Gas-phase medium recovery system and method for natural fiber crystal transformation modification based on multi-bus and multi-modification kettle parallel

A natural fiber and crystal modification technology, applied in the field of high-end textile equipment, can solve problems such as difficult dyeing, difficult spinning, wrinkling, etc., and achieve the effects of increasing service life, reducing equipment costs, and improving operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0027] The modification medium used in this example is liquid ammonia.

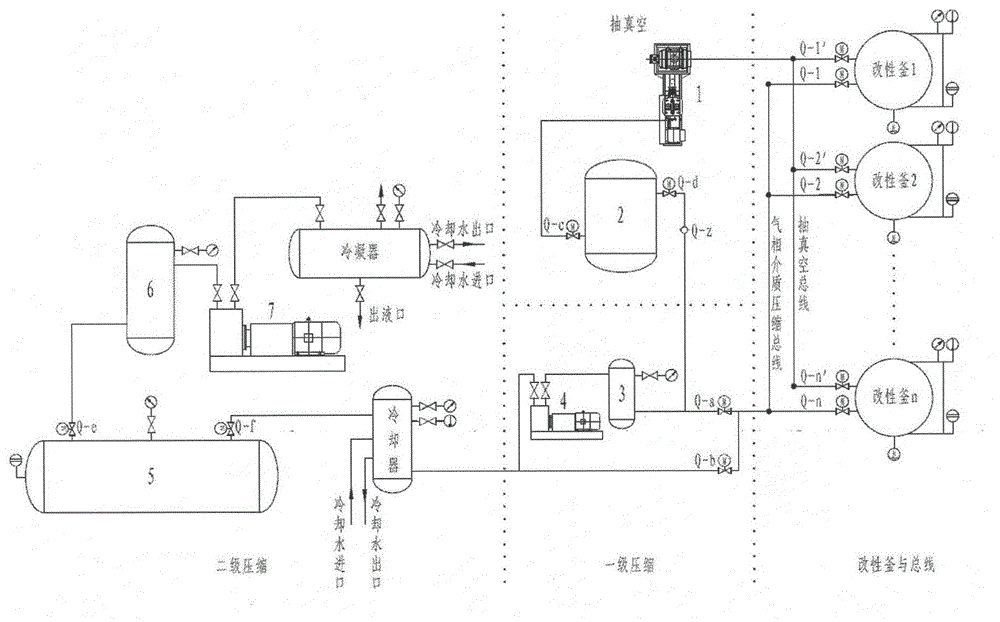

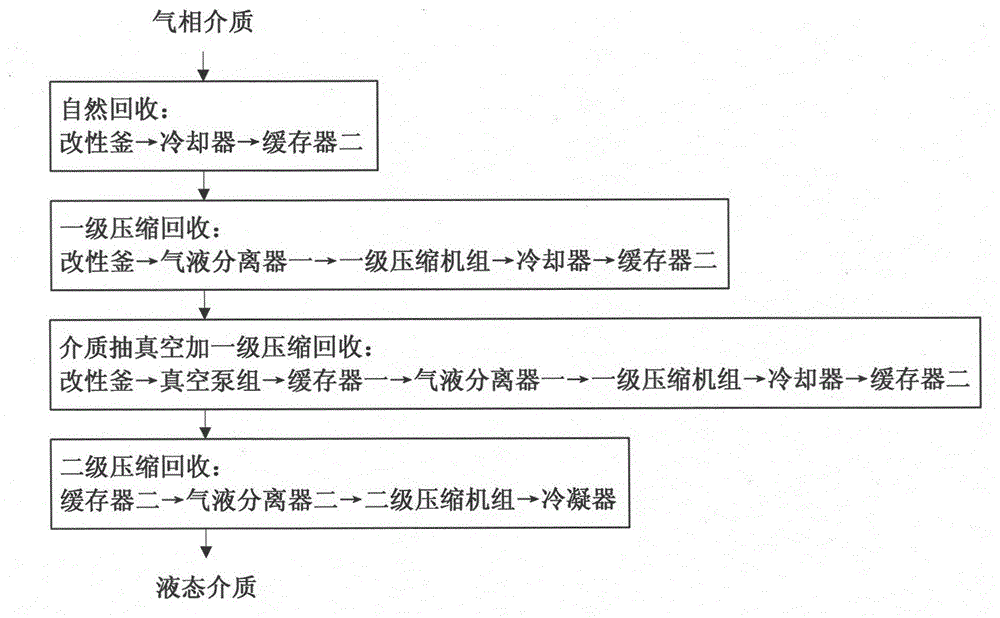

[0028] The gas-phase medium recovery system based on multi-bus and multi-modified tanks provided by the present invention is as follows: figure 1 As shown, it includes: a vacuum bus and a gas phase medium compression bus; n modified kettles connected in parallel on the vacuum bus and gas phase medium compression bus, n≥1; A first-stage compression branch on the gas phase medium compression bus, a second-stage compression branch connected in series with the first-stage compression branch; several valves.

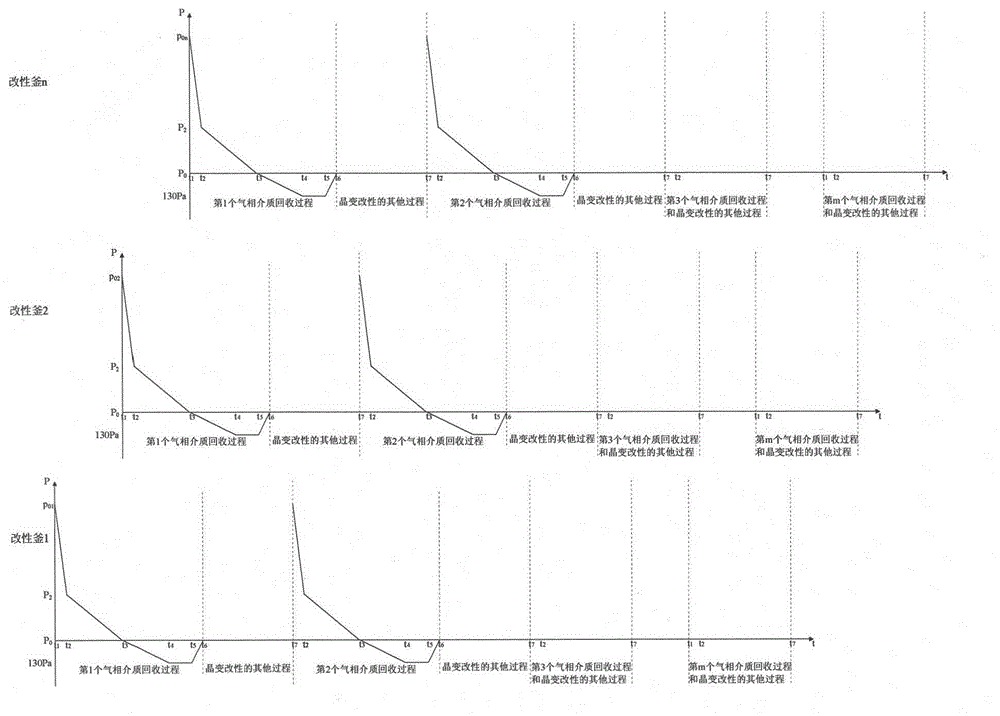

[0029] The internal pressure of modification tank i (i=1, 2,..., n) is p i (i=1, 2,..., n), the volume is equal to v i (i=1, 2, ..., n), which is equipped with a heating system and a sensor system, the natural fiber crystal modification is carried out in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com