Motor coil winding bending device

A coil winding and bending device technology, applied in the direction of electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problems that the bending range is difficult to ensure the magnet steel, affect product quality, and labor intensity is high, so as to achieve consistent bending pressure, Avoid inconsistent bending range and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

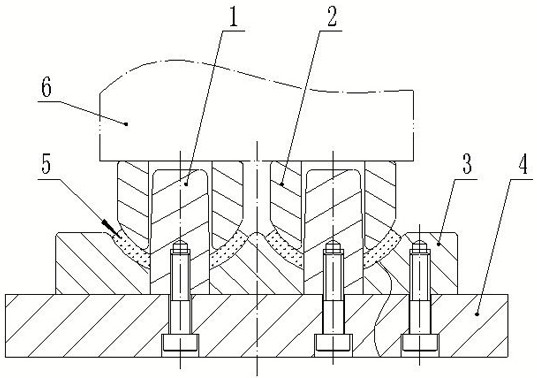

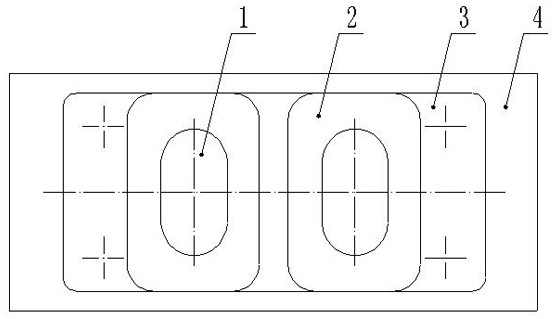

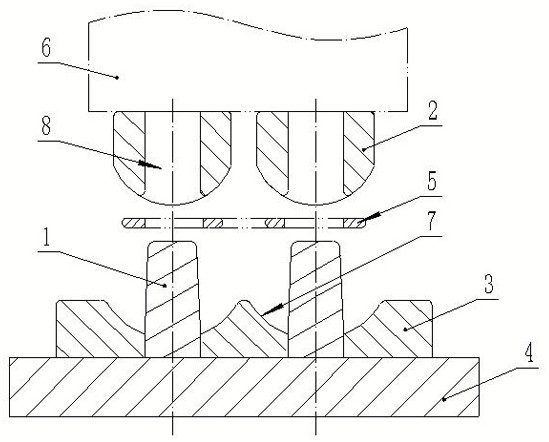

[0017] like Figure 1-5 Shown: the present invention comprises upper mold and lower mold. Wherein, the upper mold is composed of two indenters 2 fixedly arranged on the hydraulic press 6, the bottom surface of each indenter 2 is in a semi-cylindrical structure, and the central position of each indenter 2 is provided with a guide hole 8 in the shape of a kidney. The lower mold 3 is fixed on the base 4 by screws (not shown in the figure), and the surface of the lower mold 3 is arranged with two semi-cylindrical arc-shaped grooves 7 that match the shape of the bottom surface of the corresponding indenter 2; A waist-shaped positioning hole (not shown in the figure) is opened at the central position of the groove 7, and the two guide posts 1 fixed on the base 4 by screws (not shown in the figure) pass upward through the corresponding positioning ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com