Combined type brazing ultrahard abrasive grinding wheel matrix suitable for ultrahigh-speed grinding

A technology of ultra-high-speed grinding and super-hard abrasives, which is applied in the direction of abrasives, bonded grinding wheels, and metal processing equipment. The ability to resist centrifugal force deformation, the stability of the grinding process, and the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

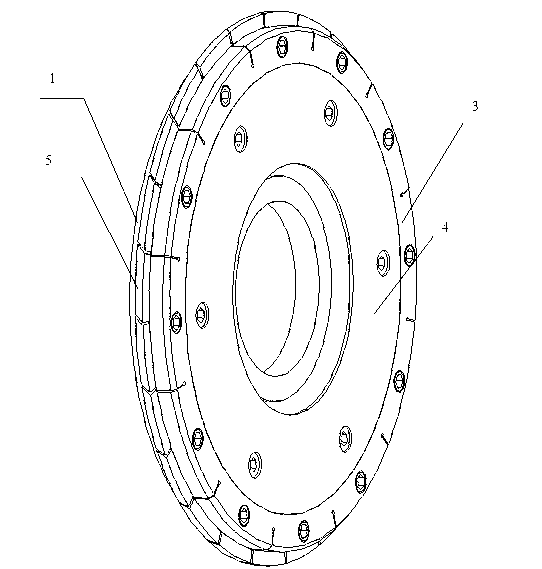

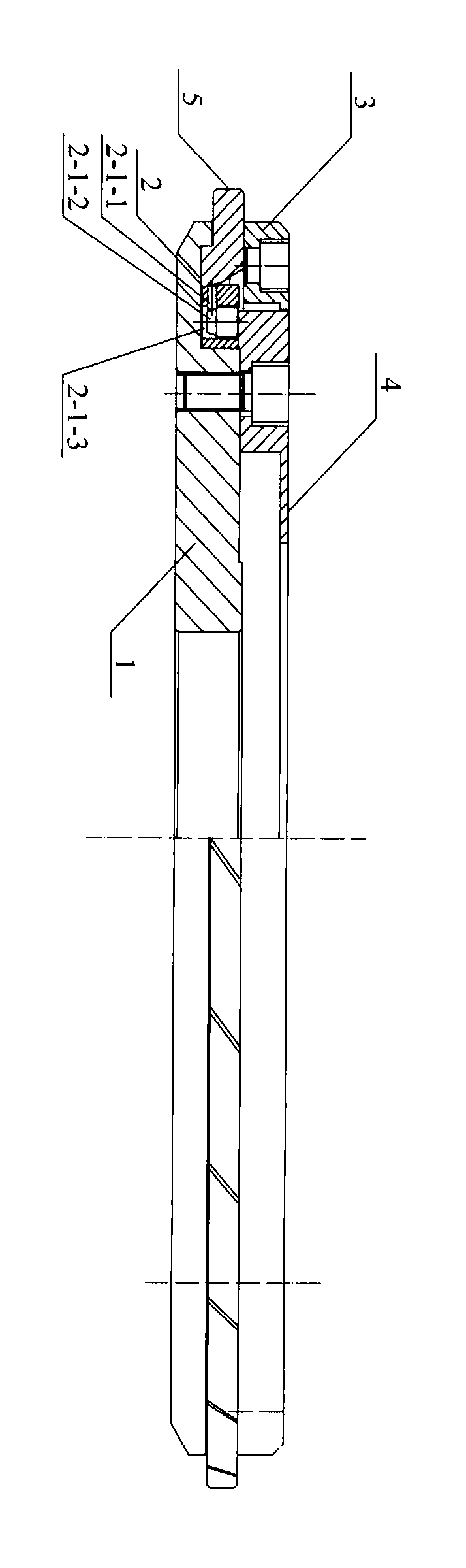

[0020] Such as figure 1 and figure 2 As shown, the base body of the ultra-high-speed grinding wheel in this embodiment includes a bottom plate 1 , a fixed ring 2 , a pressure ring 3 , a cover plate 4 and an insert 5 .

[0021] An annular groove 1-1 is provided on the upper side of the bottom plate 1 with the center of the bottom plate 1 as the center. Several installation grooves 1 - 2 are uniformly arranged on the outer wall of the annular groove 1 - 1 along the circumferential direction of the bottom plate 1 . An insert 5 is installed in each of the installation grooves 1-2.

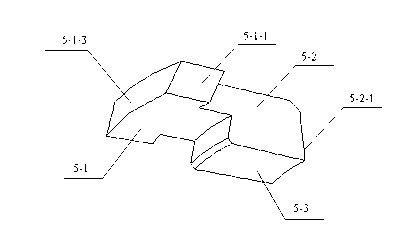

[0022] Such as image 3 and Figure 4 As shown, each insert 5 is T-shaped as a whole, which includes a first part 5-1 and a second part 5-2 connected to the first part 5-1. A stop 5-3 is attached to the underside of the second part 5-2. The two opposite end surfaces 5-1-1 and 5-1-2 of the first part 5-1 are inclined surfaces parallel to each other. Of course, the above two end faces 5-1-1 and 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com