Forage laying and airing device for animal husbandry

A technology of animal husbandry and forage, which is applied in the field of animal husbandry, which can solve the problems that the forage cannot be spread evenly at equal distances, and it is unfavorable for the forage to spread and dry, so as to improve the effect of spread and spread, improve the effect and reduce the accumulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

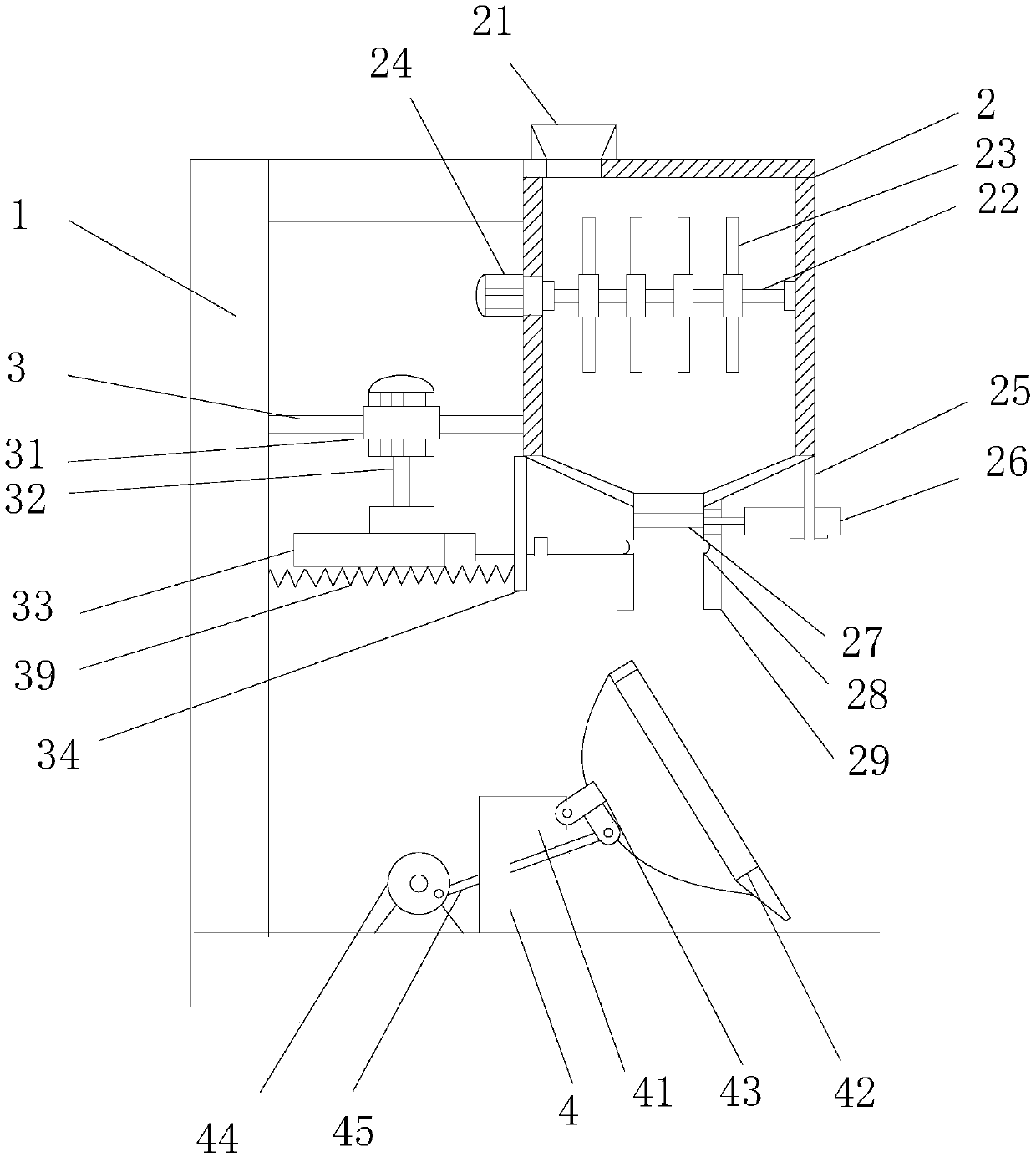

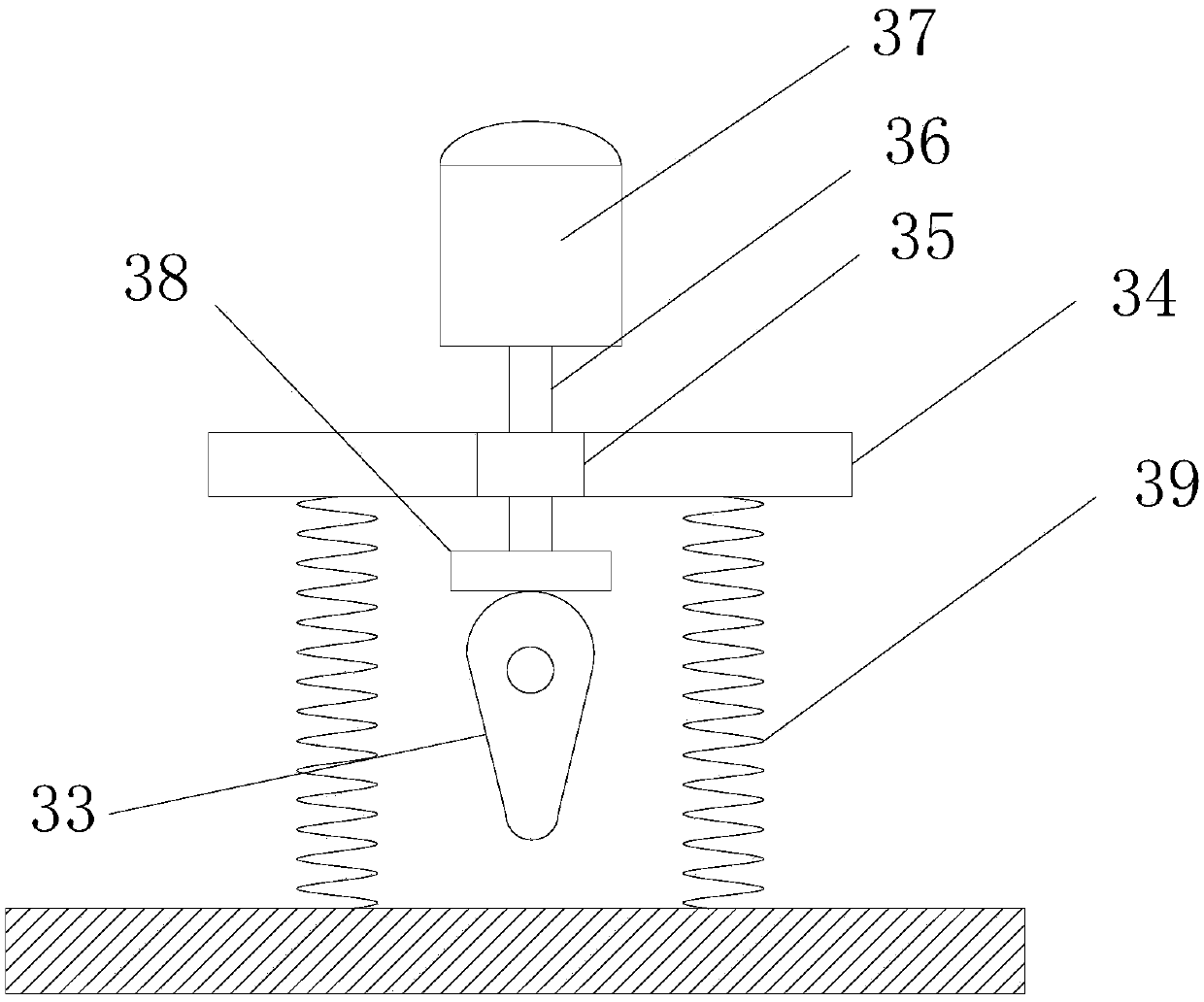

[0023] see figure 1 , a kind of forage spreading and drying device for animal husbandry, comprising a frame 1, a material barrel 2 is installed on the top of the frame 1, a throwing rack 4 is installed on the bottom of the frame 1, and the top of the material barrel 2 A receiving hopper 21 is installed, the bottom of the material barrel 2 is provided with a discharge port 29, a fixed plate 25 is installed on the side wall of the material barrel 2, and a cylinder 26 is installed on the fixed plate 25. The upper end of the feed port 29 is equipped with a discharge valve 27, the valve plug of the discharge valve 27 is connected with the telescopic rod at the driving end of the cylinder 26, and the drive frame 3 is installed between the frame 1 and the material barrel 2, the Drive motor 31 is installed on the drive frame 3, and the driving end of described drive motor 31 is equipped with drive cam 33 through drive shaft 32, and limit plate 34 is set synchronously on described driv...

Embodiment 2

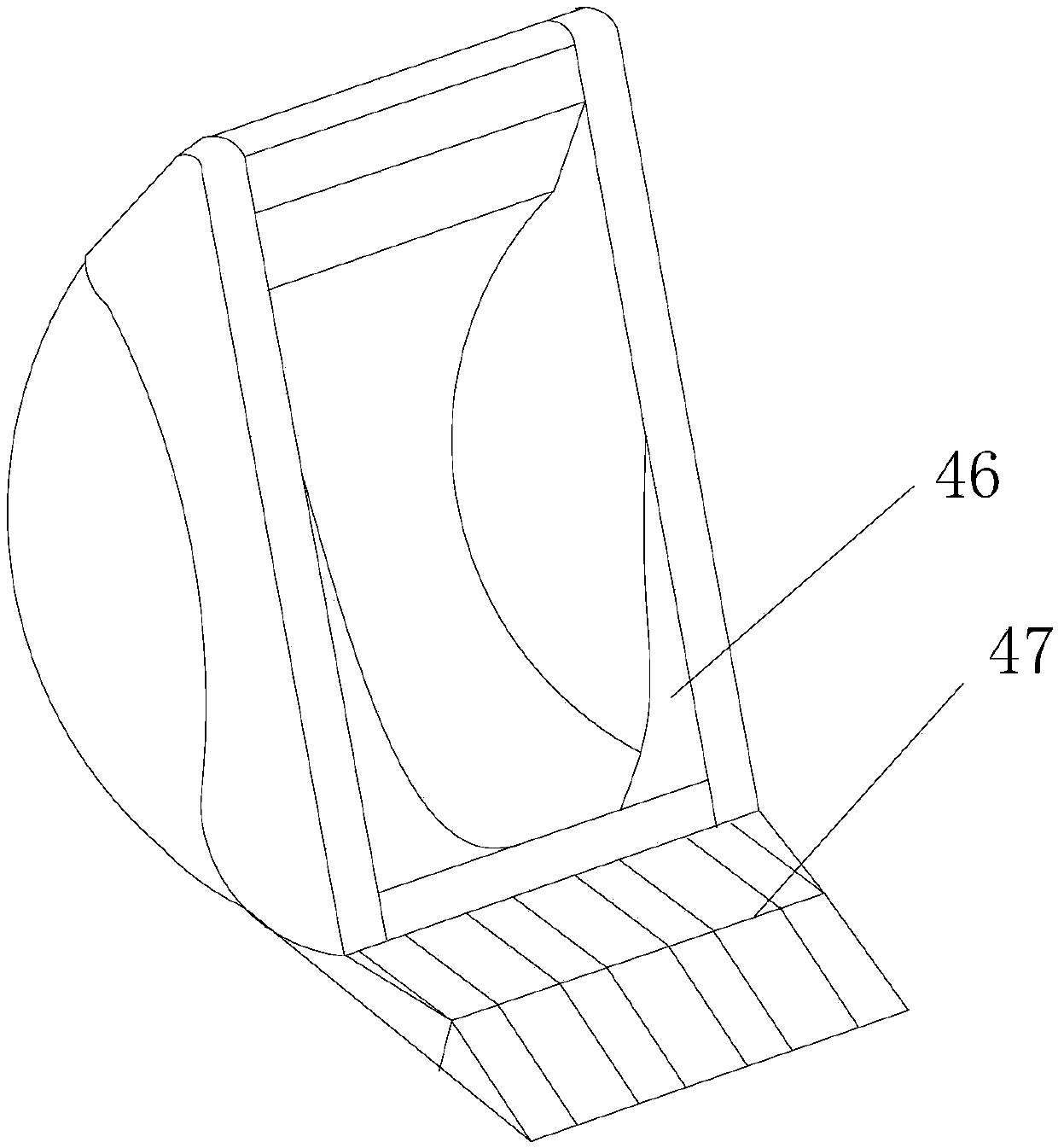

[0028] see image 3 , this embodiment is a further optimization of Embodiment 1. On the basis of it, a deflector 47 is installed on the lower edge of the mouth of the throwing hopper 42, and the deflector 47 has the effect of extending the force-bearing surface, so that The material is thrown farther, and if you need to spread it at a close distance, you can choose to disassemble it; the left and right sides of the mouth of the throwing hopper 42 are equipped with baffles 46 to prevent the material from spilling to both sides when throwing the material, thereby avoiding front and rear. The thrown material produces an intersection.

[0029] Example scattered:

[0030] see figure 1 , this embodiment is further optimized as Embodiment 1. On the basis of it, a stirring shaft 22 is installed horizontally in the material barrel 2, and several beat rollers 23 are equidistantly installed on the stirring shaft 22. The material A stirring motor 24 is installed on the side wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com