Method for manufacturing terminal member and terminal member

A terminal and component technology, applied in the direction of electrical components, manufacturing tools, welding equipment, etc., can solve the problems of complex process and low efficiency, and achieve the effects of simplifying process, improving production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

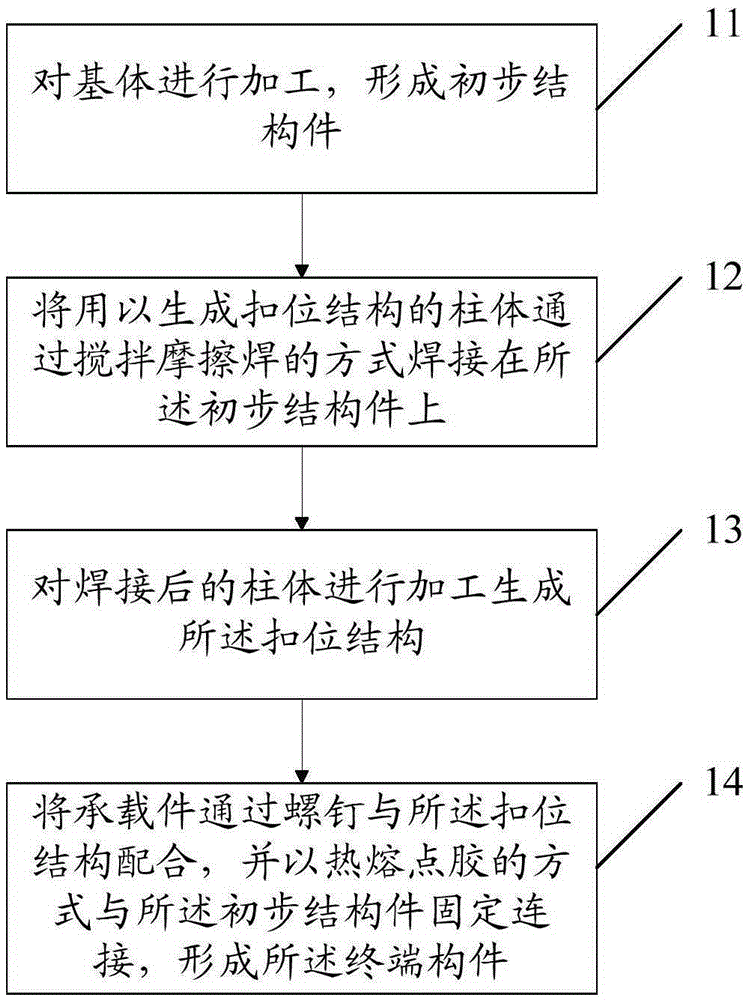

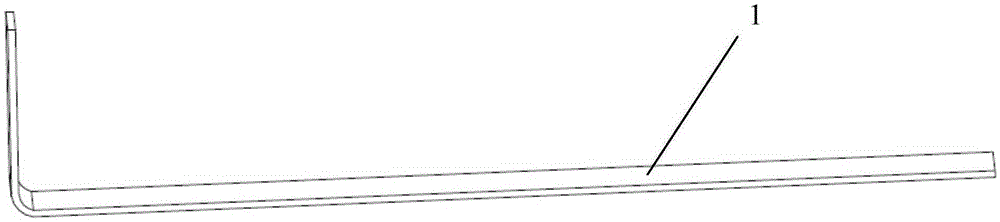

[0031] like figure 1 As shown, the preparation method of the terminal component in Embodiment 1 of the present invention includes:

[0032] Step 11: Processing the matrix to form a preliminary structural part;

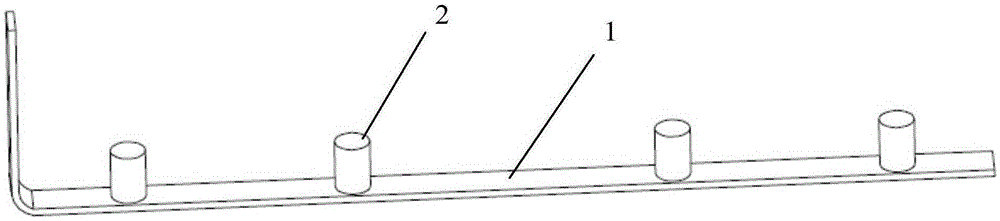

[0033] Step 12: welding the column used to generate the buckle structure on the preliminary structural member by friction stir welding;

[0034] Step 13: Processing the welded column to generate the buckle structure;

[0035] Step 14: Cooperate the bearing part with the buckle structure through screws, and fixedly connect it with the preliminary structural part by means of hot-melt dispensing to form the terminal component.

[0036] The method for preparing the terminal component provided in Embodiment 1 of the present invention connects the processed base body (preliminary structural part) and the buckle structure (formed by column processing) through friction stir welding, and then passes the bearing part through The screw is matched with the buckle structure and ...

Embodiment 2

[0050] On the basis of the first embodiment of the present invention, in order to prevent changes in the structure of the bottom material of the substrate (aluminum alloy) from affecting the anodic treatment of the material, in the second embodiment of the present invention, in the step 12, the column used to generate the buckle structure When the body is welded on the preliminary structural member by means of friction stir welding, the preparation method further includes: step 12', placing dry ice on the non-welding side of the preliminary structural member for cooling.

[0051] that is, if Image 6 As shown, the preparation method of the terminal member provided in Embodiment 2 of the present invention includes:

[0052] Step 11: Processing the matrix to form a preliminary structural part;

[0053] Step 12: welding the column used to generate the buckle structure on the preliminary structural member by friction stir welding;

[0054] Step 12': placing dry ice on the non-we...

Embodiment 3

[0061] On the basis of the first embodiment of the present invention, in order to prevent oxidation of the welding surface, in the third embodiment of the present invention, in the step 12, the cylinder used to generate the buckle structure is welded to the preliminary structure by friction stir welding When the parts are on, the preparation method further includes: step 12", injecting a nitrogen flow to the column.

[0062] that is, if Figure 7 As shown, the preparation method of the terminal component provided in Embodiment 3 of the present invention includes:

[0063] Step 11: Processing the matrix to form a preliminary structural part;

[0064] Step 12: welding the column used to generate the buckle structure on the preliminary structural member by friction stir welding;

[0065] Step 12": Injecting nitrogen flow into the column;

[0066] Step 13: Processing the welded column to generate the buckle structure;

[0067] Step 14: Cooperate the bearing part with the buckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com