Patents

Literature

30results about How to "Extend continuous stable operation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-concentration wastewater zero-discharging method

ActiveCN105198143ARealize in-depth treatment and even zero discharge problemsEfficient reverse osmosis treatmentEnergy based wastewater treatmentMultistage water/sewage treatmentHigh concentrationReverse osmosis

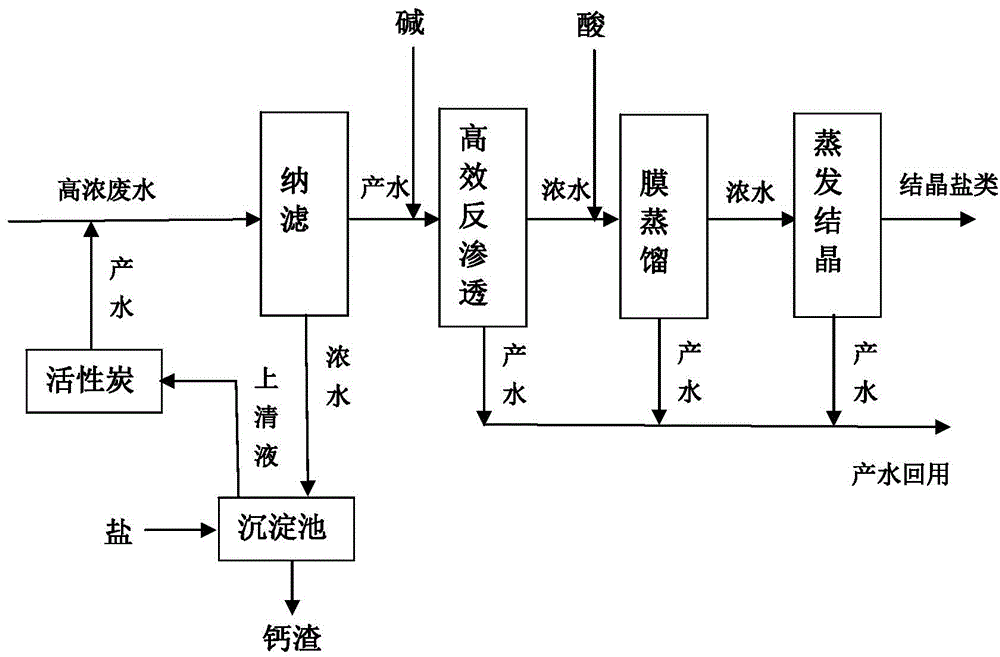

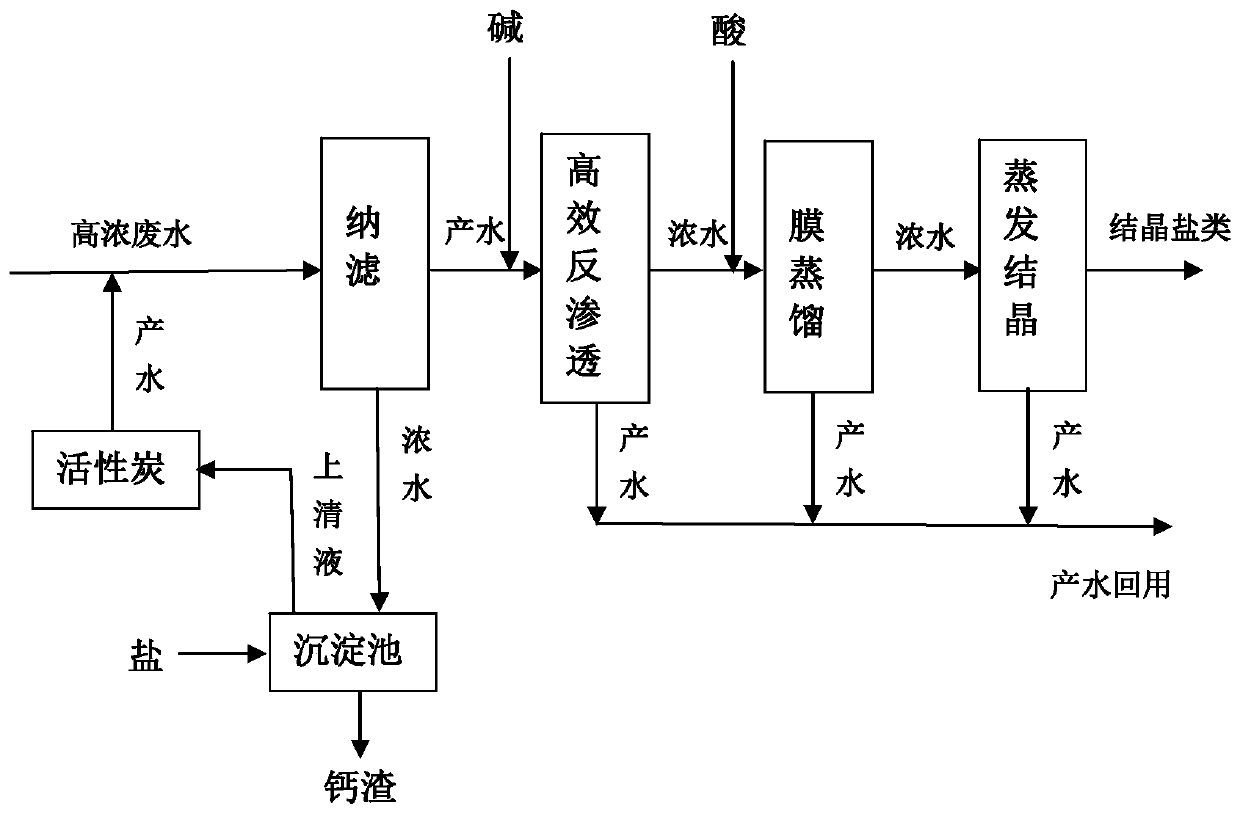

The invention relates to the field of industrial wastewater treatment, in particular to a high-concentration wastewater zero-discharging method. Accoridng to the method, a 'nanofiltration + efficient reverse osmosis + membrane distillation + evaporative crystallization' method is adopted to treat high-concentration wastewater. Firstly, nanofiltration is adopted to remove hardness, multivalent ions and parts of organic matter in the high-concentration wastewater so as to obtain nanofiltration producing water and nanofiltration concentrated water, then an efficient reverse osmosis technology is adopted to conduct deep concentration treatment on the nanofiltration producing water, deep concentration treatment is conducted on the obtained efficient reverse osmosis concentrated water through membrane distillation to obtain membrane-distillation concentrated water, further evaporative crystallization treatment is performed to enable salt solids in the membrane-distillation concentrated water to crystallize out, and centralized drying disposal is performed, wherein salt is added into the nanofiltration concentrated water to perform precipitation treatment so as to obtain calcium residues, supernate obtained after precipitation is subjected to activated carbon adsorption and then is mixed with the high-concentration wastewater, and the mixed liquid is fed into a nanofiltration unit for circular treatment. By means of the high-concentration wastewater zero-discharging method, water resources are recycled to the most degree while the problem of high-concentration wastewater discharging is solved, and zero discharging of high-concentration wastewater is basically achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

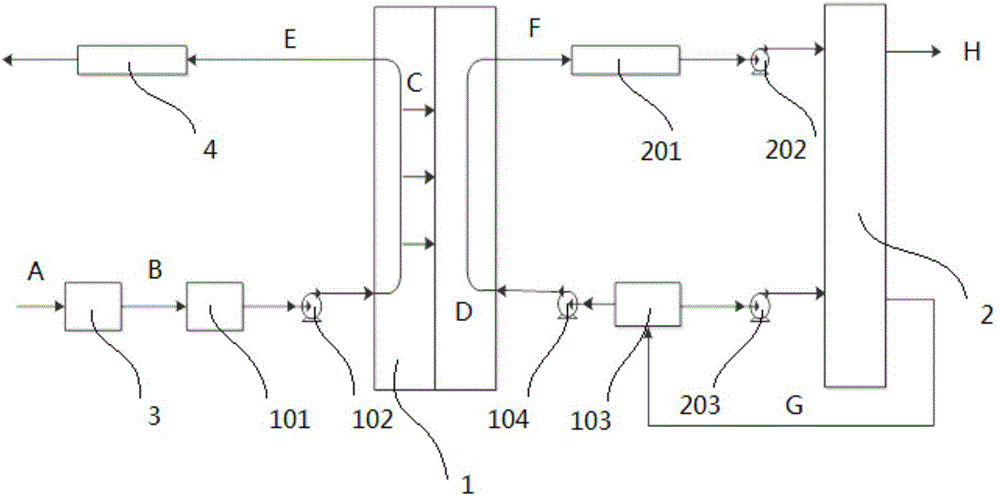

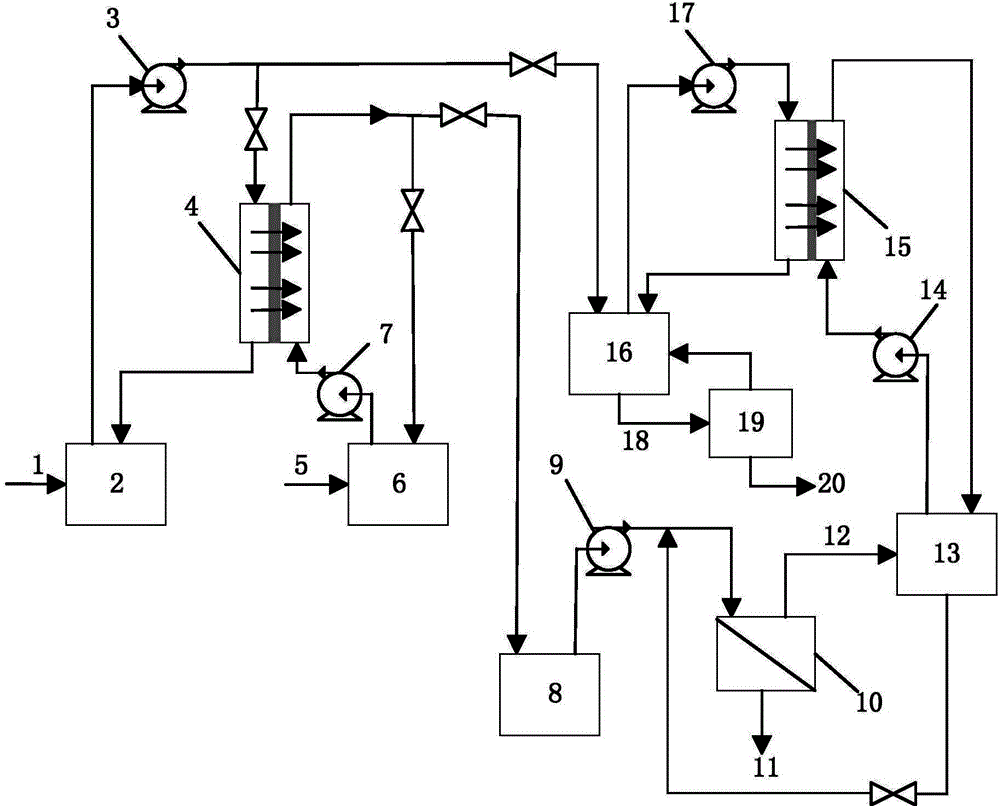

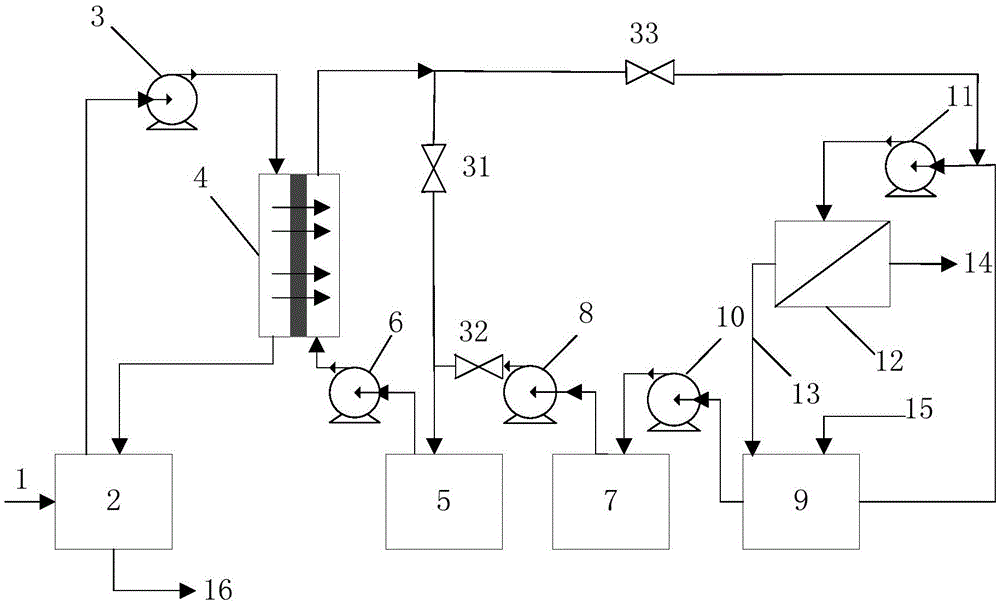

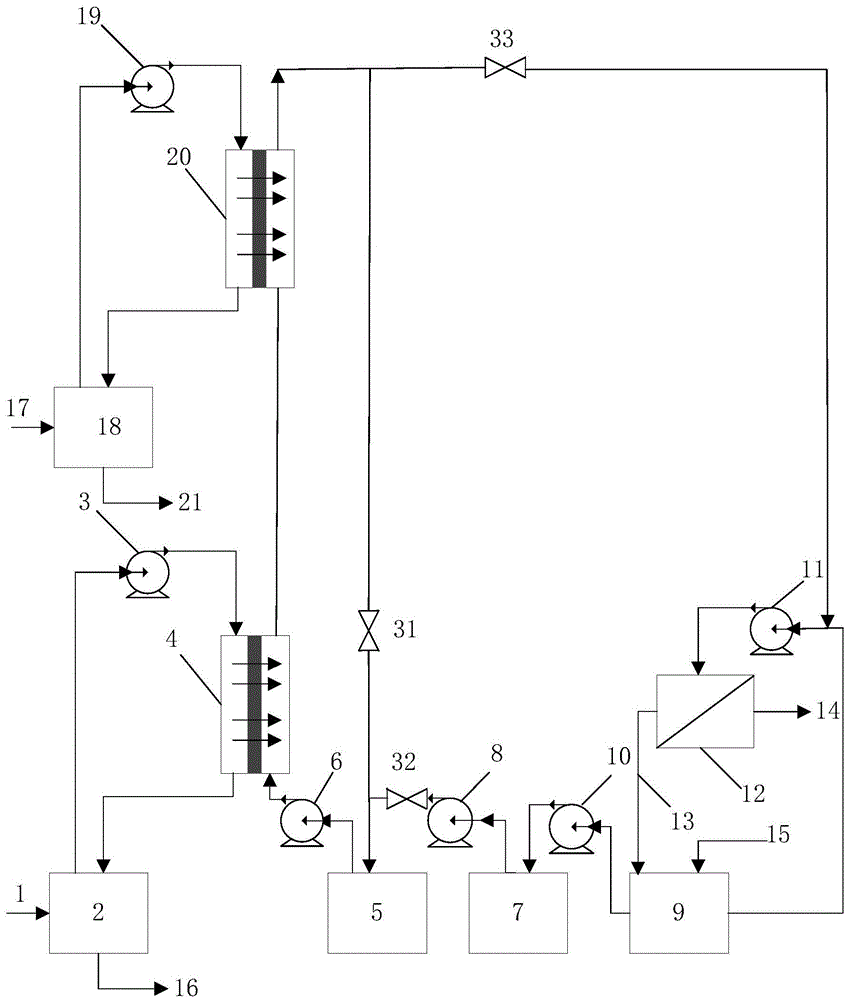

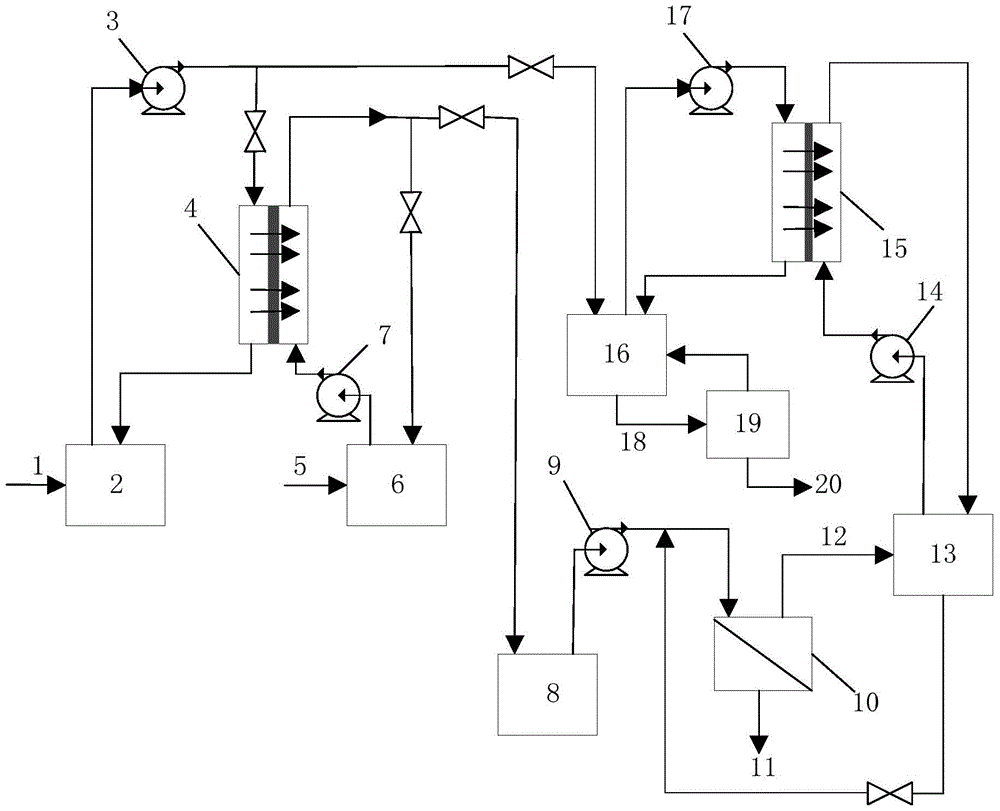

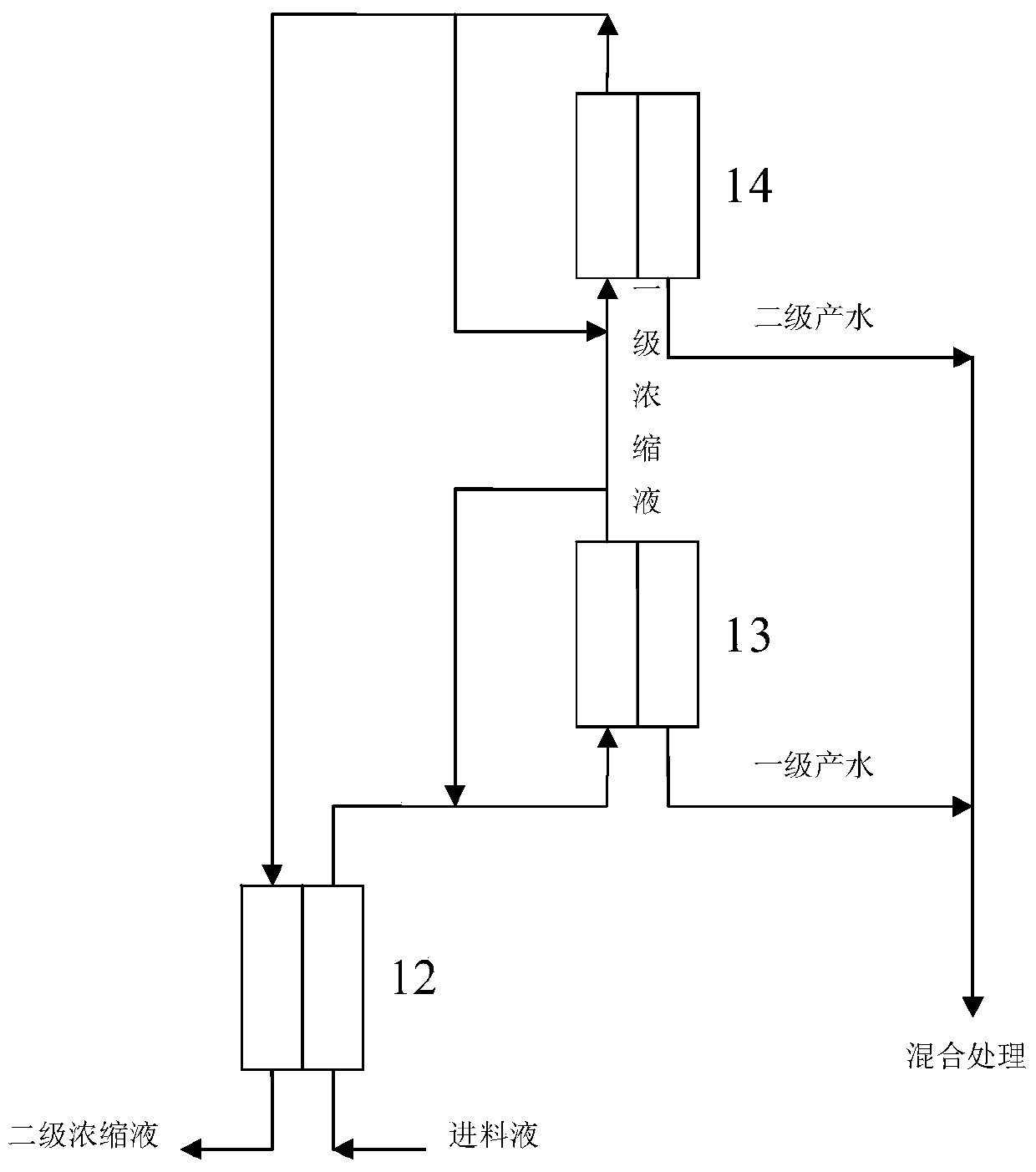

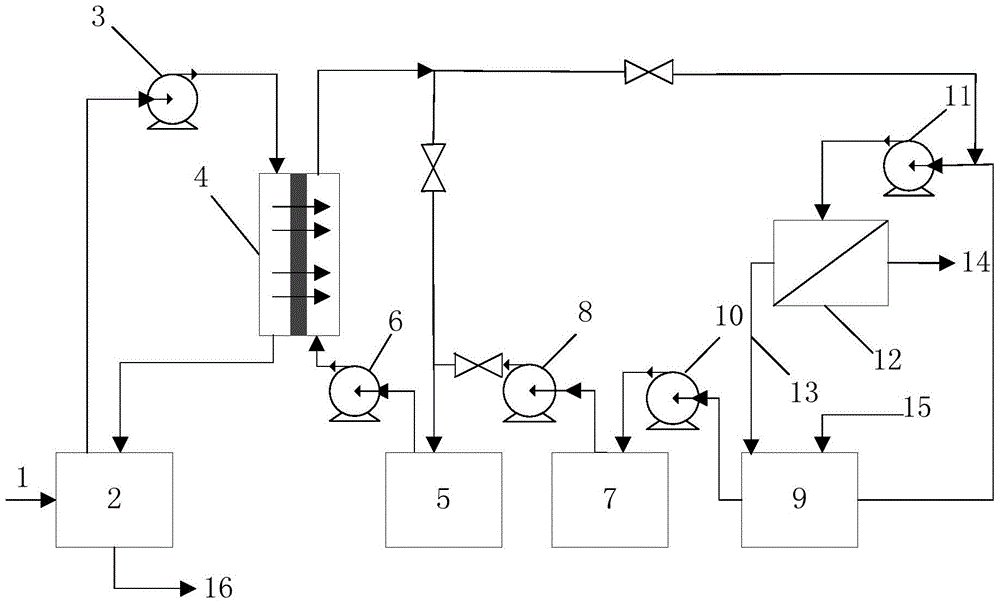

Forward osmosis coupled membrane distillation wastewater treatment apparatus and method thereof

ActiveCN104591457AEfficient use ofSimple methodWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWater resourcesWastewater

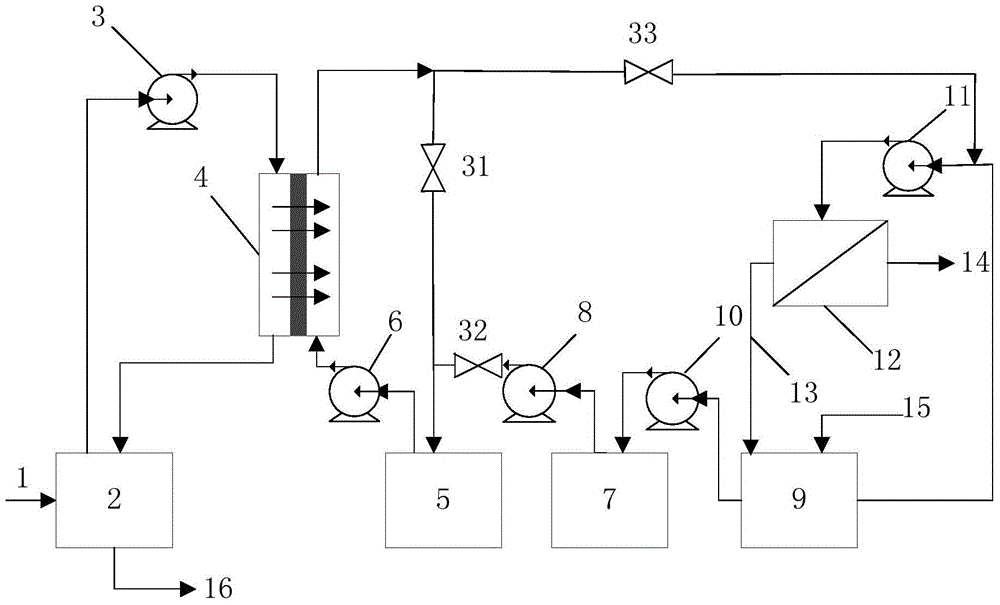

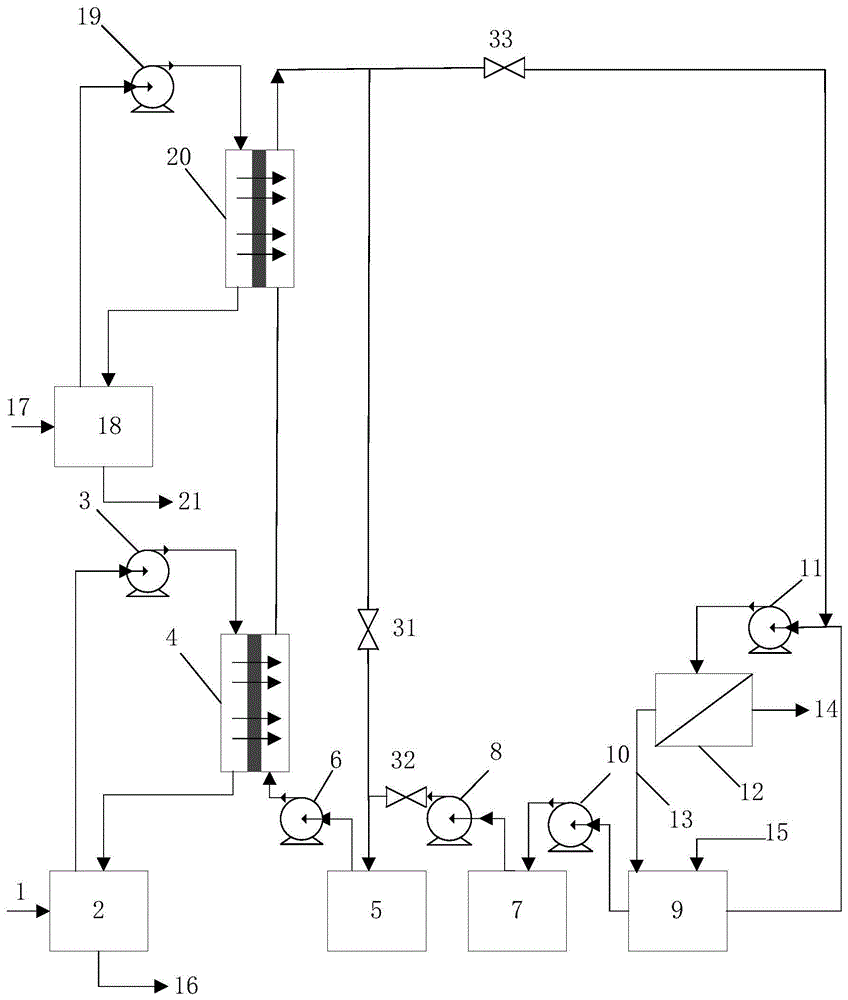

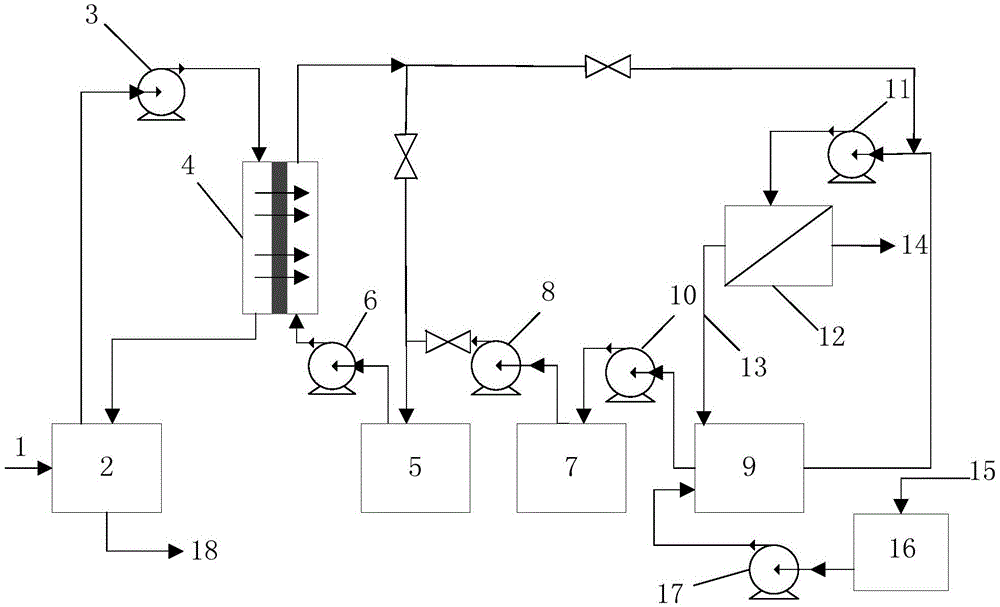

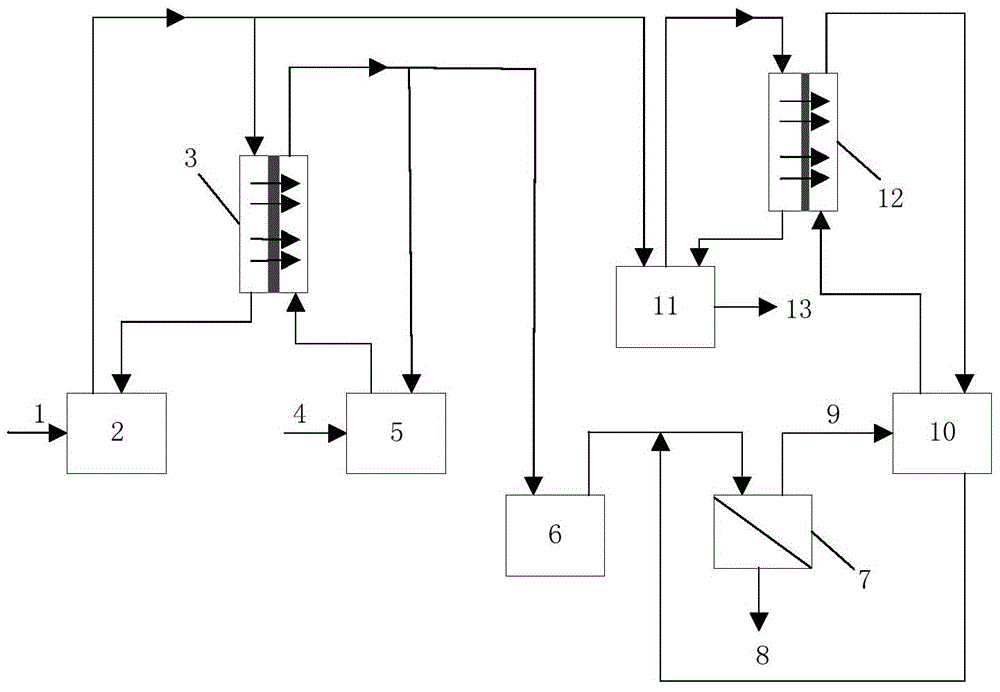

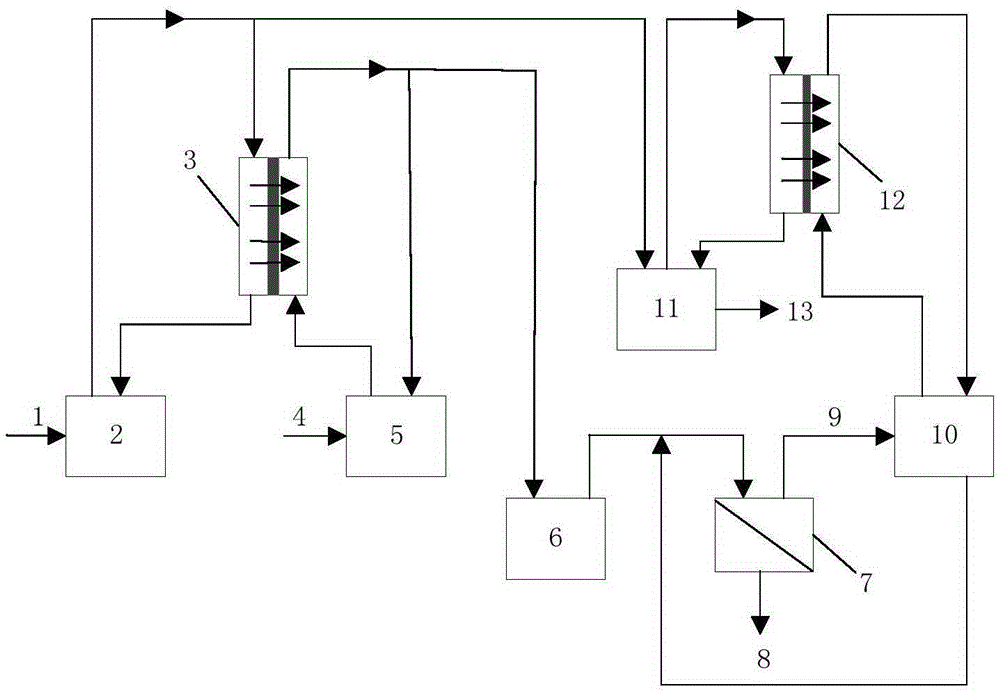

The invention provides a forward osmosis coupled membrane distillation wastewater treatment apparatus and a method thereof. The apparatus includes a first stage forward osmosis unit or a second stage forward osmosis unit and a membrane distillation unit. The above forward osmosis unit is composed of a forward osmosis raw water pool, a forward osmosis raw water pump, a forward osmosis membrane module, a forward osmosis driving liquid pool and a forward osmosis driving liquid pump; the membrane distillation unit is composed of a membrane distillation thick water raw water pool, a membrane distillation thick water pump, membrane distillation, a membrane distillation water heating pool, a membrane distillation thick water raw water pump, a membrane distillation water feeding pump and a membrane distillation assembly; and the forward osmosis unit is connected with the membrane distillation unit through a pipeline and a valve. The method comprises the following steps: high salinity wastewater treated by the membrane distillation unit is used as a forward osmosis driving liquid, membrane distillation thick water is diluted through continuous concentration of forward osmosis feeding liquid side raw water, the diluted membrane distillation thick water returns to the membrane distillation unit and is continuously treated, and above steps are cycled. The apparatus and the method effectively solve the treatment problem of the membrane distillation thick water, and maximally recover the water resource in the wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

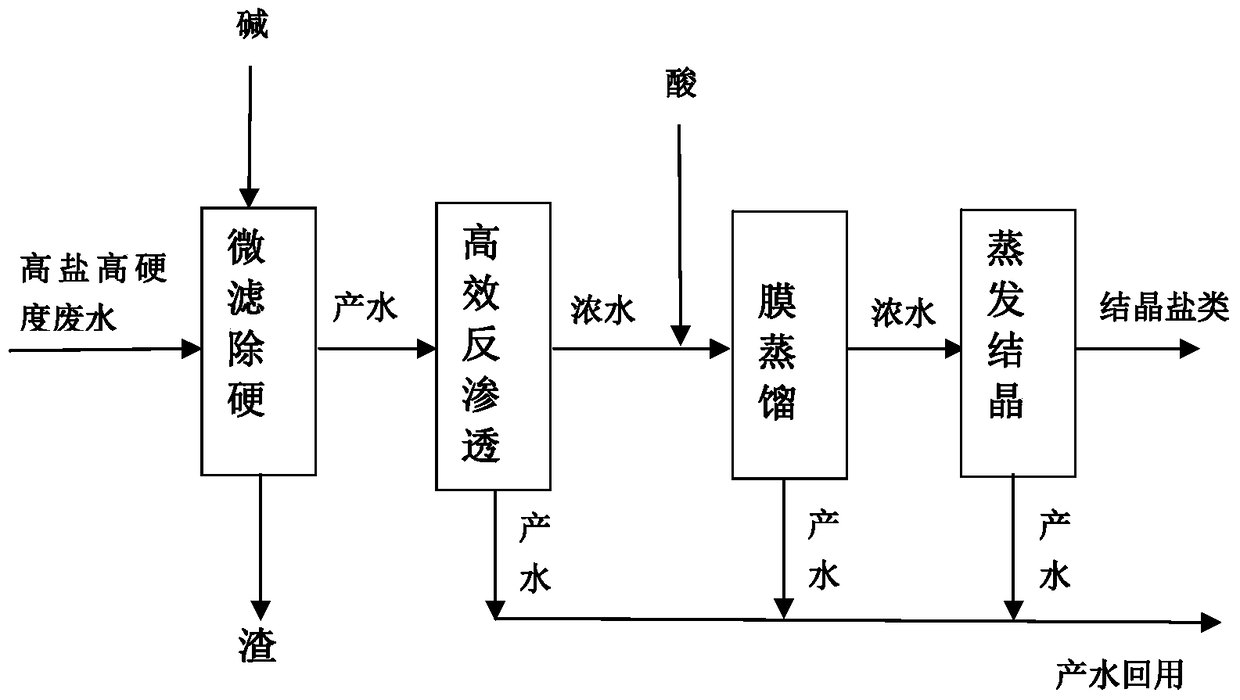

High-salinity high-hardness wastewater zero-discharging method

ActiveCN105198144AAchieving zero emissionsGuarantee continuous and stable operationMultistage water/sewage treatmentReverse osmosisWater resources

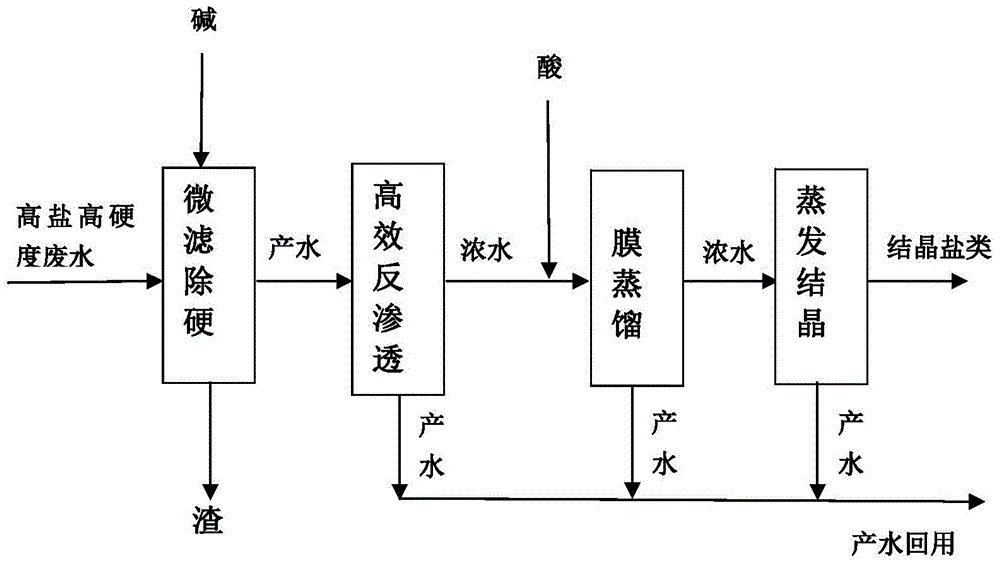

The invention relates to the field of industrial wastewater treatment, in particular to a high-salinity high-hardness wastewater zero-discharging method. According to the method, a 'microfiltration and hardness removal + efficient reverse osmosis + membrane distillation + evaporative crystallization' method is adopted to treat high-salinity high-hardness wastewater. Firstly, a microfiltration and hardness removal technology is adopted to remove hardness of the high-salinity high-hardness wastewater, then an efficient reverse osmosis technology is adopted to further concentrate the wastewater without hardness so as to obtain efficient reverse osmosis producing water and efficient reverse osmosis concentrated water, deep concentration is conducted on the efficient reverse osmosis concentrated water through membrane distillation to obtain membrane-distillation producing water and membrane-distillation concentrated water, evaporative crystallization treatment is further conducted on the membrane-distillation concentrated water to enable salt solids in the concentrated water to crystallize out, and centralized drying disposal is performed. The efficient reverse osmosis producing water, the membrane-distillation producing water and evaporative-crystallization producing water produced in the treating process can be reused for a production process, water resources are recycled to the most degree while the problem of wastewater discharging is solved, and zero discharging of high-salinity high-hardness wastewater is basically achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

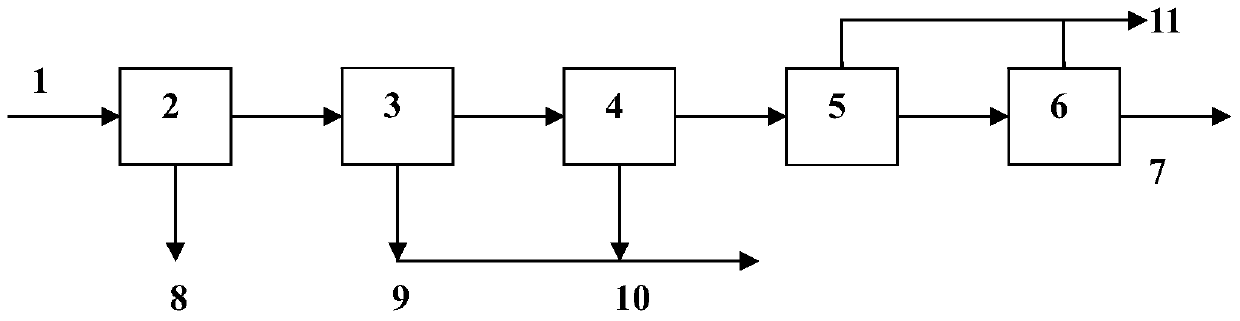

Forward osmosis draw fluid recycling method, wastewater treatment method and treatment device

InactiveCN105923704AImprove processing efficiencyReduce processingFatty/oily/floating substances removal devicesWater/sewage treatment bu osmosis/dialysisIon-exchange membranesPollution

The invention provides a recycling method of a forward osmosis draw fluid. According to the invention, diluted draw fluid produced during a forward osmosis process is subjected to a concentration treatment with an ion exchange membrane; and the concentrated draw fluid is recycled and reused in the forward osmosis process. The invention also provides a wastewater treatment method and a wastewater treatment device. According to the recycling method, the wastewater treatment method and the treatment device provided by the invention, a combination of forward osmosis and ion exchange membrane concentration is adopted. No additional pressure or small additional pressure is needed during the forward osmosis process and the ion exchange membrane concentration process. The method is simple and feasible, and has the advantages of easy operation and low energy consumption. Also, membrane pollution of the forward osmosis process and the ion exchange membrane concentration process is low, and continuous stable operation times of the two processes are prolonged. With the method, a large amount of pure product water can be obtained, and wastewater recycling rate is improved to a maximal extent. The methods and the device bring important environmental benefit.

Owner:北京新源智慧水务科技有限公司

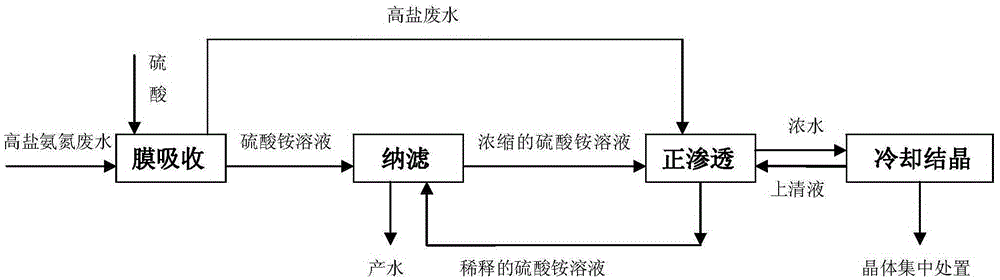

High salinity and high ammonia nitrogen wastewater treatment method

ActiveCN104591423AHigh recovery rateEmission reductionWater contaminantsMultistage water/sewage treatmentWater resourcesWater quality

The invention discloses a high salinity and high ammonia nitrogen wastewater treatment method. The method adopts a membrane absorption + nanofiltration + forward osmosis process flow. The method comprises the following steps: converting ammonia nitrogen in wastewater by adopting membrane absorption with a sulfuric acid solution as an absorption liquid to form ammonium sulfate; concentrating the ammonium sulfate solution through adopting nanofiltration; carrying out forward osmosis concentration treatment with the concentrated ammonium sulfate solution as a forward osmosis driving liquid and the high salinity wastewater with ammonia nitrogen removed through the membrane absorption as a forward osmosis inlet liquid; and diluting the ammonium sulfate solution as the driving liquid, and returning parts of the diluted ammonium sulfate solution to a nanofiltration unit for cycle concentration treatment. The method effectively solves the treatment problem of the high salinity and high ammonia nitrogen wastewater, allows the water recovery rate to be high, and allows the quality of produced water to be good. The method is adopted to carry out cycle concentration treatment of the high salinity and high ammonia nitrogen wastewater, so the discharge amount of concentrated water is extremely small, and the water resource in the high salinity and high ammonia nitrogen wastewater is maximally recovered.

Owner:CHINA PETROLEUM & CHEM CORP +1

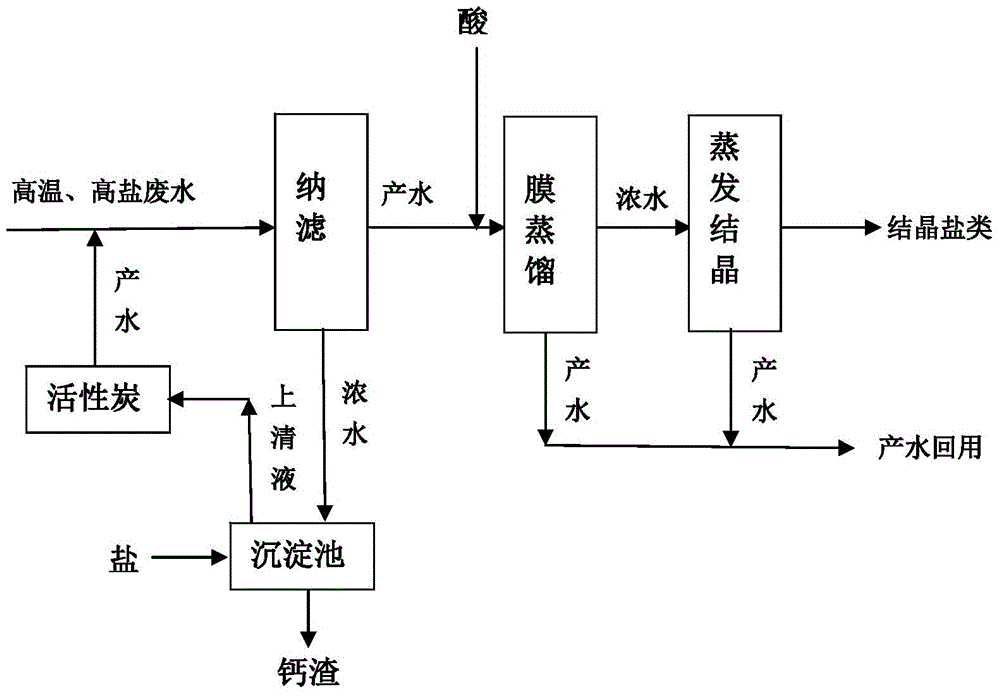

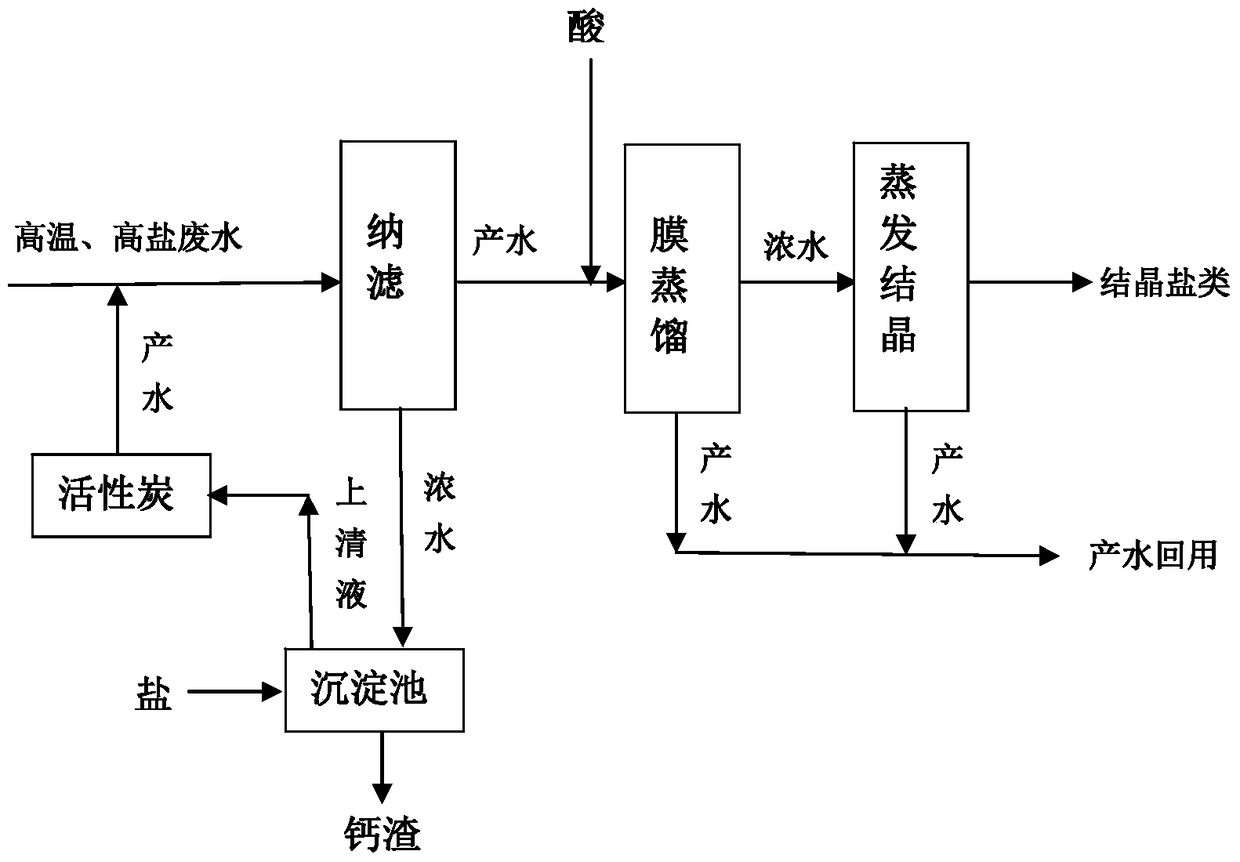

High-temperature high-salinity wastewater zero-discharging method

ActiveCN105198141ASolve the problem of advanced treatment and even zero dischargeEfficient use ofMultistage water/sewage treatmentMembrane distillationProduced water

The invention relates to a high-temperature high-salinity wastewater zero-discharging method. Firstly, a high-temperature-resisting nanofiltration membrane is adopted to remove multivalent ions and a little amount of organic matter in wastewater, then a membrane distillation technology is adopted to conduct deep concentration treatment on the wastewater, membrane-distillation concentrated water is subjected to evaporative crystallization treatment to enable salt in the membrane-distillation concentrated water to crystallize out, and centralized drying disposal is performed. Salt is added into the nanofiltration concentrated water produced in the treatment process to perform precipitation treatment so as to obtain calcium residues, centralized drying disposal is performed, supernate obtained after precipitation is subjected to activated carbon adsorption, and producing water obtained after activated carbon adsorption and nanofiltration feed water are mixed and fed into a nanofiltration unit for circular treatment. Membrane-distillation producing water and evaporative-crystallization producing water can be both reused for a production process. By means of the high-temperature high-salinity wastewater zero-discharging method, residual heat of the wastewater itself is effectively utilized while wastewater zero discharging is achieved, the energy consumption of the whole technological process is reduced, and efficient utilization of waste water resources and energy is achieved. The high-temperature high-salinity wastewater zero-discharging method has remarkable social benefit and environmental benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

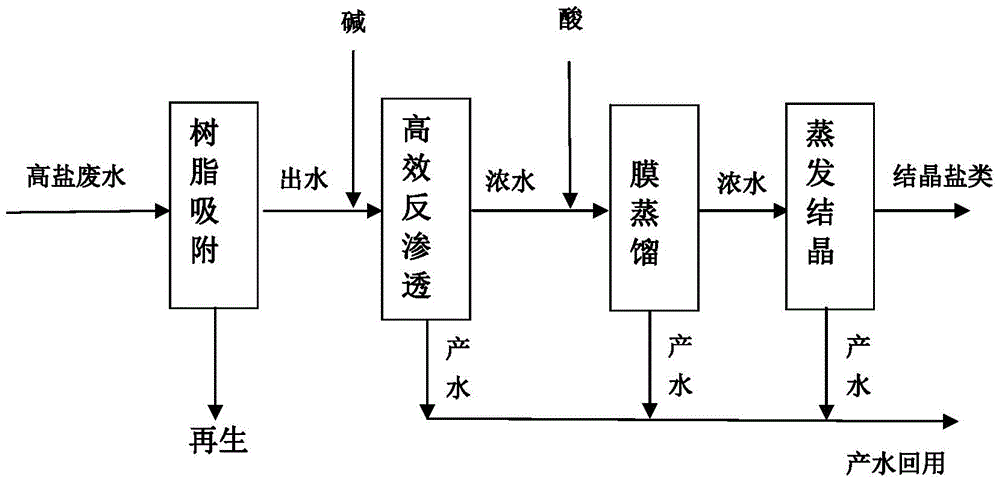

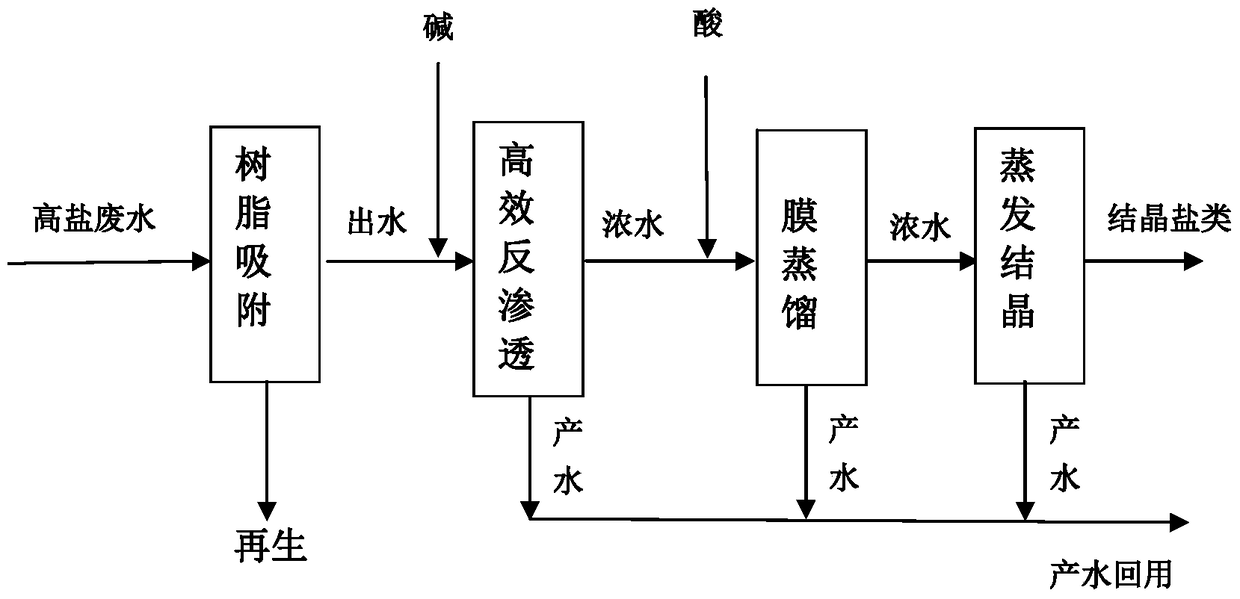

High-salinity wastewater zero-discharging method

ActiveCN105198142ARealize in-depth treatment and even zero discharge problemsReduce pollutionMultistage water/sewage treatmentWater resourcesReverse osmosis

The invention relates to the field of industrial wastewater treatment, in particular to a high-salinity wastewater zero-discharging method. According to the method, a 'resin adsorption + efficient reverse osmosis + membrane distillation + evaporative crystallization' method is adopted to treat high-salinity wastewater. Firstly, resin adsorption is adopted to remove hardness and a little amount of organic matter in the high-salinity wastewater, then efficient reverse osmosis is adopted to further concentrate the high-salinity wastewater without hardness so as to obtain efficient reverse osmosis producing water and efficient reverse osmosis concentrated water, deep concentration is conducted on the efficient reverse osmosis concentrated water through membrane distillation to obtain membrane-distillation producing water and membrane-distillation concentrated water, evaporative crystallization treatment is further conducted on the membrane-distillation concentrated water to enable salt solids in the concentrated water to crystallize out, and centralized drying disposal is performed. The efficient reverse osmosis producing water, the membrane-distillation producing water and evaporative-crystallization producing water produced in the treating process can be reused for a production process, water resources are recycled to the most degree while the problem of wastewater discharging is solved, and zero discharging of high-salinity wastewater is basically achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

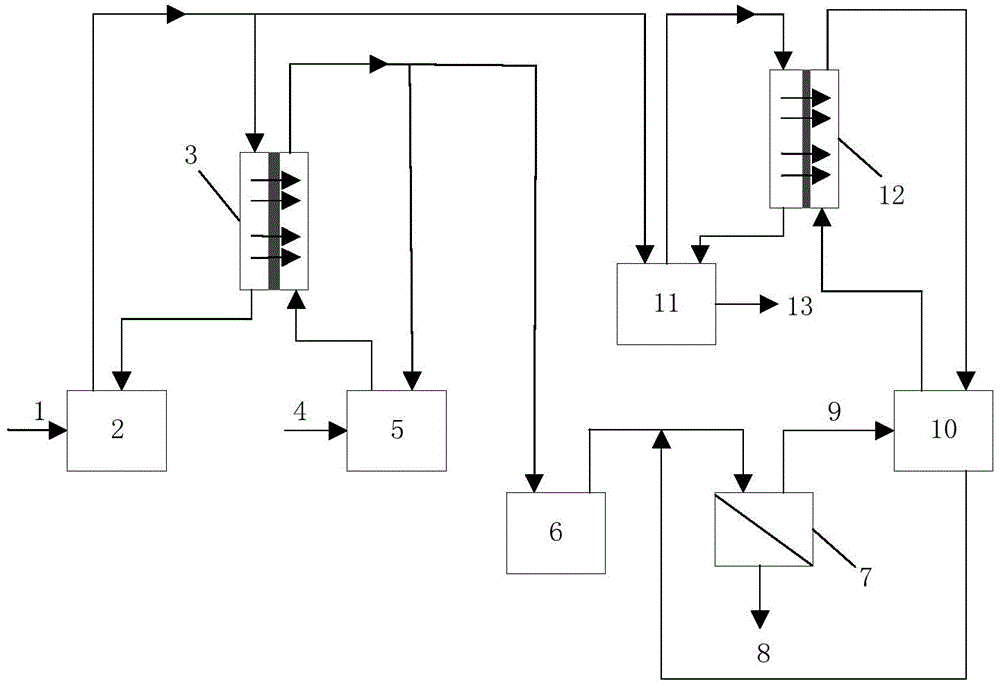

Novel solar energy reduced-pressure multiple-effect membrane distillation apparatus

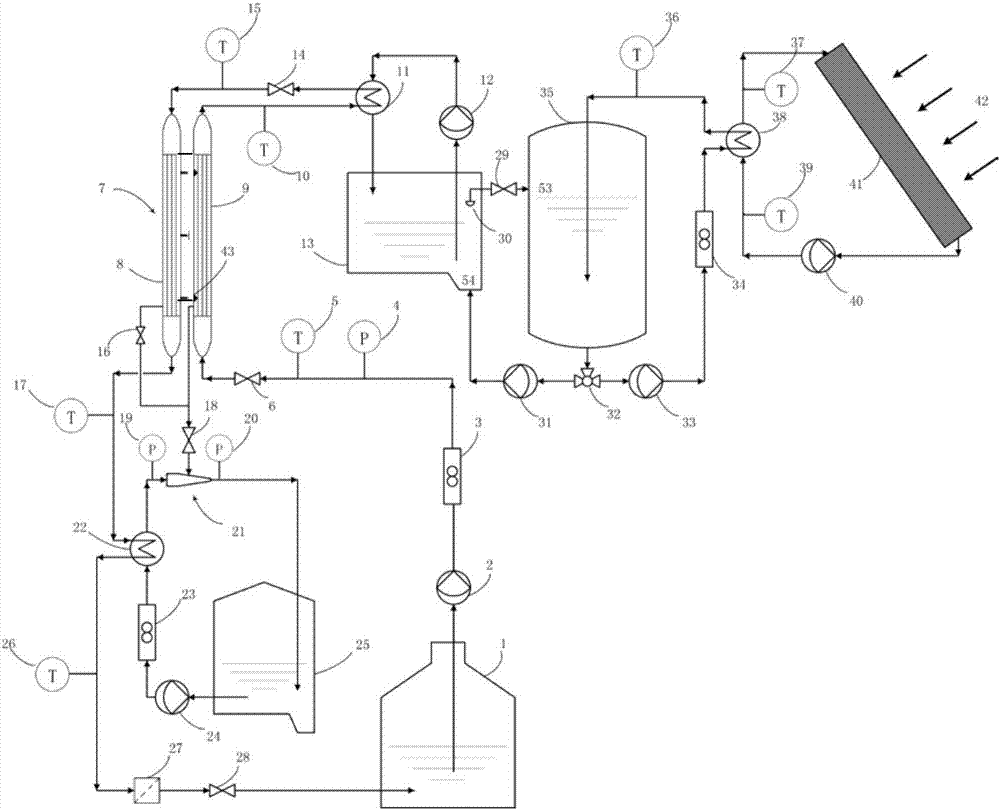

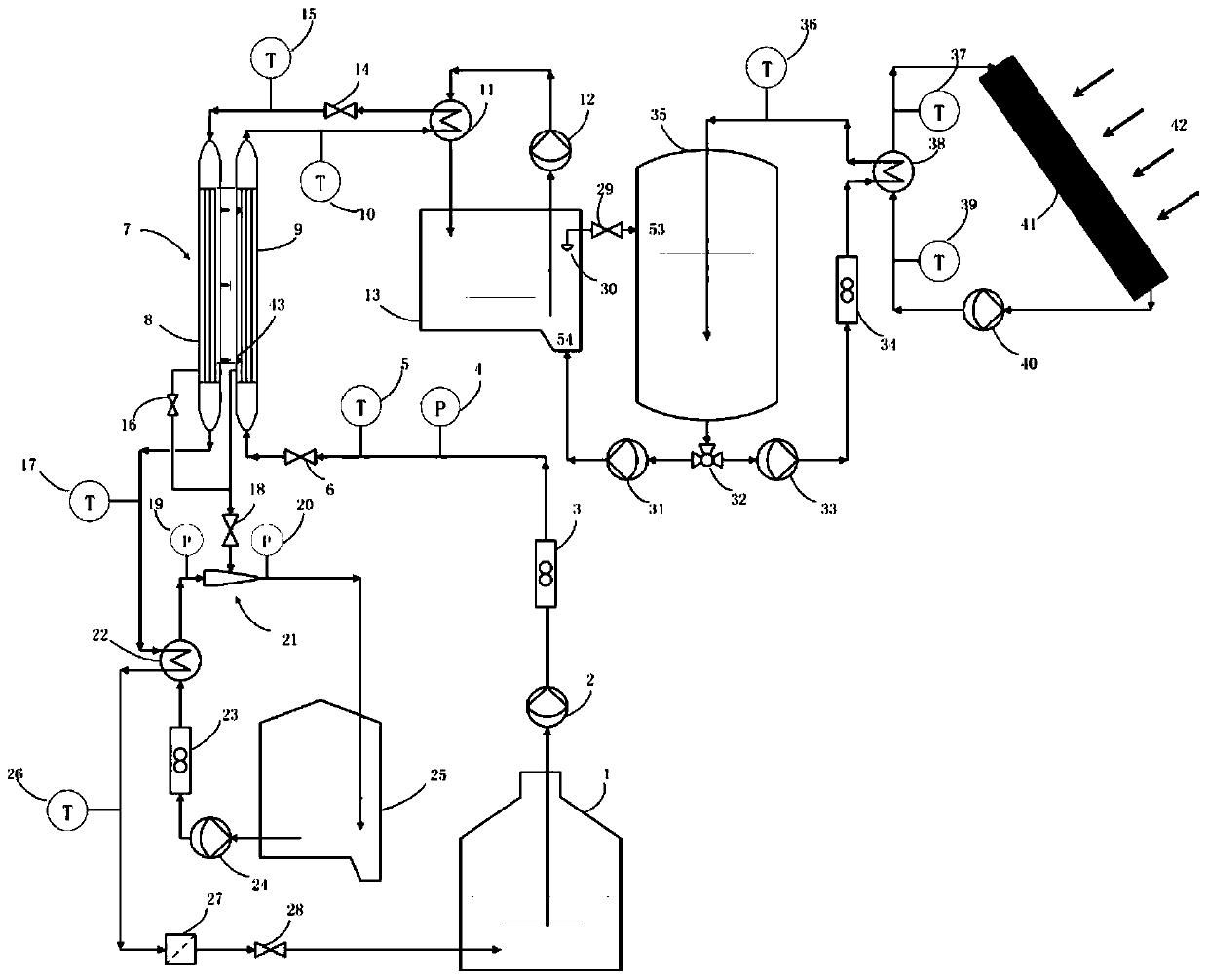

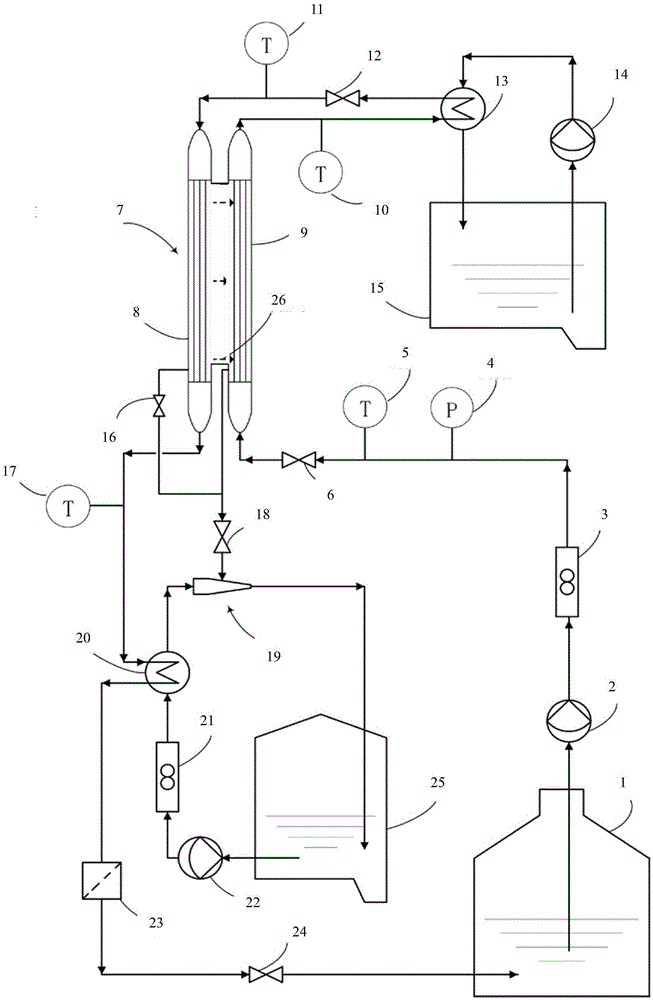

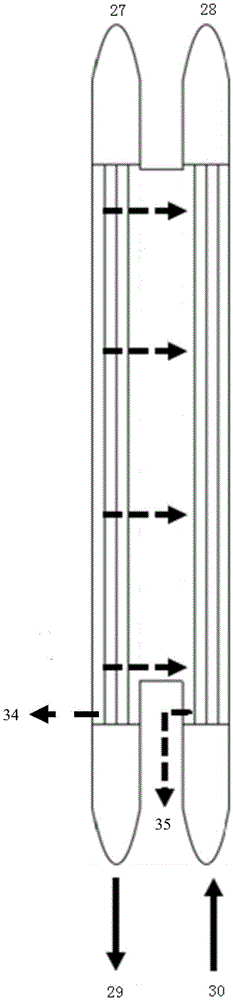

ActiveCN107213793AEfficient use ofImprove utilization efficiencyMembranesGeneral water supply conservationWater vaporProcess engineering

The invention discloses a novel solar energy reduced-pressure multiple-effect membrane distillation apparatus, and aims to utilize solar energy to replace conventional electrical heating as a heat source and heat a raw material fluid to reach a goal of saving energy and reducing consumption. A set of simple Venturi system is used to replace a vacuum pump which is used in the reduced-pressure multiple-effect membrane distillation, so that energy consumption in a membrane distillation operation process is further reduced, and 100% collection of produced water is realized, and the membrane flux is improved. The application of multiple-effect membrane components realizes the effective utilization of phase transformation heat of a water vapor, and the heat-utilization rate is improved. The novel Venturi-solar energy reduced-pressure multiple-effect membrane distillation system is adopted, so that the total energy consumption and the operation cost in the membrane distillation process are greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

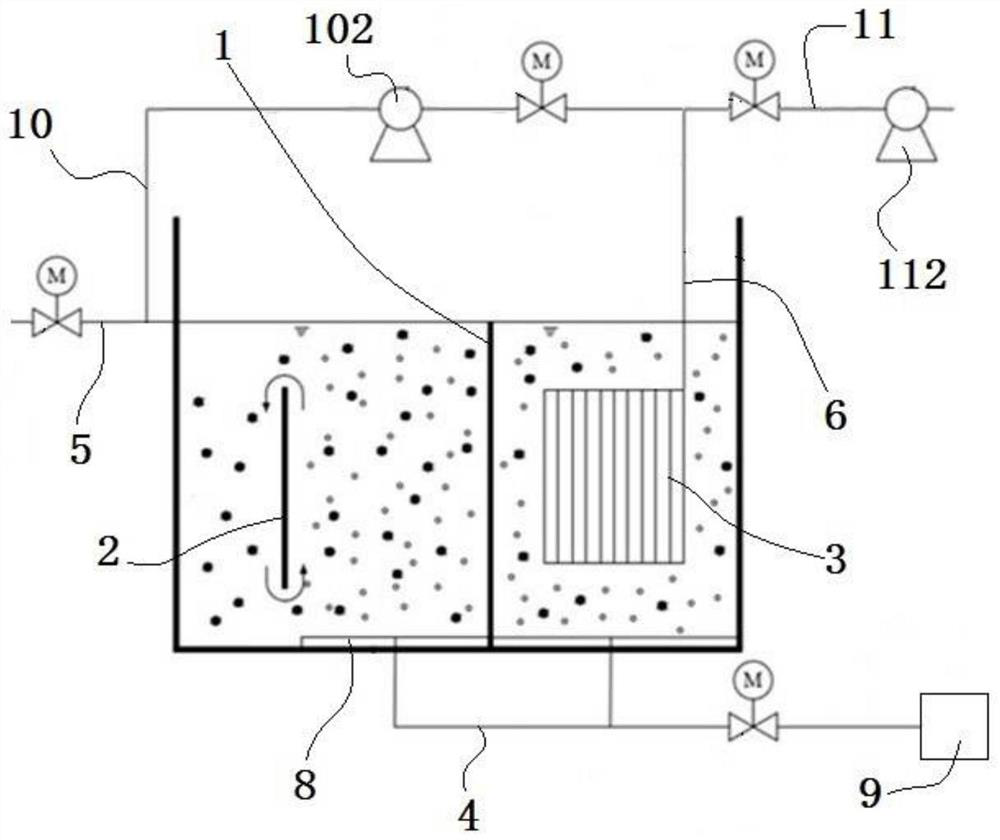

Zero release device of high-salt high-ammonia-nitrogen waste water

ActiveCN104609616AAchieving zero emissionsSolve processing problemsWater contaminantsWater/sewage treatment bu osmosis/dialysisWater qualityWater resources

The invention provides a zero release device of high-salt high-ammonia-nitrogen waste water. The zero release device is mainly used for solving problems of conventional devices that discharge standards are not reached, and water resource recovery rate is low in high-salt high-ammonia-nitrogen waste water treatment. The zero release device is a membrane coupling device, and mainly comprises a membrane absorption unit, a nanofiltration unit, a forward osmosis unit, and a cooling crystallization unit; the membrane absorption unit is connected with the nanofiltration unit, the nanofiltration unit is connected with the forward osmosis unit, the forward osmosis unit is connected with the membrane absorption unit and the cooling crystallization unit, and a plurality of circulation loops are formed via connection of the units. The zero release device is easy for operation, and is easy for realization. The zero release device can be used for solving processing problems of high-salt high-ammonia-nitrogen waste water effectively, water recovery rate is high, and quality of obtained water is high. The zero release device is used for circulating condensation of high-salt high-ammonia-nitrogen waste water, almost no concentrated water is discharged, and recovery of water resource of high-salt high-ammonia-nitrogen waste water is realized as far as possible.

Owner:CHINA PETROLEUM & CHEM CORP +1

Electrical tar precipitator

InactiveCN102974463APrevent breakdownImprove running stabilityExternal electric electrostatic seperatorElectrodes cleaningElectricityTar

The invention provides an electrical tar precipitator. The electrical tar precipitator comprises a tar precipitator body, a power supply porcelain insulator box, a high-tension porcelain insulator, a high-voltage corona wire, a sealing assembly and a spray device, wherein the high-tension porcelain insulator is arranged in the power supply porcelain insulator box; the high-voltage corona wire is arranged in the tar precipitator and connected with the high-tension porcelain insulator; the power supply porcelain insulator box is arranged above the tar precipitator body; the sealing assembly is arranged below the high-tension porcelain insulator and used for preventing air in the tar precipitator body from entering the power supply porcelain insulator box; the spray device comprises a spray tube and a reservoir, wherein the reservoir stores liquid for cleaning the high-voltage corona wire; and the spray tube is used for communicating the reservoir with the upper part of the tar precipitator body. The electrical tar precipitator provided by the invention has the characteristics of capacity of continuously and stably running for a long time, long service life, convenience for maintenance, easiness for operation and the like.

Owner:PANGANG GRP ENG TECH

Forward osmosis coupled membrane distillation device and method for treating wastewater

ActiveCN104591457BEfficient use ofSimple methodWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWastewaterWater resources

The invention provides a forward osmosis coupled membrane distillation wastewater treatment apparatus and a method thereof. The apparatus includes a first stage forward osmosis unit or a second stage forward osmosis unit and a membrane distillation unit. The above forward osmosis unit is composed of a forward osmosis raw water pool, a forward osmosis raw water pump, a forward osmosis membrane module, a forward osmosis driving liquid pool and a forward osmosis driving liquid pump; the membrane distillation unit is composed of a membrane distillation thick water raw water pool, a membrane distillation thick water pump, membrane distillation, a membrane distillation water heating pool, a membrane distillation thick water raw water pump, a membrane distillation water feeding pump and a membrane distillation assembly; and the forward osmosis unit is connected with the membrane distillation unit through a pipeline and a valve. The method comprises the following steps: high salinity wastewater treated by the membrane distillation unit is used as a forward osmosis driving liquid, membrane distillation thick water is diluted through continuous concentration of forward osmosis feeding liquid side raw water, the diluted membrane distillation thick water returns to the membrane distillation unit and is continuously treated, and above steps are cycled. The apparatus and the method effectively solve the treatment problem of the membrane distillation thick water, and maximally recover the water resource in the wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

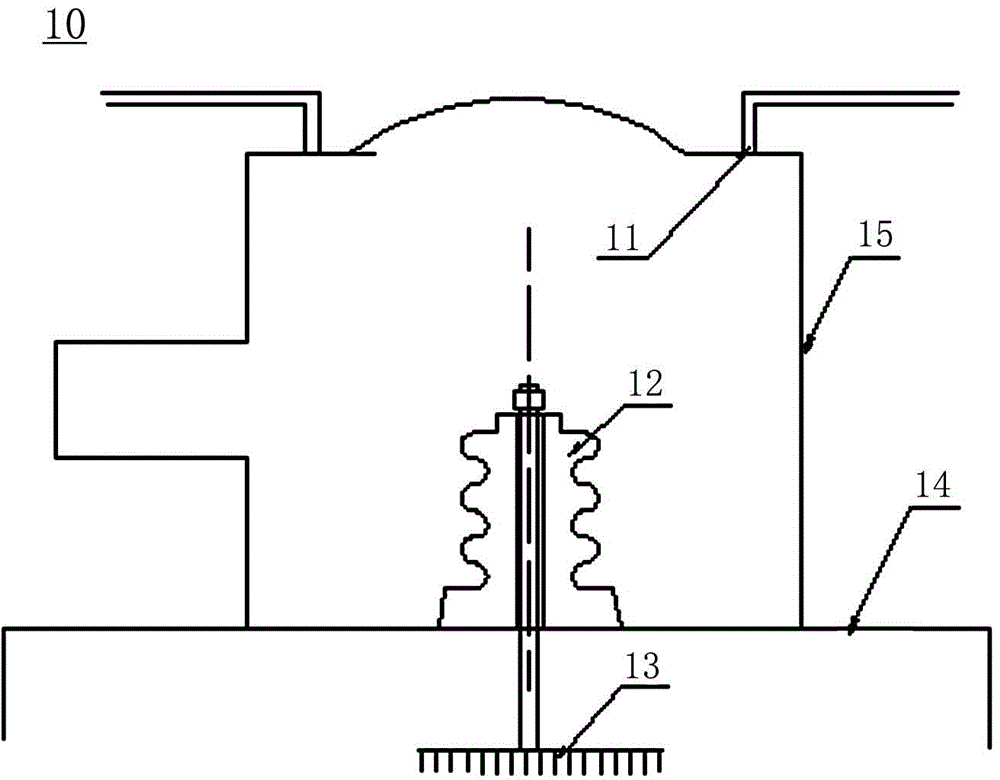

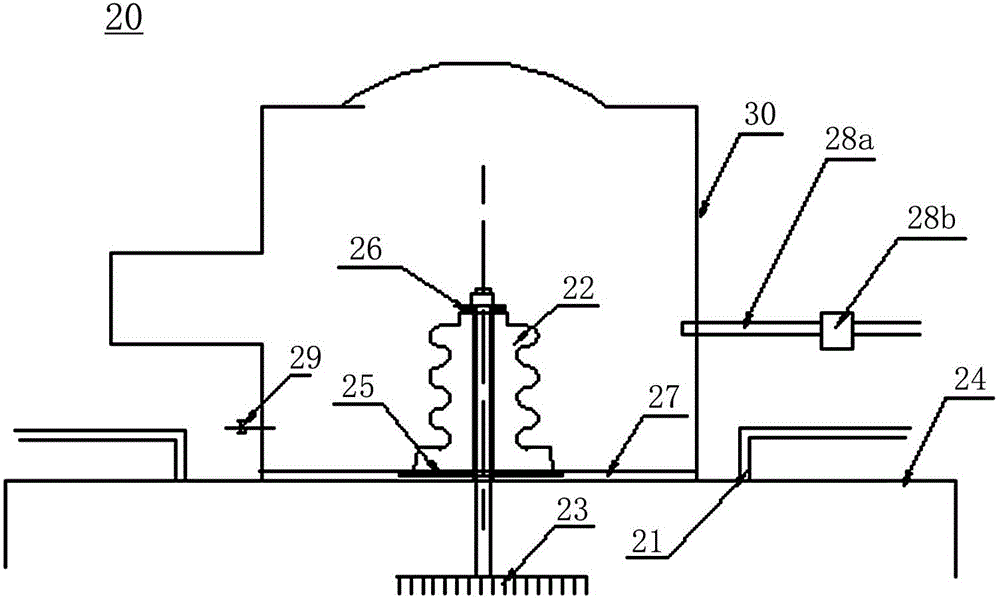

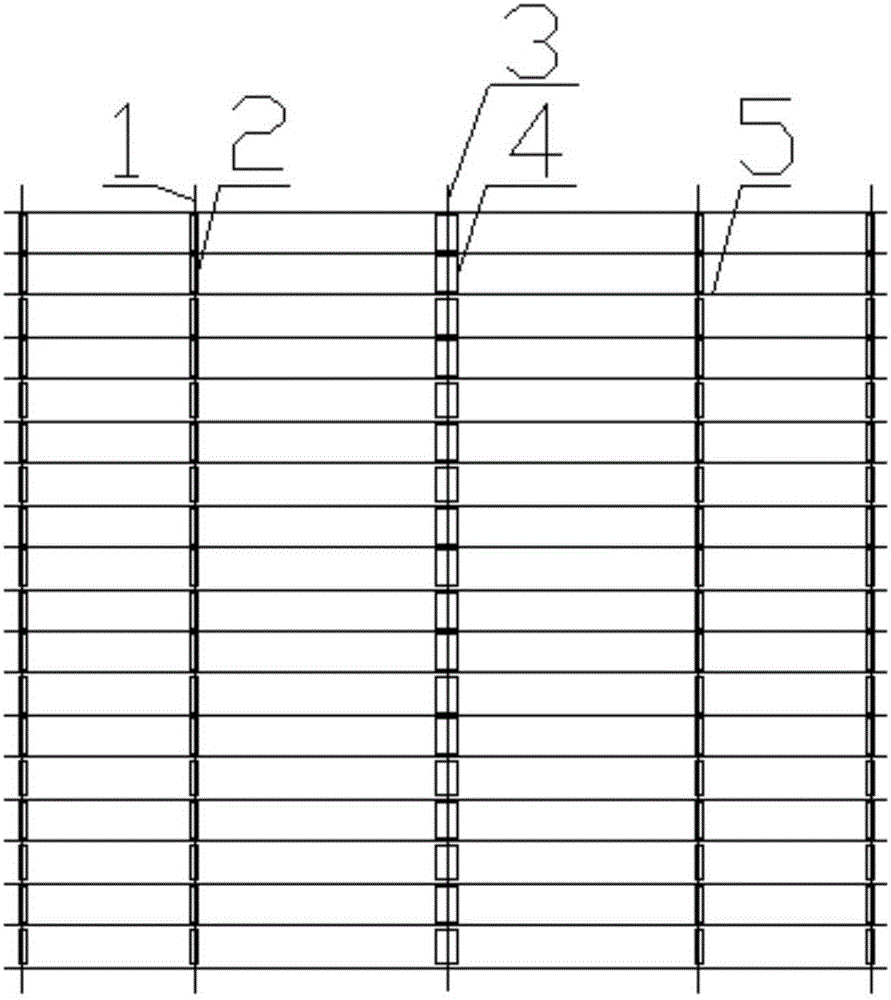

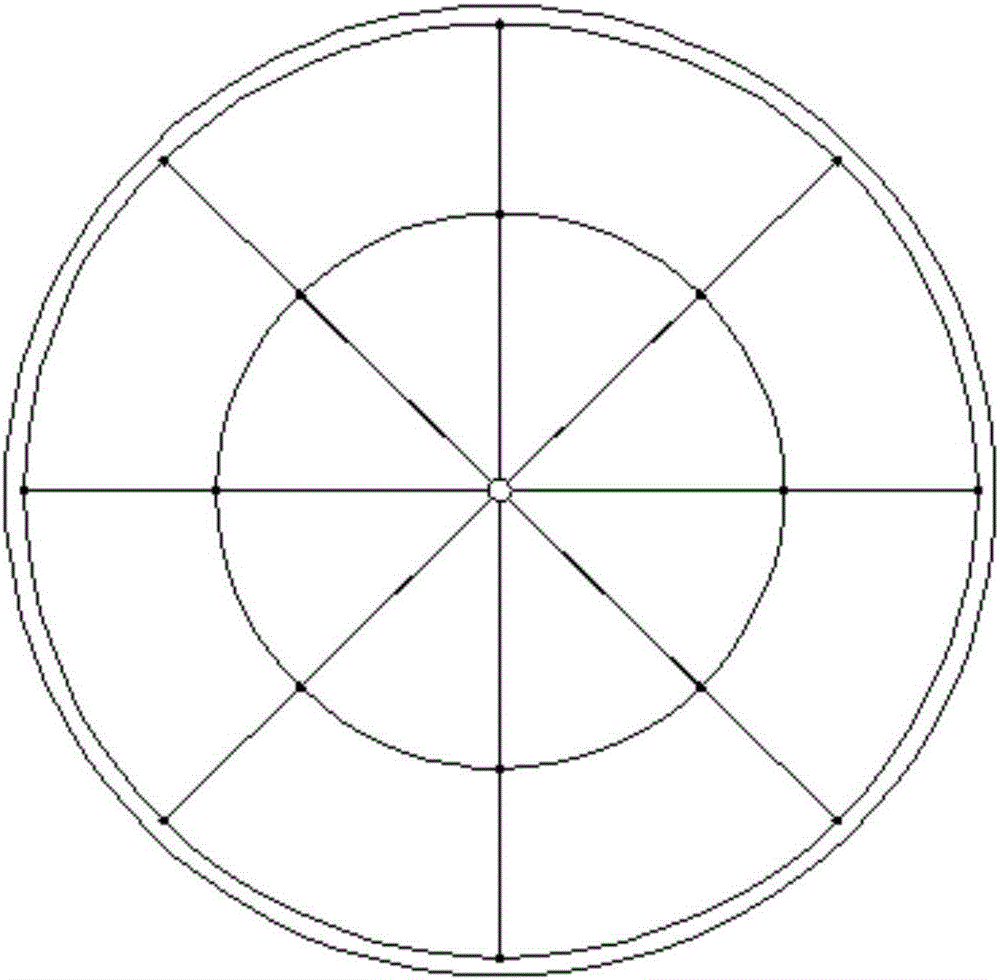

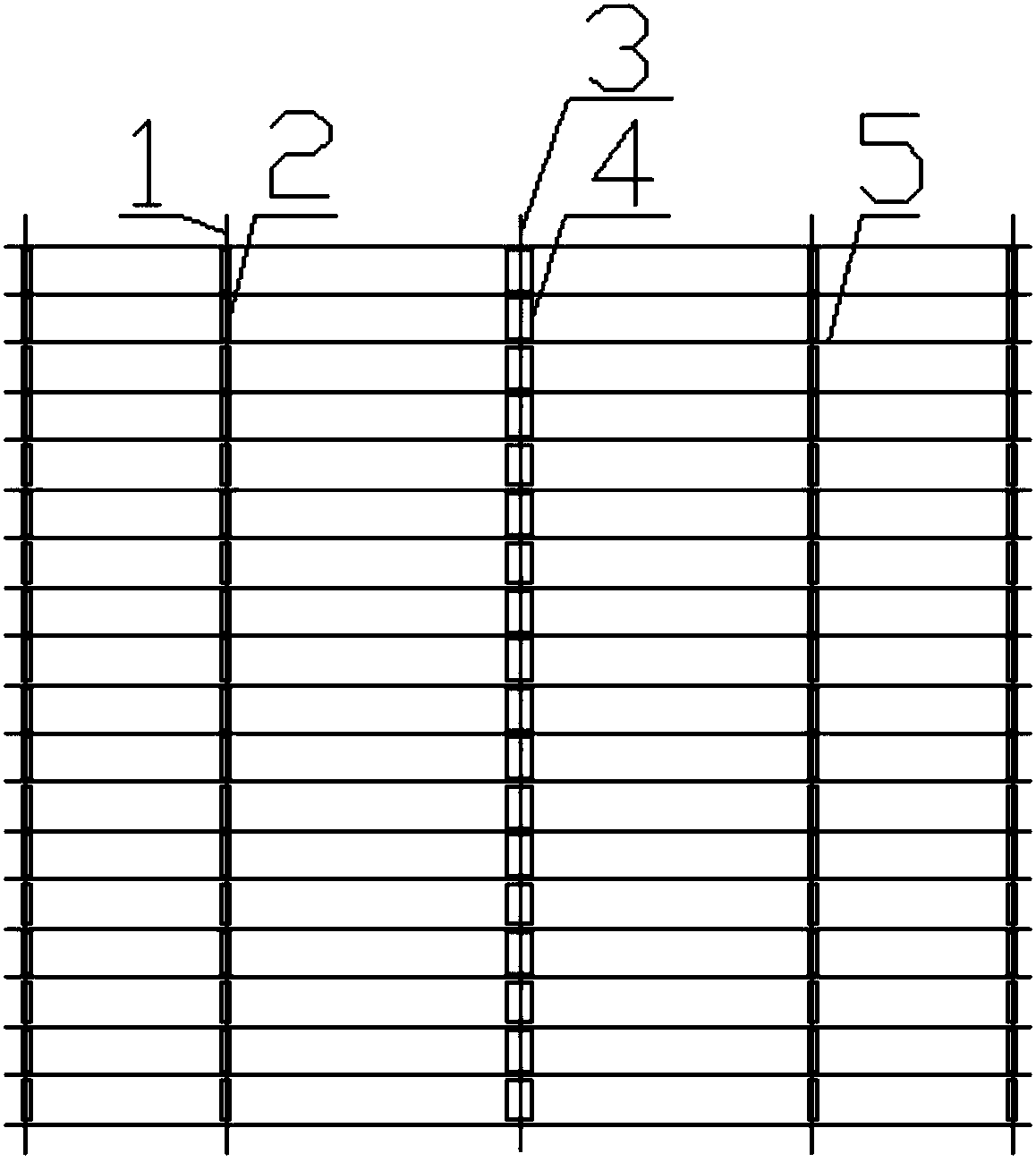

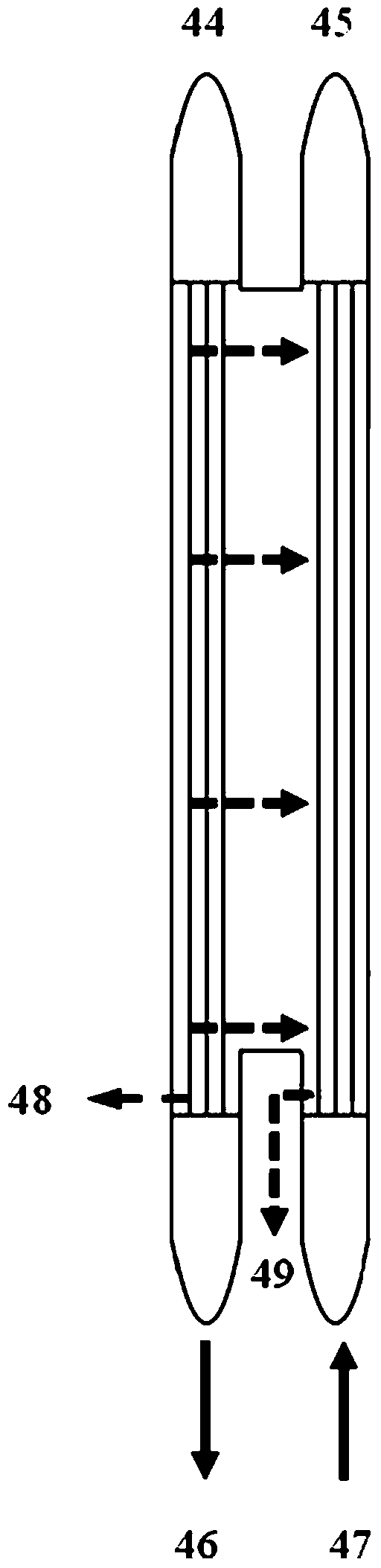

Method for fixing sieve plates of pulse sieve plate column

The invention belongs to the technical field of extraction and purification processing equipment in the field of uranium purification and production, and particularly relates to a method for fixing sieve plates of a pulse sieve plate column. According to the method for fixing the sieve plates of the pulse sieve plate columns, transverse fixing of the sieve plates is achieved through a central rod, pull rods and the like so that a gap between a column body and a plate string can be reduced, and mass transfer is sufficiently achieved. Radial fixing of the sieve plates is achieved through the pull rods and pull rod pipe spacers so that it can be guaranteed that the sieve plates are not prone to deformation, and mixed mass transfer is stable. Longitudinal fixing of the sieve plates is achieved through central pipe spacers, so that it is guaranteed that the distances between the sieve plates are equal, and mixed mass transfer is stable.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

A zero discharge device for high-salt and high-ammonia-nitrogen wastewater

ActiveCN104609616BHigh recovery rateImprove water qualityWater contaminantsWater/sewage treatment bu osmosis/dialysisWater qualityWater resources

The invention provides a zero release device of high-salt high-ammonia-nitrogen waste water. The zero release device is mainly used for solving problems of conventional devices that discharge standards are not reached, and water resource recovery rate is low in high-salt high-ammonia-nitrogen waste water treatment. The zero release device is a membrane coupling device, and mainly comprises a membrane absorption unit, a nanofiltration unit, a forward osmosis unit, and a cooling crystallization unit; the membrane absorption unit is connected with the nanofiltration unit, the nanofiltration unit is connected with the forward osmosis unit, the forward osmosis unit is connected with the membrane absorption unit and the cooling crystallization unit, and a plurality of circulation loops are formed via connection of the units. The zero release device is easy for operation, and is easy for realization. The zero release device can be used for solving processing problems of high-salt high-ammonia-nitrogen waste water effectively, water recovery rate is high, and quality of obtained water is high. The zero release device is used for circulating condensation of high-salt high-ammonia-nitrogen waste water, almost no concentrated water is discharged, and recovery of water resource of high-salt high-ammonia-nitrogen waste water is realized as far as possible.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for fixing pulse sieve plate column sieve plate

ActiveCN106702183BExtended service lifeExtend continuous stable operation timeProcess equipmentPlate column

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

A zero-discharge method for high-salt wastewater

ActiveCN105198142BRealize in-depth treatment and even zero discharge problemsReduce pollutionMultistage water/sewage treatmentReverse osmosisWater resources

The invention relates to the field of industrial wastewater treatment, in particular to a high-salinity wastewater zero-discharging method. According to the method, a 'resin adsorption + efficient reverse osmosis + membrane distillation + evaporative crystallization' method is adopted to treat high-salinity wastewater. Firstly, resin adsorption is adopted to remove hardness and a little amount of organic matter in the high-salinity wastewater, then efficient reverse osmosis is adopted to further concentrate the high-salinity wastewater without hardness so as to obtain efficient reverse osmosis producing water and efficient reverse osmosis concentrated water, deep concentration is conducted on the efficient reverse osmosis concentrated water through membrane distillation to obtain membrane-distillation producing water and membrane-distillation concentrated water, evaporative crystallization treatment is further conducted on the membrane-distillation concentrated water to enable salt solids in the concentrated water to crystallize out, and centralized drying disposal is performed. The efficient reverse osmosis producing water, the membrane-distillation producing water and evaporative-crystallization producing water produced in the treating process can be reused for a production process, water resources are recycled to the most degree while the problem of wastewater discharging is solved, and zero discharging of high-salinity wastewater is basically achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of treatment recovery method of phosphoric acid waste liquid

ActiveCN104973725BPromote regenerationSimple and fast operationMultistage water/sewage treatmentPhosphorus compoundsLiquid wasteIndustrial waste water

Owner:CHINA PETROLEUM & CHEM CORP +1

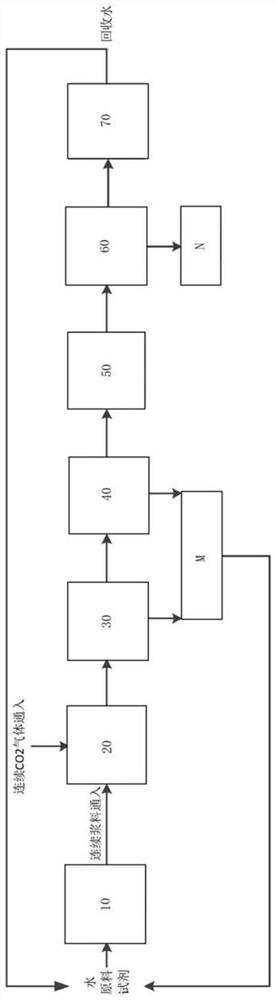

Carbon dioxide-based hydrometallurgical multistage reaction and separation system

ActiveCN111558606BReduce lossesContinuous responseSolid waste disposalSedimentation separationHydrometallurgySlurry

This application discloses a multi-stage reaction and separation system for hydrometallurgy based on carbon dioxide, including: a raw material pre-washing device, industrial waste or ore raw materials or tailings, reagents and water are continuously put into the raw material pre-washing device according to a certain ratio and fully mixed The reaction device, the slurry is continuously injected into the reaction device, the carbon dioxide is continuously injected into the reaction device, and the reacted slurry is continuously discharged; the multi-stage solid-liquid separation device performs multi-stage solid-liquid separation of the slurry, and the solid-liquid The separated unreacted solid particles are circulated to the expected pre-washing device; the third product preparation device, which contains the target calcium ions and magnesium ions in the clear liquid to prepare calcium and magnesium products; the recovery water circulation device, the recovered water is recycled to the system. The application can realize continuous reaction, realize the maximization of processing capacity, and also provide possibility for multi-stage circulation reaction, and also reduce the loss of carbon dioxide in the discharge process of batch reaction.

Owner:GREENORE CLEANTECH (SHANGHAI) CO LTD

A zero-discharge method for high-concentration wastewater

ActiveCN105198143BRealize in-depth treatment and even zero discharge problemsEfficient reverse osmosis treatmentMultistage water/sewage treatmentEnergy based wastewater treatmentHigh concentrationPost precipitation

The invention relates to the field of industrial wastewater treatment, in particular to a zero-discharge method for high-concentration wastewater. The present invention adopts the method of "nanofiltration + high-efficiency reverse osmosis + membrane distillation + evaporation crystallization" to treat high-concentration wastewater. Afterwards, high-efficiency reverse osmosis technology is used to carry out deep concentration treatment on nanofiltration product water, and the obtained high-efficiency reverse osmosis concentrated water is then subjected to membrane distillation deep concentration treatment, and the obtained membrane distillation concentrated water is then subjected to evaporation and crystallization treatment, and the membrane distillation concentrated water The salt solids crystallize out and are concentrated and dried for disposal. Among them, the nanofiltration concentrated water is added with salt for precipitation treatment to obtain calcium slag, and the supernatant after precipitation is adsorbed by activated carbon and mixed with high-concentration wastewater into the nanofiltration unit for recycling treatment. The method of the invention not only solves the problem of high-concentration wastewater discharge, but also recycles water resources to the greatest extent, and basically realizes zero discharge of high-concentration wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

A new type of solar decompression multi-effect membrane distillation device

ActiveCN107213793BEfficient use ofImprove utilization efficiencyMembranesGeneral water supply conservationThermodynamicsWater vapor

The invention discloses a novel solar energy reduced-pressure multiple-effect membrane distillation apparatus, and aims to utilize solar energy to replace conventional electrical heating as a heat source and heat a raw material fluid to reach a goal of saving energy and reducing consumption. A set of simple Venturi system is used to replace a vacuum pump which is used in the reduced-pressure multiple-effect membrane distillation, so that energy consumption in a membrane distillation operation process is further reduced, and 100% collection of produced water is realized, and the membrane flux is improved. The application of multiple-effect membrane components realizes the effective utilization of phase transformation heat of a water vapor, and the heat-utilization rate is improved. The novel Venturi-solar energy reduced-pressure multiple-effect membrane distillation system is adopted, so that the total energy consumption and the operation cost in the membrane distillation process are greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A zero-discharge method for high-temperature and high-salt wastewater

ActiveCN105198141BSolve the problem of advanced treatment and even zero dischargeEfficient use ofMultistage water/sewage treatmentMembrane distillationProduced water

Owner:CHINA PETROLEUM & CHEM CORP +1

A zero-discharge method for high-salt and high-hardness wastewater

ActiveCN105198144BRealize in-depth treatment and even zero discharge problemsGood dehardening effectMultistage water/sewage treatmentReverse osmosisWater resources

The invention relates to the field of industrial wastewater treatment, in particular to a high-salinity high-hardness wastewater zero-discharging method. According to the method, a 'microfiltration and hardness removal + efficient reverse osmosis + membrane distillation + evaporative crystallization' method is adopted to treat high-salinity high-hardness wastewater. Firstly, a microfiltration and hardness removal technology is adopted to remove hardness of the high-salinity high-hardness wastewater, then an efficient reverse osmosis technology is adopted to further concentrate the wastewater without hardness so as to obtain efficient reverse osmosis producing water and efficient reverse osmosis concentrated water, deep concentration is conducted on the efficient reverse osmosis concentrated water through membrane distillation to obtain membrane-distillation producing water and membrane-distillation concentrated water, evaporative crystallization treatment is further conducted on the membrane-distillation concentrated water to enable salt solids in the concentrated water to crystallize out, and centralized drying disposal is performed. The efficient reverse osmosis producing water, the membrane-distillation producing water and evaporative-crystallization producing water produced in the treating process can be reused for a production process, water resources are recycled to the most degree while the problem of wastewater discharging is solved, and zero discharging of high-salinity high-hardness wastewater is basically achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

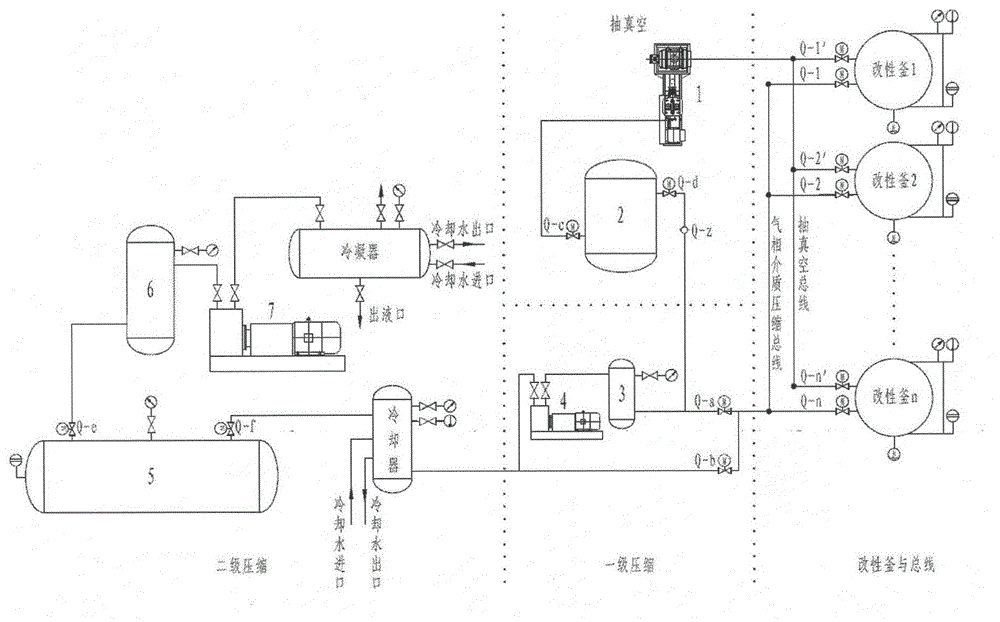

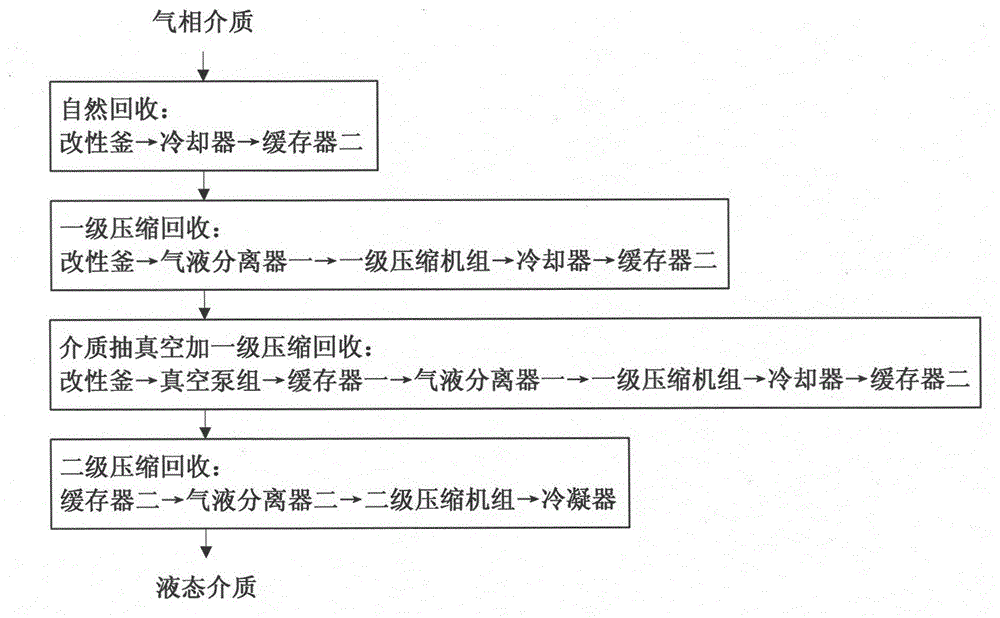

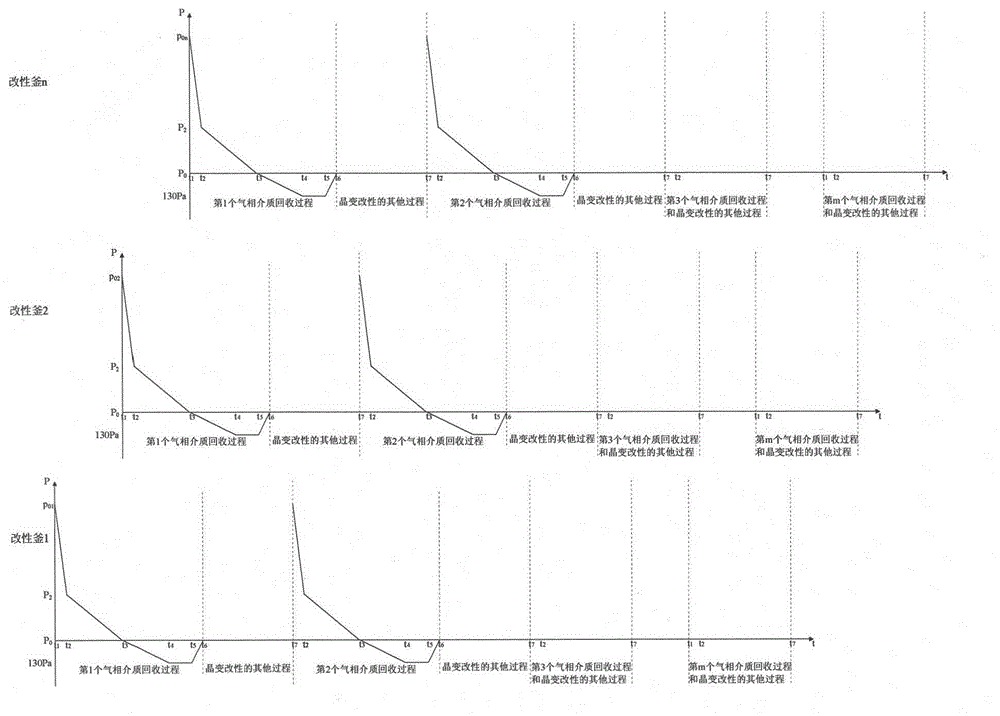

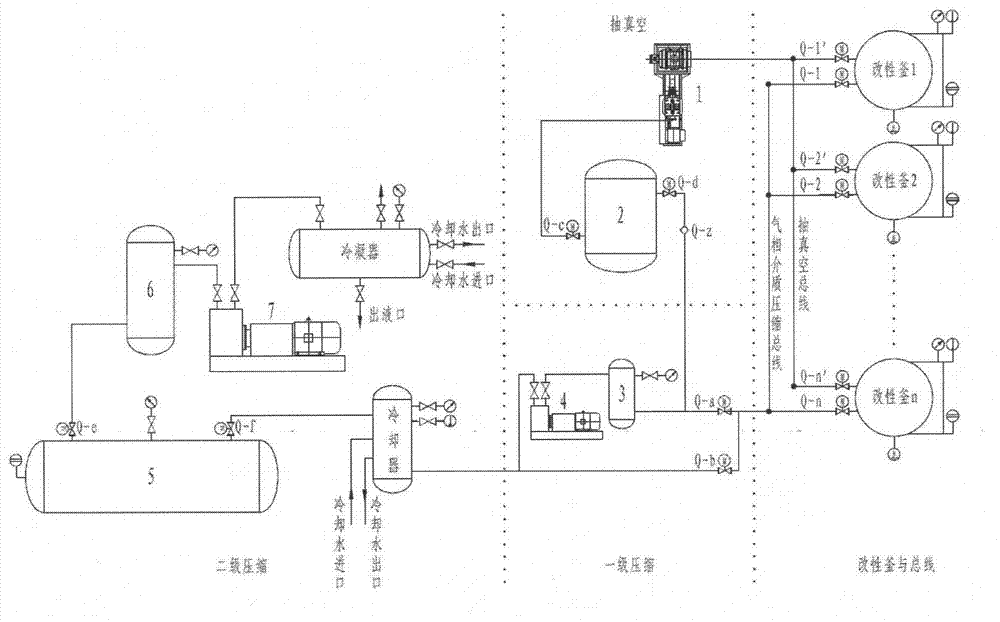

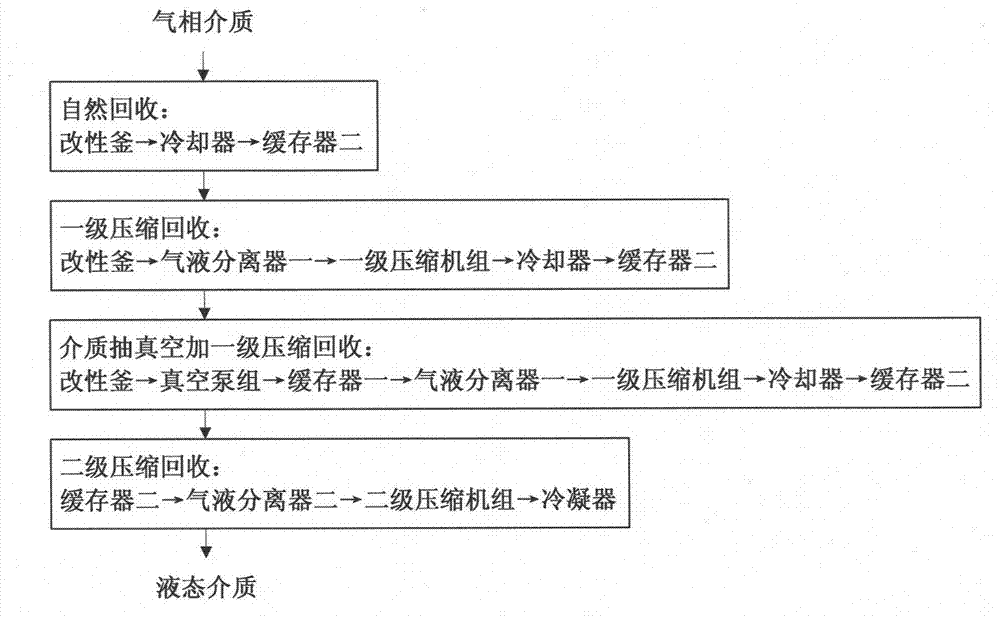

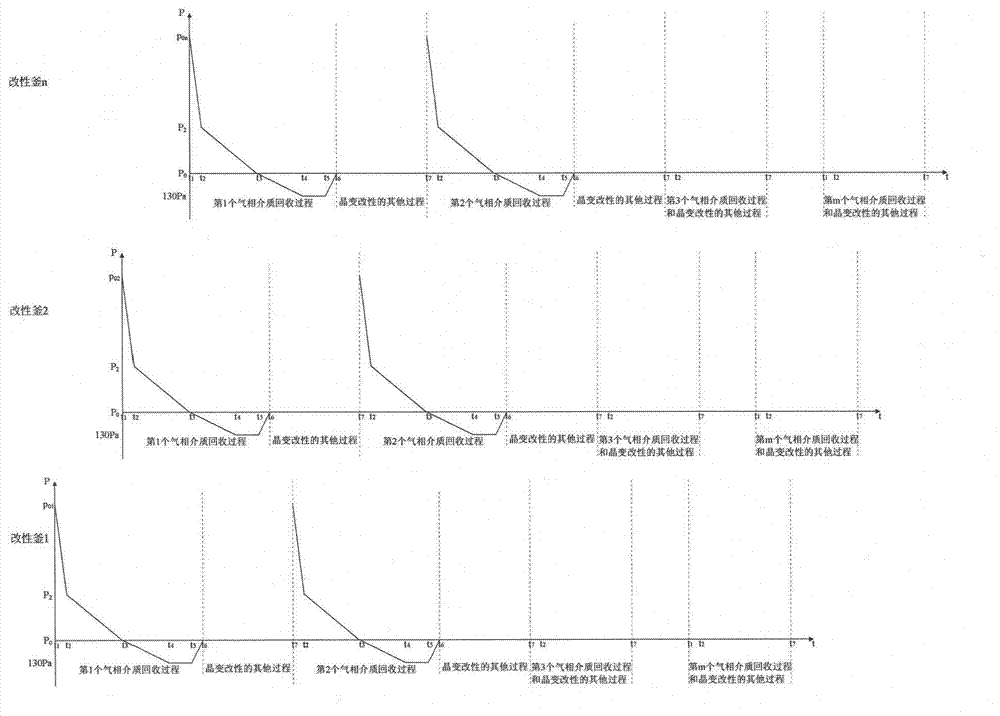

Gas-phase medium recovery system and method for natural fiber crystal transformation modification based on multi-bus and multi-modification kettle parallel

InactiveCN103031683BIncrease profitIncrease productivityTextile treatment machine arrangementsGas phaseProcess engineering

The invention provides a system for recovering a natural fiber crystallized and modified gaseous phase medium on basis of multi-bus and multi-modification reactor parallel operation. The system comprises a vacuum bus, a gaseous phase medium compression bus, n modification reactors which are connected to the vacuum bus and the gaseous phase medium compression bus in parallel, vacuum branches which are connected onto the vacuum bus in parallel, a first-level compression branch which is connected onto the gaseous phase medium compression bus in parallel, a second-level compression branch which is connected onto the first-level compression branch in series and a plurality of valves, wherein n is not less than 1. The invention further provides a method for recovering the natural fiber crystallized and modified gaseous phase medium on basis of multi-bus and multi-modification reactor parallel operation. The method comprises natural recovering, first-level compression recovering, medium vacuumizing and first-level compression recovering and second-level compression recovering. By the system and method, the modified medium is completely recovered, efficiently condensed and circularly used, so that a non-pollution and zero emission modifying process is realized, energy is saved and consumption is reduced; and the system and the method have the advantages that a set of medium recovering equipment serves a plurality of modification reactors, the modification reactors operate in parallel, the utilization rate and production efficiency of the equipment are increased, the equipment cost and the production cost are lowered.

Owner:DONGHUA UNIV +1

A zero-discharge method for high-salt and high-ammonia-nitrogen wastewater

ActiveCN104609587BHigh recovery rateImprove water qualityWater contaminantsMultistage water/sewage treatmentSalt-wastingWater quality

The invention discloses a treatment method of high-salt high-ammonia-nitrogen waste water. The treatment method comprises steps of membrane absorption, nanofiltration, forward osmosis, and cooling crystallization. According to the treatment method, a sulfuric acid solution is taken as an absorption liquid, ammonia nitrogen in waste water is changed into ammonium sulfate via membrane absorption; obtained ammonium sulfate solution is concentrated further via nanofiltration; the concentrated ammonium sulfate solution is taken as a driving liquid of forward osmosis, a high-salt waste water obtained after ammonia nitrogen removing via membrane absorption is taken as a feed liquid of forward osmosis, and forward osmosis concentration is carried out; the ammonium sulfate solution is diluted, and a part of the diluted ammonium sulfate solution is recycled to a nanofiltration unit for concentration of a second time; after a plurality of forward osmosis concentration, concentrated water of a forward osmosis unit is subjected to cooling crystallization; and an obtained supernate is recycled for circulating concentration, and obtained crystal is dried and is subjected to concentrated disposal. The treatment method is used for treatment of high-salt high-ammonia-nitrogen waste water, almost no concentrated water is discharged, problems of high-salt high-ammonia-nitrogen waste water treatment are solved effectively, water recovery rate is high, quality of obtained water is high, and recovery of water resource of high-salt high-ammonia-nitrogen waste water is realized as far as possible.

Owner:CHINA PETROLEUM & CHEM CORP +1

A treatment method for high-salt wastewater

ActiveCN104609621BEfficient use ofSimple methodSeawater treatmentWater/sewage treatment bu osmosis/dialysisSalt-wastingEvaporation

The invention discloses a high-salt waste water treatment method. According to the high-salt waste water treatment method, concentration of high-salt waste water is carried out via membrane distillation; an obtained membrane distillation concentrated water is taken as a driving liquid of forward osmosis; the membrane distillation concentrated water is diluted via continuous concentration of forward osmosis feeding liquid collateral circulation raw water, when the concentration of the diluted membrane distillation concentrated water is equal to a certain concentration, the membrane distillation concentrated water is recycled to a membrane distillation unit for concentration treatment; and the above steps are repeated, so that deep concentration of the high-salt waste water is realized, and water of the high-salt waste water and forward osmosis raw water is recycled as far as possible. The high-salt waste water treatment method can be used for processing high-salt waste water, and can also be used for concentration treatment of river water, brackish water, seawater, surface water, municipal wastewater, petrochemical wastewater, landfill leachate, and solutions containing medicines and protein. No impressed pressure or little impressed pressure is needed for treatment; the high-salt waste water treatment method is simple and convenient; operation is simple; and operation cost is low compared with multiple-effect evaporation.

Owner:CHINA PETROLEUM & CHEM CORP +1

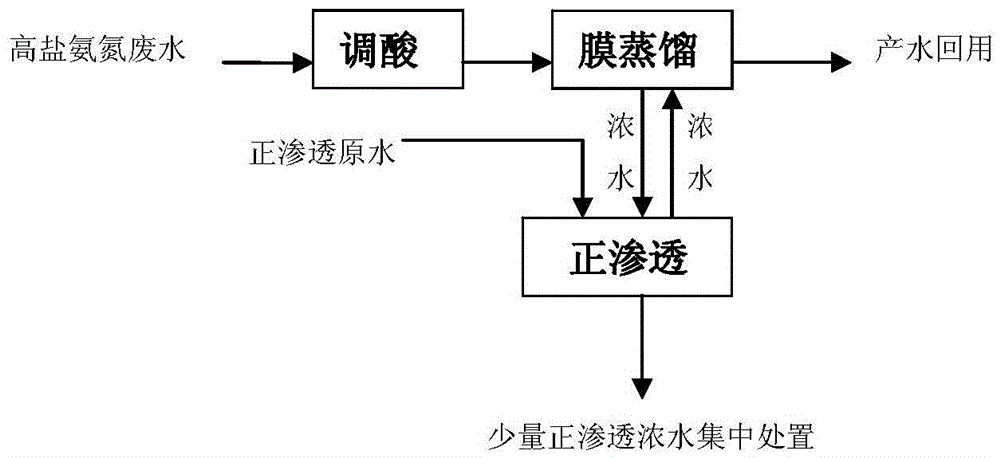

A treatment method for high-salt ammonia nitrogen wastewater

ActiveCN104591456BEfficient use ofSimple methodMultistage water/sewage treatmentWater qualityMembrane distillation

The invention discloses a high salinity ammonia nitrogen wastewater treatment method. The method adopts an acid adjustment + membrane distillation + forward osmosis process flow. The method is characterized in that acidity adjustment pretreatment of high salinity ammonia nitrogen wastewater is carried out according to the characteristics of wastewater and the characteristic of most ammonia nitrogen existing in the ammonia nitrogen wastewater with a low pH value as NH<+>, a membrane distillation technology is adopted to concentrate the acid adjusted high salinity ammonia nitrogen wastewater, high salinity membrane distilled concentrated water is used as a driving liquid of forward osmosis and is diluted through the continuous concentration of raw water at a forward osmosis inlet liquid side, and when the membrane distilled concentrated water is diluted to a specific concentration, the diluted concentrated water returns to a membrane distillation unit and is continuously concentrated. The process flow is cycled, and the advanced concentration treatment of the high salinity ammonia nitrogen wastewater is carried out to obtain a large amount of pure water and solve a problem that the membrane distilled concentrated water generated in the high salinity ammonia nitrogen wastewater treatment is difficult to treat, so the wastewater recovery rate is maximally improved, and the method has important environmental benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

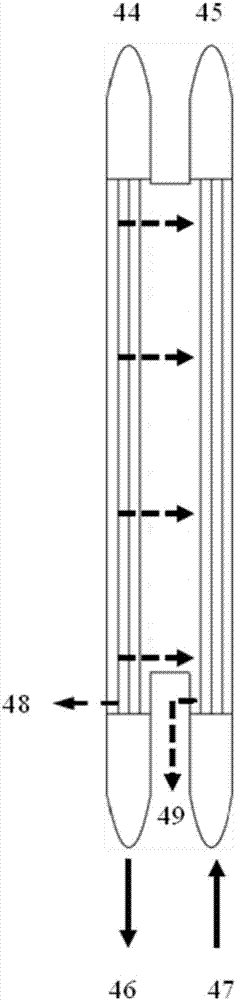

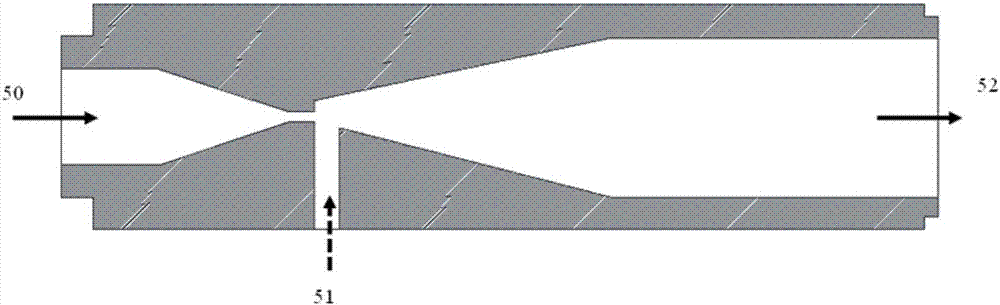

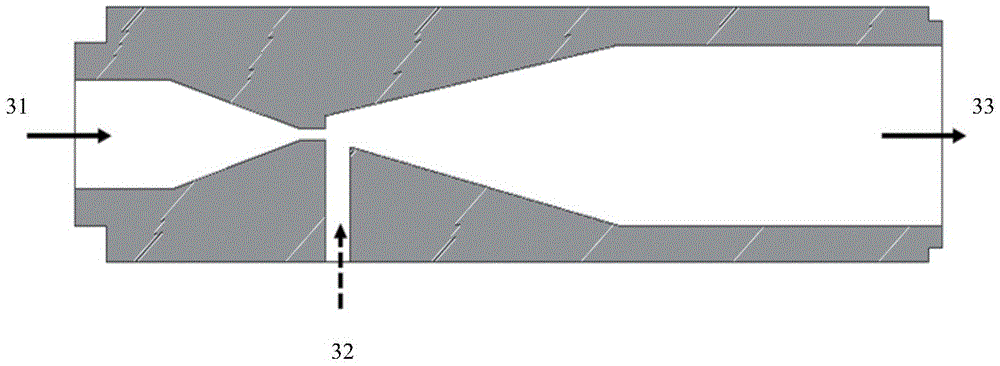

Vacuum multiple-effect membrane distillation device coupled with venturi effect

InactiveCN107174953AReduce energy consumptionRealize the collectionDistillationDiaphragm pumpWater vapor

The invention discloses a vacuum multiple-effect membrane distillation device coupled with a venturi effect, which aims to utilize a multiple-effect membrane distillation component for recycling water vapor transformation heat and improving heat efficiency of a membrane distillation process. In order to further reduce energy consumption of the multiple-effect membrane distillation operation process, a set of simple and easy venturi system is used for replacing a vacuum pump used in the vacuum multiple-effect membrane distillation device. The venturi system is formed by a venturi tube, a control valve, a rotormeter, a diaphragm pump and a producing water / cold water basin. By using the venturi-vacuum multiple-effect membrane distillation system, energy consumption produced during a pump vacuumizing process can be reduced, the damage on the vacuum pump caused by water vapor during long-time operation is avoided, the continuous and stable operation time of the system is prolonged, an existing vacuum multiple-effect membrane distillation system is optimized and simplified, and the overall operation cost of the membrane distillation process is reduced. Meanwhile, producing water is completely collected, transformation heat is fully utilized, and heat efficiency of the membrane distillation process is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

System and method for recovering natural fiber crystallized and modified gaseous phase medium on basis of multi-bus and multi-modification reactor parallel operation

InactiveCN103031683AGuaranteed non-interferenceIncrease profitTextile treatment machine arrangementsGas phaseProcess engineering

The invention provides a system for recovering a natural fiber crystallized and modified gaseous phase medium on basis of multi-bus and multi-modification reactor parallel operation. The system comprises a vacuum bus, a gaseous phase medium compression bus, n modification reactors which are connected to the vacuum bus and the gaseous phase medium compression bus in parallel, vacuum branches which are connected onto the vacuum bus in parallel, a first-level compression branch which is connected onto the gaseous phase medium compression bus in parallel, a second-level compression branch which is connected onto the first-level compression branch in series and a plurality of valves, wherein n is not less than 1. The invention further provides a method for recovering the natural fiber crystallized and modified gaseous phase medium on basis of multi-bus and multi-modification reactor parallel operation. The method comprises natural recovering, first-level compression recovering, medium vacuumizing and first-level compression recovering and second-level compression recovering. By the system and method, the modified medium is completely recovered, efficiently condensed and circularly used, so that a non-pollution and zero emission modifying process is realized, energy is saved and consumption is reduced; and the system and the method have the advantages that a set of medium recovering equipment serves a plurality of modification reactors, the modification reactors operate in parallel, the utilization rate and production efficiency of the equipment are increased, the equipment cost and the production cost are lowered.

Owner:DONGHUA UNIV +1

Membrane coupling method for treating high-salt and high-ammonia-nitrogen wastewater

ActiveCN104609588BHigh recovery rateEmission reductionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSalt-wastingCoupling

The invention discloses a method used for processing high-salt high-ammonia-nitrogen waste water via membrane coupling. The method comprises steps of membrane absorption, reverse osmosis, and forward osmosis coupling. According to the method, an acid solution is taken as an absorption liquid, ammonia nitrogen in waste water is changed into ammonium salts via membrane absorption; obtained ammonium salt solution is concentrated further via reverse osmosis; the concentrated ammonium salt solution is taken as a driving liquid of forward osmosis, a high-salt waste water obtained after ammonia nitrogen removing via membrane absorption is taken as a feed liquid of forward osmosis, and forward osmosis concentration is carried out; the driving liquid ammonium salt solution is diluted, and a part of the ammonium salt solution is recycled to a reverse osmosis unit for recycling concentration. The method is capable of solving processing problems of high-salt high-ammonia-nitrogen waste water, water recovery yield is high, and quality of obtained water is excellent. The method is used for recycling concentration of high-salt high-ammonia-nitrogen waste water, concentrated water discharge amount is extremely low, and recovery of high-salt high-ammonia-nitrogen waste water is realized as far as possible.

Owner:CHINA PETROLEUM & CHEM CORP +1

A treatment method for high-salt and high-ammonia-nitrogen wastewater

ActiveCN104591423BHigh recovery rateEmission reductionWater contaminantsMultistage water/sewage treatmentWater qualityWater resources

Owner:CHINA PETROLEUM & CHEM CORP +1

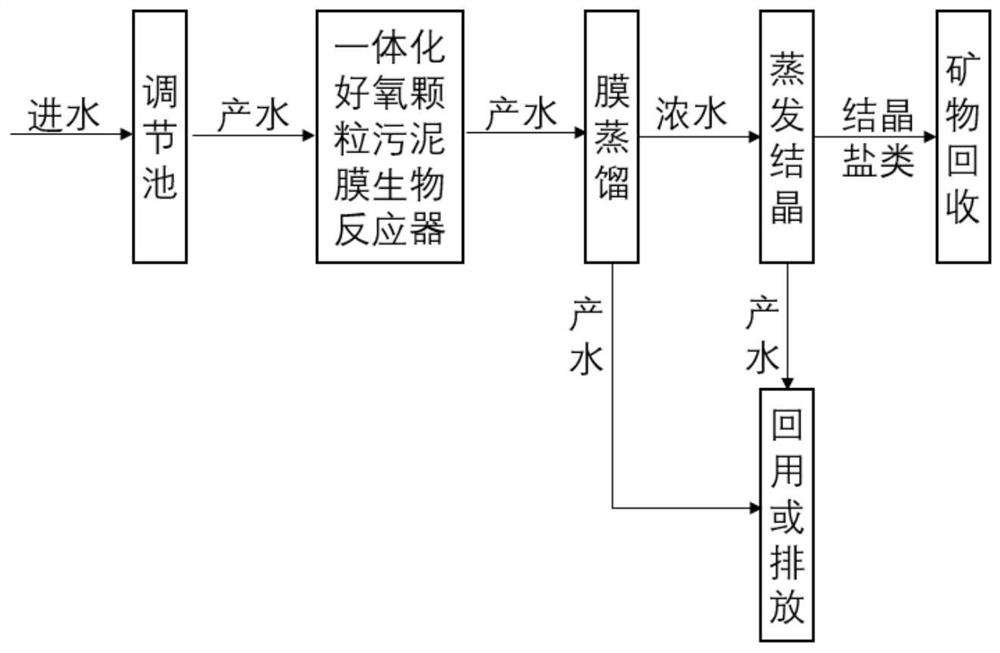

A treatment system for resource utilization and zero discharge of high-salt and high-organic waste water

ActiveCN110577325BSolve resource problemsSolve zero emissionsCalcium/strontium/barium chloridesWater contaminantsWater resourcesMembrane distillation

The invention discloses a high-salt and high-organic-matter wastewater resource utilization and zero-discharge treatment system, comprising a regulating tank, an integrated aerobic granular sludge membrane bioreactor, a membrane distillation unit and an evaporation crystallization unit. The regulating tank stabilizes the water quality and quantity and precipitates part of the suspended matter, the integrated aerobic granular sludge membrane bioreactor removes most of the suspended matter and organic matter in the wastewater, and the membrane distillation unit removes ions and some remaining organic matter in the waste water, evaporates and crystallizes The unit treats membrane distillation concentrated water, evaporates and recovers water resources, crystallizes and recovers salt solids in membrane distillation concentrated water, and finally realizes the purpose of high-salt and high-organic wastewater water resources and salt resources recycling and zero discharge of wastewater. The invention can effectively solve the problem of resource utilization and zero discharge of high-salt and high-organic waste water, recycle water resources and salt resources to the greatest extent, and simultaneously realize zero discharge in the production process of high-salt and high-organic matter, and has important environmental benefits.

Owner:重庆阁林环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com