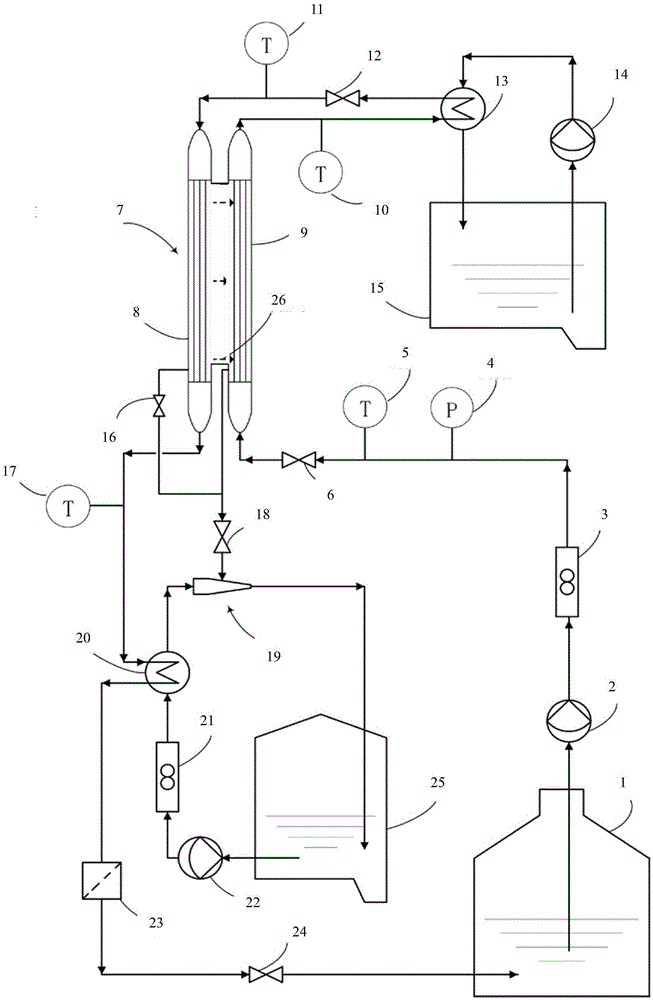

Vacuum multiple-effect membrane distillation device coupled with venturi effect

A multi-effect membrane distillation and Venturi effect technology, which is applied in the field of vacuum multi-effect membrane distillation devices, can solve problems such as vacuum multi-effect membranes that have not yet been applied, so as to prolong continuous and stable operation time, reduce overall energy consumption and operating costs, and reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0067] In my country, the Venturi-vacuum multi-effect membrane distillation system has broad application prospects. In areas where fresh water resources are scarce but brackish water is abundant, this system can be used to prepare drinking water, domestic and production water. In addition, the device can also be used to treat high-salt wastewater produced by the chemical industry.

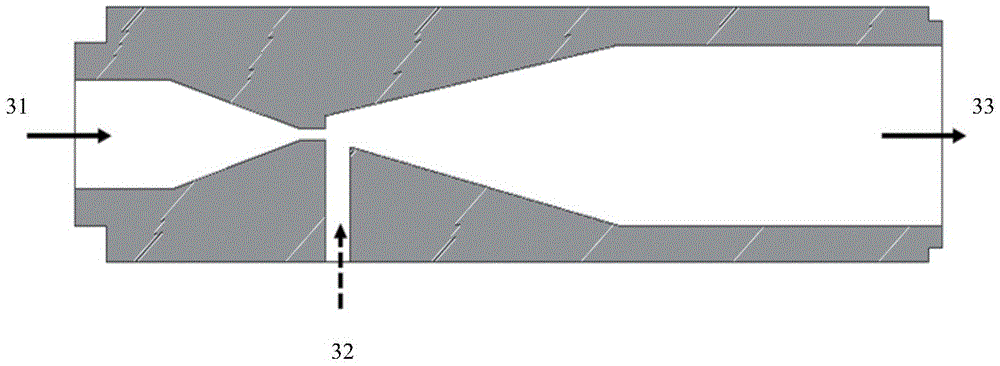

[0068] The use concentration is 35g·L -1 The NaCl salt solution is used as the raw material solution, and the flow rate is controlled by a rotameter to 120L h -1 , the flow of hot water in the hot water tank 15 is 600L·h -1 , the temperature of the raw material liquid is controlled at 80°C before entering the evaporation zone 8, and the flow rate of the cold water in the Venturi system (cold side) is controlled at 360L h -1 , the pressure generated at the water vapor inlet 32 is 10kPa, and the maximum membrane flux obtained is 32L·m after continuous operation for 72 hours -2 h -1 , the conduc...

Embodiment example 2

[0076] The use concentration is 35g·L -1 The NaCl salt solution is used as the raw material solution, and the flow rate is controlled by a rotameter to 120L h -1 , the hot water flow in the hot water tank 15 is 600L·h -1 , the temperature of the raw material liquid before entering the evaporation zone 8 is 65°C, and the flow rate of the cold water in the Venturi system (cold side) is controlled at 360L h -1 , the pressure generated at the water vapor inlet 32 is 10kPa, the continuous operation is 104 hours, and the maximum membrane flux obtained is 12L m -2 h -1 , the conductivity of the product water is 6 μS cm -1 Around, the desalination rate is greater than 99.9%, and the water vapor phase change heat recovery rate is 52.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com