A zero discharge device for high-salt and high-ammonia-nitrogen wastewater

A high-ammonia-nitrogen, zero-discharge technology, applied in the direction of water pollutants, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of substandard discharge and low recovery rate of water resources, so as to improve recovery rate and yield The effect of good water quality and prolonged continuous and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

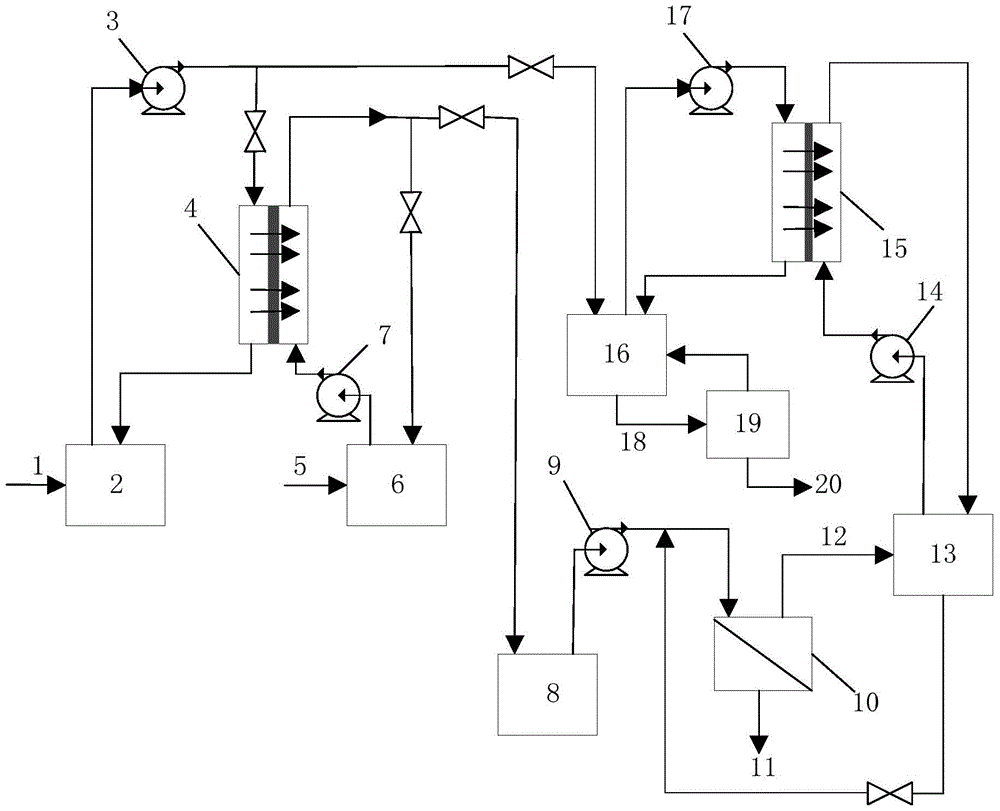

[0046] The zero discharge device for high-salt and high-ammonia-nitrogen wastewater involved in this embodiment is as follows: figure 1 shown.

[0047] The main components of the zero discharge device include: membrane absorption raw water tank 2: used to store raw water to be absorbed by the membrane; membrane absorption feed pump 3: used to pump raw water to be absorbed by the membrane into the membrane absorption module; membrane absorption module 4: It is used to separate the gas in the raw water; the absorption liquid tank 6: is used to store the absorption liquid required for the membrane absorption process; the absorption liquid feed pump 7: is used to pump the absorption liquid into the membrane absorption module; the nanofiltration raw water tank 8: uses Used to store the salt solution to be nanofiltration; nanofiltration raw water pump 9: used to pump the salt solution to be nanofiltration into the nanofiltration membrane module; nanofiltration membrane module 10: us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com