High-flowability easy-demolding nylon 6 composite material and preparation method thereof

A composite material and easy-release technology, which is applied in the field of high-flow and easy-release nylon 6 composite materials and its preparation, can solve the problems of undisclosed nucleating agents, flow modifiers and antioxidants, and technicians can't realize it. Achieve the effects of reducing the risk of warpage, reducing the shrinkage of the part, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

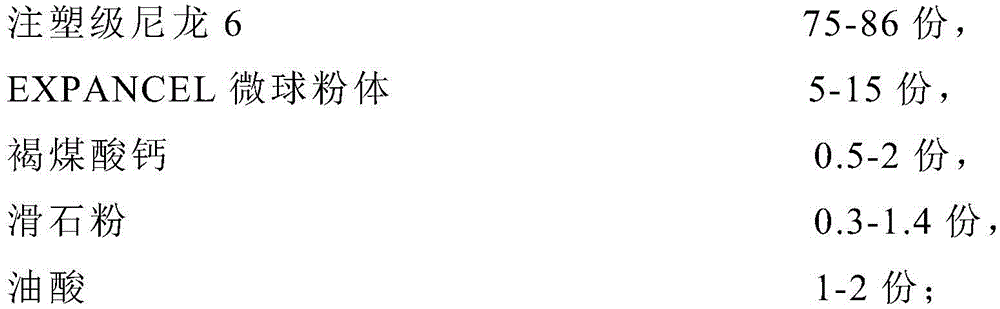

Method used

Image

Examples

Embodiment 1

[0023] A kind of preparation method of the nylon 6 composite material of high fluidity easy demoulding, comprises the following steps,

[0024] A, material preparation, including the following components by mass: injection molding grade nylon 675kg, EXPANCEL microsphere powder 5kg, calcium montanate 0.5kg, talcum powder 0.3kg, oleic acid 1kg;

[0025] EXPANCEL microsphere powder is AkzoNobel's EXPANCEL microsphere powder, and the model of the microsphere powder is 920DU20. Talc powder is made by mixing talc powder with a particle size of 1500 mesh and talc powder with a particle size of 800 mesh at a mass ratio of 4:6. Injection molding grade nylon 6 is selected from commercially available products.

[0026] B, mixing, the components in the step A are fully mixed to obtain a blend;

[0027] The components were mixed by a high-speed mixer for more than 20 minutes, and discharged at 60° C. for later use to obtain a blend.

[0028] C. Preparation: Extrude the blend in step B t...

Embodiment 2

[0031] The preparation method of this embodiment is basically the same as that of Example 1, except that, in this embodiment, the preparation step includes the following components in parts by mass:

[0032] Injection molding grade nylon 686kg, EXPANCEL microsphere powder 15kg, calcium montanate 2kg, talcum powder 1.4kg, oleic acid 2kg.

Embodiment 3

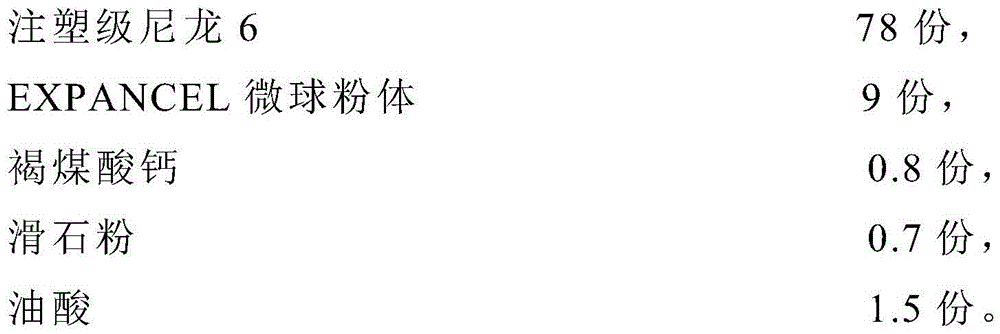

[0034] The preparation method of this embodiment is basically the same as that of Example 1, except that, in this embodiment, the preparation step includes the following components in parts by mass:

[0035] Injection grade nylon 678kg, EXPANCEL microsphere powder 9kg, calcium montanate 0.8kg, talcum powder 0.7kg, oleic acid 1.5kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com