Preparation method for one-size nano-particle fluorescence microsphere

A nanoparticle and fluorescent microsphere technology, which is applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of uneven size, difficulty in stability, and inability to achieve control, and achieve basically consistent coupling between particles, The method is simple and the effect of improving the degree of aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 2.35mmol Cd(ClO 4 ) 2 2H 2 O was dissolved in 125ml of water, 5.7mmol of amino mercaptan was added under constant stirring, and the pH value of the system was adjusted to 5-7 by adding 1M NaOH solution. Nitrogen was passed through the system for about 30 minutes to ensure that the air was exhausted. With constant stirring, H 2 Te gas (by 0.46mmol Al 2 Te 3 with 15-20ml of 0.5M H 2 SO 4 (formed by reaction in a nitrogen environment) was slowly driven by nitrogen into the reaction system for 20 minutes, and the system was refluxed and heated to 100° C. in an air environment to obtain aminothiol-coated CdTe nanoparticles.

[0035] Add more than 30% propanol by volume to the nanoparticle aqueous solution, centrifuge, remove the supernatant solution, repeat washing with propanol for more than 6 times, add ultrapure water, and obtain a monodisperse nanoparticle aqueous solution from which impurities are removed.

Embodiment 2

[0037] In a glove box filled with high-purity nitrogen, dissolve 0.158g of selenium powder into 2ml of trioctyl phosphate, dissolve 0.12g of cadmium acetate in 3ml of trioctyl phosphate, and heat 8 grams of tri-n-octylphosphine oxide in a vacuum environment Keep at 180°C for 1 hour, cool down to 100°C, add 5g of hexadecylamine and 0.15g of n-tetradecyl phosphoric acid, keep at 120°C for 20 minutes in a vacuum environment, fill the reactor with flowing nitrogen, and dissolve the selenium Powdered trioctyl phosphate is added to the mixture, heated to 300°C, injected with trioctyl phosphate dissolved in cadmium acetate, and kept at 260°C for different times (5 minutes to 1 hour), to obtain CdSe nanoparticles of different particle sizes, Cool down to 140°C, stop nitrogen, and pass H over the liquid surface at a rate of 2ml per 10 minutes. 2 S gas, stir the solution, keep it for 30 minutes, cool down to 100°C, stir for 1 hour, stop adding H 2 S gas, lower the temperature to 50°C, ...

Embodiment 3

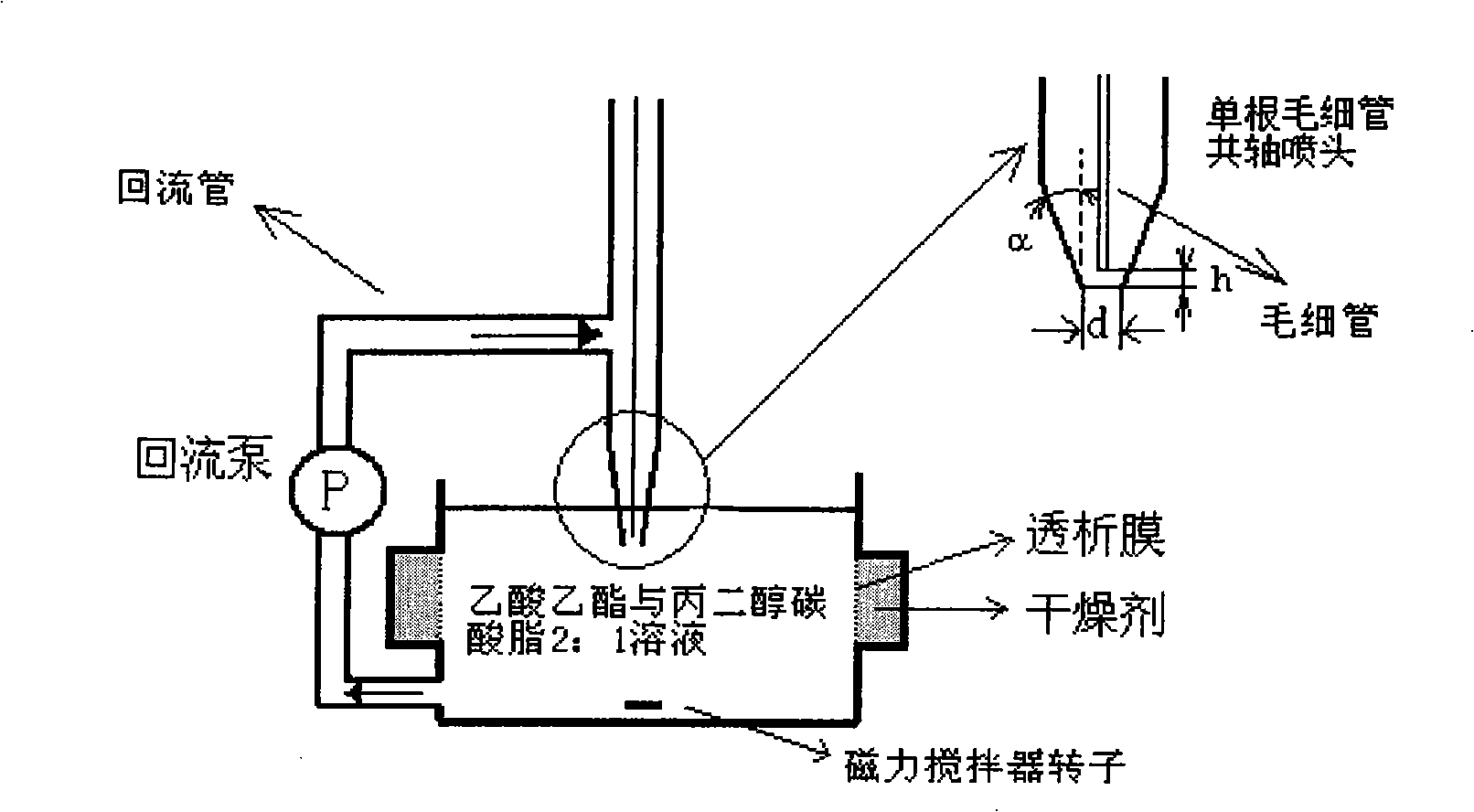

[0039] according to Figure 1 The design and preparation device shown, the oil phase solvent is a mixed solution of analytical pure ethyl acetate and 1-2 propylene glycol carbonate with a volume ratio of 2:1, the total volume is 200ml, the container and the return pipe are all made of polytetrafluoroethylene, and the return pump A stainless steel gear pump is used with a flow range of 1.3-2.6ml / sec. Take the above-mentioned quantum dot aqueous solution, adjust the concentration to 1 micromol, and inject it into the capillary ( figure 1 ), adjust the flow rate to 0.5-2.5ml / min, inject for 15 seconds, and the interval is 5 minutes; the coaxial capillary nozzle is made of hydrophobic treated glass material, the inner diameter of the capillary is 0.1mm, the outer diameter is 0.2mm, the inner diameter d of the outer tube is 1mm, and the capillary The end is flat, the distance h between the end and the opening of the outer tube is 1mm, the end of the outer tube is tapered, the openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com