Plastics film composed of rigid polyvinyl chloride (rpvc) and process for its production

A technology of rigid polyvinyl chloride and plastic film, applied in the field of plastic film, can solve the problem of high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

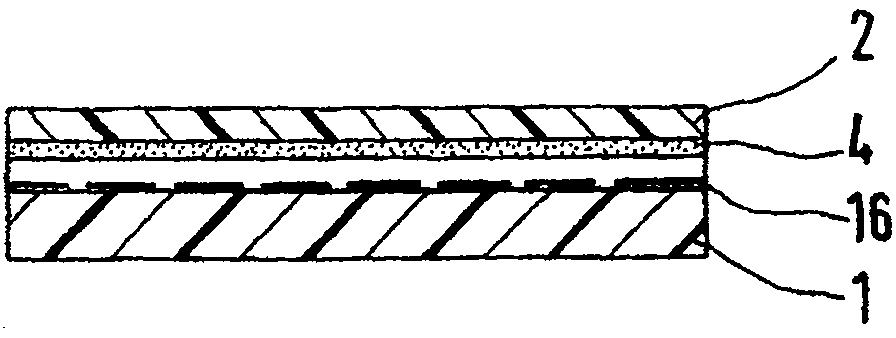

[0035] figure 1 A plastic film 1 is shown to which a protective cover film 2 has been applied by lamination with an adhesive layer 4 . The plastic film 1 is made of calendered rigid polyvinyl chloride (RPVC) film, and the thickness of the plastic film 1 is in the range of 25 to 40 μm, specifically, the thickness of the film is 25, 35, or 37 μm. Similarly, the protective covering film 2 is also made of rigid polyvinyl chloride material, and its thickness is in the range of 10 to 25 μm. Specifically, if the thickness of the plastic film 1 is 25 μm, the thickness of the protective cover film 2 is 25 μm. If the plastic film 1 has a thickness of 35 μm, the protective cover film 2 has a thickness of 20 μm. If the thickness of the plastic film is 37 μm, the thickness of the protective cover film is between 10 μm and 20 μm. The top surface of the plastic film has a printed layer 16 .

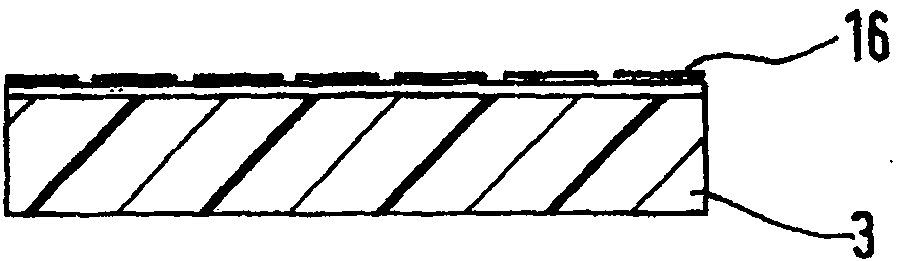

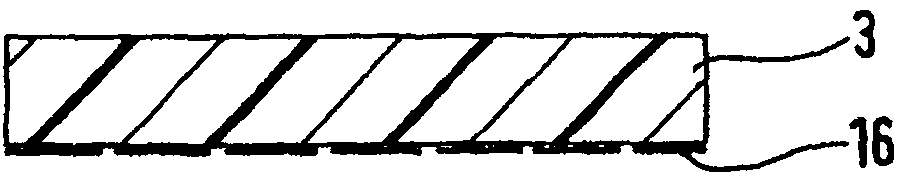

[0036] figure 2 A plastic film 3 is shown, which is a single-layer film structure with a thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com