Method for fixing sieve plates of pulse sieve plate column

The technology of pulse sieve plate and fixing method is applied in the field of pulse sieve plate column sieve plate fixing, which can solve the problems of many equipment failures, affecting the mass transfer effect, large vibration, etc., and achieves convenient installation and disassembly, reduced labor intensity, and strong reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

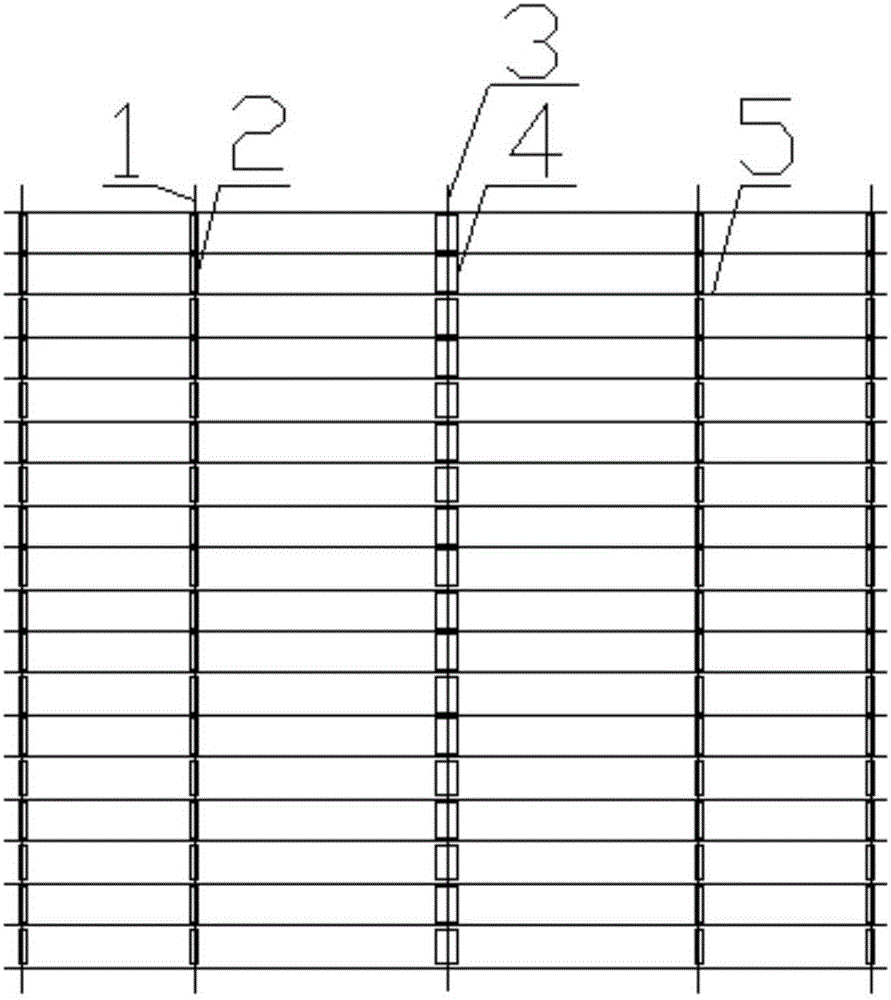

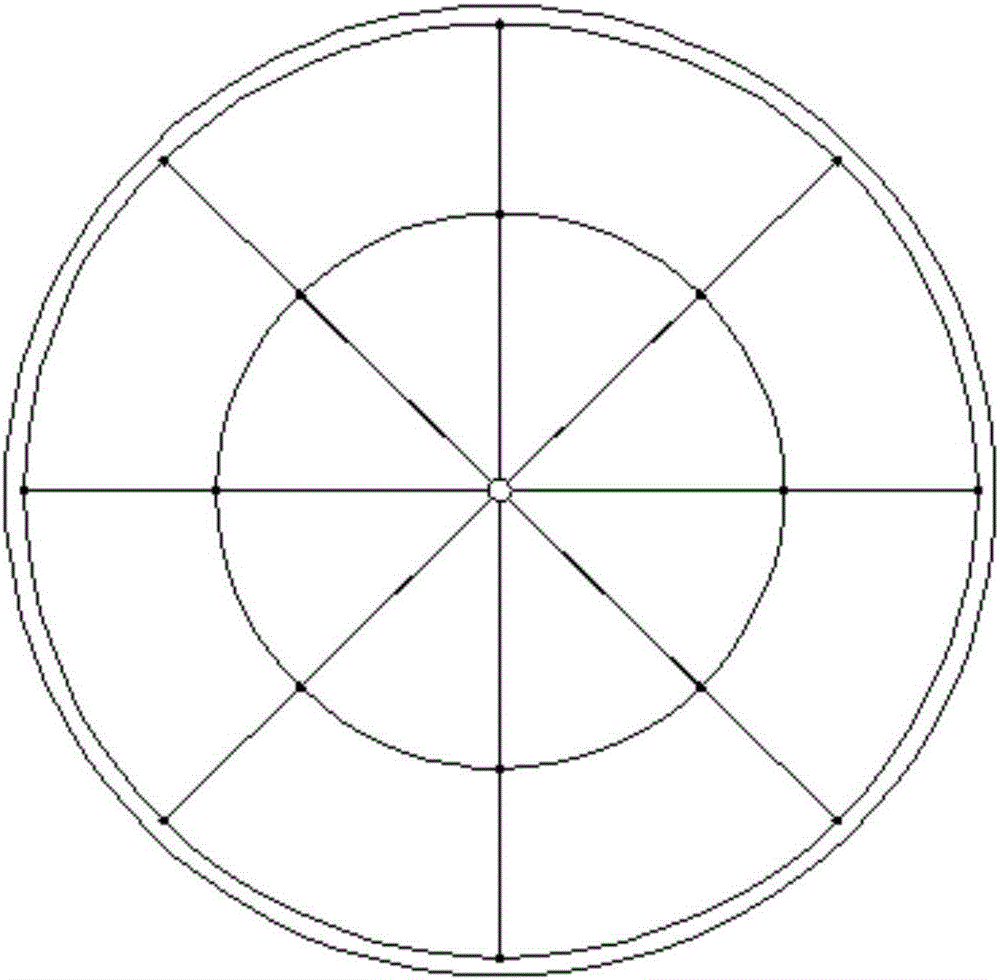

[0035] Such as figure 1 and figure 2 As shown, the present invention 1. A method for fixing the sieve plate of the pulse sieve plate column is applied in the extraction and purification process in the uranium purification production. The outlet of the bottom water phase flows out, and the organic phase enters from the inlet of the organic phase at the bottom of the column. Relying on the buoyancy and pulse force, it enters the top of the column through the sieve plate hole and flows out from the outlet of the organic phase; in the process of two-phase countercurrent, they are fully contacted to achieve qualitative separation. exchange to complete the uranium stripping operation;

[0036] It is characterized in that: comprising the following steps:

[0037] (1) Determine the main components

[0038] The main comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com