Stereo garage bottom plate

A technology of three-dimensional garage and bottom plate, which is applied in the direction of buildings, building types, buildings, etc. where cars are parked, and can solve serious and safety accidents and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

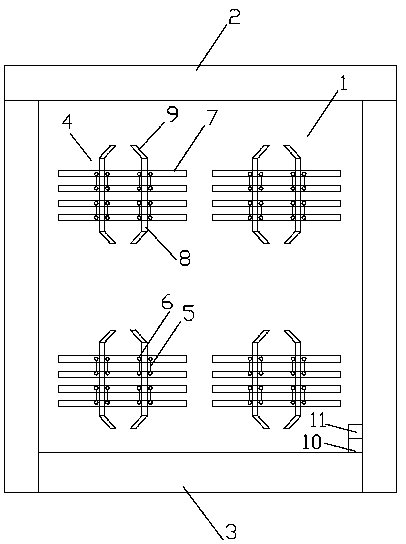

[0014] A kind of three-dimensional garage base plate comprises base plate main body 1, and the surrounding of described base plate main body 1 is provided with baffle plate 2, wherein the baffle plate 2 that the automobile entrance and exit direction of base plate main body 1 is provided with is telescopic baffle plate 3; There are at least two tire fixing devices, the tire fixing device includes a pair of tire pressure plates 4, the bottom of the tire pressure plate 4 is provided with a connecting column 5, the bottom of the connecting column 5 is provided with a pulley 6, and the bottom plate main body 1 is provided with a There is at least one transverse slide rail 7, and the pulley 6 is matched with the transverse slide rail 7. When the automobile enters the floor main body 1, it will be surrounded by the baffles 2 around the floor main body 1 to provide basic protection. Secondly, through the freely adjustable tire pressure plate 4 structure on the floor main body 1, the l...

Embodiment 2

[0016] A kind of three-dimensional garage base plate comprises base plate main body 1, and the surrounding of described base plate main body 1 is provided with baffle plate 2, wherein the baffle plate 2 that the automobile entrance and exit direction of base plate main body 1 is provided with is telescopic baffle plate 3; There are at least two tire fixing devices, the tire fixing device includes a pair of tire pressure plates 4, the bottom of the tire pressure plate 4 is provided with a connecting column 5, the bottom of the connecting column 5 is provided with a pulley 6, and the bottom plate main body 1 is provided with a There is at least one transverse slide rail 7, and the pulley 6 is matched with the transverse slide rail 7.

[0017] The tire pressure plate 4 includes a vertical portion 8 and inclined portions 9 located on both sides of the vertical portion 8, and the inclined portion 9 is arranged towards the direction of the tire.

[0018] The bottom of the telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com