Carbon dioxide-based hydrometallurgical multistage reaction and separation system

A carbon dioxide and multi-stage reaction technology, applied in hydrometallurgy technology, solid waste resource utilization, utilization and storage, and carbon dioxide adsorption fields, can solve the problems of wasting time, the processing capacity per unit time cannot be fully utilized, etc., to reduce losses , Realize the recycling of resources, realize the effect of carbon emission reduction and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The idea, specific structure and technical effects of the present application will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present application.

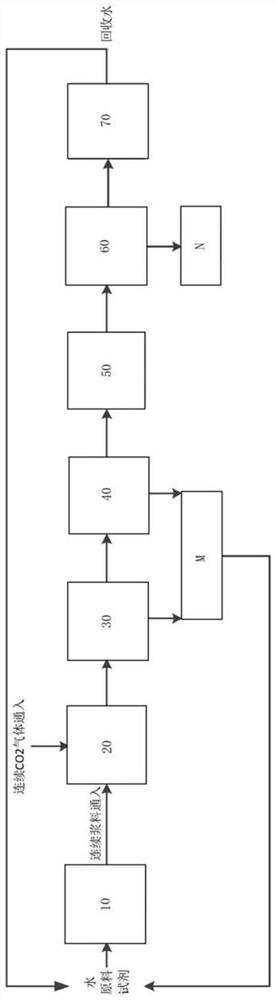

[0037] like figure 1 As shown, in one of the embodiments of the present application, a hydrometallurgical multistage reaction and separation system based on carbon dioxide, the system includes:

[0038] Raw material pre-washing device 10, industrial waste or ore raw materials or tailings, reagents and water are continuously put into the raw material pre-washing device 10 according to a certain proportion and fully mixed;

[0039] The reaction device 20, the above-mentioned slurry that has been fully mixed by the raw material pre-washing device 10 is continuously injected into the reaction device 20 through a power device; carbon dioxide is continuously injected into the reaction device 20 under a certain pressure and mixed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com