Quick decomposing roll changing rolling mill

A split and fast technology, applied in the direction of metal rolling stands, metal rolling mill stands, metal rolling, etc., can solve the problems of long occupation time, difficult to realize automation, high labor intensity, etc., and achieve convenient maintenance and shortening. The time for disassembling and assembling the rack and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

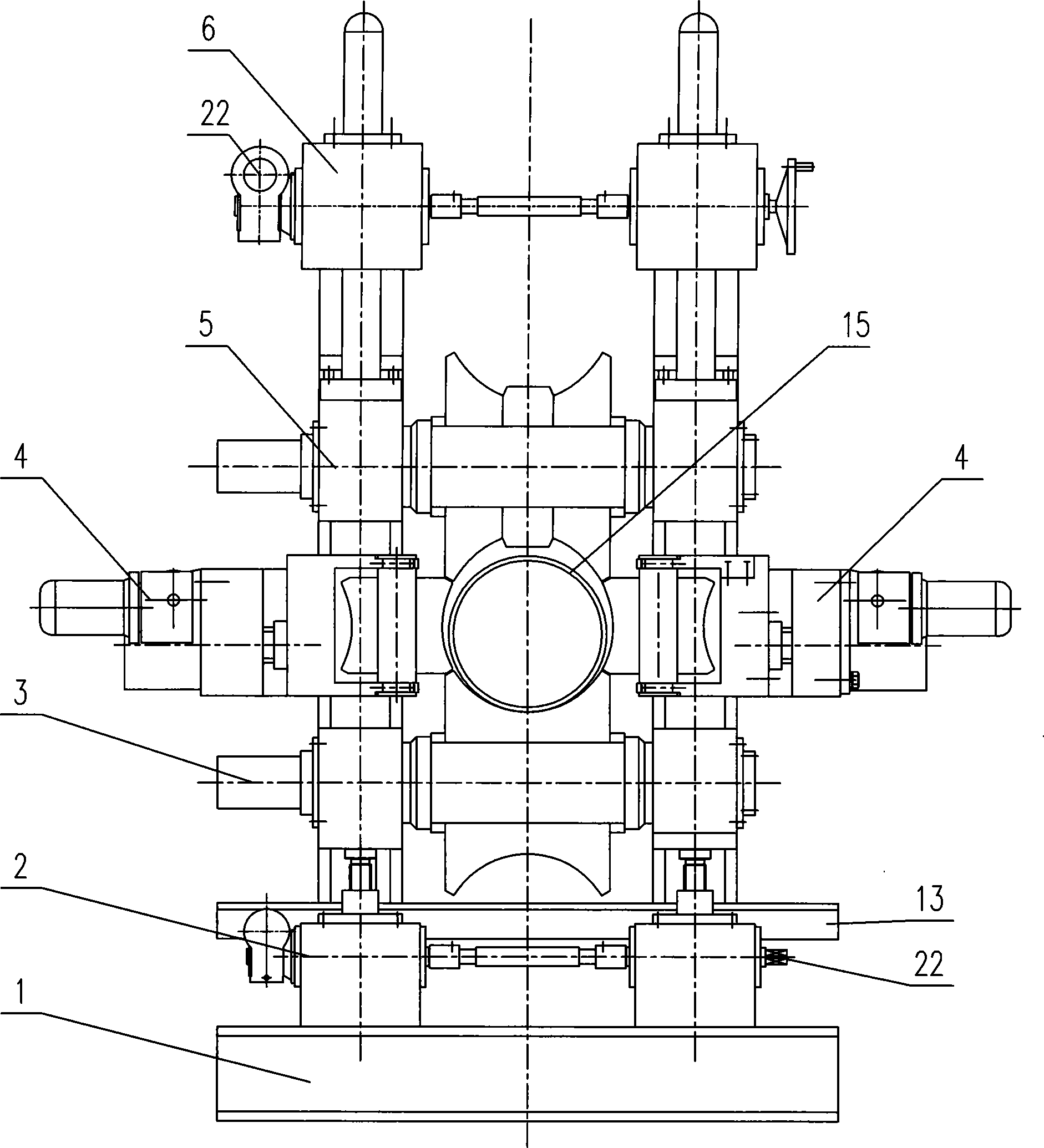

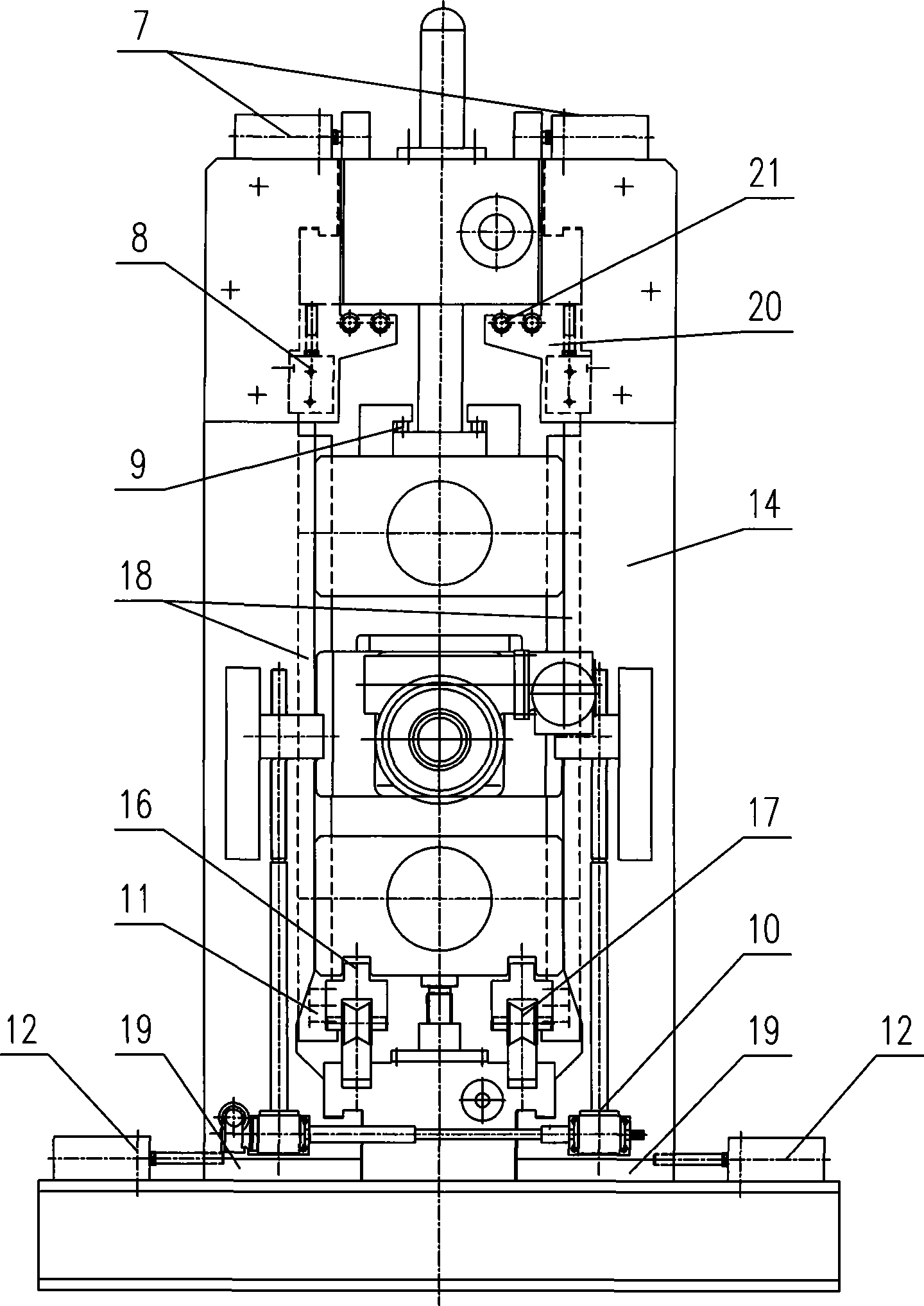

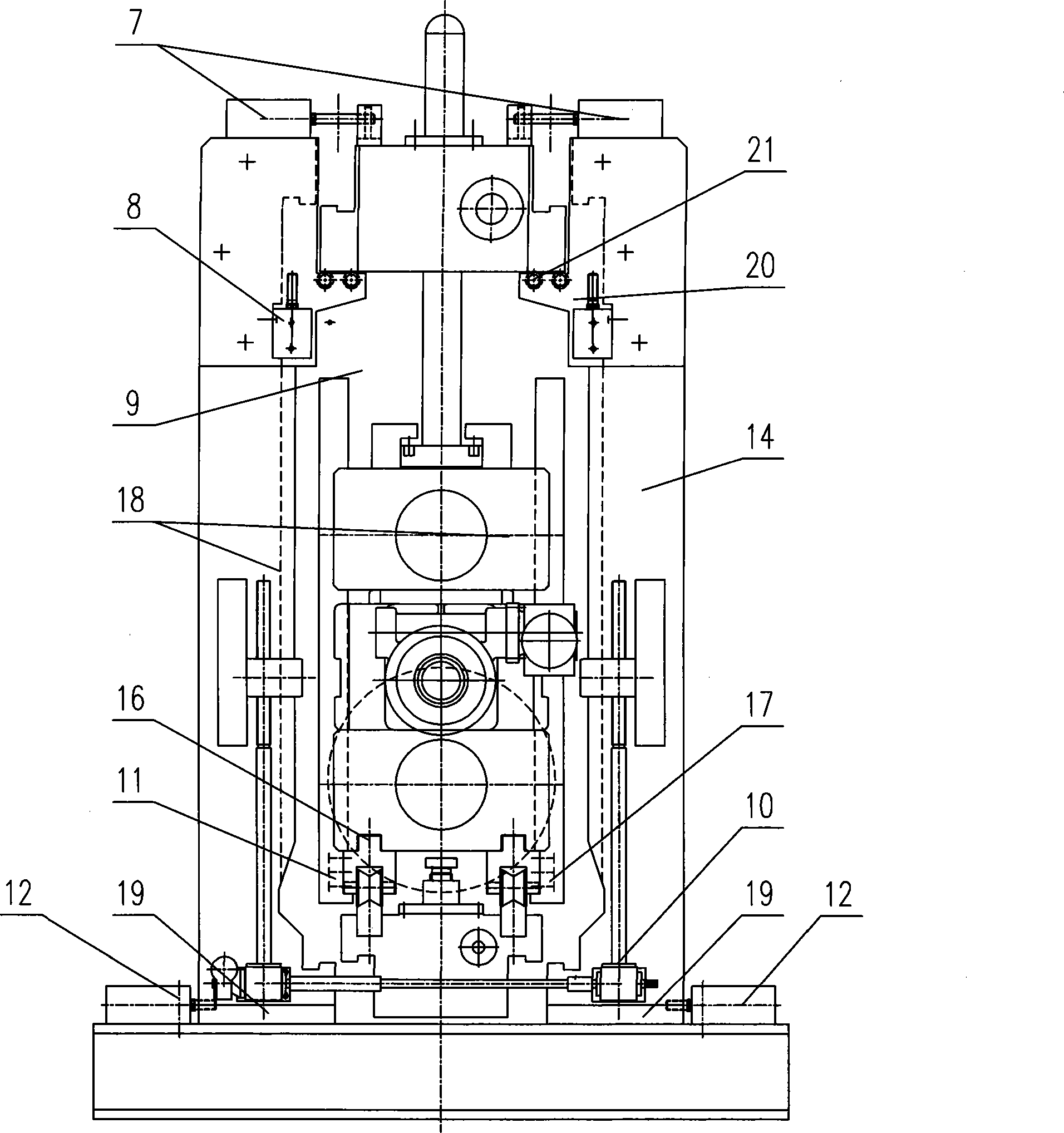

[0024] figure 1 , 2 Shown in , 3 is the specific embodiment of the present invention, and it is the rolling mill of the quick dismantling formula roll change that installs in the high-frequency welded pipe rolling mill production line; Its structure comprises stand 1, the stand on stand 1, in The lower shaft system on the frame, the side roller 4, the side roller lifting adjustment device 10, and the upper shaft system are characterized in that: a split-type combined frame is installed on the machine base 1, and the split-type combined machine The frame is composed of the upper beam 6, the upper roller lifting adjustment device, the lower beam 2, the lower roller lifting adjustment device and the columns 14 on both sides, and the upper beam 6, the lower beam 2 and the columns 14 on both sides are all made into independent parts The upper beam 6 and the lower beam 2 are assembled into a detachable combined frame between the columns 14 on both sides with embedded fit, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com