Large thick-wall special-shaped pipe cold roll forming method

A technology of cold forming and special-shaped pipes, which is applied in metal rolling, metal rolling racks, manufacturing tools, etc., can solve the problems of inability to produce large special-shaped pipes, and achieve the effects of saving money, increasing strength, and wide forming range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

[0038] A cold-bending forming method for large-scale thick-walled special-shaped pipes, characterized in that it includes the following steps:

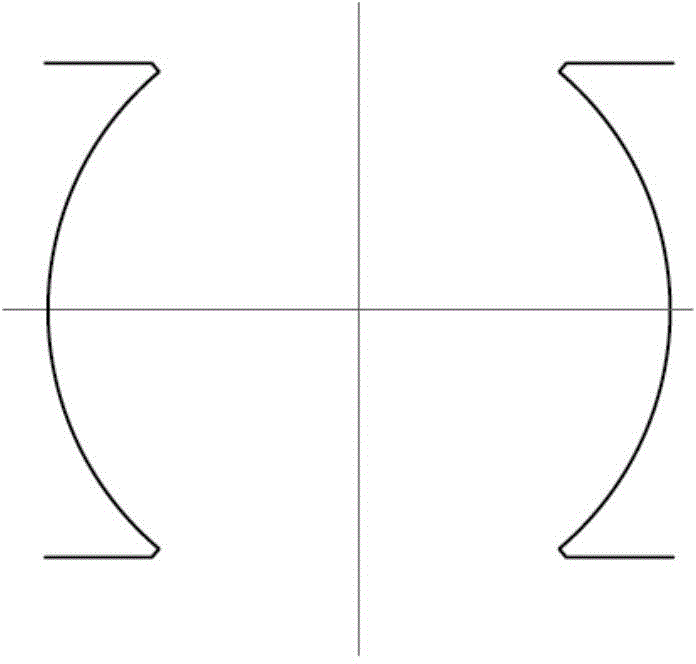

[0039] The first step is the round pipe selection stage; select the round pipe with the corresponding diameter according to the specifications of the required square or rectangular pipe;

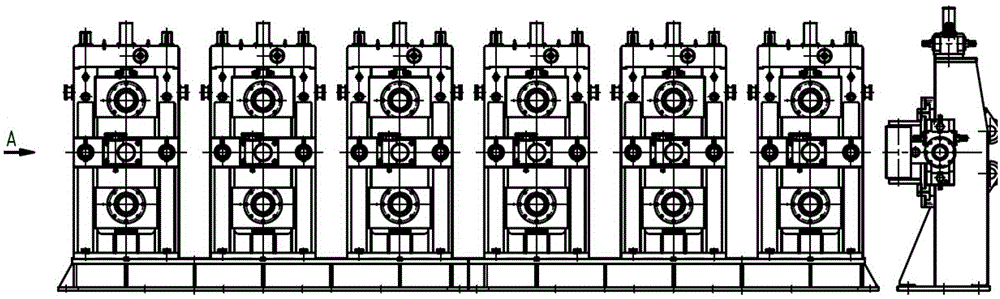

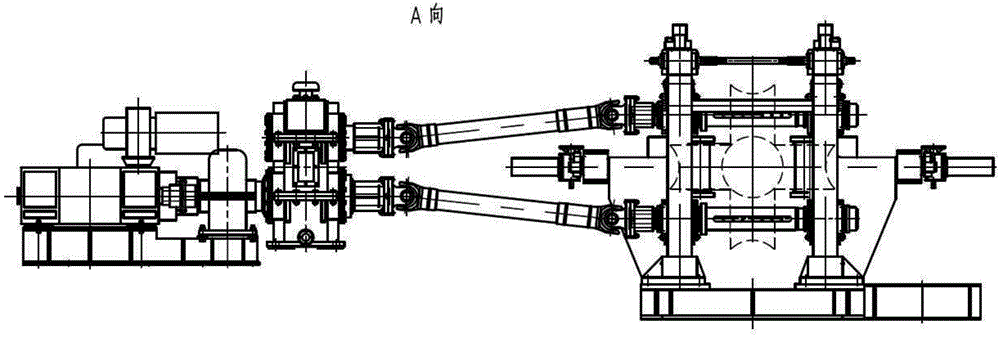

[0040] The second step is the rough forming stage; a total of 5 sets of universal rolling mills, using mutually symmetrical and vertical deformed rolls of flat and vertical rolls, to form round tubes into required square and rectangular tubes; it is divided into the following two steps:

[0041] A The first frame is the bite roller: bite the round pipe into the unit;

[0042] B The second to fifth stands are forming rolls: during the whole forming process, the diameter of the rolls changes from small to large, and finally becomes 180 0 ; The le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com