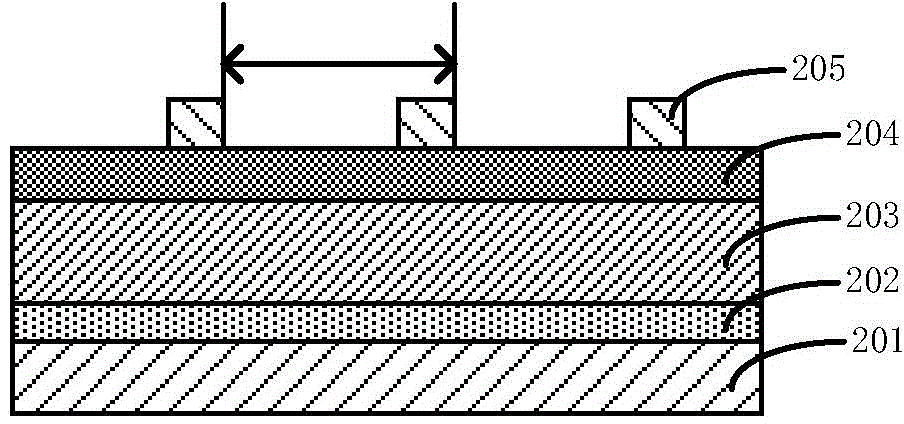

Method of pattern transfer

ActiveUS7887996B2High resolutionReduce defectsPhotosensitive materialsPhoto-taking processesEngineeringHard mask

Pattern transfer is achieved by forming a first patterned hard mask layer with a circuit pattern and a plurality of dummy patterns on a substrate, forming a second pattern mask layer on the substrate, exposing the circuit pattern of the first pattern mask layer, and removing a portion of the substrate exposed by the first patterned mask layer, so as to transfer the circuit pattern to the substrate.

Owner:NAN YA TECH

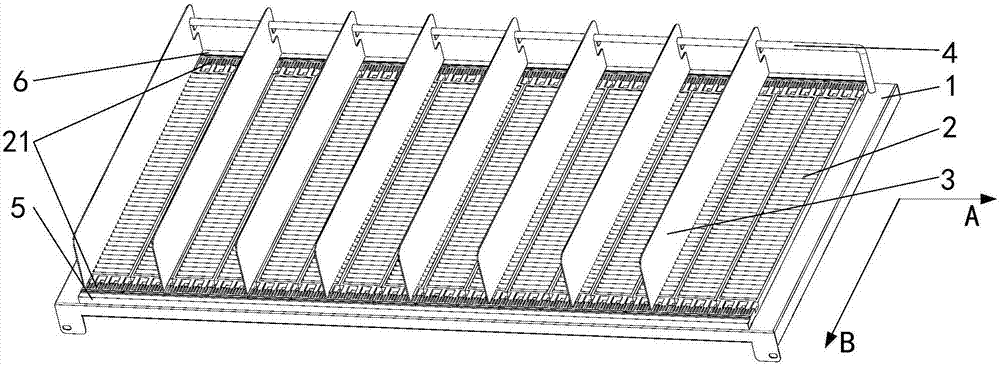

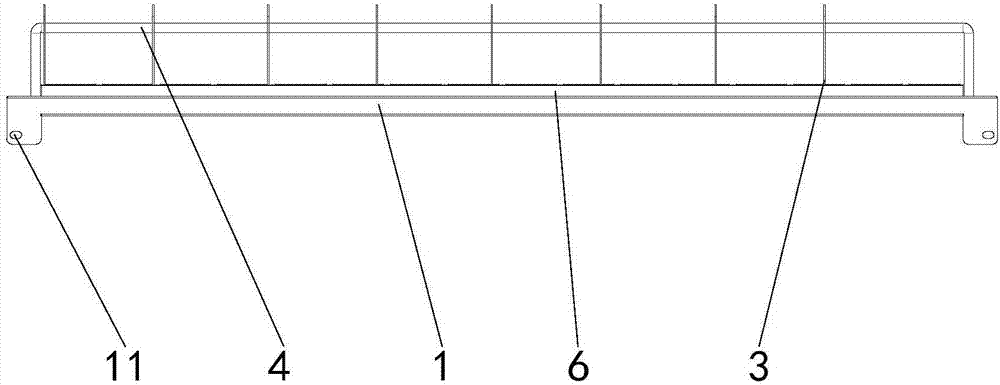

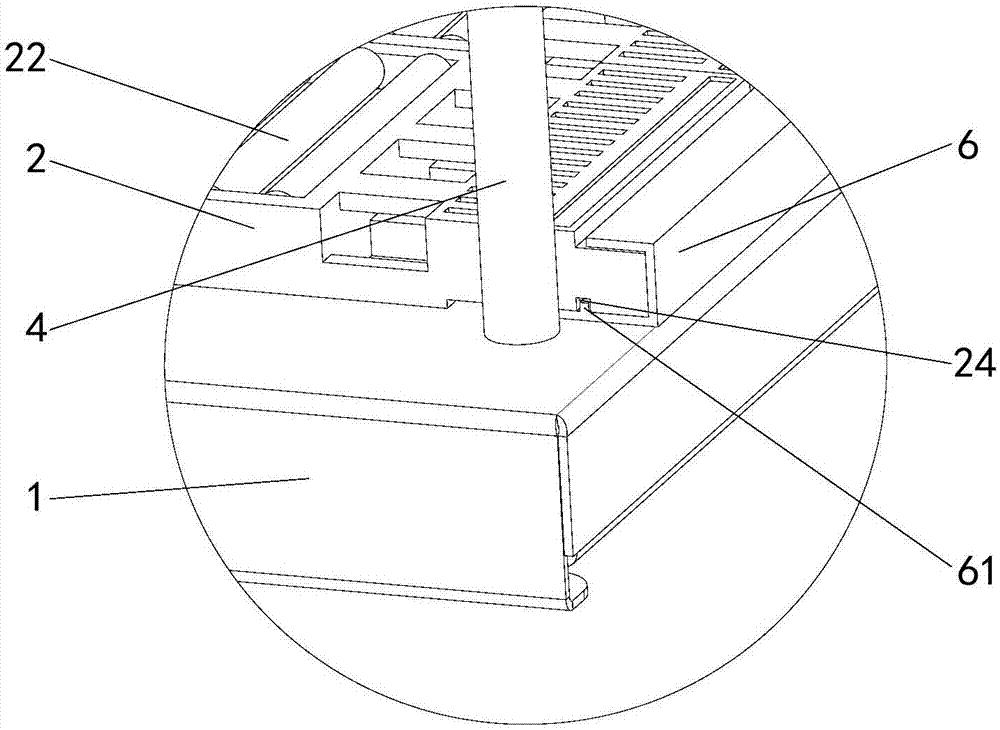

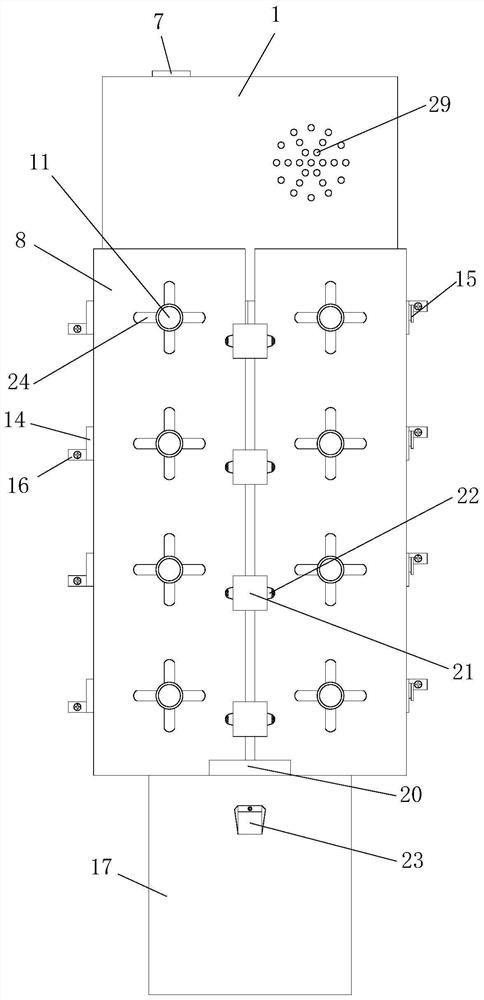

Automatic vending machine dynamic commodity path and automatic vending machine

PendingCN107331046AEasy to movePrevent fallingCoin-freed apparatus detailsApparatus for dispensing discrete articlesProcess engineeringComputer science

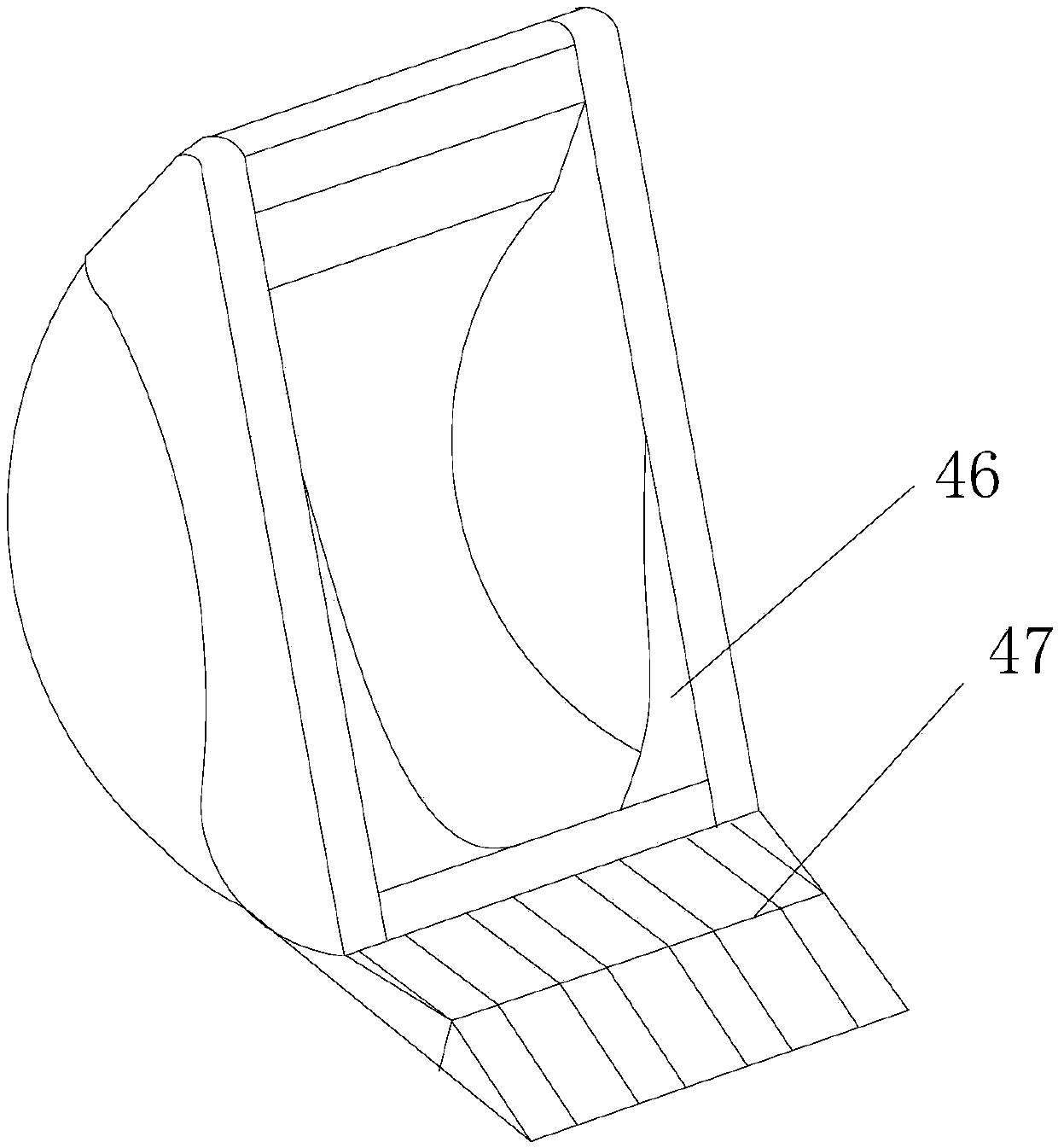

The invention provides an automatic vending machine dynamic commodity path and an automatic vending machine, and relates to the technical field of automatic vending machines.The automatic vending machine comprises shelf trays, multiple rolling boards, multiple partition boards and trayblocking bars, the rolling boards are arranged on the shelf trays in sequencein the length direction of the shelf trays in a connected mode, the tray blocking bars are connected with the sidesof the shelf trays, away from the commodity delivering side, locating parts are arranged on the bottoms of the partition boards, a plurality of locating grooves are formedin the rolling boards, and the tray blocking bars provide a supporting force for the partitionboards, so that the positions of the partitionboards are easy to move, meanwhile the commoditiesare prevented from falling from the commodity shelf trays, and through the coordination of the locating parts and the locating grooves, free disassembling and installation of the partition boardsareachieved,the operation is simple and convenient, and a user can adjust the width of the adjacent partition boards according to thesizes of the commodities;the automatic vending machine has the regulative property, the range of application of the vending machine is increased, and the diverse selectivity of the user is improved.

Owner:BEIJING YUNJING YUANPU INFORMATION TECH CO LTD

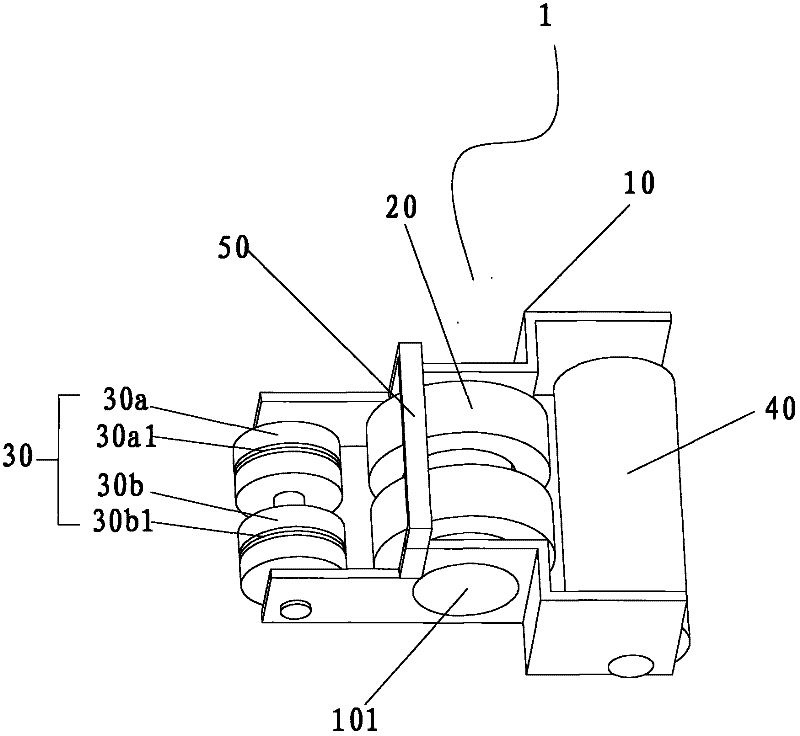

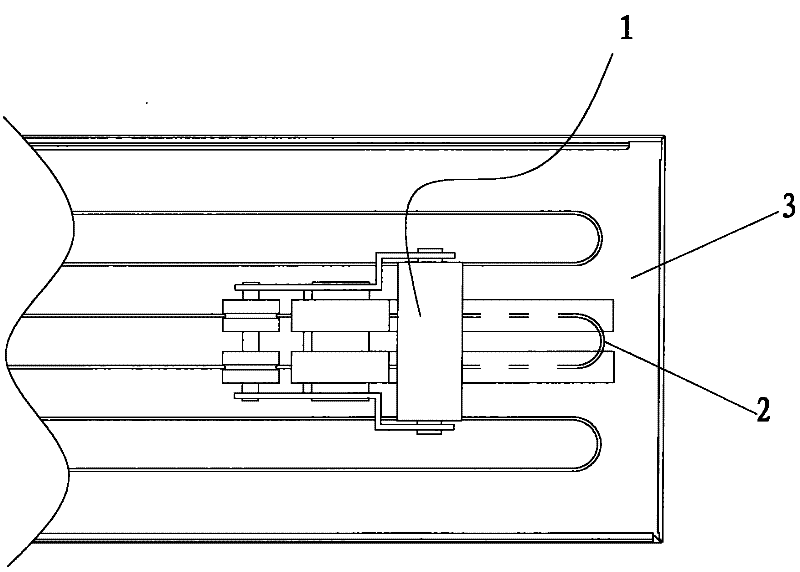

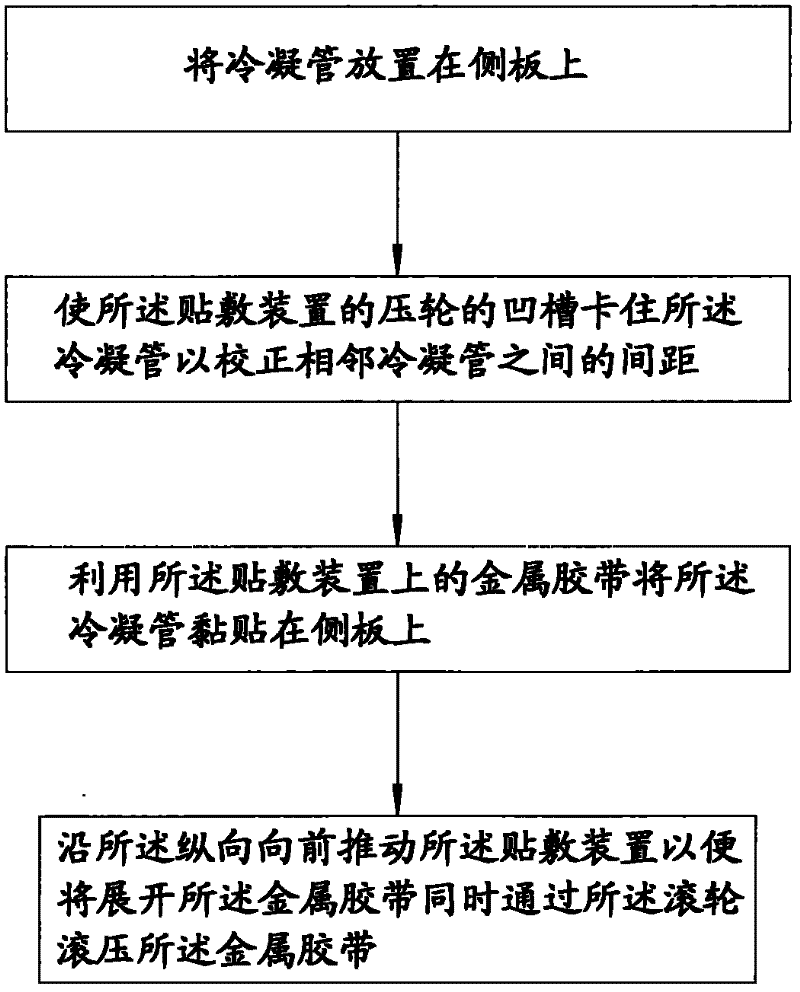

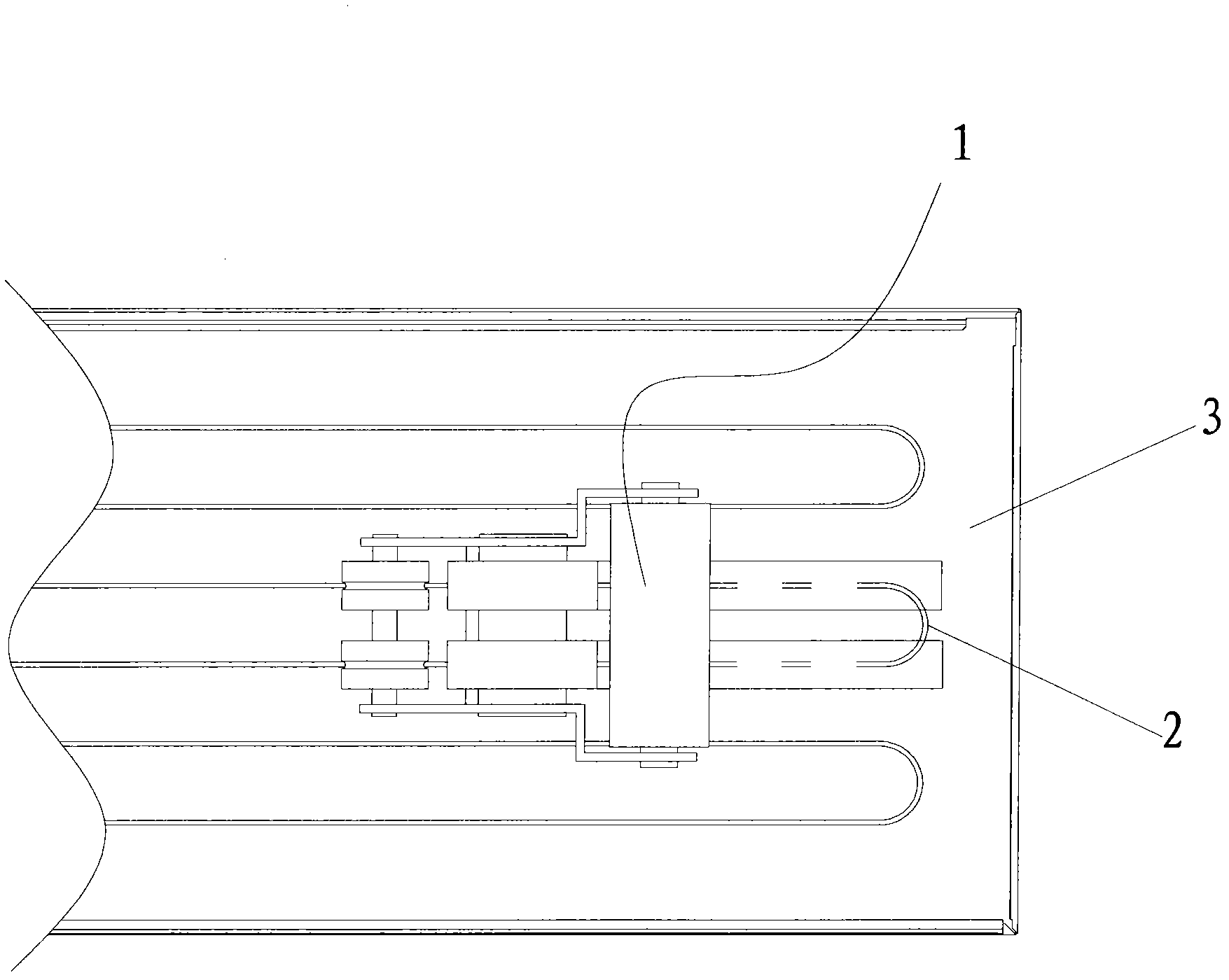

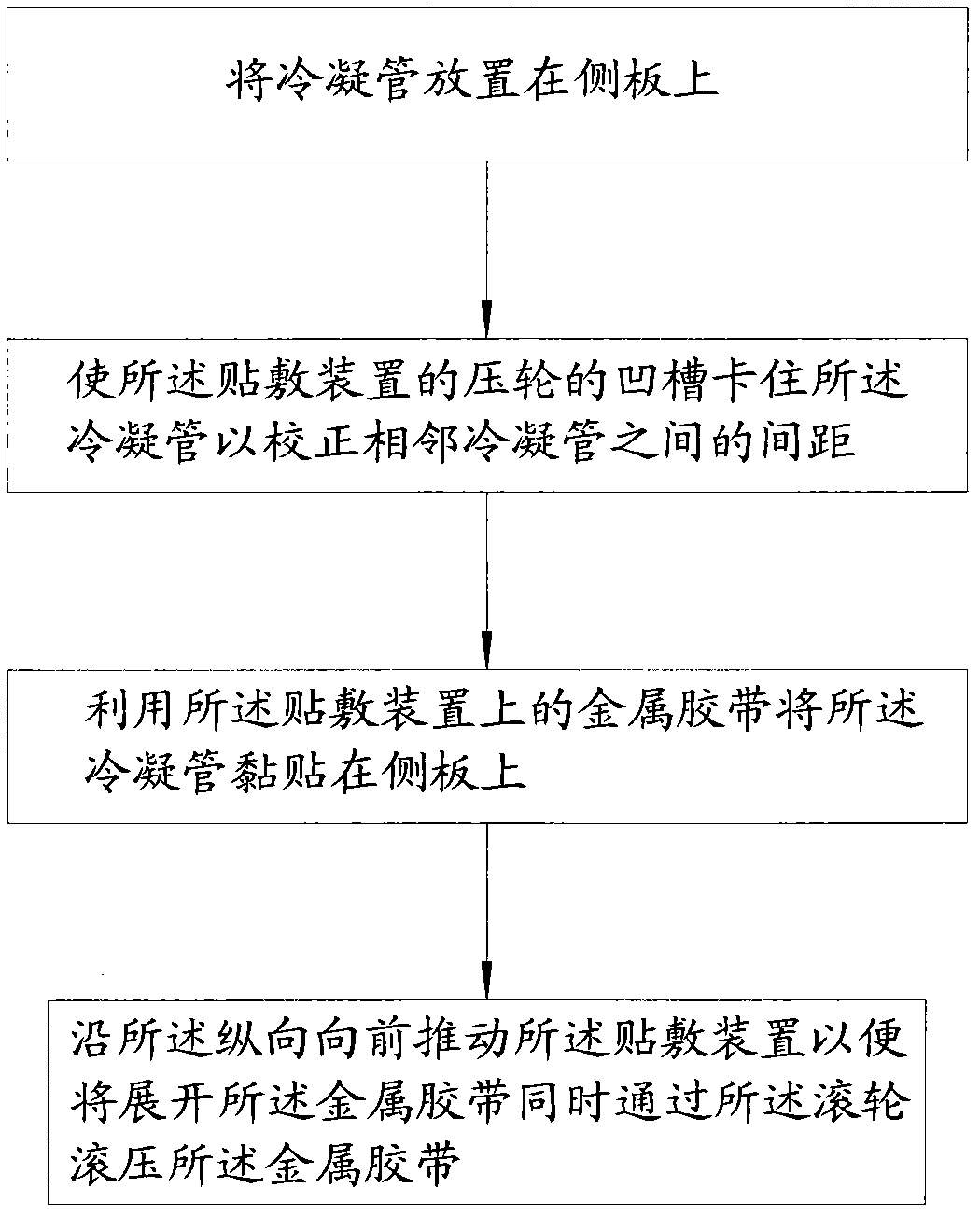

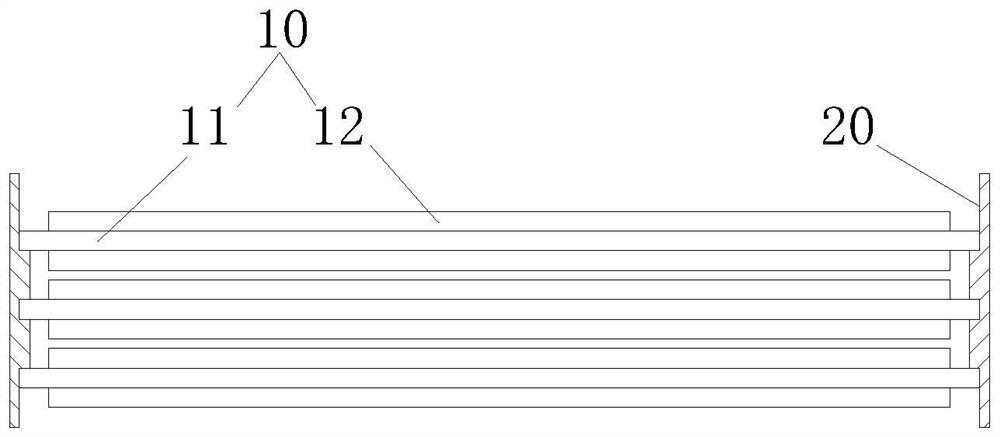

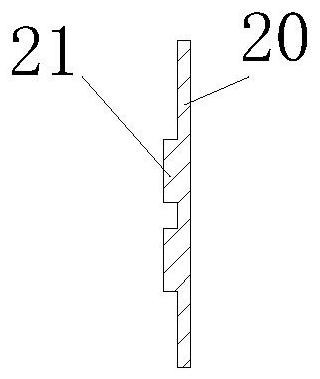

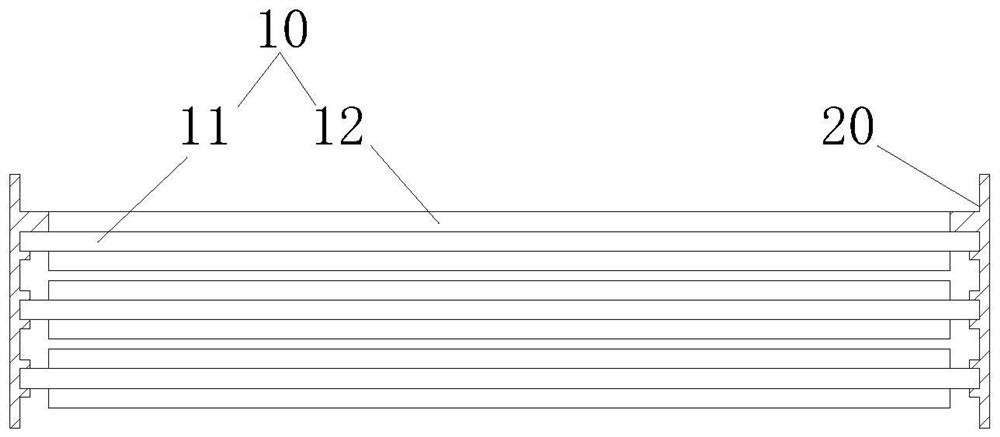

Applying device for applying condenser and production process of built-in condenser

The invention discloses a process for producing a built-in condenser by using an applying device for applying a condenser, which comprises the following steps: A, putting condenser pipes on a side plate; B, clamping the condenser pipes to correct distances between adjacent condenser pipes by using a groove of a pinch roller of the applying device; C, pasting the condenser pipes on the side plate by using a metal adhesive tape roll on the applying device; D, pushing forward the applying device along the longitudinal direction so as to fold the metal adhesive tape roll and meanwhile roll the metal adhesive tape through the roller; and repeating the above steps B-D. According to the process for producing the built-in condenser by using the applying device for applying the condenser applying device disclosed by an embodiment of the invention, equal space among condensation pipes and rapid adhesion of an adhesive tape can be realized; the condensation pipes are tightly adhered on a side plate; and the efficiency can be improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

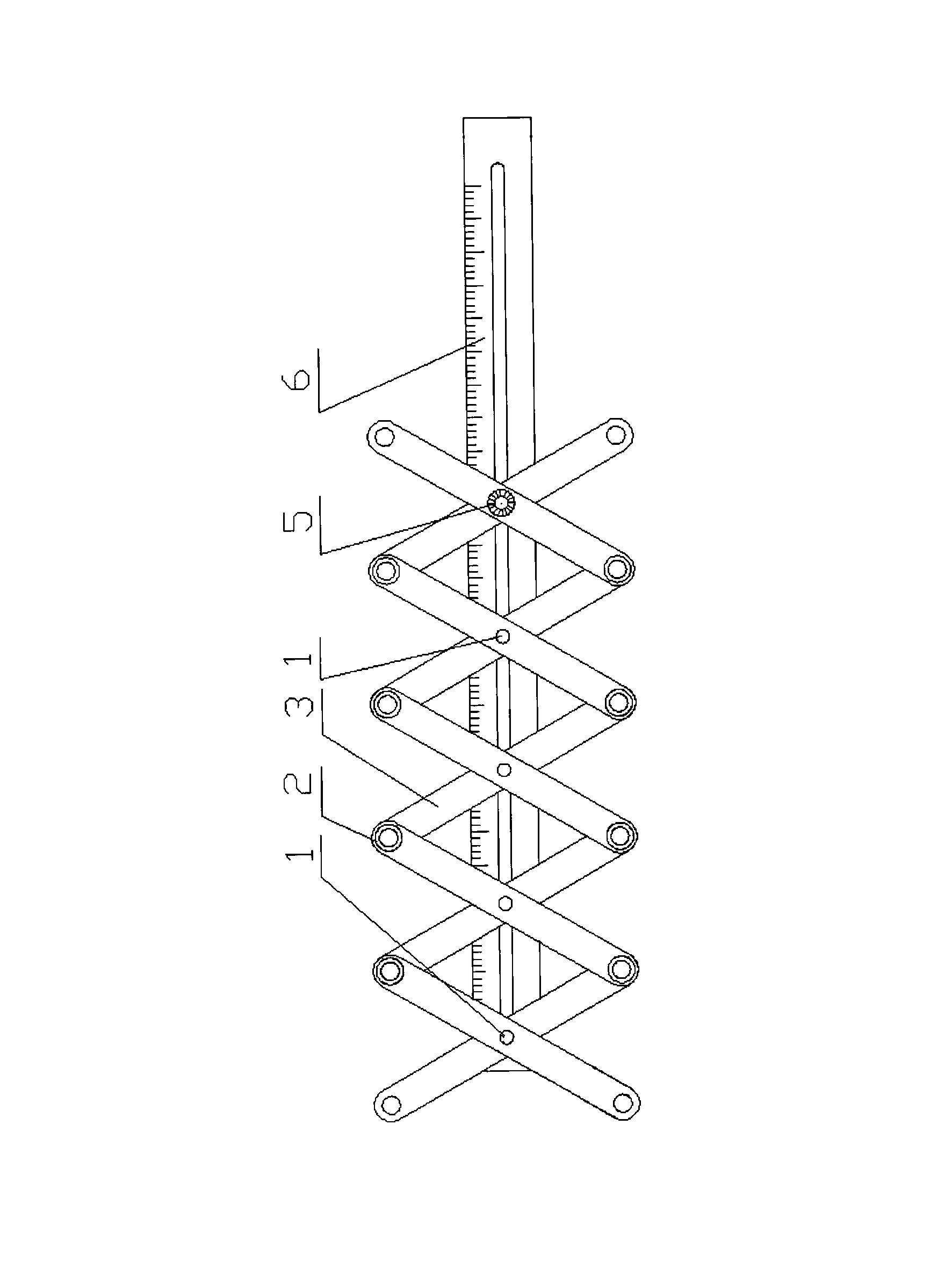

Equidistant scribing ruler

The invention relates to an equidistant scribing ruler. An elongated hole is formed in a ruler body provided with scales in the length direction. A positioning hole is formed at each end of each of a plurality of movable rods, heads and tails of the movable rods are movably connected through hollow rotary shafts, a distance-adjusting rotary shaft is arranged in the middle of each of the movable rods, and the distance-adjusting rotary shafts are disposed in the elongated hole successively. By means of the equidistant scribing ruler, the scribing time is shortened, the scribing quality of a product is improved, and drilling can be completed efficiently and accurately.

Owner:SHENYANG AIRCRAFT CORP

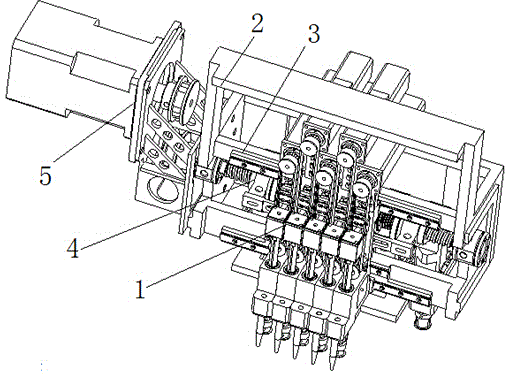

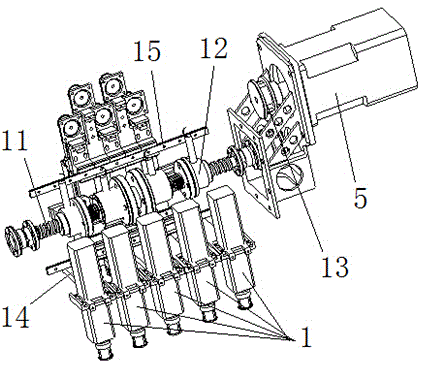

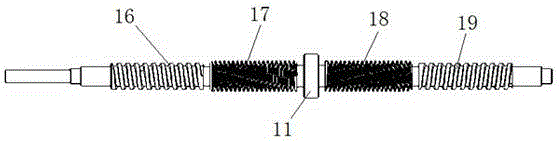

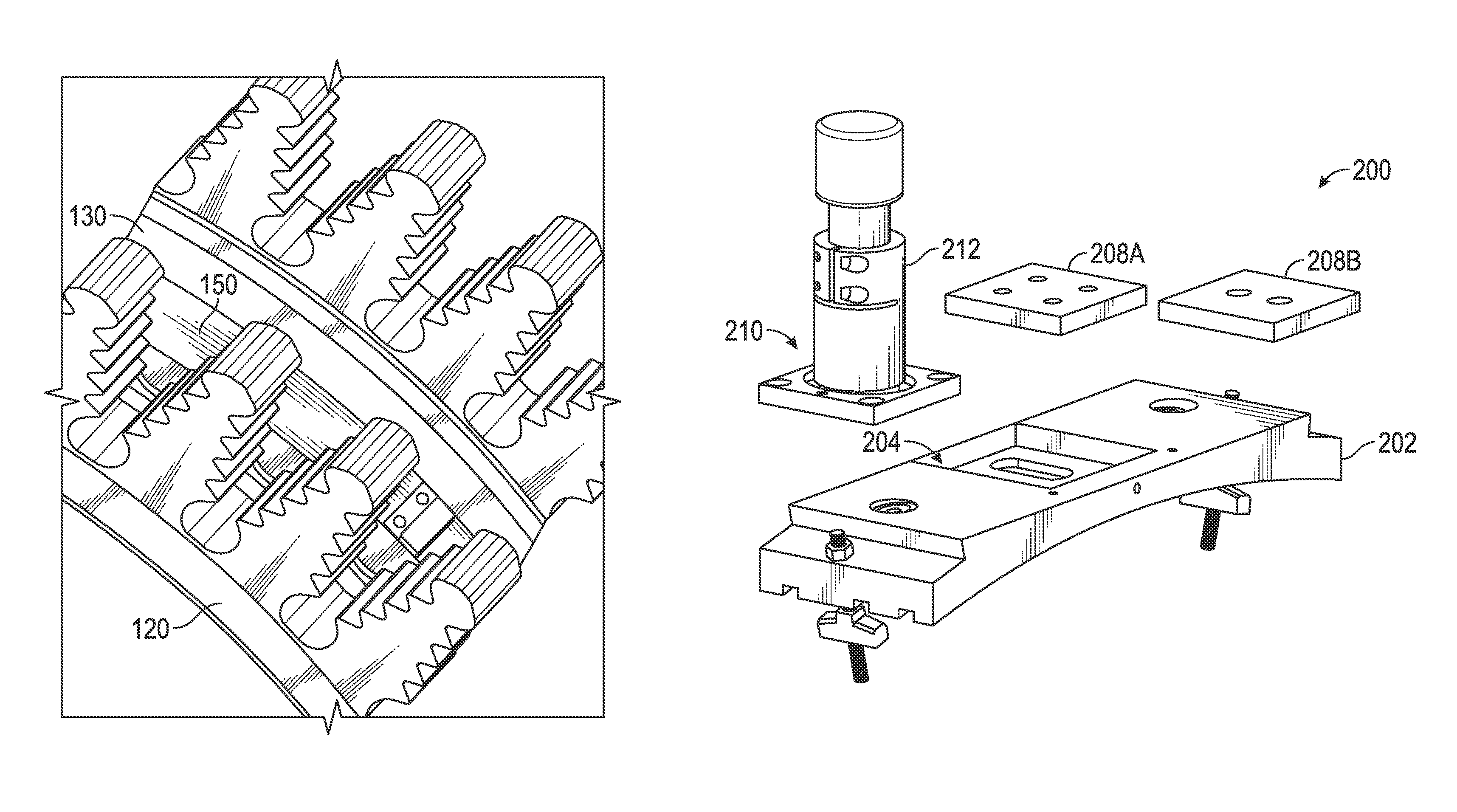

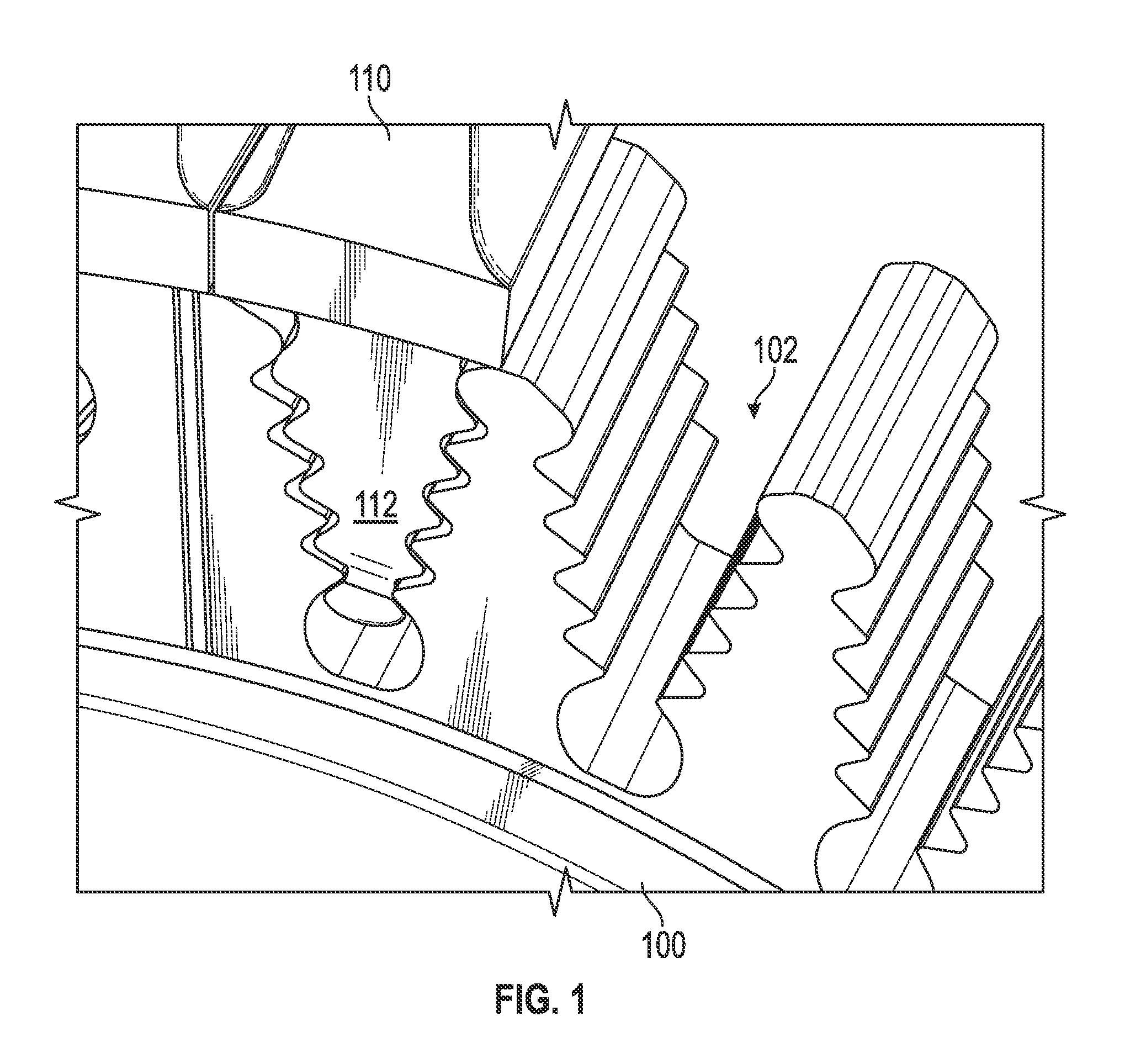

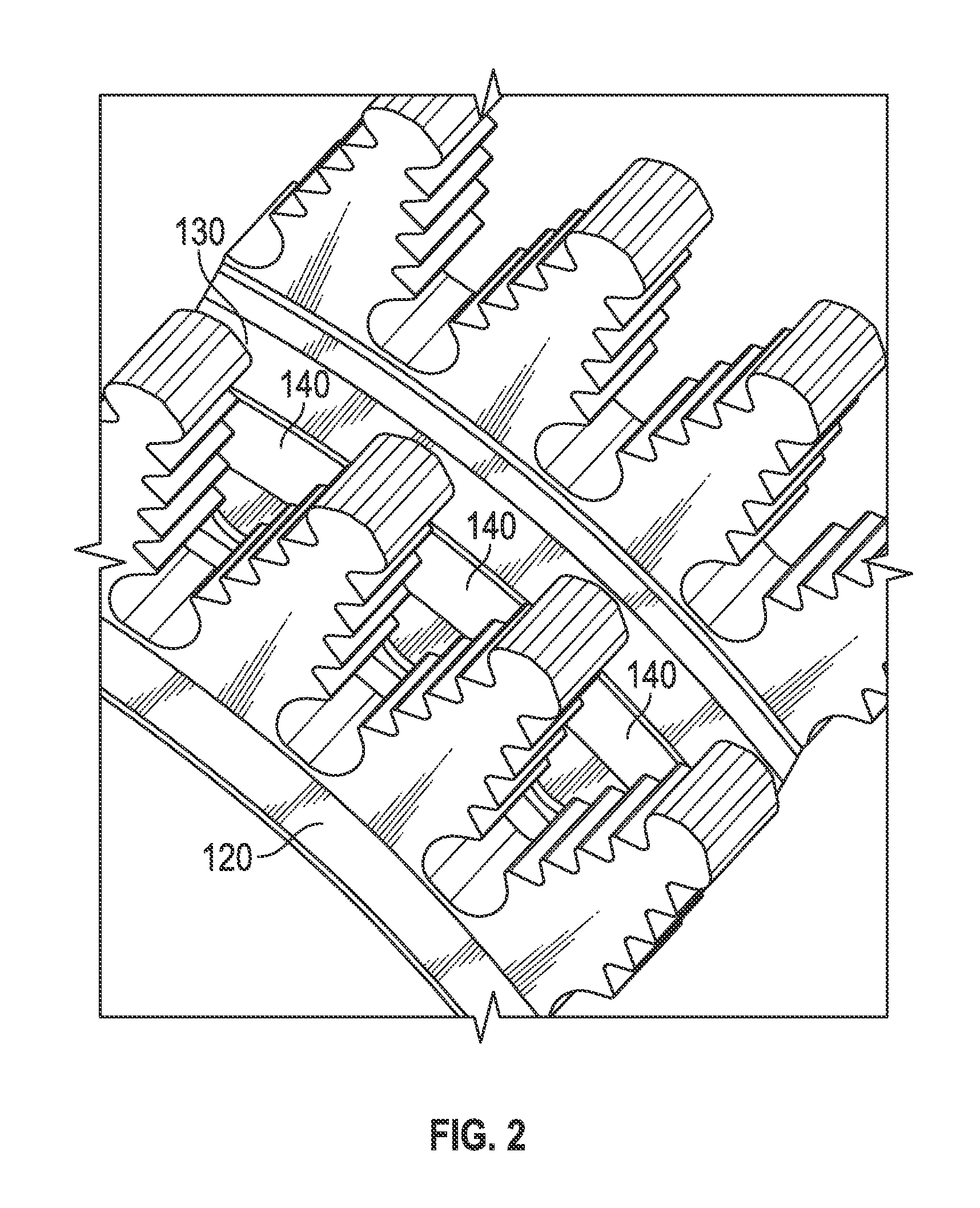

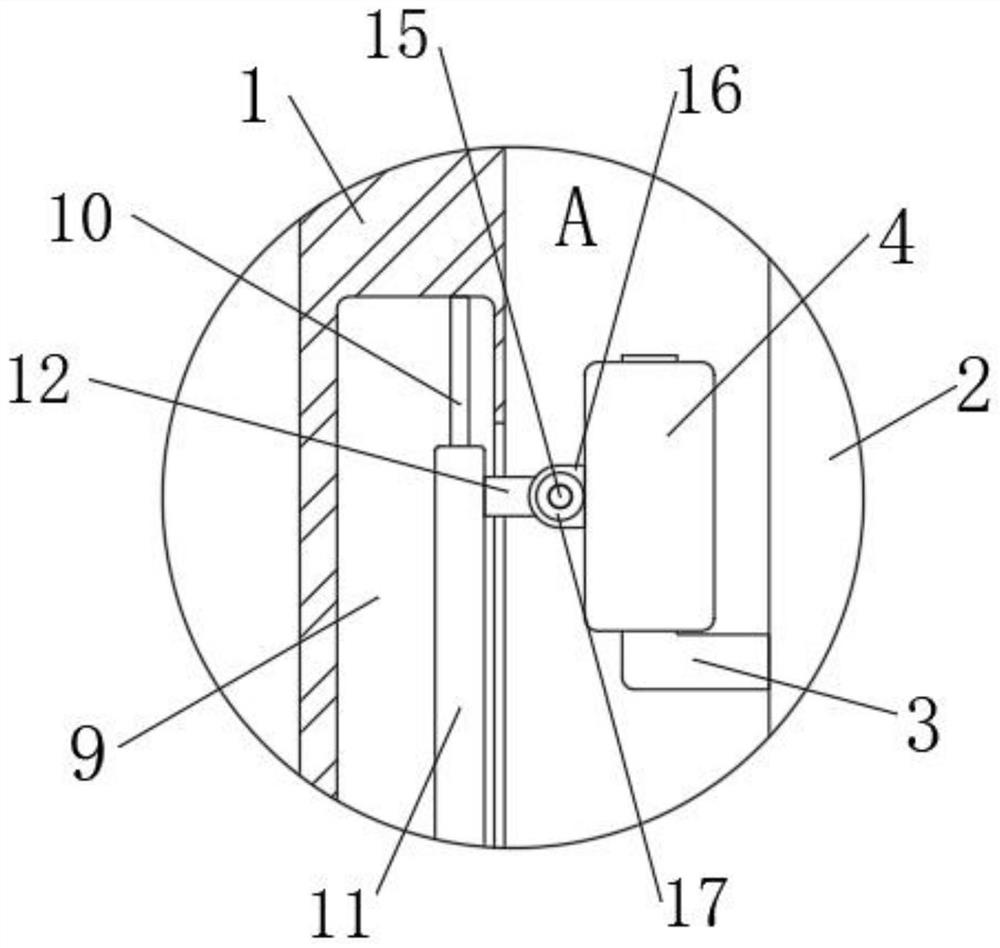

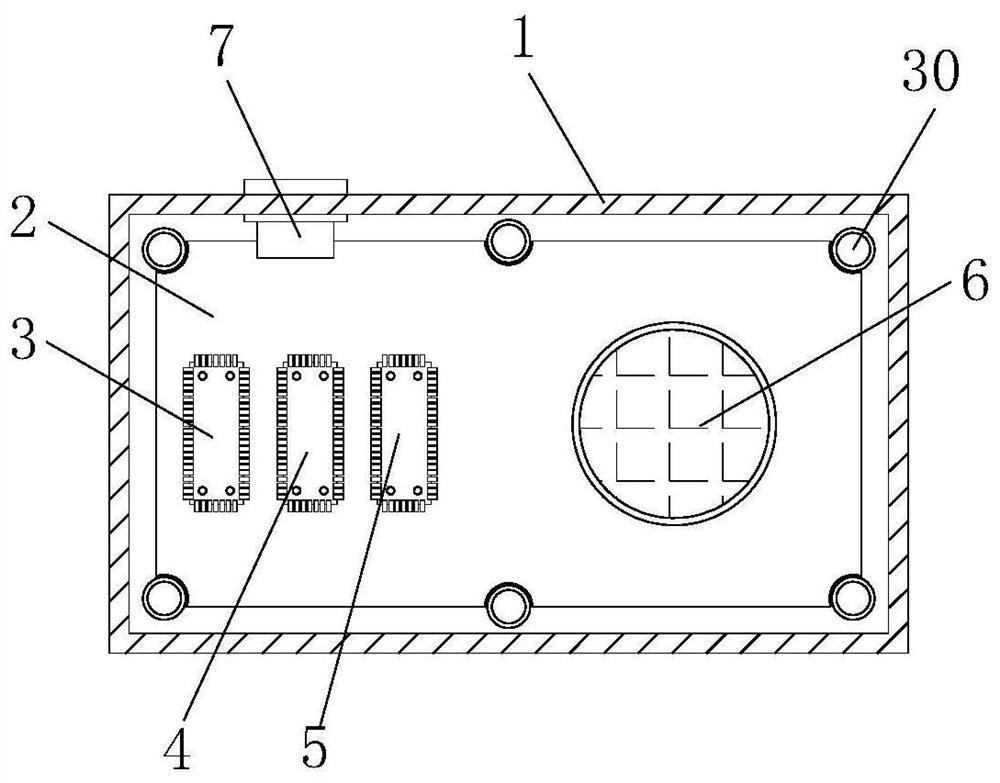

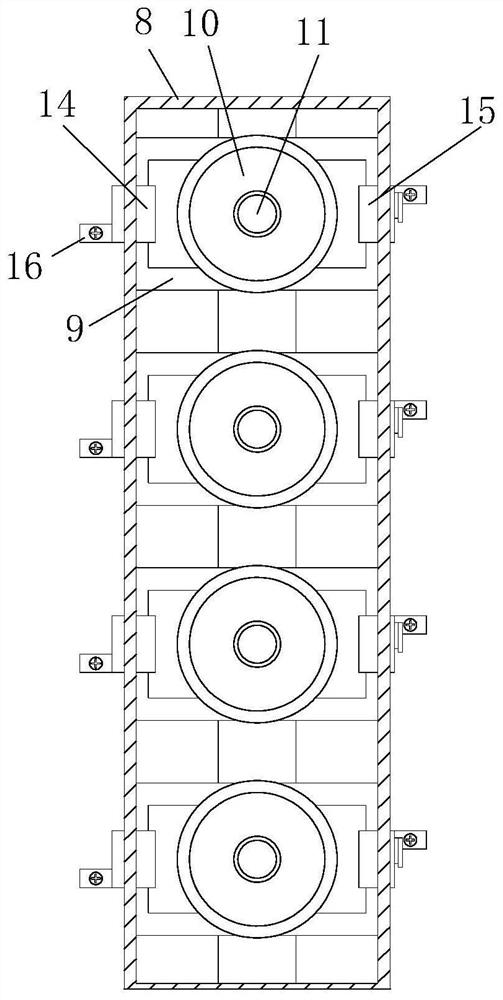

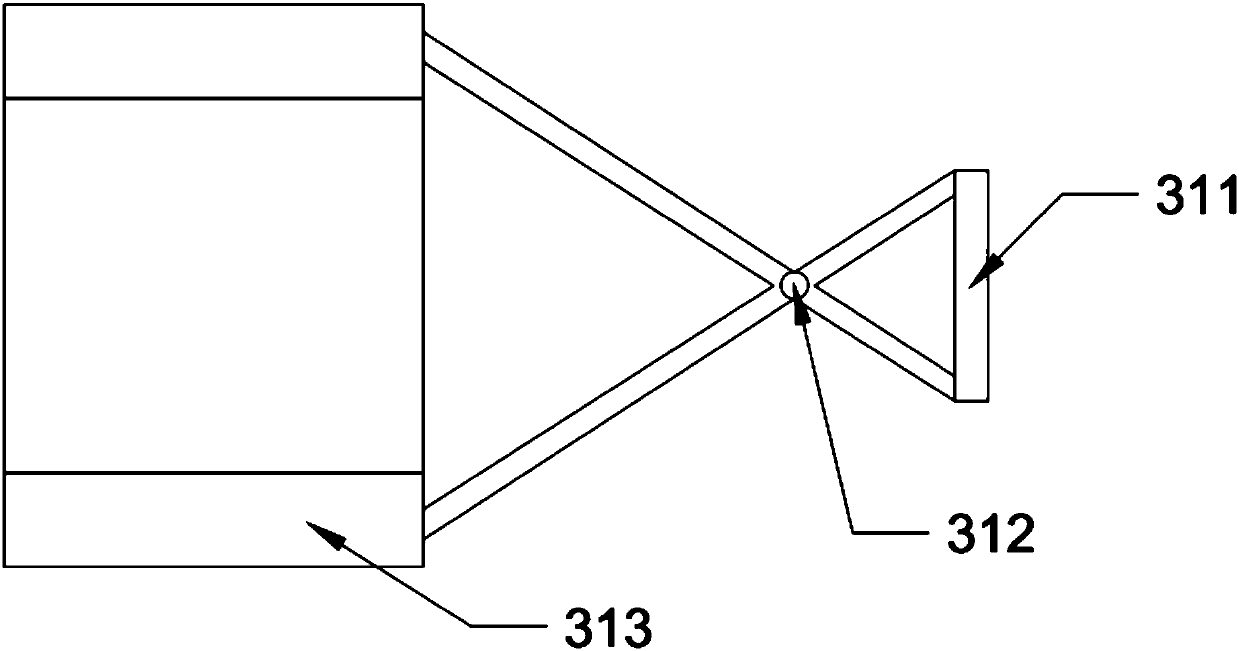

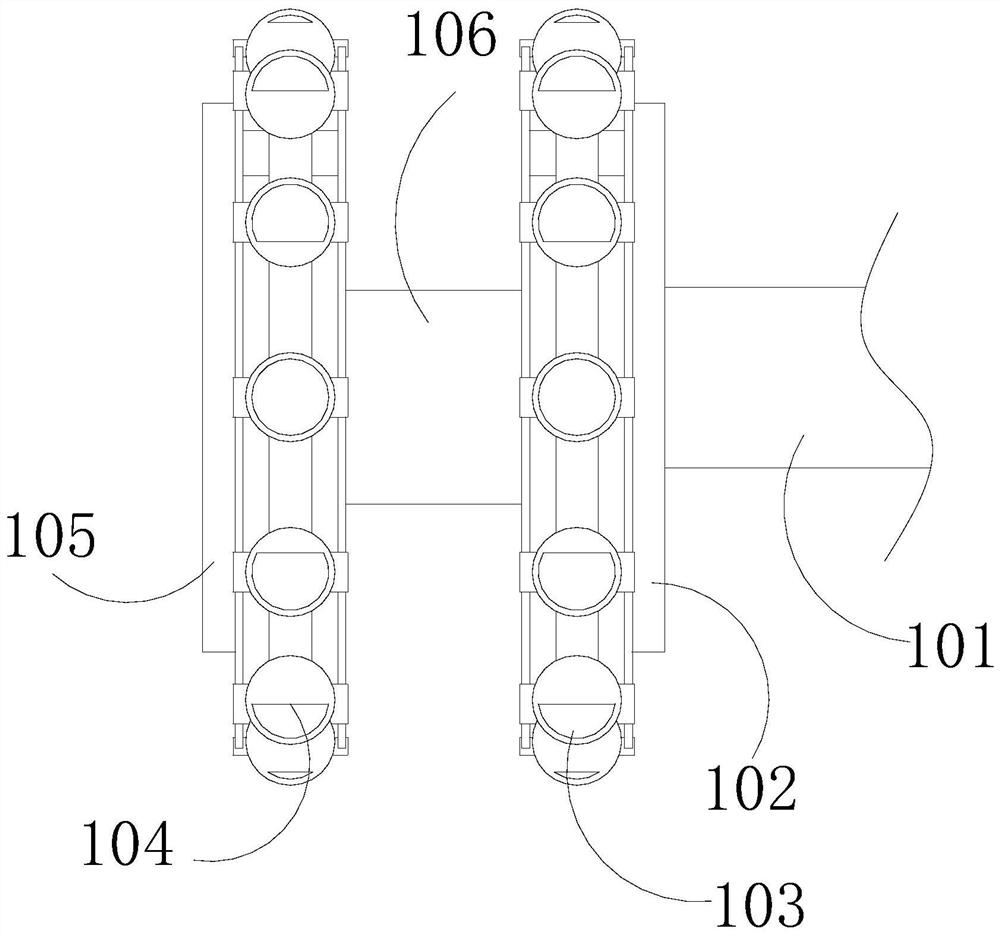

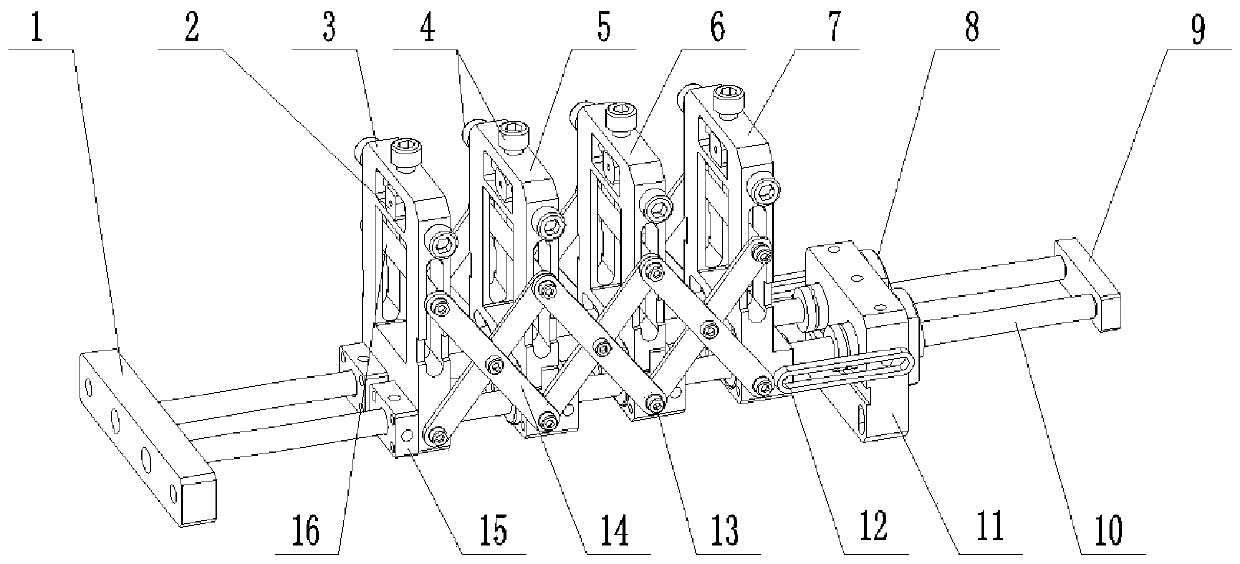

Positive and reverse spiral amplitude chip mounting head for chip mounting machine and amplitude change method of positive and reverse spiral amplitude chip mounting head

InactiveCN104640371AEqual spacingRealize the amplitude change functionPrinted circuit assemblingElectrical and Electronics engineeringNozzle

The invention provides a positive and reverse spiral amplitude chip mounting head of a chip mounting machine and an amplitude change method of the positive and reverse spiral amplitude chip mounting head. The positive and reverse spiral amplitude chip mounting head comprises more than two chip mounting suction nozzle assemblies, wherein the plurality of chip patching nozzle assemblies are arranged in parallel and combined together, are arranged on a chip mounting head support frame, and can slide along a p-axis linear guide rail. The chip mounting head is characterized in that an amplitude change mechanism is also arranged on the chip mounting support frame, the amplitude change mechanism is connected with each movable chip mounting suction nozzle assembly, the patch suction nozzle assemblies are driven by the amplitude change mechanism arranged on the chip mounting head support frame to slide along the p-axis linear guide rail, and are driven by a servo motor to do amplitude change regulation movement through the amplitude change mechanism, and in addition, an identical space between suction nozzles arranged on each chip mounting suction nozzle assembly is always maintained in the amplitude change process.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

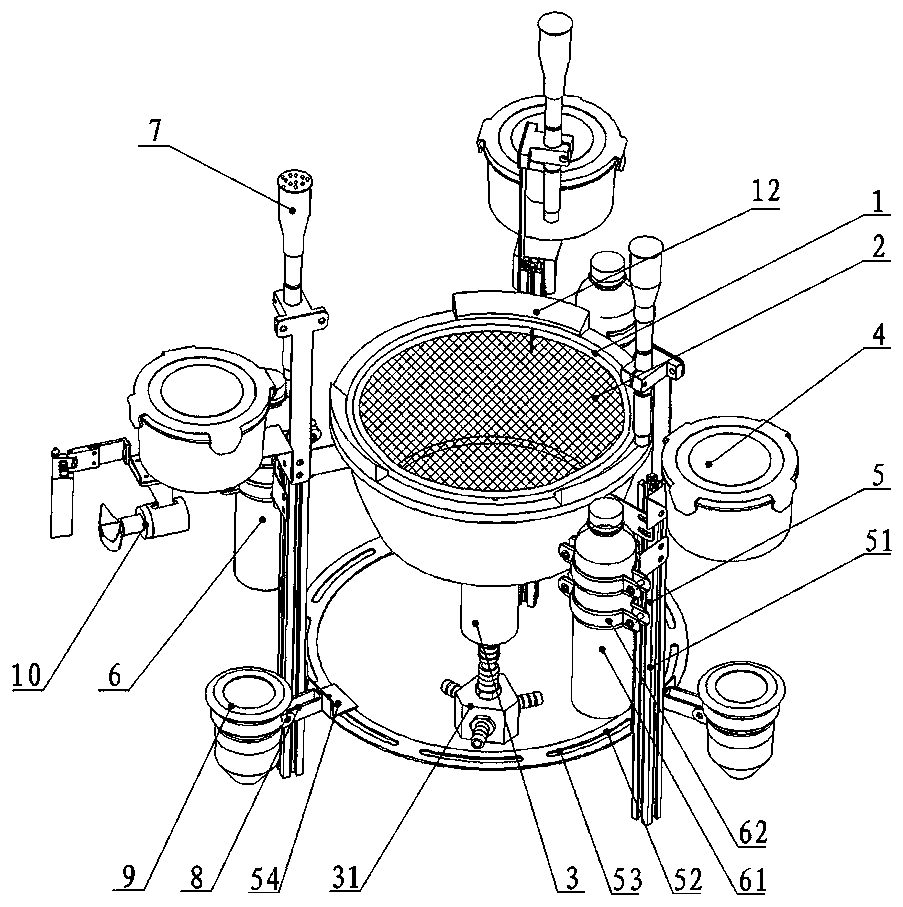

Moving floating overwater garbage cleaning device

PendingCN110306505AImprove collection efficiencyAvoid leaningWater cleaningUsing subsonic/sonic/ultrasonic vibration meansWater storageLeveling mechanism

The invention relates to the field of garbage treatment, in particular to a moving floating overwater garbage cleaning device which comprises a garbage can body with an opening in the upper end and awater absorption hole reserved in the lower end, a mesh cover, a water absorption pump, a control box, a levelling rack and a levelling part. A water inlet of the water absorption pump is connected tothe water absorption hole of the garbage can body; the upper end of the mesh cover is opened, the lower end of the mesh cover is closed, and the whole mesh cover is placed in the garbage can body; the levelling mechanism comprises vertical supports and a horizontal fixed frame; the vertical supports are fixed onto the outer wall of the garbage can; the horizontal fixed frame is an annular ring connected to the lower ends of the three vertical supports; and equal number of water storage tanks are arranged on the three vertical supports and are fixed onto the vertical supports through encircling hoops. The device has flexibility on cleaning garbage in a moving floating way and can alarm after the garbage are full, so that a sanitation worker can conveniently and timely fish up and take outthe garbage; and in addition, through the levelling part, the device can horizontally float and move, so that the occurrence of the phenomenon that the garbage is dumped into water so as to be incapable of being cleaned is avoided.

Owner:CHONGQING ELECTROMECHANICAL VOCATIONAL INST

Method for producing fine mesoporous silica particles, fine mesoporous silica particles, liquid dispersion of fine mesoporous silica particles, composition containing fine mesoporous silica particles and molded article containing fine mesoporous silica particles

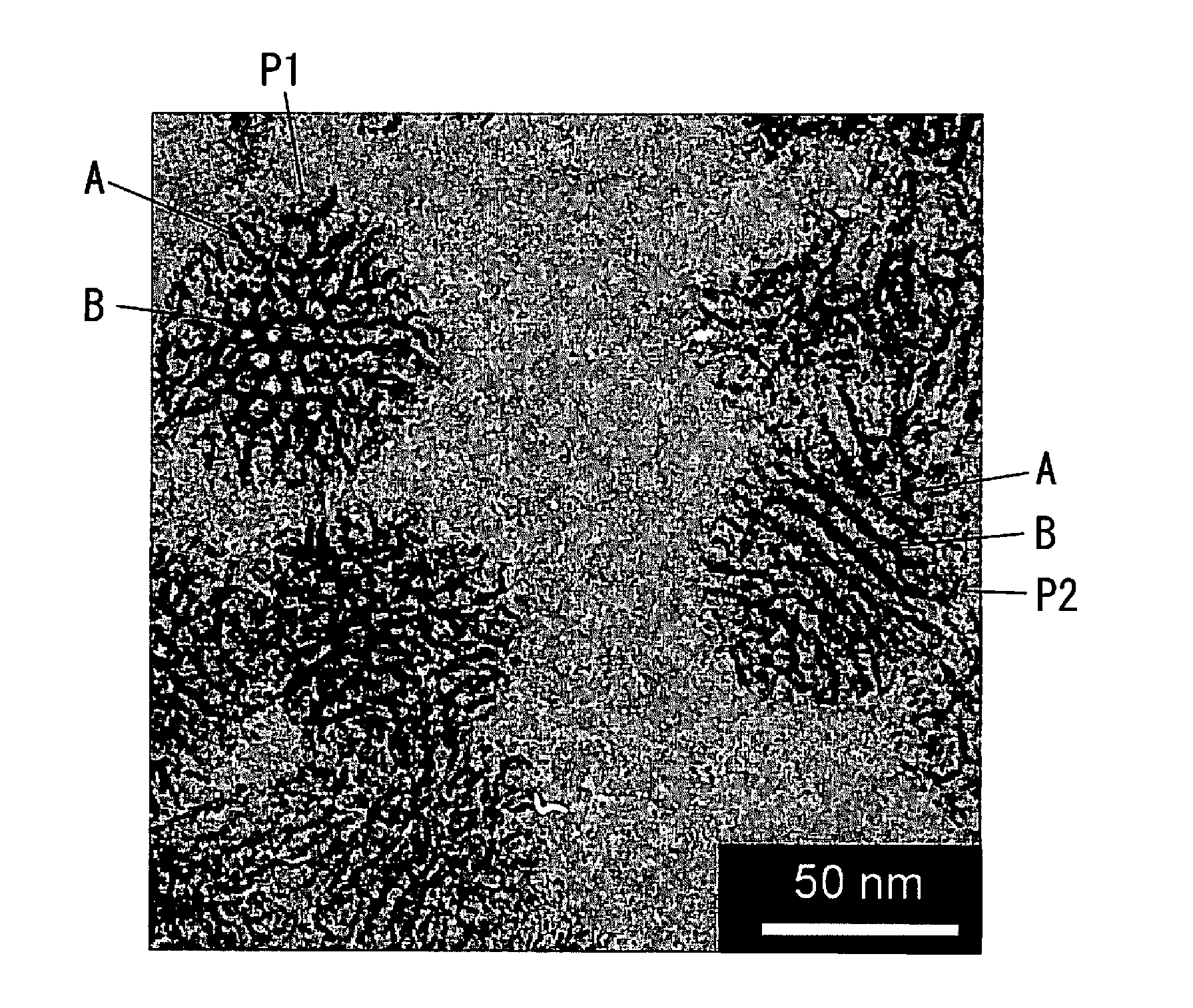

ActiveUS8999052B2High strengthFunction increasePigmenting treatmentSilicaSilica particleMesoporous silica

Fine mesoporous silica particles are provided by which not only the functions of low reflectance (Low-n), low dielectric constant (Low-k) and low thermal conductivity but also improved strength of a molded article are achieved. The fine mesoporous silica particles are manufactured by a process including a surfactant composite fine silica particle preparation step and a mesoporous particle formation step. In the silica fine particle preparation step, a surfactant, water, an alkali and a hydrophobic part-containing additive including a hydrophobic part for increasing the volume of micelles are mixed with a silica source to thereby prepare surfactant composite fine silica particles. In the mesoporous particle formation step, the mixture is mixed with an acid and an organosilicon compound to thereby remove the surfactant and hydrophobic part-containing additive from the surfactant composite fine silica particles and provide the surface of each silica fine particle with an organic functional group. The fine mesoporous silica particles have mesopores inside each particle, and are modified on the surface with organic functional groups.

Owner:PANASONIC CORP +1

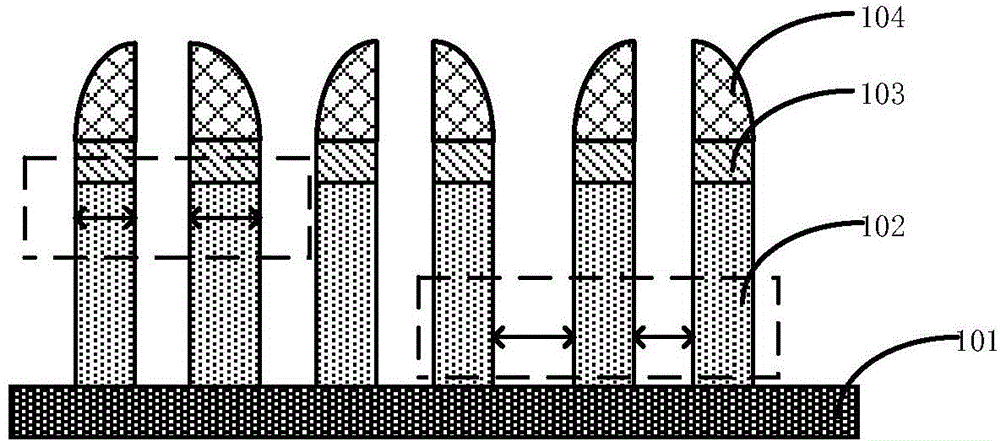

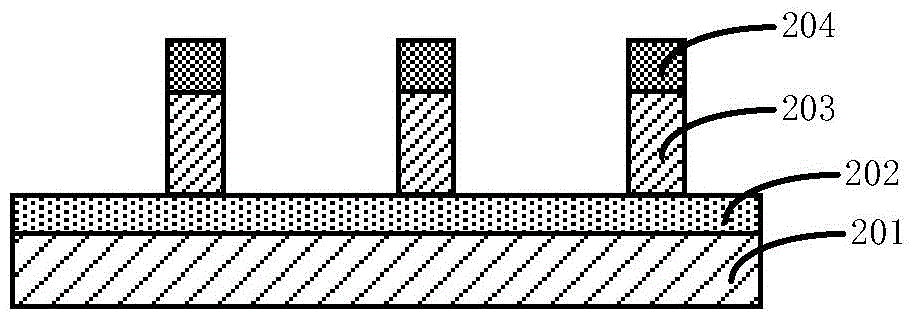

Semiconductor device based on double patterns and manufacturing method thereof and electronic device

ActiveCN105470117AGood craft windowGood workmanshipSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusKey sizeEngineering

The invention relates to a semiconductor device based on double patterns and a manufacturing method thereof and an electronic device. The method comprises the steps that step S1: a semiconductor substrate is provided, and multiple virtual nuclear lamination layers which are arranged in a spacing way are formed on the semiconductor substrate; step S2: square first clearance walls and second clearance walls are formed on the sidewalls of the virtual nuclear lamination layers in turn; step S3: the virtual nuclear lamination layers are removed so that clearance wall arrays formed by the first clearance walls and the second clearance walls are obtained; and step S4: the first clearance walls or the second clearance walls are back etched so that distance between the clearance wall arrays is enabled to be equal. Advantages of the semiconductor device based on the double patterns and the manufacturing method thereof and the electronic device are that (1) the method has better process window and process margin for an SADP technology; (2) homogeneity and consistency of the key size of the patterns can be better controlled; (3) the distance between the clearance wall array patterns is equal; and (4) clearance wall array patterns have great homogeneity and consistency so that final patterns can be greatly controlled, and the final patterns are enabled to have great homogeneity and consistency.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method and apparatus for improved turbine bellyband rotor seal machining, installation and life

ActiveUS9273611B2Uniform sizeUniform shapeTurbinesDrilling/boring measurement devicesMilling cutterEngineering

A method and apparatus for improved turbine bellyband rotor seal machining, installation and life are disclosed. A fixture is provided which can be temporarily attached to the turbine disks in a position straddling the gap between the disks, without destacking the turbine rotor. The fixture accepts power tools including a drill and a mill, and positions the power tools to drill and grind a rectangular slot into the disks, where the slot has the exact size and shape needed to receive an anti-rotation block which is integral to the replacement bellyband. Measuring tools are also provided which enable precise location of each of the four slots which must be machined in the disks. The resulting slots have a uniform size and shape, and are equally spaced around the circumference of the disk, thereby facilitating installation of the service bellyband from four identical segments.

Owner:SIEMENS ENERGY INC

Applying device for applying condenser and production process of built-in condenser

The invention discloses a process for producing a built-in condenser by using an applying device for applying a condenser, which comprises the following steps: A, putting condenser pipes on a side plate; B, clamping the condenser pipes to correct distances between adjacent condenser pipes by using a groove of a pinch roller of the applying device; C, pasting the condenser pipes on the side plate by using a metal adhesive tape roll on the applying device; D, pushing forward the applying device along the longitudinal direction so as to fold the metal adhesive tape roll and meanwhile roll the metal adhesive tape through the roller; and repeating the above steps B-D. According to the process for producing the built-in condenser by using the applying device for applying the condenser applying device disclosed by an embodiment of the invention, equal space among condensation pipes and rapid adhesion of an adhesive tape can be realized; the condensation pipes are tightly adhered on a side plate; and the efficiency can be improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

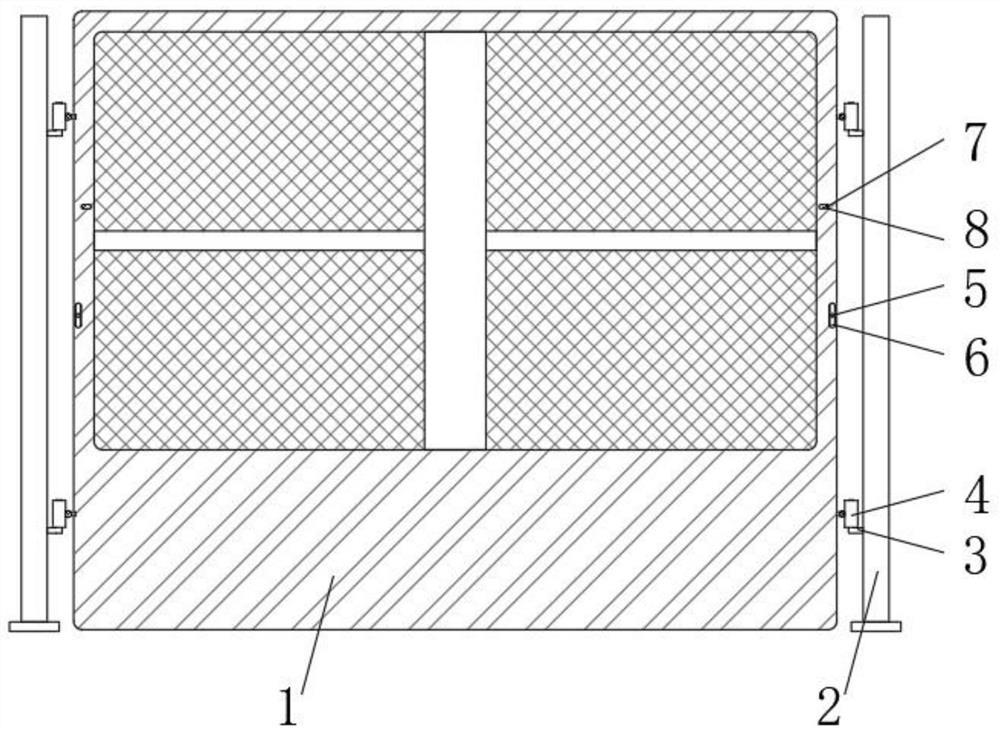

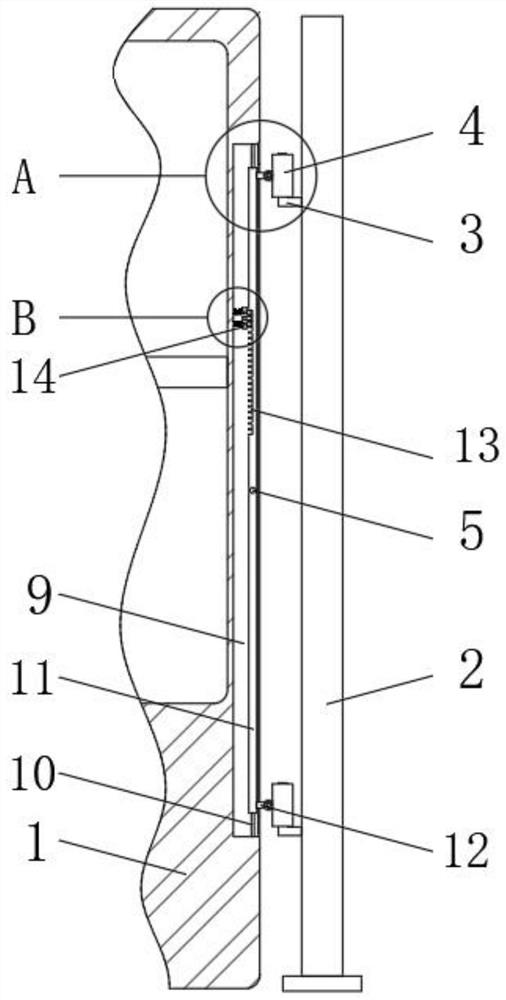

Warning fence for engineering safety near-edge protection

ActiveCN112049521AEqual spacingFencingBuilding material handlingStructural engineeringMechanical engineering

The invention discloses a warning fence for engineering safety near-edge protection. The fence comprises a fence plate and fence columns located at the two sides of the fence plate, vertical cavitiesare formed at the two sides of a frame of the fence plate correspondingly, and guide rods are fixedly connected between the upper inner walls and the lower inner walls of the two vertical cavities correspondingly. The two vertical cavities are each movably sleeved with a vertical plate through two guide rods. By means of the rotatable design of fixing cylinders in the vertical direction, when L-shaped fixing pieces and the fixing cylinders are staggered in the vertical direction and cannot be matched, the L-shaped fixing pieces can be matched by rotating and adjusting the vertical angles of the fixing cylinders; and through the adjustable design of the vertical height of the fixing cylinders, when the vertical heights of the L-shaped fixing pieces and the fixing cylinders are staggered andcannot be matched, the L-shaped fixing pieces can be matched by adjusting the height of the fixing cylinders, the device can adjust the heights of the two fixing cylinders located at the same side atthe same time, and it is guaranteed that the distance between the two fixing cylinders at the same side is always equal to the distance between the two L-shaped fixing pieces at the same side.

Owner:上海三笃工程管理服务有限公司

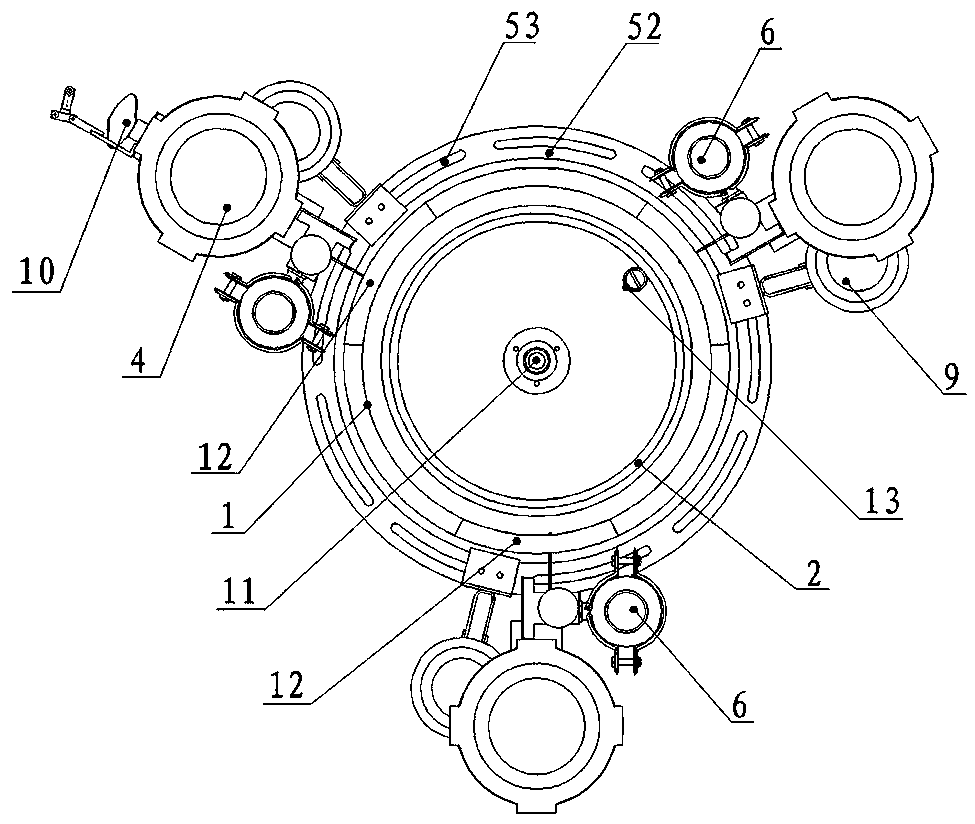

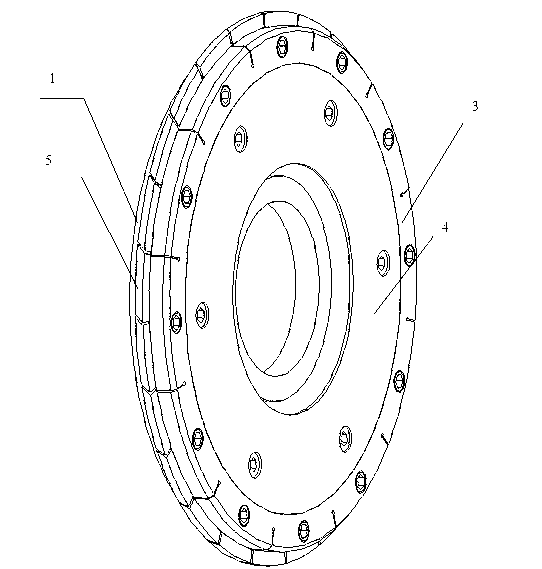

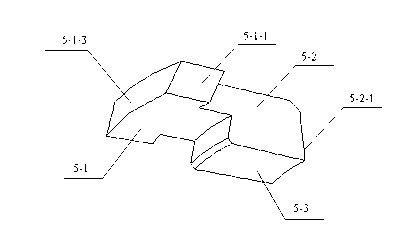

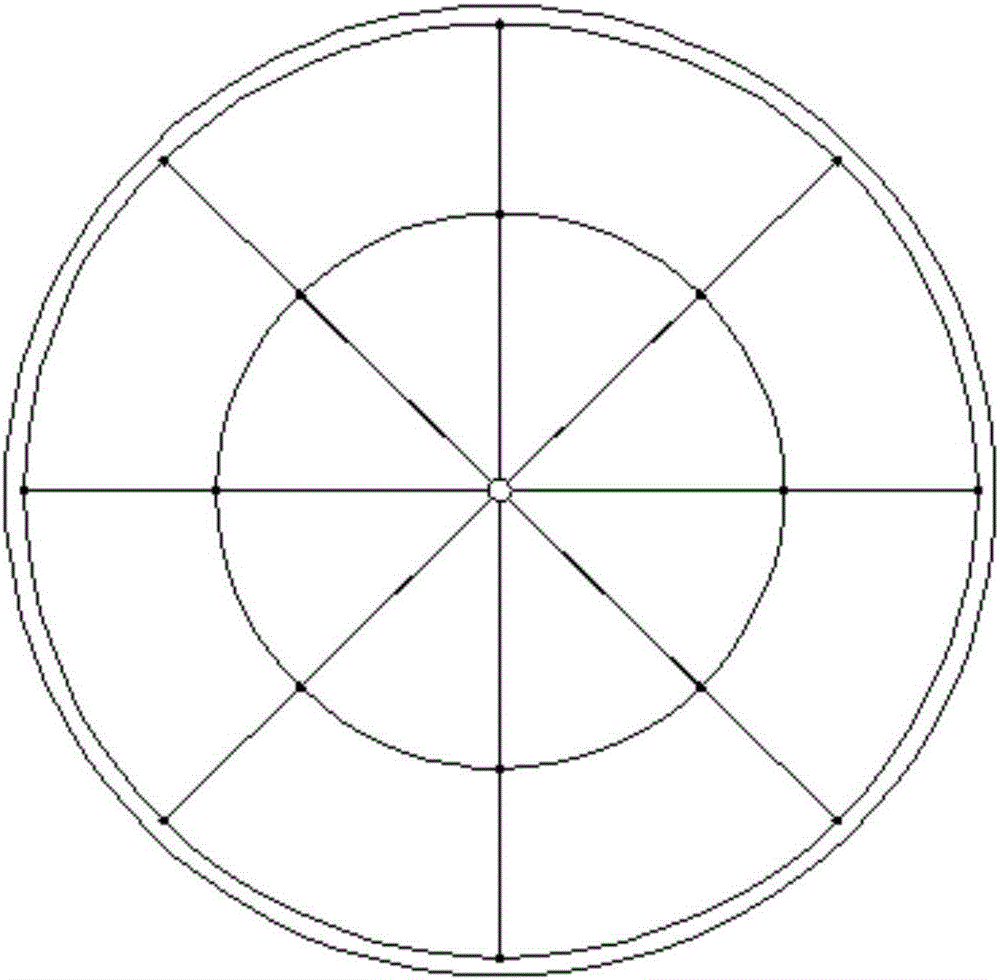

Combined type brazing ultrahard abrasive grinding wheel matrix suitable for ultrahigh-speed grinding

The invention discloses a combined type brazing ultrahard abrasive grinding wheel matrix suitable for ultrahigh-speed grinding. The combined type brazing ultrahard abrasive grinding wheel matrix provided by the invention comprises a bottom plate, a fixing ring, a pressing ring, a cover plate and embedded lumps, wherein the outer side wall of the annular groove is uniformly provided with multiple installation grooves along the circumference of the bottom plate; one embedded lump which is integral in a T shape is arranged in each installation groove; the fixing ring is arranged in the annular ring in a matching mode and mutually connected with the bottom plate, and the fixing ring is used for limiting the multiple embedded lumps; a pushing mechanism for propping the embedded lumps against the outer side wall of the annular groove is connected to the fixing ring corresponding to each embedded lump; the pressing ring is covered above all the embedded lumps and mutually connected with the bottom plate, and the pressing ring is used for pressing the embedded lumps; the cover plate is arranged in the central circular opening of the pressing ring in a matching mode and connected to the bottom plate; and a part of the cover plate is covered on the fixing ring. The combined type brazing ultrahard abrasive grinding wheel matrix provided by the invention has the advantages of less connecting seam width and good integrity of the embedded lumps, reliable working properties, and safe structure suitable for the ultrahigh-speed grinding.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

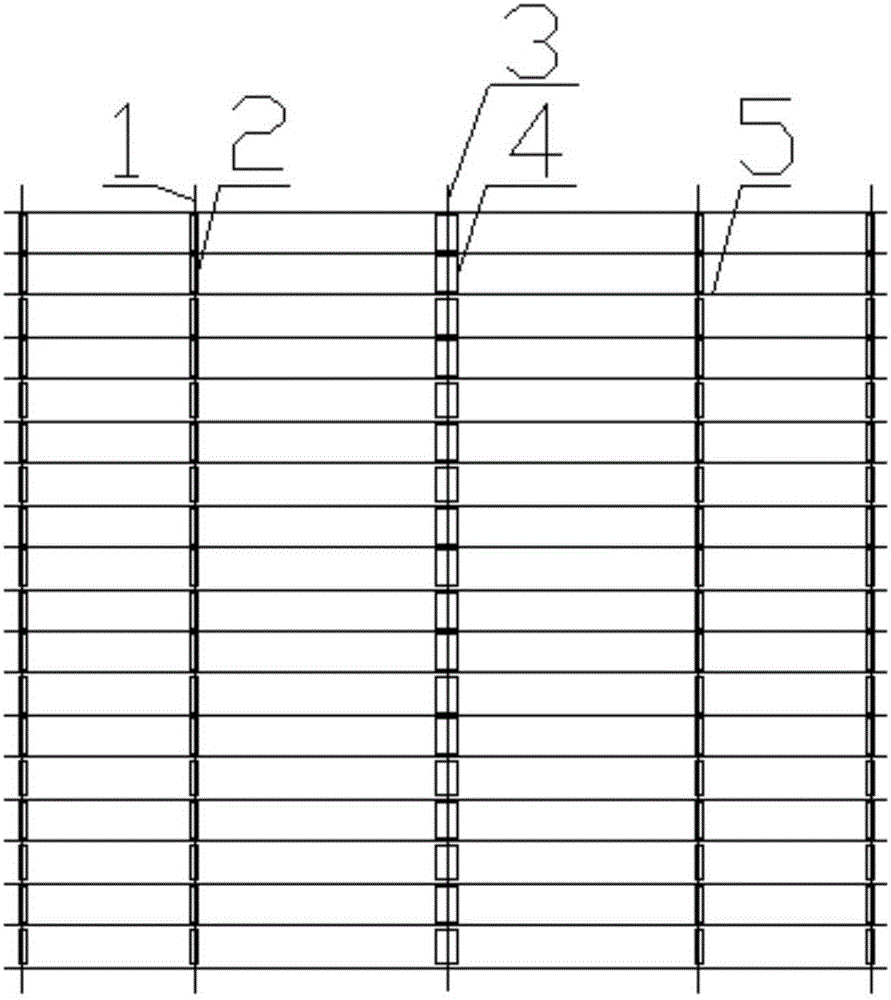

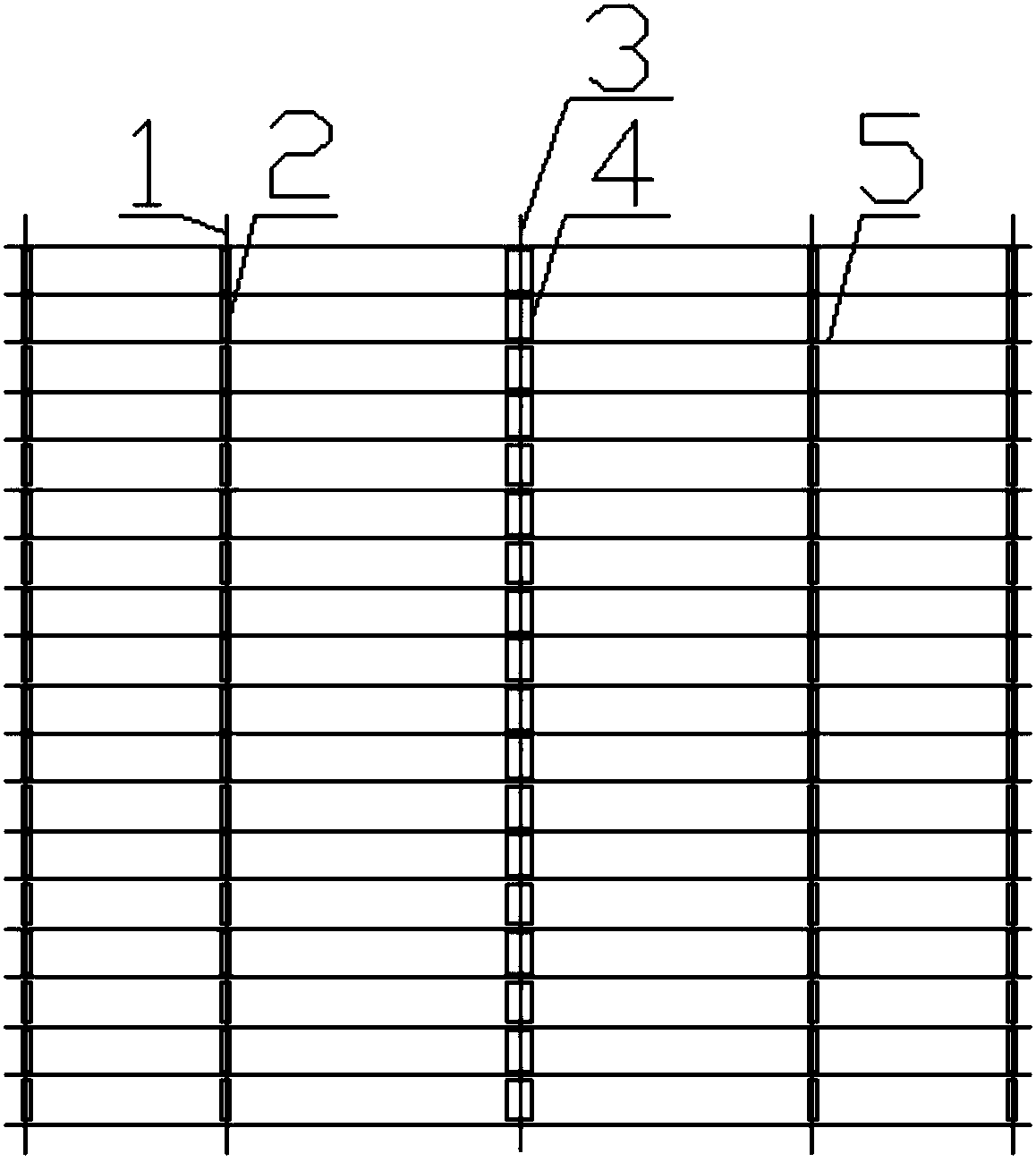

Low-cost and high-quality warp-knitted unidirectional fabric and production process thereof

ActiveCN107099927ACumulative error ensuresCumulative errors ensure that noWarp knittingPulp and paper industryWeft yarn

The invention discloses a low-cost and high-quality warp-knitted unidirectional fabric and a production process thereof. A multiaxial warp knitting machine is adopted. The production process comprises the following steps that 1, weft yarns are laid, wherein the weft yarns are laid in a weft yarn laying zone of the multiaxial warp knitting machine, and it is ensured that the separation distances of the weft yarns are equal; 2, weft insertion and binding are performed, wherein the laid weft yarns are conveyed to a warp knitting machine head of the multiaxial warp knitting machine, are compounded with 0-degree warp yarns and then are bound by binding yarns, it is limited that one weft yarn is inserted every one rotating circle of the machine head and is bound. By adopting the process, the weft yarns equal in separating distance can be produced, the unidirectional fabric with the independently bound weft yarns has a flat cloth cover and is flat and straight, the weft yarns can be rough yarns of 200 tex and 300 tex, the raw materials are relatively lower in price, and the fabric cost is lower. In addition, fabric width adjustment is more convenient, waste is relatively little, the cost can be also controlled through device change, and the process is smooth and stable in operation.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

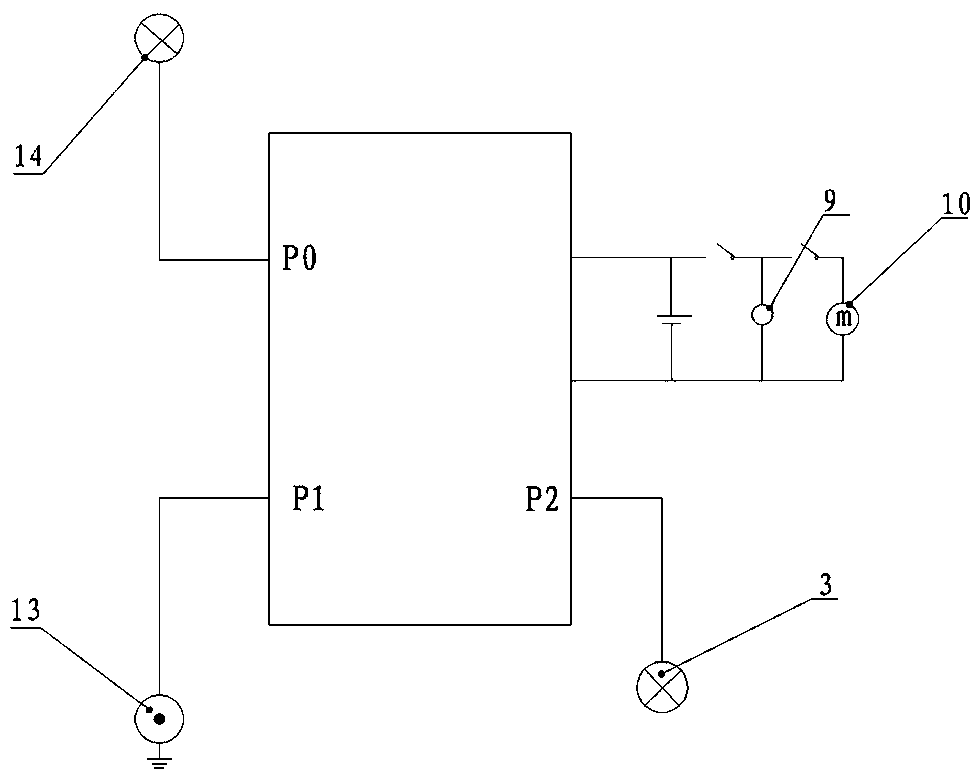

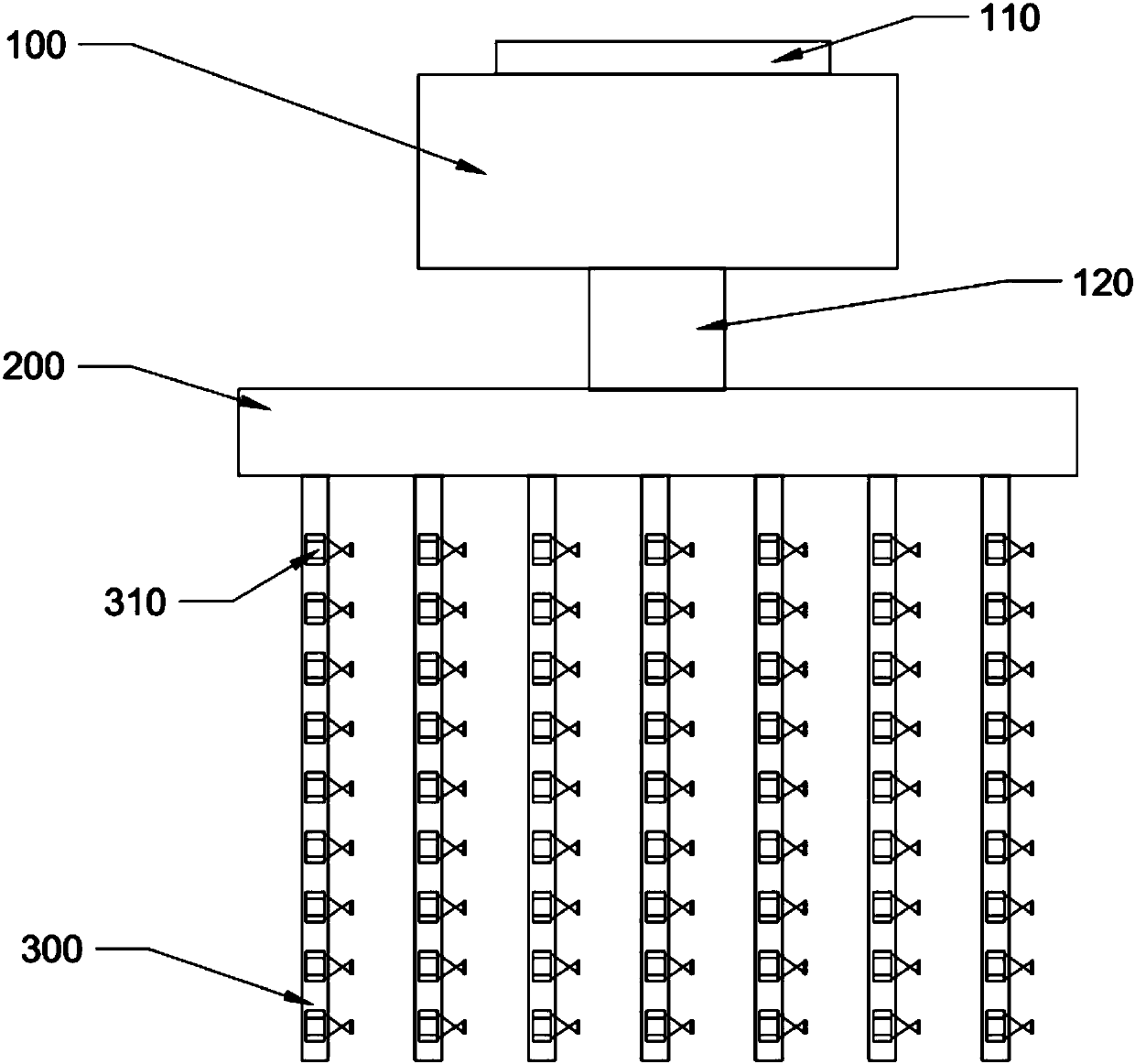

Contact-free elevator key control device

PendingCN112551290AReduce the risk of transmissionSafe spaceLavatory sanitoryElevatorsKey pressingArduino

The invention relates to the technical field of elevator control, in particular to a contact-free elevator key control device. The technical problems that an existing device is complex in operation, inconvenient to adjust and prone to generating germs are solved. In order to solve the technical problems, the contact-free elevator key control device is provided and consists of a main control mechanism, a trigger mechanism and a disinfection mechanism. By arrangement of a Raspberry Pi control module, an Arduino control module, a voice recognition module, an infrared photoelectric sensor, a pickup microphone, an electromagnet and a relay, a user can achieve key pressing without touching an elevator button with the hand during use, and therefore, the possibility of epidemic situation cross infection is avoided, the spreading risk is greatly reduced, and a safer elevator taking space is provided for passengers; and when the user cannot conveniently press the elevator button with the two hands, control over elevator floor keys can be achieved in a voice mode, and convenience and rapidness are greatly improved.

Owner:潘昶安

Air conditioner internal unit capable of achieving temperature self-adjusting

InactiveCN107940562AMaintain a constant temperatureSolve the problem of temperature differenceDucting arrangementsLighting and heating apparatusShunt DeviceEngineering

The invention relates to an air conditioner internal unit capable of achieving temperature self-adjusting. The air conditioner internal unit comprises a unit body and a shunt device, wherein an air inlet and an air outlet are formed in the unit body; and the shunt device communicates with the air outlet. The shunt device communicates with a plurality of air outlet pipelines. Each air outlet pipeline is provided with a plurality of valves which self-adjust the air outlet speed according to the temperature. Each valve comprises a thermosensitive strip block, an amplifying mechanism and a follow-up opening. One end of each amplifying mechanism is connected with the corresponding thermosensitive strip block. The other end of each amplifying mechanism is connected with the corresponding follow-up opening. The air conditioner internal unit capable of achieving temperature self-adjusting can solve the problem of local temperature difference in an air conditioner room.

Owner:SUZHOU QINGRUI AIR SYST

Tunnel arch foot connecting plate positioning tool and steel arch construction method

PendingCN113605939AEqual spacingPrecise positioningUnderground chambersTunnel liningShotcreteEngineering

Owner:NO 5 ENG OF CHINA RAILWAY 19 BUREAU GRP +1

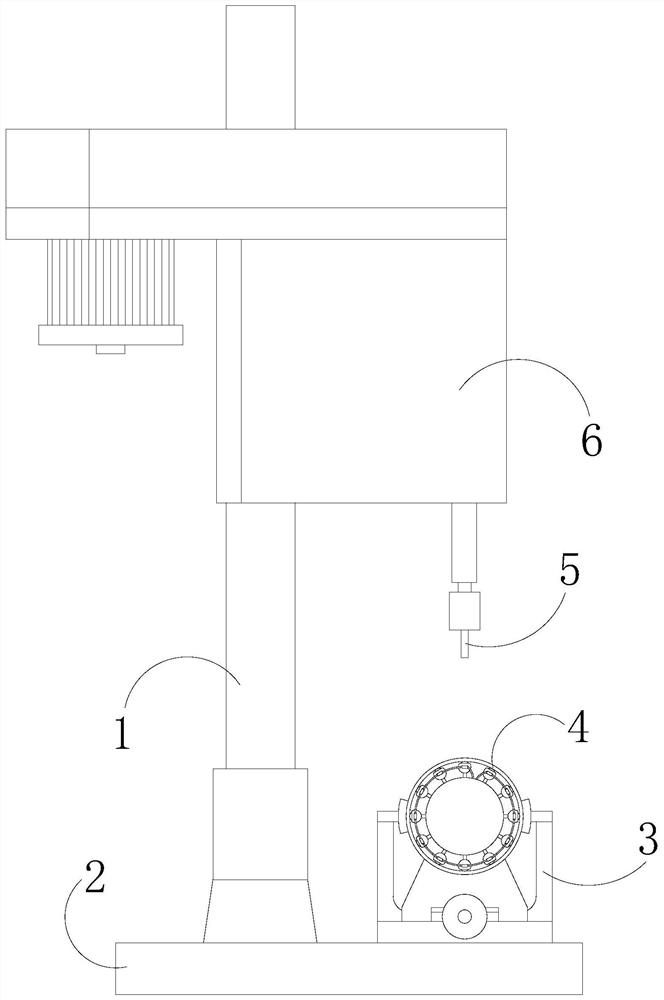

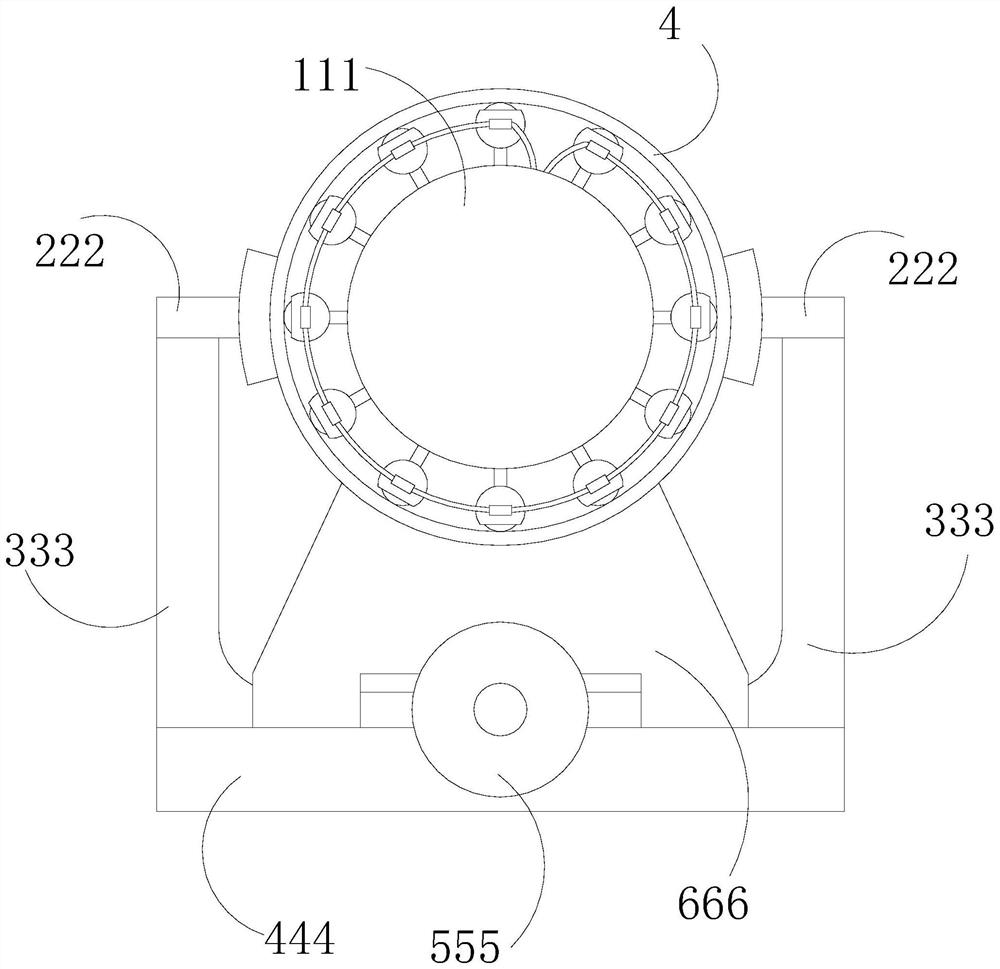

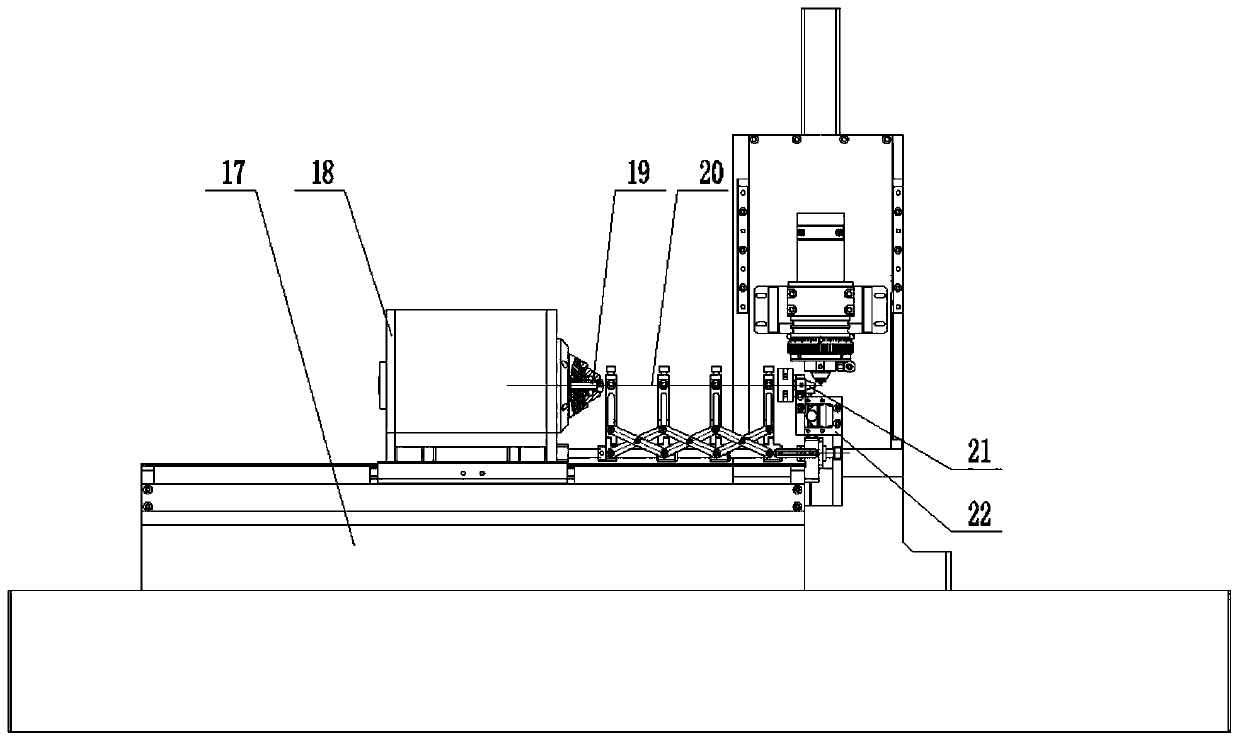

Anti-deformation metal pipe drilling machine

ActiveCN111993132AAccurate displacementEqual spacingFeeding apparatusPositioning apparatusThermodynamicsMachine

The invention discloses an anti-deformation metal pipe drilling machine. The anti-deformation metal pipe drilling machine structurally comprises a stand column, a base, a workbench, a metal pipe, a drill bit and a machine body, wherein the stand column is vertically connected with the base, the machine body is fixed to the stand column, the drill bit is installed on the machine body, the workbenchis arranged below the drill bit, the workbench is fixed to the base, and the metal pipe is placed on the workbench. Compared with the prior art, the anti-deformation metal pipe drilling machine has the beneficial effects that through combined arrangement of a supporting device, a clamp, an L-shaped connecting frame, a foundation seat, a sliding rail assembly and a supporting table, the to-be-drilled part can be internally supported, the supporting stability can be greatly improved through the characteristics and hydraulic pressure of a clockwork spring, a metal pipe is effectively prevented from deforming in the drilling process, meanwhile, the device can adapt to supporting of metal pipes with different calibers, and the application range is wide.

Owner:上海世柯仓储设备工程有限公司

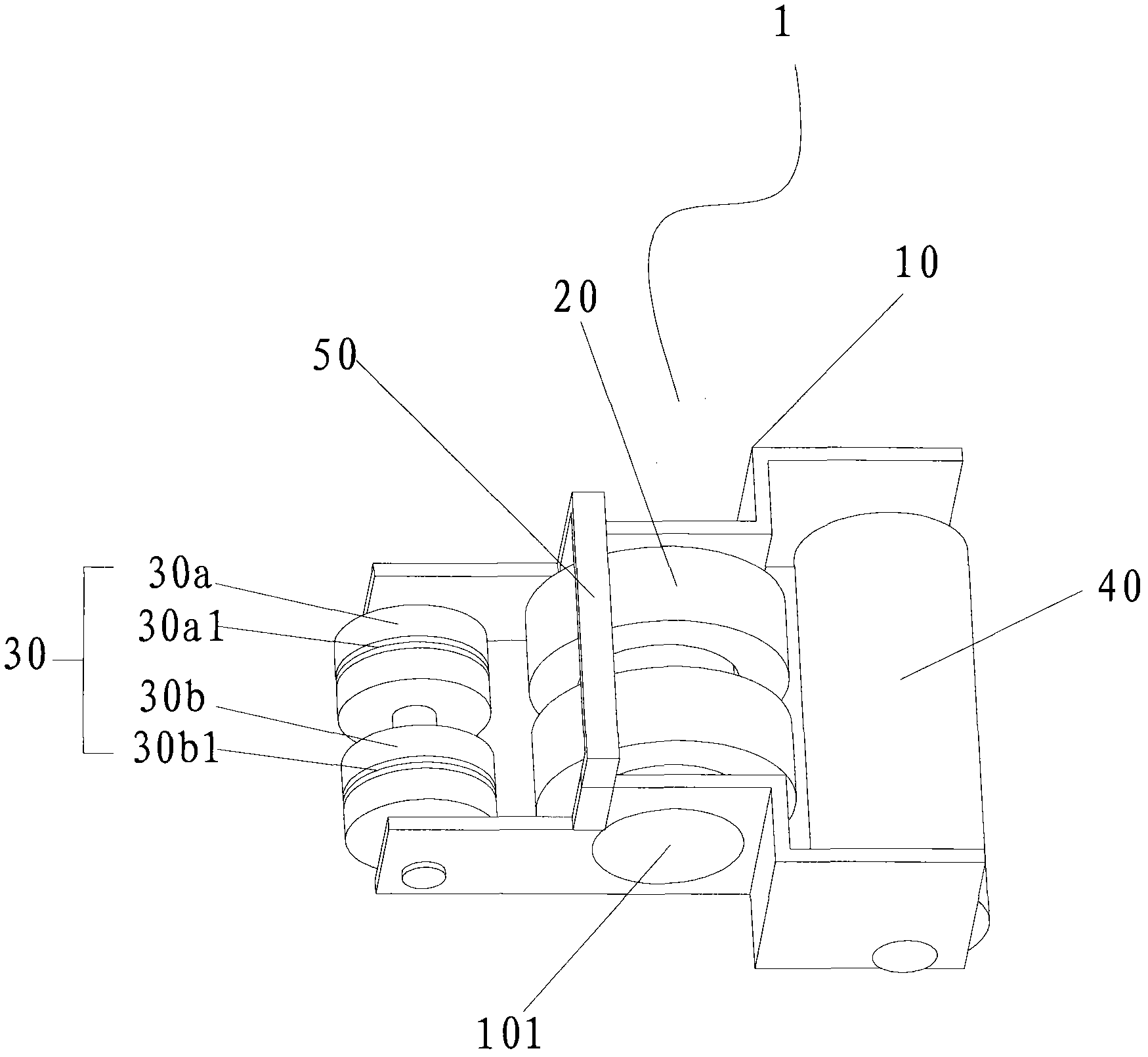

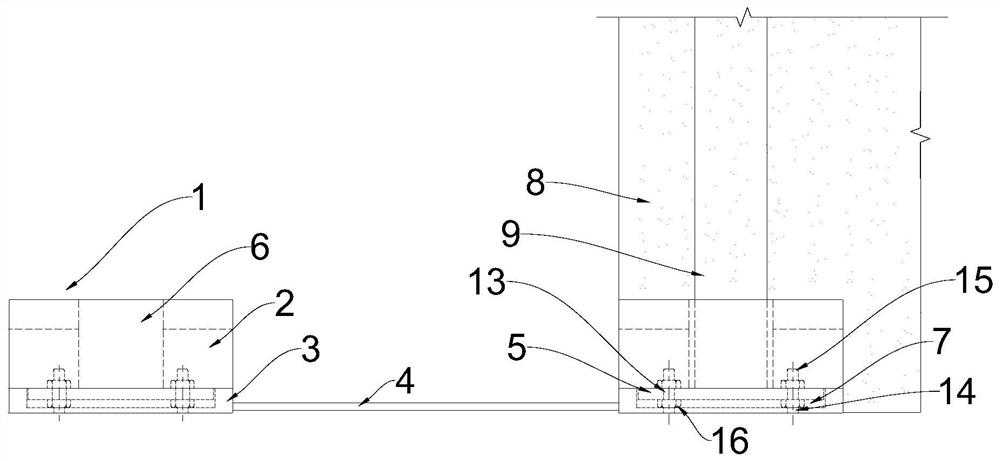

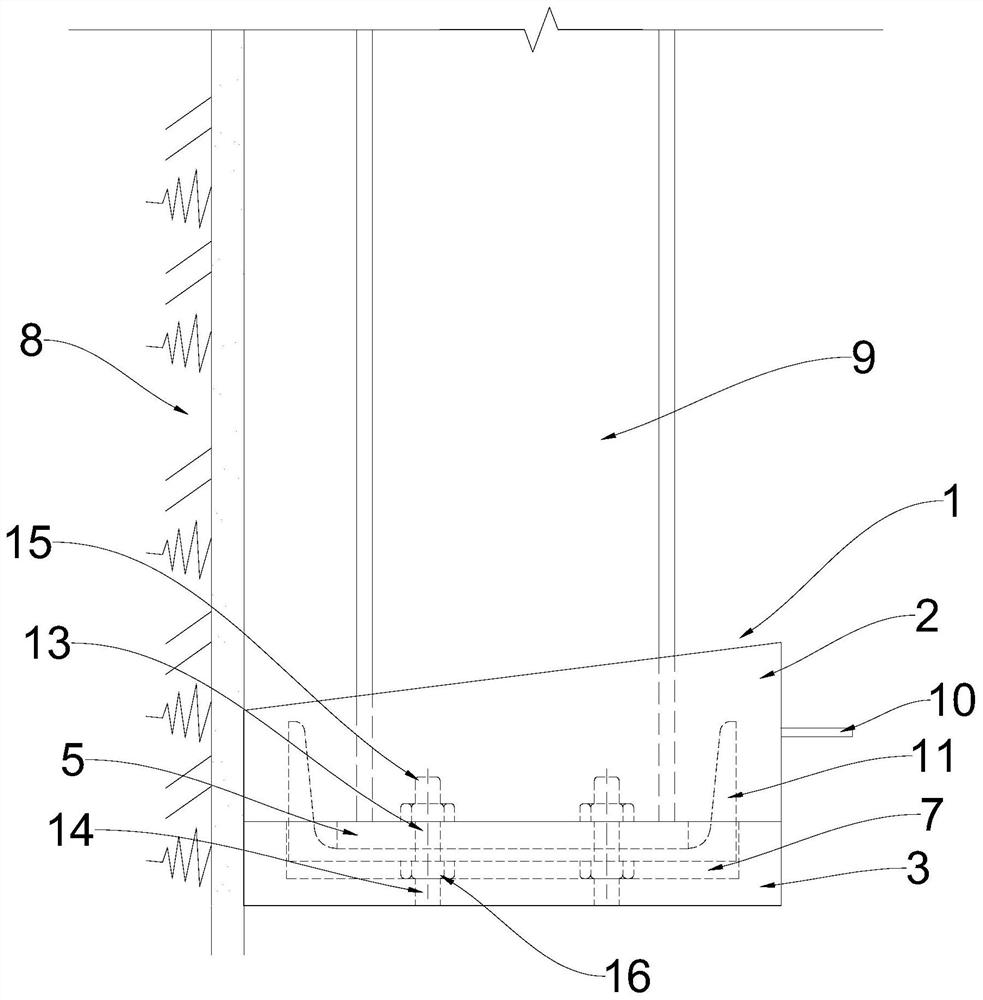

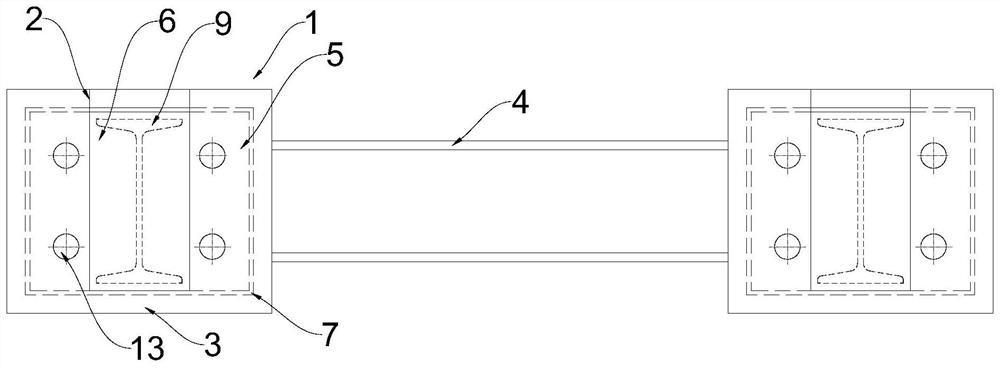

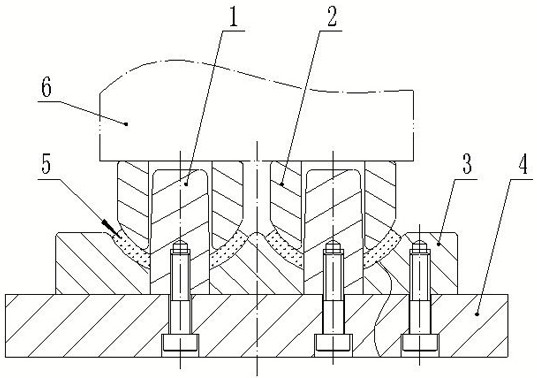

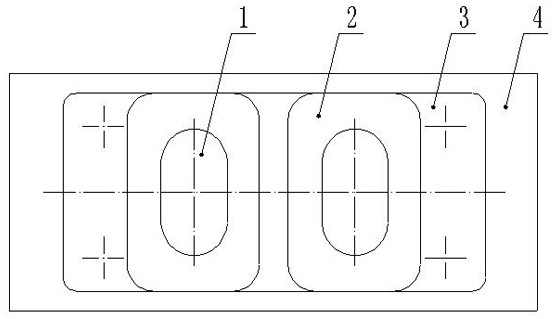

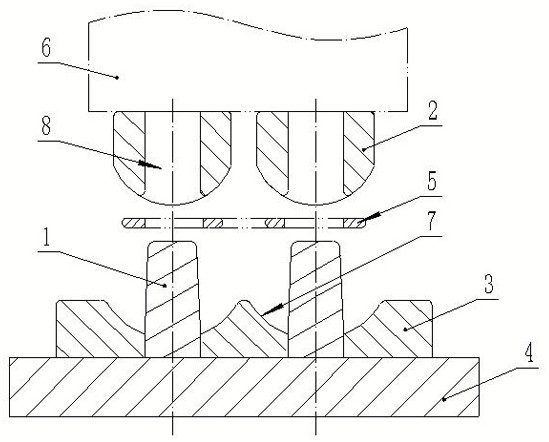

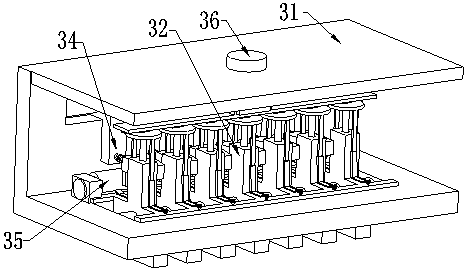

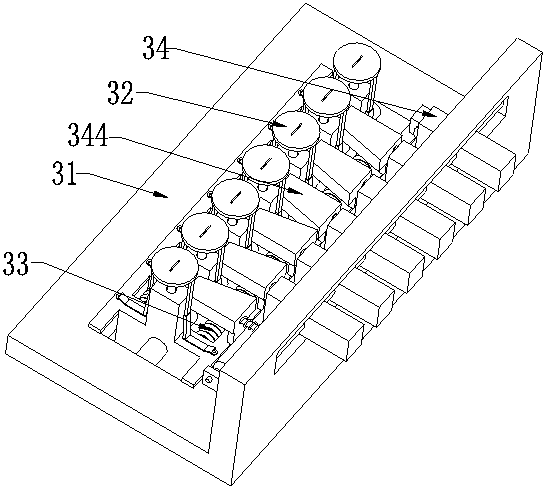

Motor coil winding bending device

PendingCN112510938APrecise positioningEqual spacingManufacturing dynamo-electric machinesElectric machineryMachine

The invention discloses a bending device, and belongs to tools. The objective of the invention is to disclose a motor coil winding bending device which is high in bending efficiency and good in bending forming precision. The device comprises an upper die and a lower die, the upper die is composed of two pressing heads (2) fixedly arranged on a hydraulic machine, the bottom face of each pressing head (2) is of a semi-cylindrical structure, and a kidney-shaped guide hole (8) is formed in the center of each pressing head (2); the lower die (3) is fixed on the base (4), and two arc-shaped grooves(7) which are of semi-cylindrical structures and are matched with the bottom surfaces of the corresponding pressing heads (2) in shape are formed in the surface of the lower die (3); a kidney-shaped positioning hole is formed in the center of each arc-shaped groove (7), and two guide columns (1) fixed to the base (4) penetrate through the corresponding positioning holes and are matched with the corresponding guide holes (8). The device is simple in structure and convenient to use.

Owner:GUIYANG AVIATION MOTOR

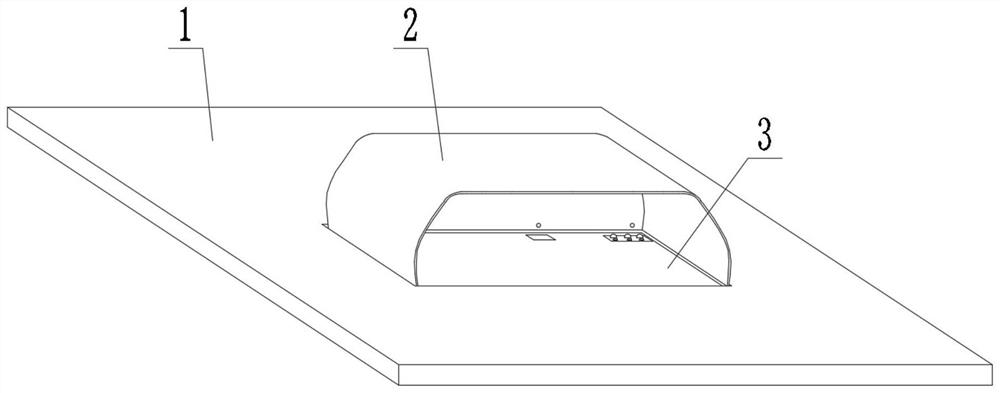

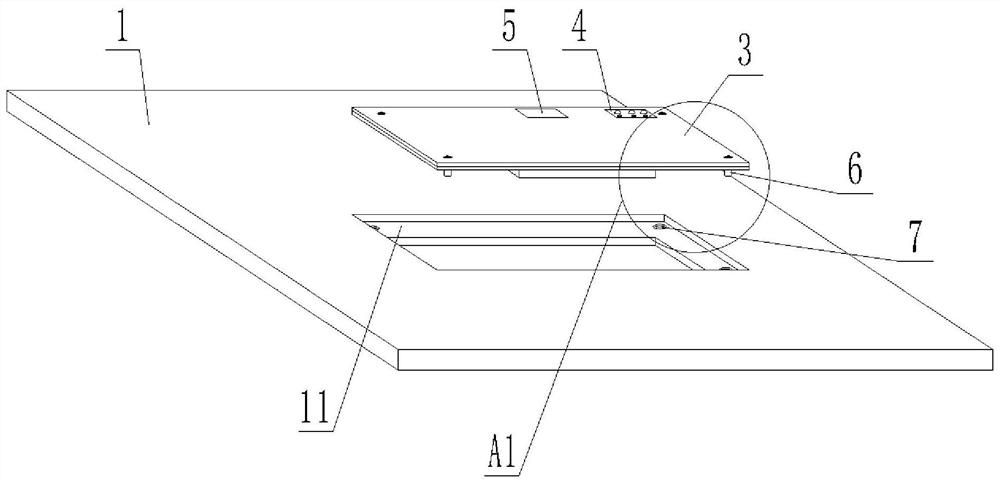

Office table mat with heating function and heating method

InactiveCN114081268AReduce churnReduce convectionOhmic-resistance heating detailsTablesTemperature controlDisplay device

The invention discloses an office table mat with a heating function and a heating method, relates to the technical field of heat preservation office table mattresses, and solves the technical problem on how to prevent hands from being frozen in the existing office process. A groove body is formed in a table top of an office table; an isolation hood is arranged in the groove body; a heating mat is arranged below the isolation hood; the heating pad is connected to the groove bottom of the groove body; the isolation hood is located between the heating pad and the groove body and connected to the side wall of the groove body; a heating plate is installed in the heating pad; and a temperature control switch and a display are installed on the heating pad. The heating pad is installed on the office table, the groove body is formed in the office table and used for containing the isolation hood, a keyboard or a mouse is manually placed on the heating pad, so that a hand warming function can be achieved during working, and hand warming and working do not affect each other. As the isolation hood is installed on the office table and plays an isolation role, temperature loss is relieved, cold and hot air convection is reduced, and noise transmission generated by knocking the keyboard is reduced.

Owner:SICHUAN TECH & BUSINESS UNIV

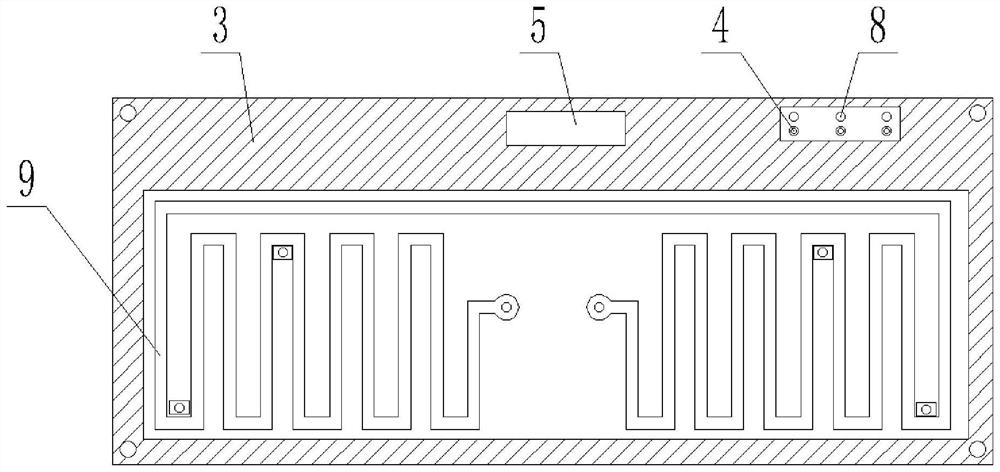

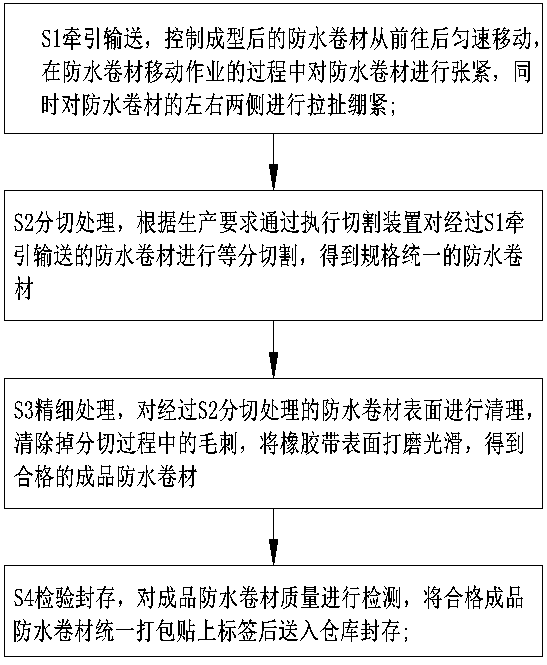

Production process for polyethylene and rubber blended waterproof coiled material

ActiveCN111531600AIncrease production costEqual spacingMetal working apparatusMachiningIndustrial engineering

The invention relates to a production process for a polyethylene and rubber blended waterproof coiled material. In the production process, cutting equipment is adopted. The cutting equipment mainly involves the procedures of traction conveying, cutting treatment, fine treatment, inspection, sealed storage and the like. The production process can solve the following problems in an existing formingand processing process of the polyethylene and rubber blended waterproof coiled material that the efficiency of manually cutting the formed waterproof coiled material according to specified regulations is low, the waterproof coiled material cannot be equally divided according to specified requirements, traditional machining equipment cannot simultaneously control a plurality of cutters to cut thewaterproof coiled material at equal intervals, workers need to adjust the distance between the cutters, adjustment errors exist, and the quality of the processed and formed waterproof coiled materialis affected.

Owner:深圳市松立建设集团有限公司

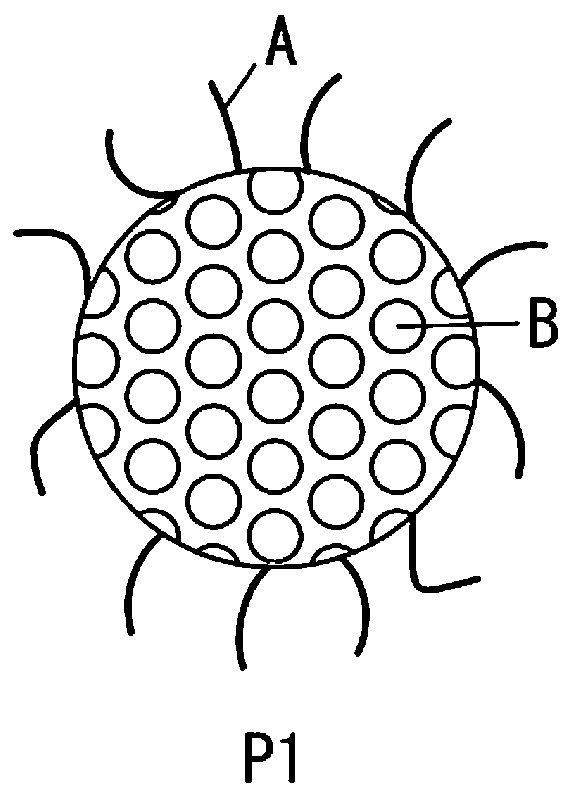

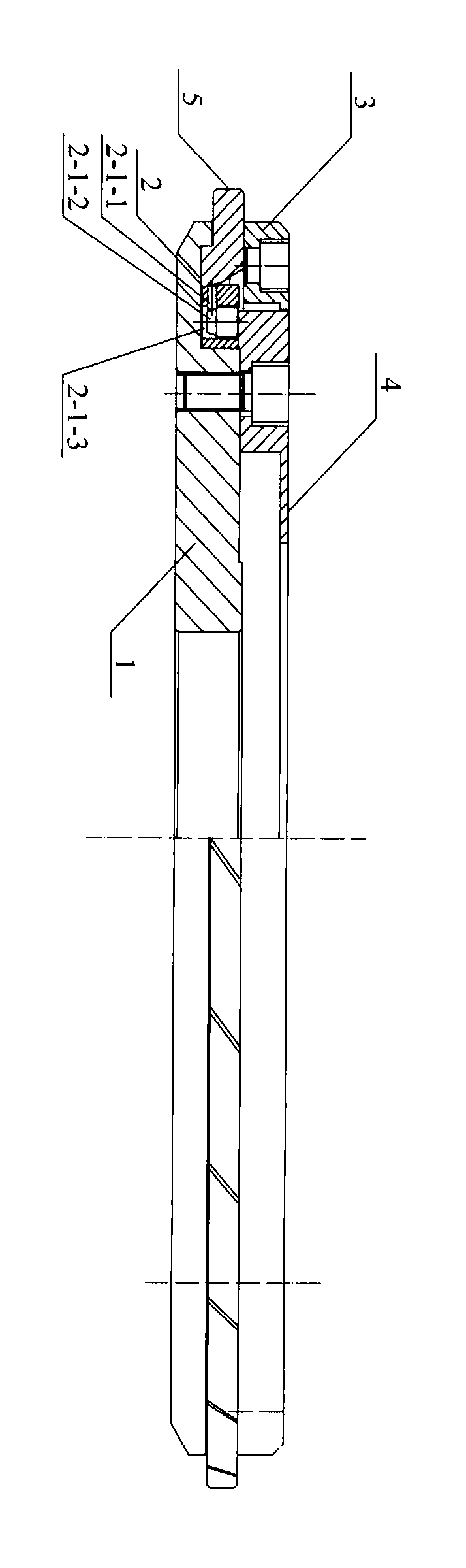

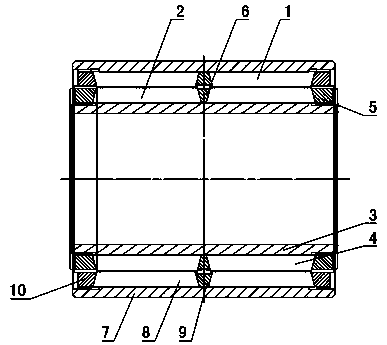

Method for fixing sieve plates of pulse sieve plate column

The invention belongs to the technical field of extraction and purification processing equipment in the field of uranium purification and production, and particularly relates to a method for fixing sieve plates of a pulse sieve plate column. According to the method for fixing the sieve plates of the pulse sieve plate columns, transverse fixing of the sieve plates is achieved through a central rod, pull rods and the like so that a gap between a column body and a plate string can be reduced, and mass transfer is sufficiently achieved. Radial fixing of the sieve plates is achieved through the pull rods and pull rod pipe spacers so that it can be guaranteed that the sieve plates are not prone to deformation, and mixed mass transfer is stable. Longitudinal fixing of the sieve plates is achieved through central pipe spacers, so that it is guaranteed that the distances between the sieve plates are equal, and mixed mass transfer is stable.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

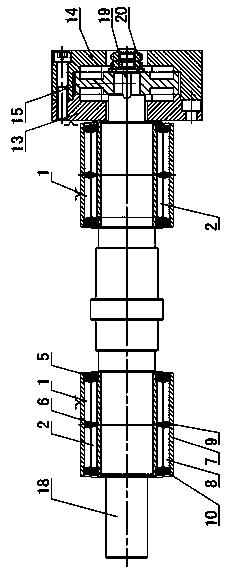

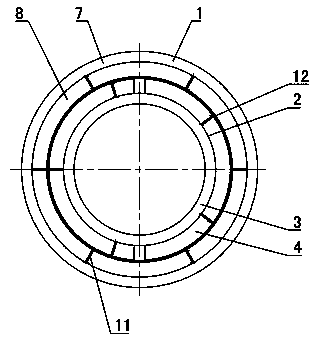

Permanent magnet type magnetic bearing pair

The invention belongs to the technical field of bearings and discloses a permanent magnet type magnetic bearing pair. The permanent magnet type magnetic bearing pair is characterized in that an innerring (3) of a radial bearing sleeves a shaft (18), outer ring magnetic steel (8) is coaxially mounted on the inner wall of an outer ring (7), inner ring magnetic steel (4) is coaxially mounted on theouter wall of the inner ring (3), and the outer wall of the inner ring magnetic steel (4) and the inner wall of the outer ring magnetic steel (8) are identical in magnetic polarity. One side, close toa thrust collar (22) of a thrust disc (15) of an axial bearing is provided with annular rotating magnetic steel (17). One side, close to the thrust disc (15), of the thrust collar (22) is provided with annular fixed magnetic steel (16). Adjacent sides of the rotating magnetic steel (17) and the fixed magnetic steel (16) are identical in magnetic polarity. The permanent magnet type magnetic bearing pair is free of noise and heat generation, lubrication in a utilization process is avoided, long service life is realized, and bearing of both radial force generated by a radial load and axial forcegenerated by an axial load can be realized.

Owner:SHANDONG FENGGANG MACHINERY EQUIP

Pipe auxiliary supporting jig for machine tool and machine tool

PendingCN111331397AReliable processingReliable clampingMetal working apparatusPositioning apparatusRotational axisButt joint

The invention discloses a pipe auxiliary supporting jig for a machine tool and the machine tool. Various sliding blocks are fixed through cooperation of a rotating shaft end fixed plate, a limit stop,guide shafts, linear bearings, an X-axis end fixed plate and a sliding block fixing seat, the sliding blocks can be arranged between a collet chuck and a bush of the machine tool along the guide shafts, so that lifting and supporting are provided for the middle of a workpiece through supporting shaft sleeves at the tops of the sliding blocks. By means of the pipe auxiliary supporting jig for themachine tool and the machine tool, it can be ensured that the workpiece can be firmly clamped in the process that the machine tool machines precise thin-walled pipes with the outer diameter being 1 mmor below, the workpiece is precisely located, and machining to the workpiece is more stable and reliable. Through lifting to the supporting shaft sleeves and the sliding blocks, the conventional problems of pipe concaving and butt joint dislocation happening during locating and clamping and continuous machining to the workpiece can be avoided. Machining of precise thin-walled pipes with the outerdiameter being 1 mm or below can be achieved, and certain reference is provided for machining of other similar fine rotary parts.

Owner:KUNSHAN YUNCO PRECISION IND TECH

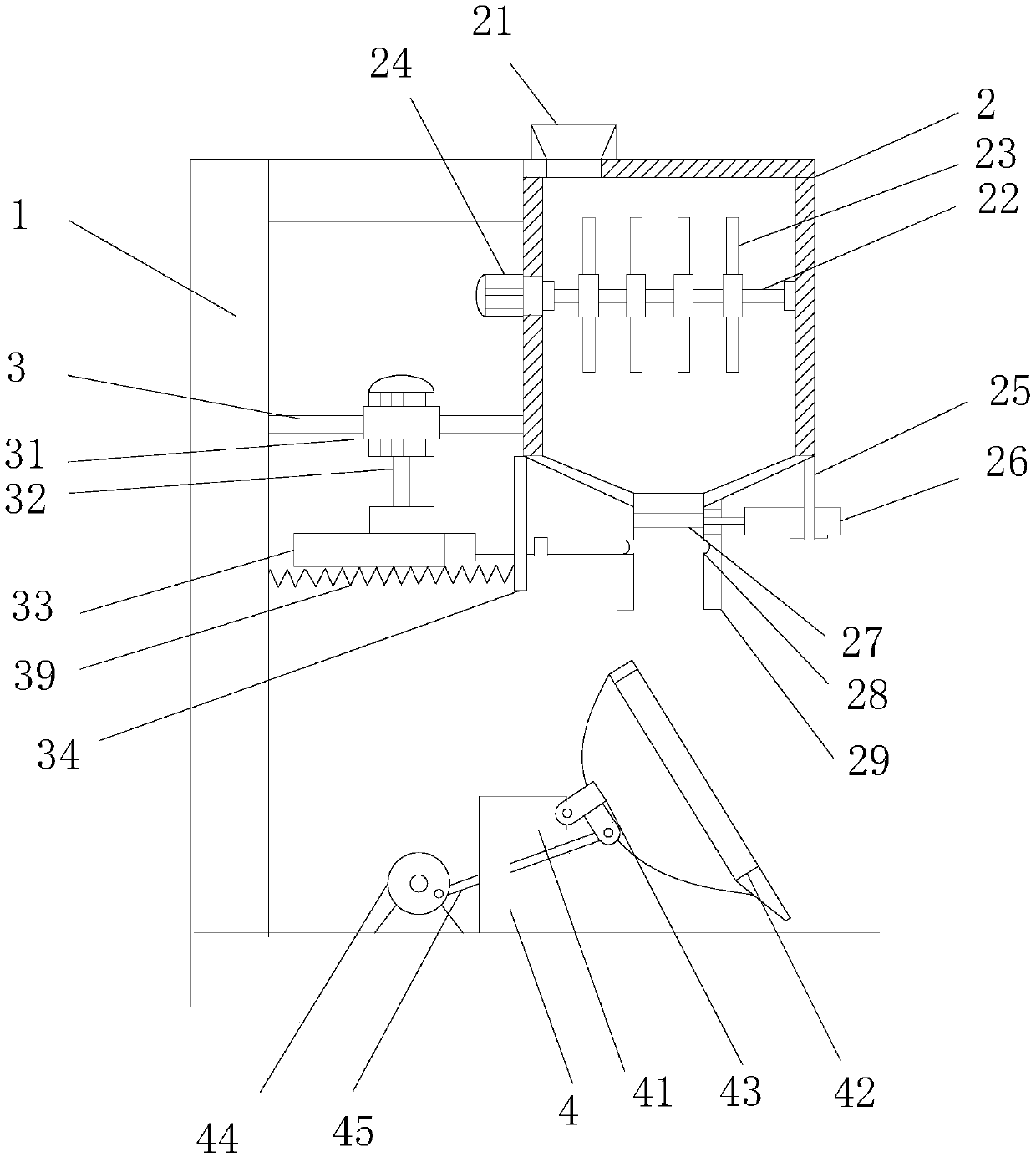

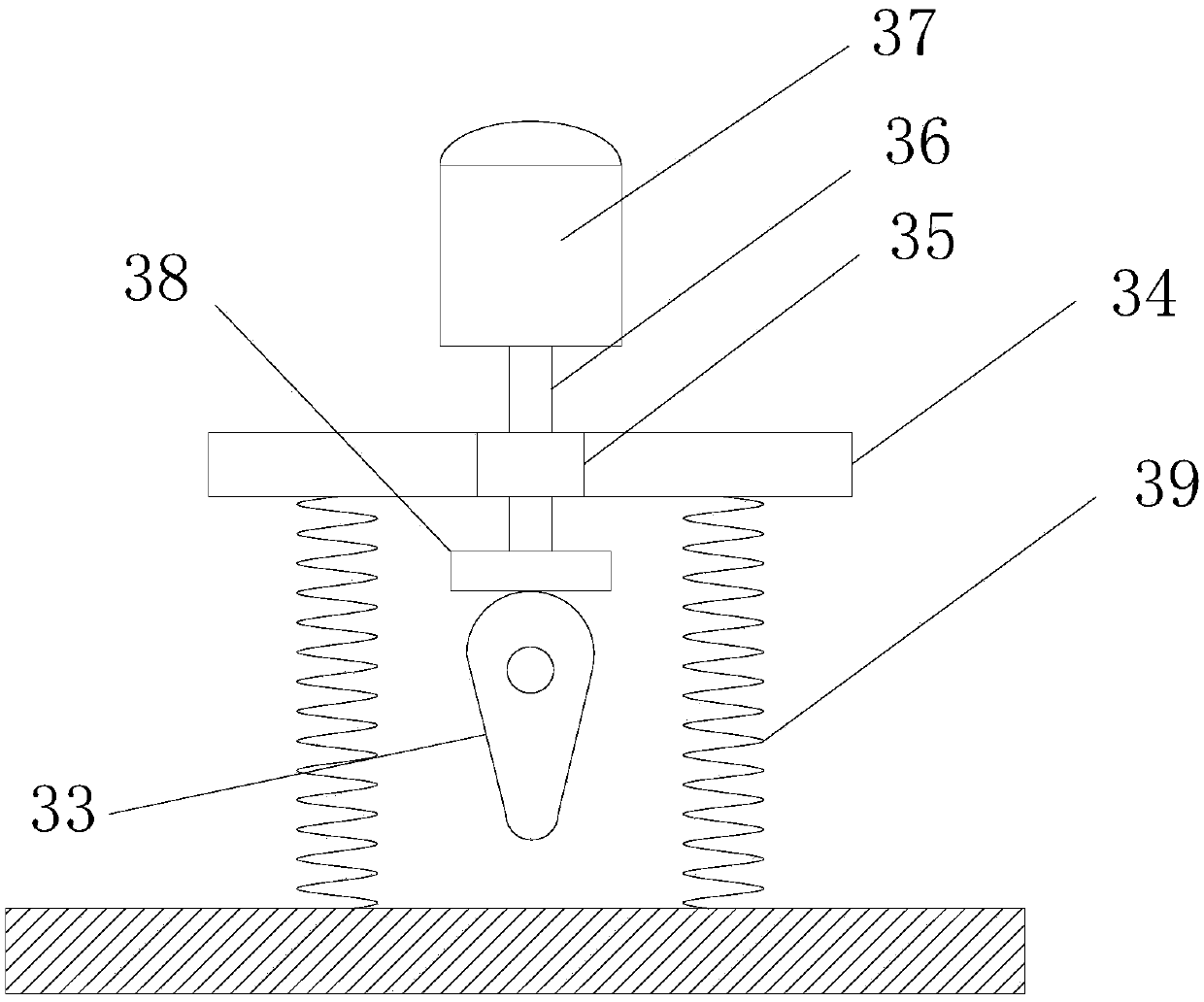

Forage laying and airing device for animal husbandry

The invention relates to the field of the animal husbandry, in particular to a forage laying and airing device for the animal husbandry. The forage laying and airing device for the animal husbandry comprises a rack, wherein a material barrel is mounted on the top of the rack; a discharging opening is formed in the bottom end of the material barrel; a driving rack is mounted between the rack and the material rack; a driving motor is mounted on the driving rack; a transmission cam is mounted at the driving end of the driving motor through a driving shaft; the driving rack is synchronously provided with a limiting plate; a locking sleeve is mounted in the middle of the limiting plate; a push rod is mounted in the locking sleeve; an extrusion plate is mounted at the rear end of the push rod; astopping plate is mounted at the front end of the push rod; the transmission cam is attached to the extrusion plate; and a clamping groove is formed in the lower end of the discharging opening. By cooperation of cam transmission and an elastic resetting mechanism, gap type discharging is implemented, materials are laid and scattered on a foundation in small piles, it ensures that the distances among the different piles of materials are equal, and the laying and airing effect is improved.

Owner:钱巍

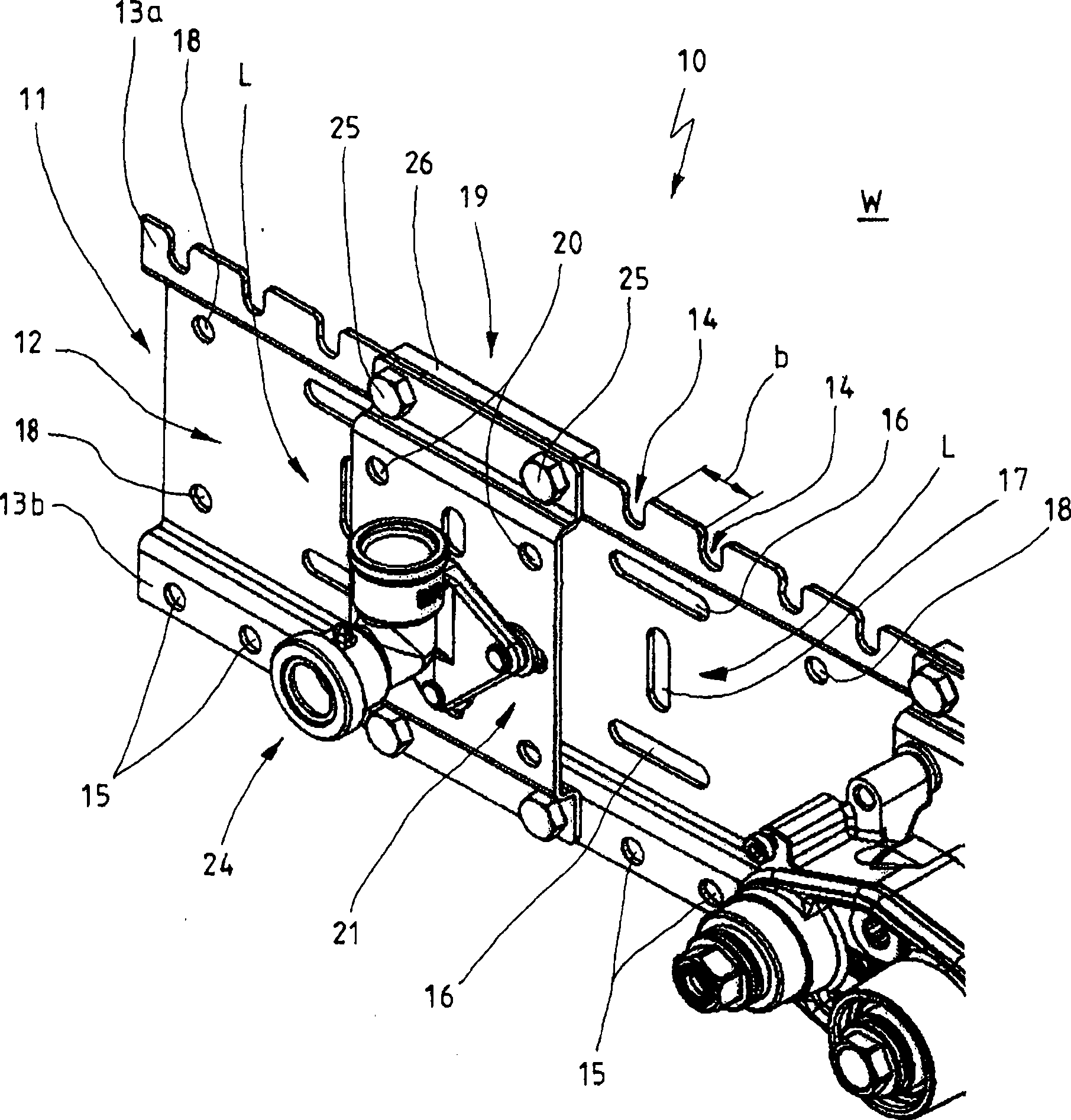

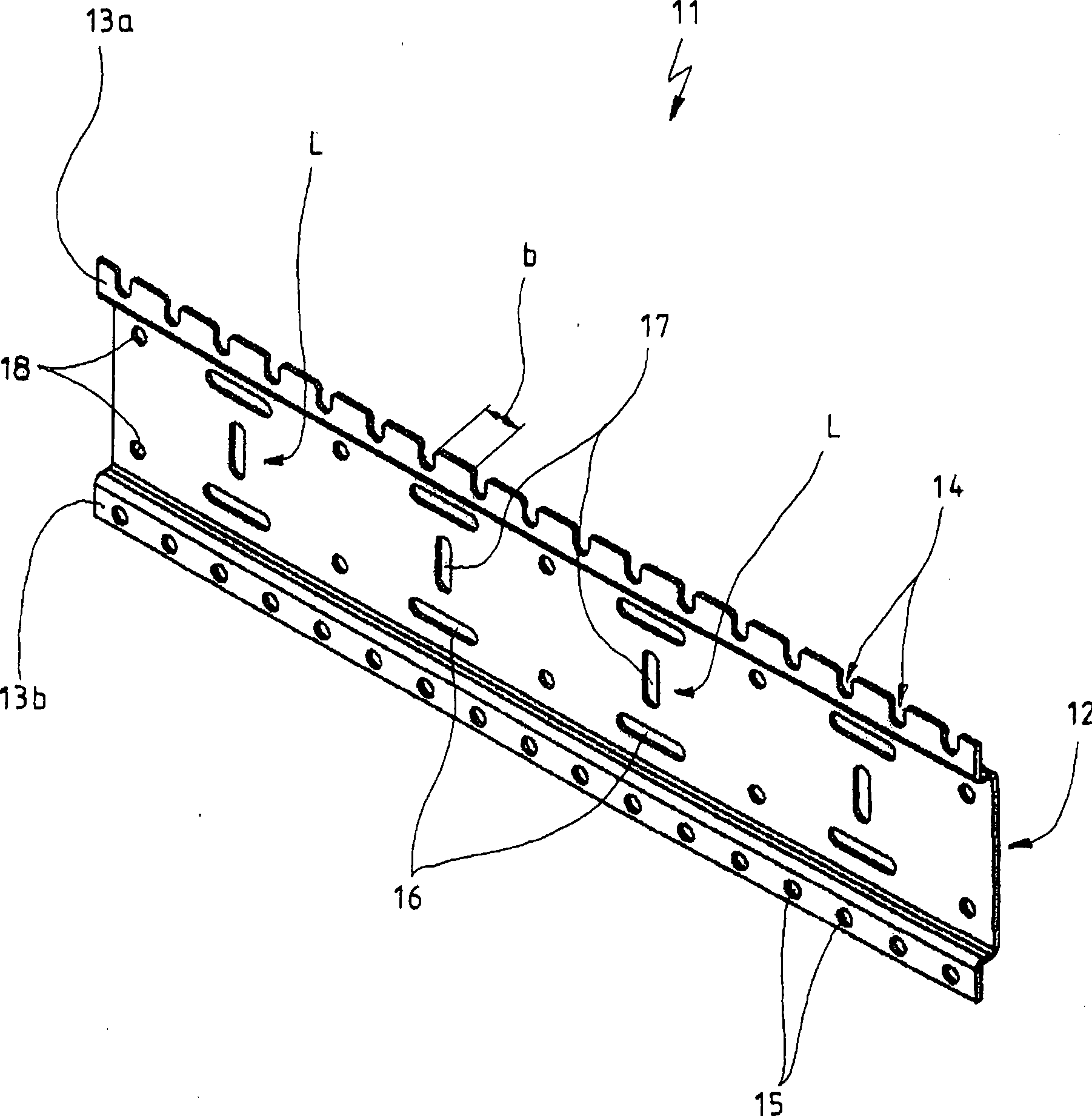

Device for fixing built-in sanitary elements

InactiveCN101440627AAccurate spacingEqual spacingDomestic plumbingFlexible pipesEngineeringNew device

Shown and described is a device for back a plumbing fixture, in particular to a wall, essentially comprising a mounting rail preferably made of metal, which contains a large number of holes, slots or the like provided for the wall mounting and to the mounting of mounting plates for a plumbing fixture, the two rail longitudinal edges being designed as attachment zones offset from the mounting level. The object of the invention is to create a new device for back mounting a plumbing fixture with which in a simple fashion a number of a plumbing fixture can be mounted to a wall with precisely the same spacing from each other and in a precise arrangement to each other. The solution of the object is the result of at least one rail longitudinal edge having a plurality of notches, slots, slits or the like, and that the mounting plates are provided with holes corresponding to the notches, slots, slits or the like, in which the screws are mounted which are fixed by anchor blocks, whereby the mounting plates are brought into a defined premounting position by the hanging of the windings of the screws in the notches of the mounting rails.

Owner:ALOYS F DORNBRACHT

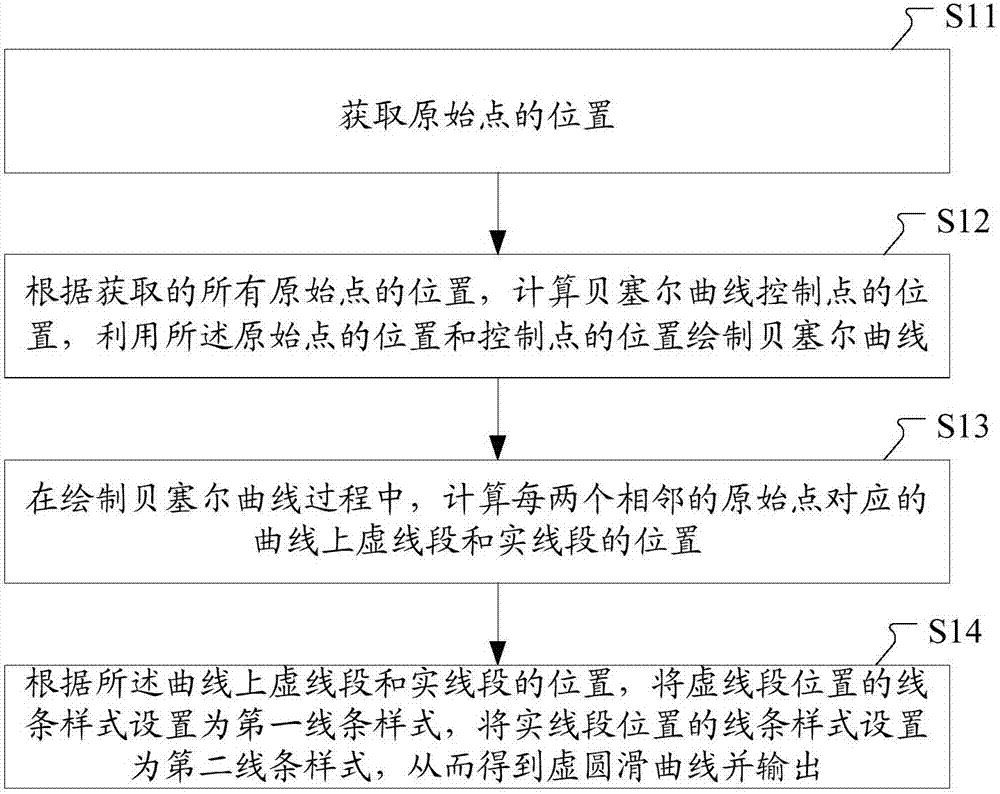

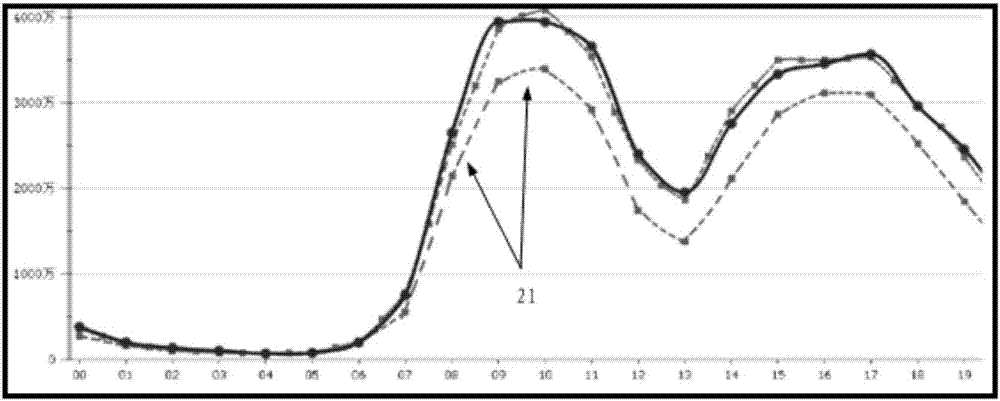

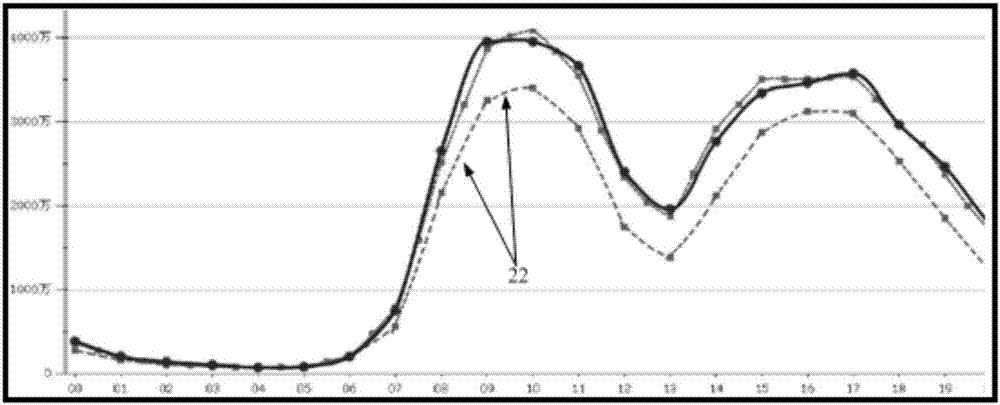

Method and device for generating virtual smooth curve

The invention discloses a method and a device for generating a virtual smooth curve. The method includes the following steps: acquiring the positions of original points; calculating the positions of Bessel curve control points according to the acquired positions of all the original points; drawing a Bessel curve based on the positions of the original points and the positions of the control points; in the drawing process of the Bessel curve, calculating the positions of virtual line segments and solid line segments on the curve corresponding to every two adjunct original points; and setting the line style at the positions of the virtual line segments as a first line style and the line style at the positions of the solid line segments as a second line style according to the positions of the virtual line segments and the solid line segments on the curve to get a virtual smooth curve, and outputting the virtual smooth curve. The method is implemented based on the Bessel curve. Because the Bessel curve is smooth, the original points are connected using a smooth curve. A virtual line style is set at the positions of the virtual line segments on the curve. Therefore, a virtual smooth curve is drawn.

Owner:ULTRAPOWER SOFTWARE

Thick film chip winding and planar chip

InactiveCN113707427AEqual spacingControl clearanceTransformers/inductances coils/windings/connectionsElectrical and Electronics engineeringMechanical engineering

The invention discloses a thick film chip winding and a planar chip. The thick film chip winding comprises more than two single-piece winding units and a plurality of pin headers; each single-piece winding unit comprises an insulating base material and a winding layer, wherein the winding layer is connected to the surface of the insulating base material, and the winding layer comprises at least one winding coil segment; the winding coil segments of more than two single-piece winding units are connected to form at least one winding coil; the side edges of the insulating base materials are fixed by the pin headers, the pin headers connect the more than two single-piece winding units in a series connection mode, a space is reserved between every two adjacent insulating base materials, and the space is determined by the pin headers; and the pin headers are mutually insulated or are conducted through at least one winding coil segment. According to the thick film chip winding provided by the invention, the distance between the two insulating base materials is determined by customizing the pin headers, so that it can be ensured that the distance between the two insulating base materials is equal.

Owner:无锡燊旺和电子科技有限公司

A method for fixing pulse sieve plate column sieve plate

ActiveCN106702183BExtended service lifeExtend continuous stable operation timeProcess equipmentPlate column

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com