Temper mill with roll bending and shifting functions

A technology of skin pass mill and roll shifting, which is used in manufacturing tools, metal rolling stands, metal rolling mill stands, etc., can solve the problem of sub-coiling, the inability to change the leveling mode quickly, affecting the service life of work rolls, and scratching work rolls Surface and other problems, to achieve the effect of increasing the effective utilization rate, compact structure, and short roll changing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

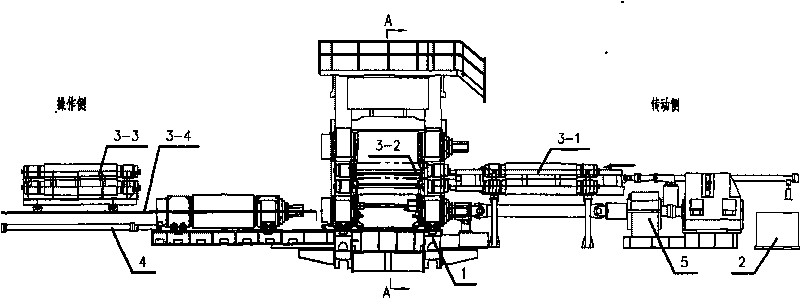

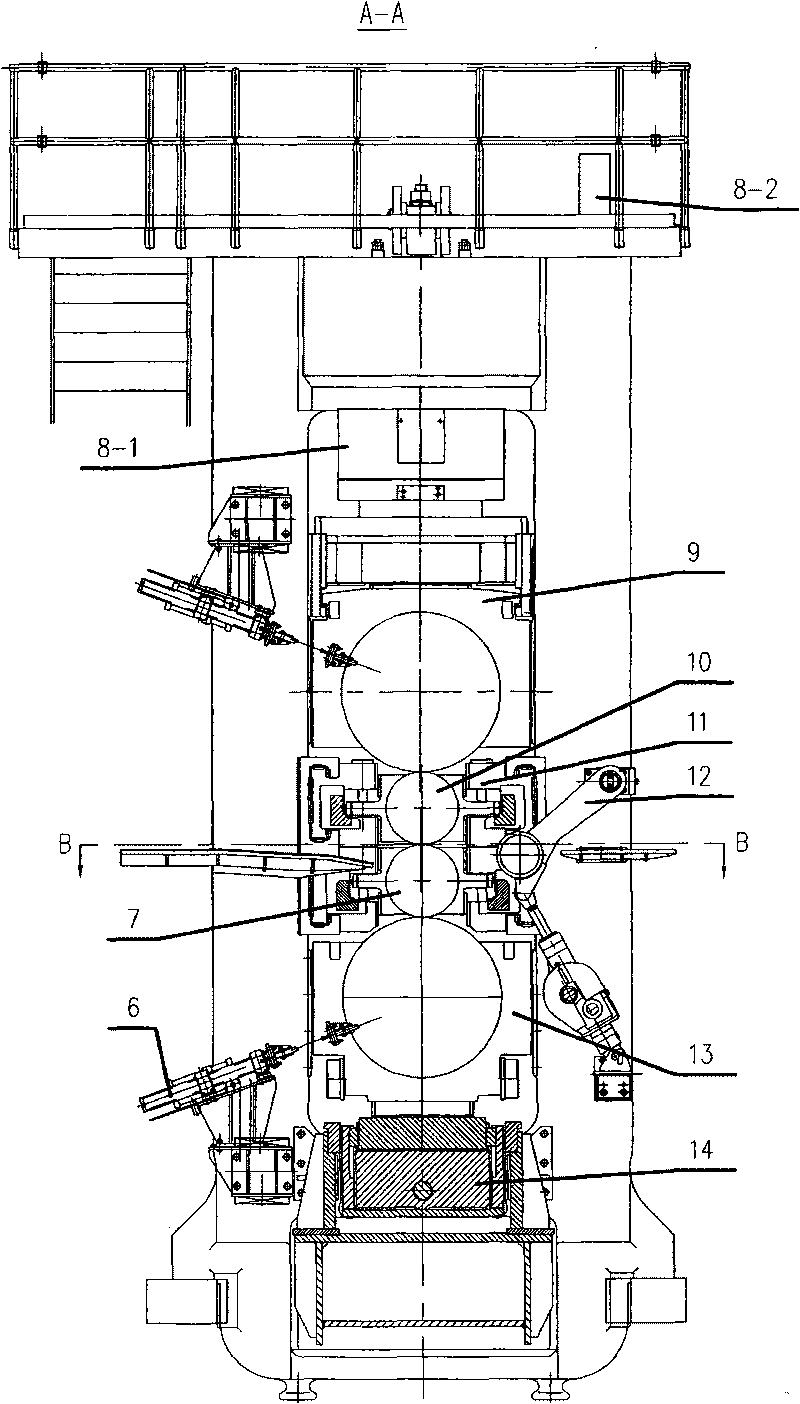

[0012] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

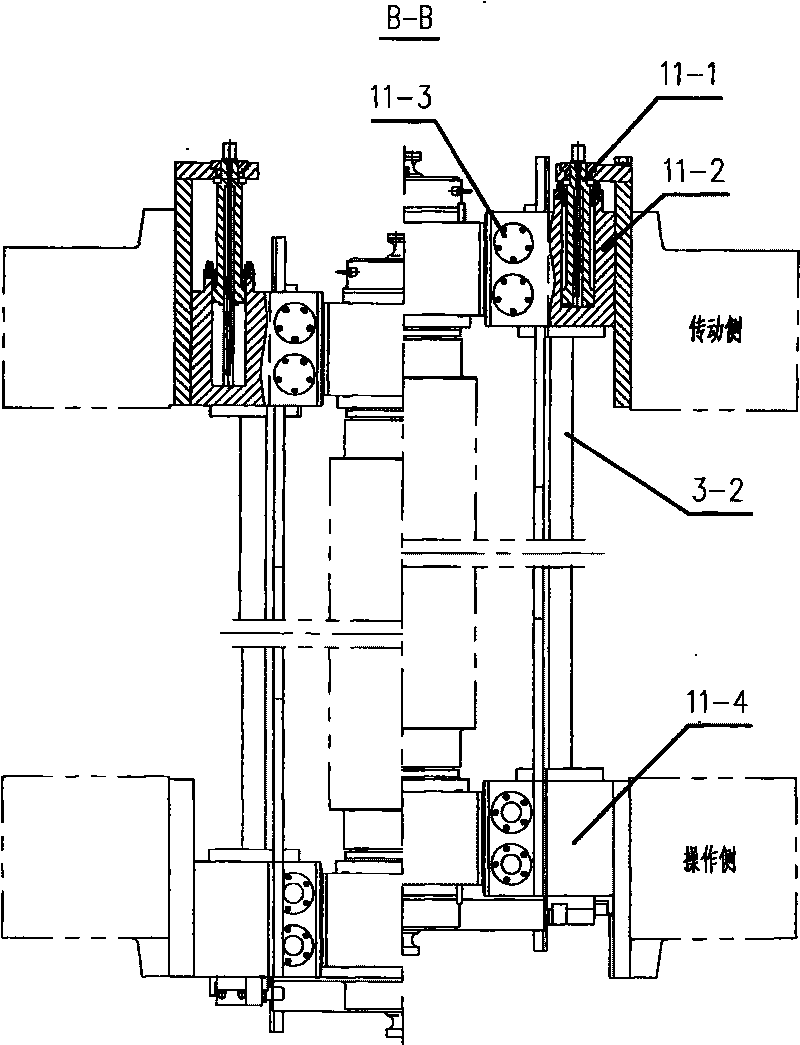

[0013] The frame 1 of the tempering machine is composed of two left and right archways, which are installed on the civil foundation through anchor bolts, and the frame bears rolling force, bending force and transmission overturning moment. The back-up roll wiping device 6, anti-vibration roll 12 and rolling line level adjustment device 14 are installed on the temper mill frame 1 through notches and bolts, and the work roll shifting and roll bending devices are embedded in the temper mill archway window. The positive and negative roll bending cylinders and the roll shifting cylinder body on the transmission side are integrated on a bending and shifting integrated block 11-2, and the roll shifting cylinder piston rod 11-1 is fixedly installed on the archway through the E-shaped block. Positive and negative roll bending cylinders are integrated on a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com