High salinity and high ammonia nitrogen wastewater treatment method

A treatment method and high-ammonia nitrogen technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of running time, high ammonia nitrogen removal rate and high water recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

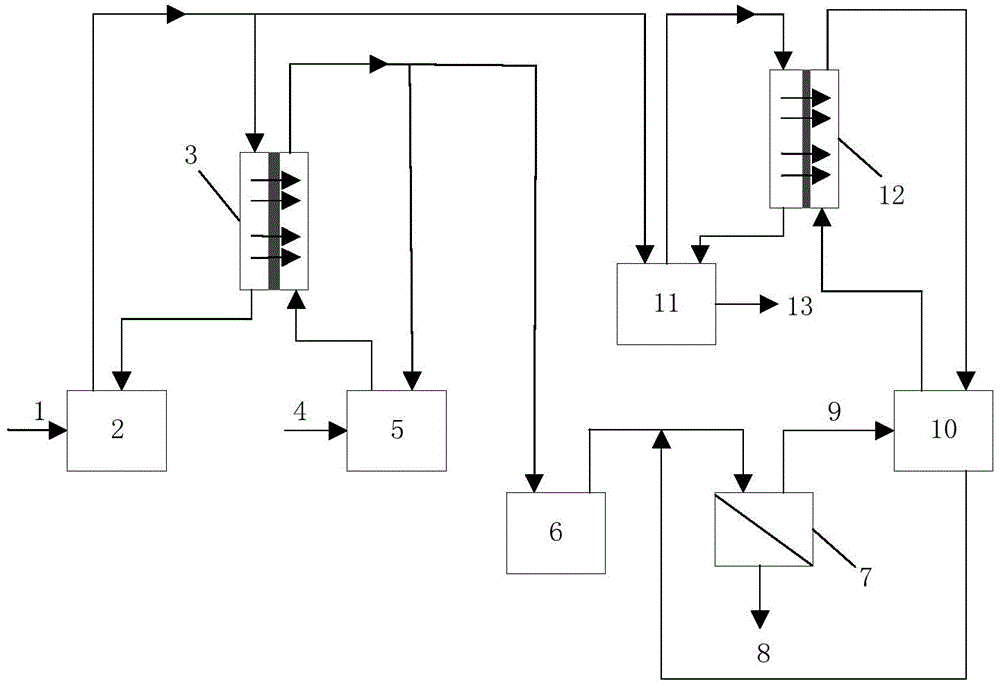

[0054] For a schematic diagram of the process, see figure 1 . The water quality characteristics of high-salt and high-ammonia-nitrogen wastewater 1 in the figure are: wastewater pH 8.5, conductivity 5mS / cm, COD cr 80mg / L, SS 100mg / L, Na + 1000mg / L, NO 3 - 2000mg / L, Cl - 50mg / L, Ca 2+ 0mg / L, NH 4 -N 500mg / L.

[0055] The membrane absorption module used is a polytetrafluoroethylene (PTFE) hollow fiber microporous hydrophobic membrane module with a membrane pore size of 0.2 μm; the nanofiltration membrane module used is a polyamide roll-type membrane module with a membrane pore size of 2 nm; the forward osmosis membrane module used is Cellulose acetate plate and frame membrane module;

[0056] The steps are as follows: (1) film absorption. High-salt and high-ammonia-nitrogen waste water 1 enters the membrane absorption raw water tank 2, and the high-salt and high-ammonia nitrogen waste water in the membrane absorption raw water tank 2 is pumped into the feed liquid s...

Embodiment 2

[0061] For a schematic diagram of the process, see figure 1 . The water quality characteristics of high-salt and high-ammonia-nitrogen wastewater 1 in the figure are: wastewater pH 9.3, conductivity 25mS / cm, COD cr 80mg / L, SS 100mg / L, Na + 5000mg / L, NO 3 - 10000mg / L, Cl - 270mg / L, Ca 2+ 20mg / L, NH 4 -N 6000mg / L.

[0062] The membrane absorption module used is a polytetrafluoroethylene (PTFE) hollow fiber microporous hydrophobic membrane module with a membrane pore size of 0.2 μm; the nanofiltration membrane module used is a polyamide roll-type membrane module with a membrane pore size of 2 nm; the forward osmosis membrane module used is Cellulose acetate plate and frame membrane module;

[0063] The operating steps are different from Example 1 in that: the absorption liquid used in the step (1) has a concentration mass fraction of 7 % sulfuric acid solution; after step (1) when the pH of the ammonium sulfate solution reaches 4, enter step (2) concentration treatm...

Embodiment 3

[0068] For a schematic diagram of the process, see figure 1 . The water quality characteristics of high-salt and high-ammonia-nitrogen wastewater 1 in the figure are: wastewater pH 10, conductivity 50mS / cm, COD cr 80mg / L, SS200mg / L, Na + 10000mg / L, NO 3 - 20000mg / L, Cl - 500mg / L, Ca 2+ 30mg / L, NH 4 -N 10000mg / L.

[0069] The membrane absorption module used is a polytetrafluoroethylene (PTFE) hollow fiber microporous hydrophobic membrane module with a membrane pore size of 0.2 μm; the nanofiltration membrane module used is a polyamide roll-type membrane module with a membrane pore size of 2 nm; the forward osmosis membrane module used is Cellulose acetate plate and frame membrane module;

[0070] The operating steps are different from Example 1 in that: the absorption liquid used in the step (1) has a concentration mass fraction of 10 % sulfuric acid solution; after step (1) when the pH of the ammonium sulfate solution reaches 5, enter step (2) concentration treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com