PCB jointed board determination method and device, electronic equipment and storage medium

A panel and single panel technology, applied in the field of electronics, can solve the problems of high design cost, inability to balance panel quality and utilization rate, etc., and achieve the effect of reducing utilization rate, reducing warpage risk, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

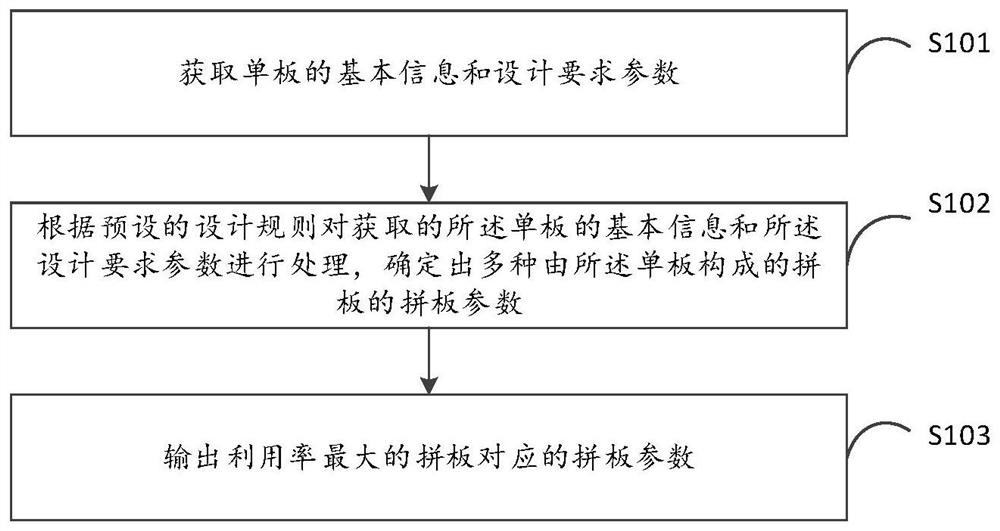

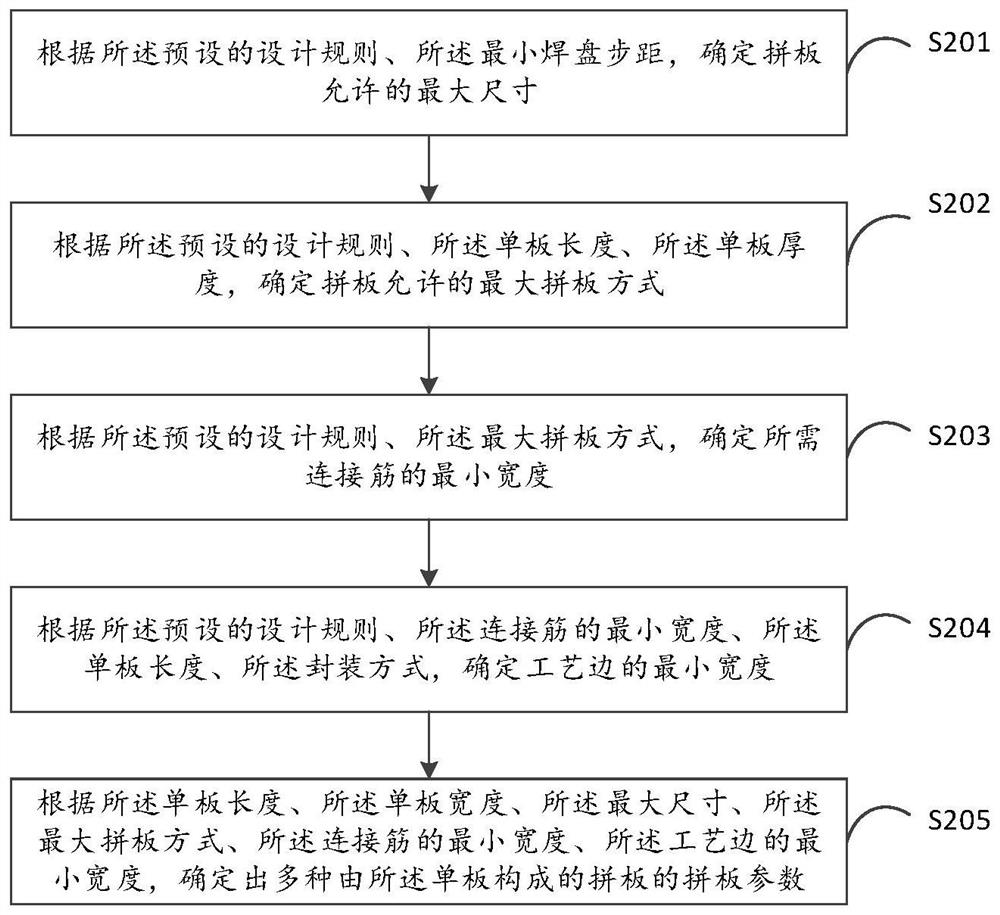

[0041] In one embodiment, the processing procedure of step S102 may be as follows figure 2 shown. Including the following steps:

[0042] Step S201: Determine the maximum size allowed by the panel according to the preset design rules and the minimum pad step.

[0043] For example, the preset design rules stipulate that: the minimum pad step ≤ 0.20mm, the maximum size allowed for the panel is 100*100mm; 0.2mm 0.35mm, the maximum size allowed for the panel is 200*200mm. Assuming that the minimum pad step is 0.35mm, according to the preset design rules and the minimum pad step, it can be determined that the maximum size allowed by the panel is 150*150mm.

[0044] Step S202: According to the preset design rules, the length of the veneer, and the thickness of the veneer, determine the maximum panelization mode allowed for panelization.

[0045] For example, the preset design rule stipulates that if the plate thickness is 35*35mm, the maximum allowable combination method is 3 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com