Positive and reverse spiral amplitude chip mounting head for chip mounting machine and amplitude change method of positive and reverse spiral amplitude chip mounting head

A patch head and helical technology, which is applied to the forward and reverse helical luffing patch head of the placement machine and its luffing field, can solve the problems of equal nozzle spacing and can be automatically adjusted, and achieves simple structure and improved performance. Reliable performance and action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

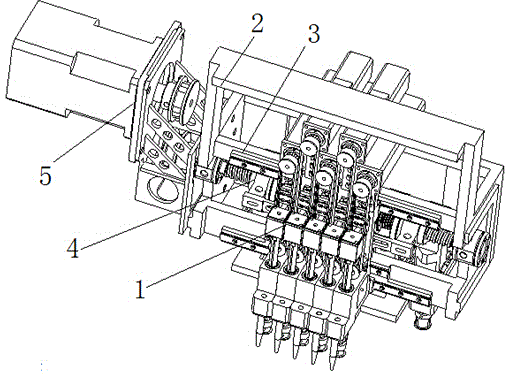

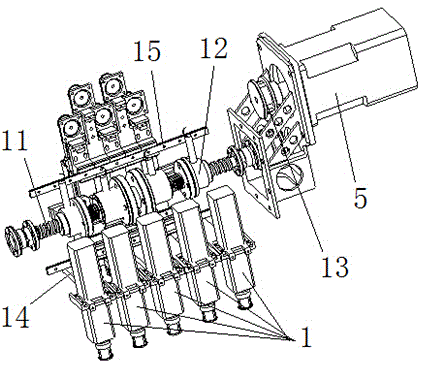

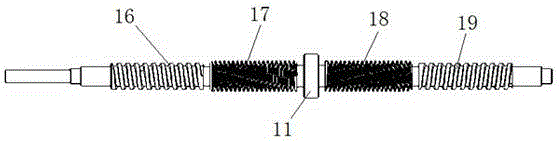

[0031] attached Figure 1-4 A technical embodiment of the present invention is given. It can be seen from the drawings that the present invention relates to a forward and reverse spiral amplitude mounter head, which includes more than two patch suction nozzles 1, and multiple patch suction nozzles 1 are arranged in parallel and combined together. Installed on the patch head bracket 2, and can slide along the p-axis linear guide rail 3, it is characterized in that a luffing mechanism 4 is also installed on the patch head bracket 2, and the luffing mechanism is connected with each patch suction nozzle assembly Together, the multiple patch suction nozzles 1 are driven by the luffing mechanism 4 installed on the patch head bracket 2 to slide along the p-axis linear guide rail 3, and are driven by the servo motor 5 through the luffing mechanism 4. Amplitude adjustment movement.

[0032] Further, among them, No. 3 suction nozzle assembly 6 is in the middle position, fixed on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com